Preparation method of lithium iron phosphate cathode material

A positive electrode material, lithium iron phosphate technology, applied in the direction of chemical instruments and methods, phosphorus compounds, battery electrodes, etc., can solve problems that hinder application and development, low tap density, poor low temperature performance, etc., and achieve low production cost and raw material Extensive, cost-reducing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

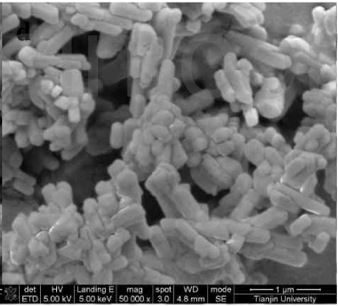

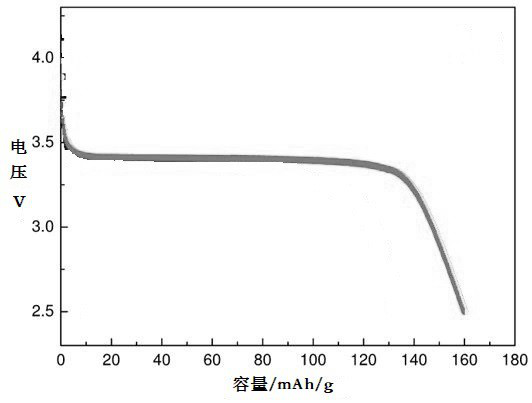

Image

Examples

Embodiment 1

[0023] A lithium iron phosphate positive electrode material, which is synthesized in one step by hydrothermal stripping method using cheap and easy-to-obtain ferrous salt or iron salt, lithium dihydrogen phosphate and an organic extractant as raw materials, according to the following steps:

[0024] (1). Preparation of iron-containing organic solution

[0025] In the beaker, add extractant and diluent sequentially at a volume ratio of 2:1, add ammonia water for saponification under stirring, and then add FeCO 3 solution, stirred for 30 minutes, and then separated and washed to obtain Fe-containing 2+ organic solution;

[0026] (2). Preparation of water phase

[0027] Molebi Fe 2+ : Li + Weigh LiOH at a ratio of 1:1, add water until it is completely dissolved, and add 3mol / L H 3 PO 4 , so that Li + and PO 4 3- The molar ratio is 1.2:1, and then add a small amount of ascorbic acid;

[0028] (3). Hydrothermal stripping synthesis

[0029] Put the iron-containing organi...

Embodiment 2

[0032] A lithium iron phosphate positive electrode material, the same steps as in Example 1, except that the ferrous salt is different, which is FeCl 2 , follow the steps below:

[0033] (1). Preparation of iron-containing organic solution

[0034] In the beaker, add extractant and diluent sequentially at a volume ratio of 2:1, add ammonia water for saponification under stirring, and then add FeCl 2 solution, stirred for 30 minutes, and then separated and washed to obtain Fe-containing 2+ organic solution.

[0035] (2). Preparation of water phase

[0036] Molebi Fe 2+ : Li + Weigh LiOH at a ratio of 1:1, add water until completely dissolved, add a certain volume of 3mol / L H under stirring conditions 3 PO 4 and Li + PO 4 3- The molar ratio is 1.3:1 and a small amount of ascorbic acid.

[0037] (3). Hydrothermal stripping synthesis

[0038] Put the iron-containing organic phase and the water phase into the high-pressure reactor, seal it well and start stirring, heat...

Embodiment 3

[0040] A lithium iron phosphate positive electrode material, the same steps as in Example 1, except that the hydrothermal reaction conditions are different, which is FeCl 2 , follow the steps below:

[0041] (1). Preparation of iron-containing organic solution

[0042] In the beaker, add extractant and diluent sequentially at a volume ratio of 2:1, add ammonia water for saponification under stirring, and then add FeCO 3 solution, stirred for 30 minutes, and then separated and washed to obtain Fe-containing 2+ organic solution;

[0043] (2). Preparation of water phase

[0044] Molebi Fe 2+ : Li + Weigh LiOH at a ratio of 1:1, add water until completely dissolved, add a certain volume of 3mol / L H under stirring conditions 3 PO 4 and Li + PO 4 3- A molar ratio of 2:1 and a small amount of ascorbic acid;

[0045] (3). Hydrothermal stripping synthesis

[0046] Put the iron-containing organic phase and the water phase into the autoclave, seal it well, start stirring, he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com