Patents

Literature

32results about How to "Meet the density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

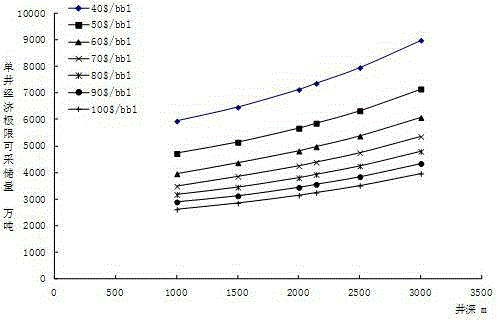

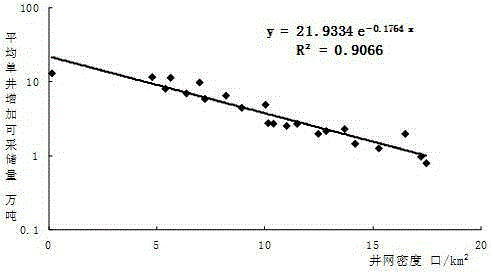

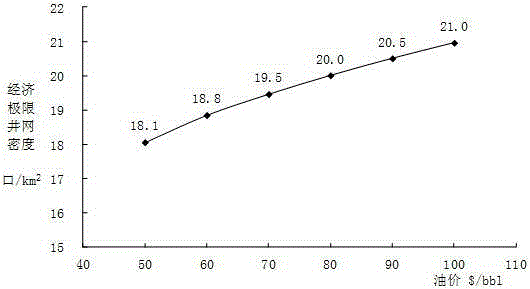

Novel method for measuring and calculating well pattern thickening potential

The invention provides a novel method for measuring and calculating well pattern thickening potential comprising following steps: 1. determining oil well single well economic limit recoverable reserves; 2. determining the relationship between the average single well increased recoverable reserves of a close-spaced well and the well density; 3. determining the density of the economic limit well pattern; 4. calculating the drilling well workload of well pattern thickening; 5. calculating the potential of well pattern thickening for increasing recovery efficiency. The novel method for measuring and calculating well pattern thickening potential can satisfy the demand of calculating technical economical policy limit such as economic limit well pattern density and limit thickening potential of extra high water reservoir, and can be more objective in evaluating the exploitation potential of oil reservoirs and guiding the oil field development production practice.

