Double-side inclined multi-roller backflow shoe and cylindrical backflow rail system

A cylindrical, return rail technology, used in power rails, current collectors, electrical components, etc., can solve problems such as stray current, rail return current receiving shoes wear, etc., to reduce wear, ensure reliable operation, and improve Reliability and operational cycle effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific implementation methods.

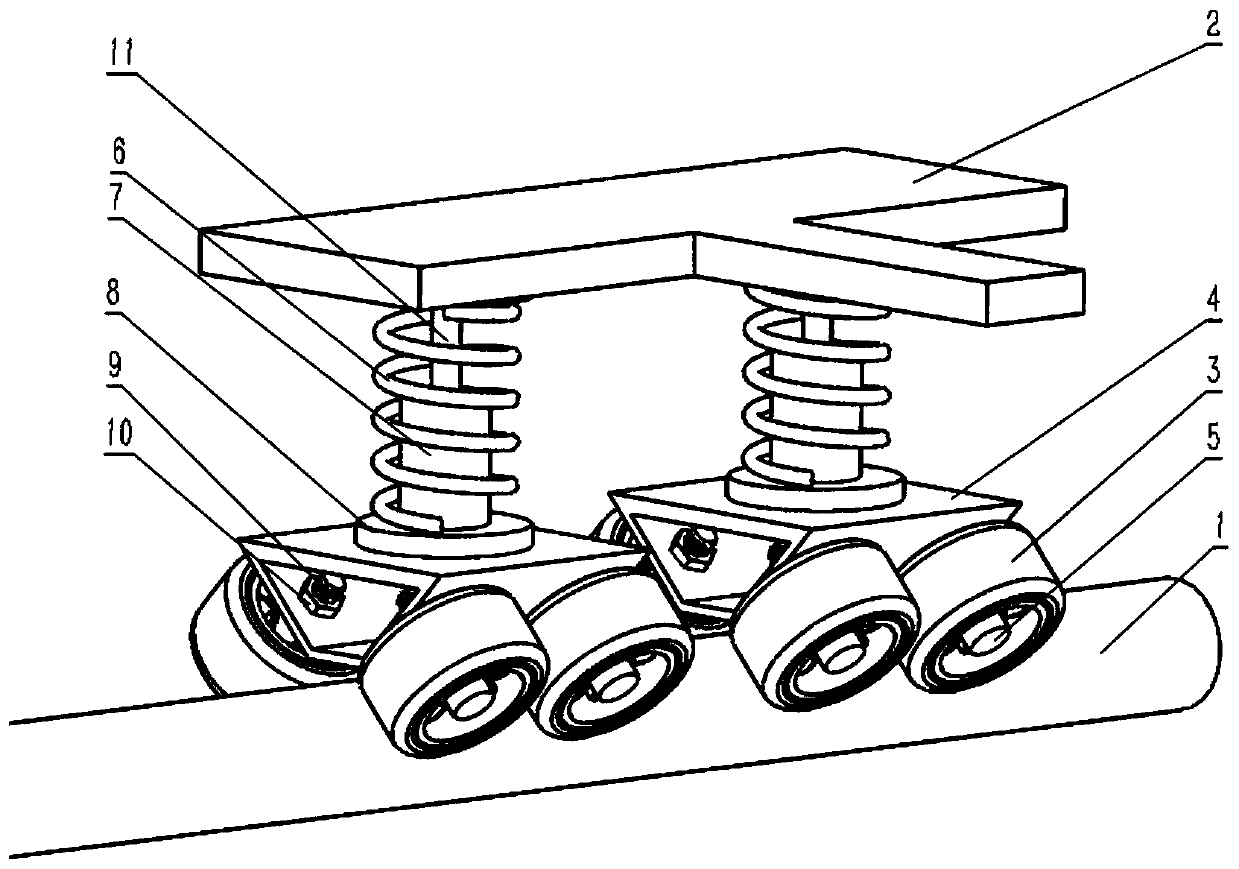

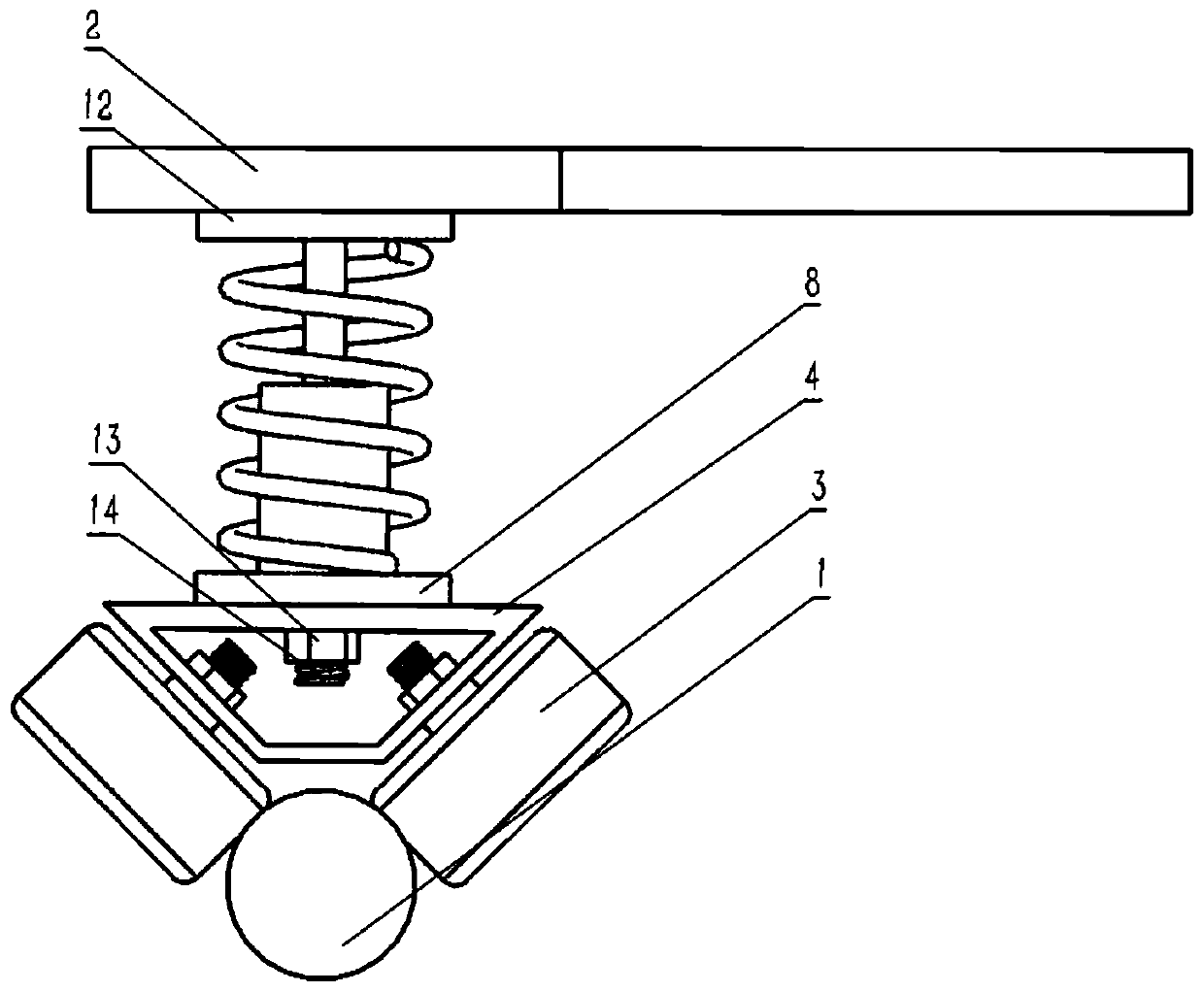

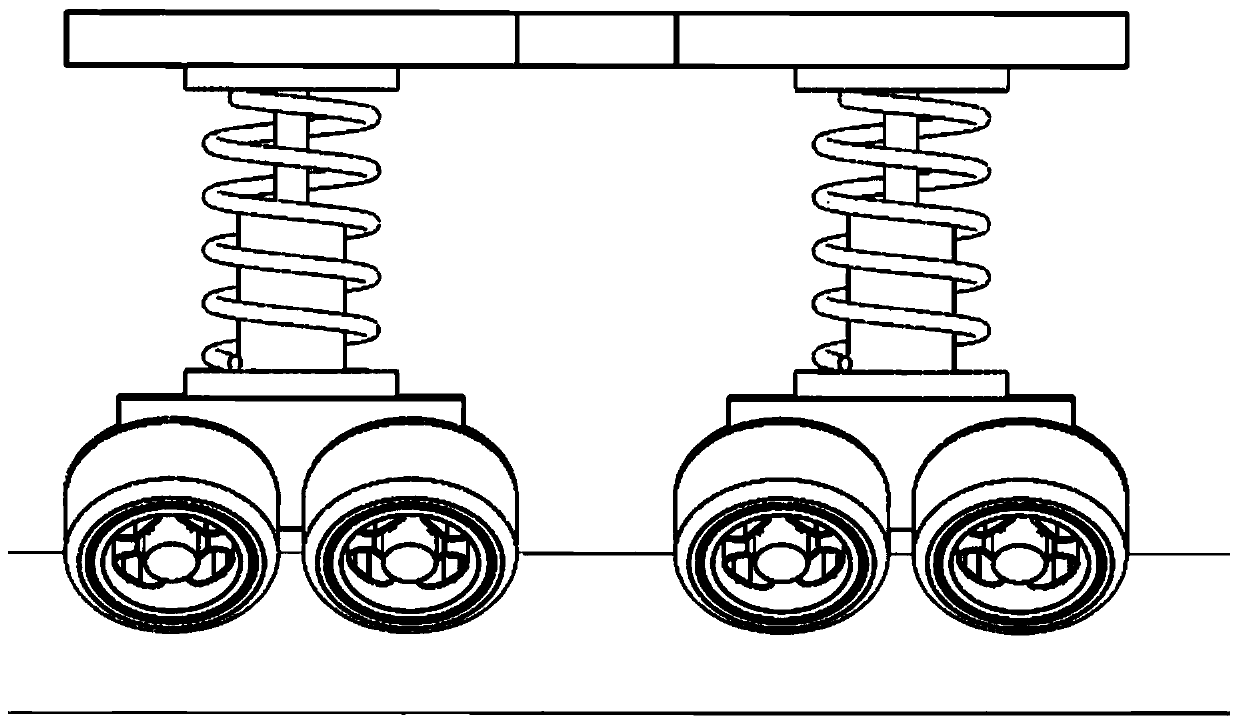

[0033] A double-sided inclined multi-roller return shoe and cylindrical return rail system of the present invention, its structural composition is as follows Figure 1-Figure 3 As shown, it includes the return shoe and the cylindrical return rail 1, the support plate 2 of the return shoe is connected to the roller bracket 4 through the shock absorber, and four rollers 3 are symmetrically placed on the bottom slope of the roller bracket 4; the rollers 3 are in rolling contact with the cylindrical return rail 1 .

[0034] Roller 3 as Figure 6 As shown, it includes a roller metal layer 20, a bearing ball fixing layer 23 and a metal slot layer 24 from outside to inside; four carbon brushes 22 and a number of bearing balls 21 are evenly distributed in the bearing ball fixing layer 23. The metal slot layer 24 is evenly distrib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com