Owner:CHINA PETROLEUM & CHEM CORP +1

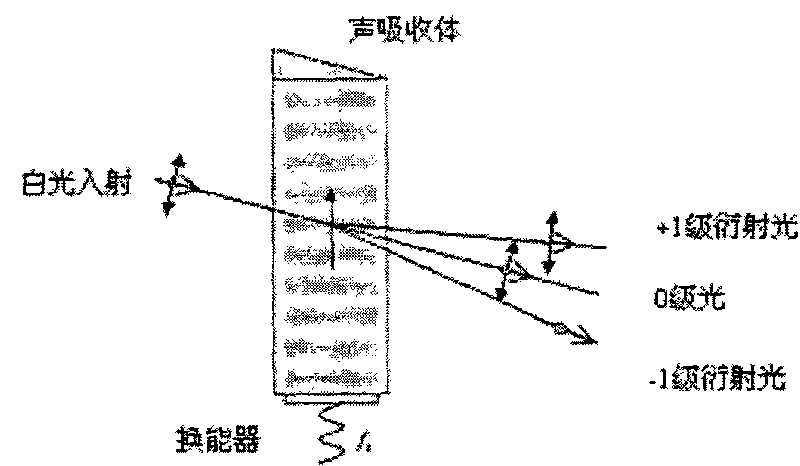

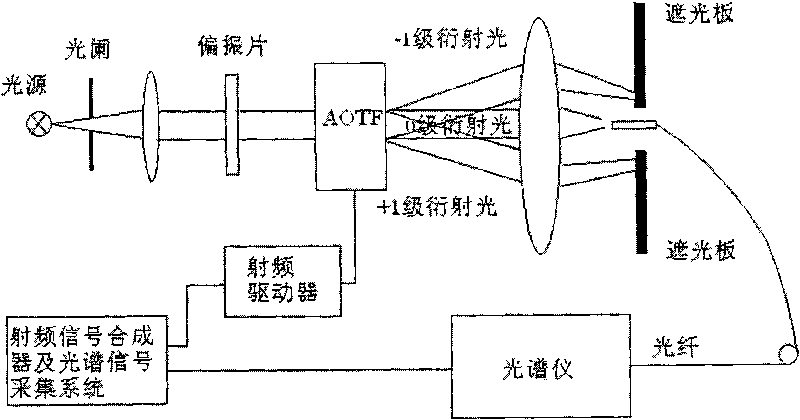

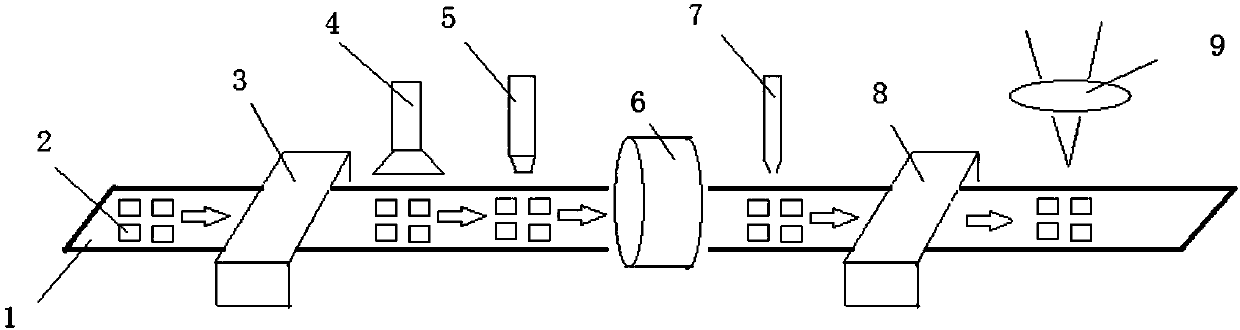

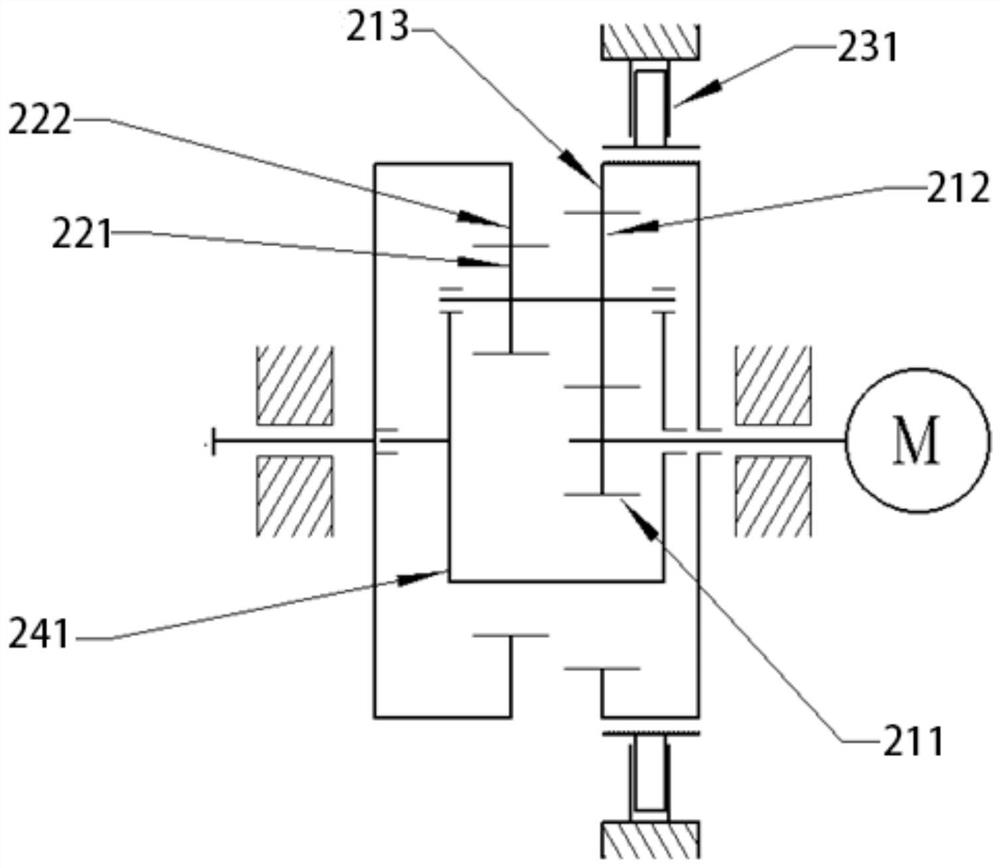

System and method for testing diffraction efficiency of acousto-optic tunable filter

InactiveCN101706361AMeet the densityMeet needsTesting optical propertiesBeam splittingAcousto-optics

The invention discloses a system for testing the diffraction efficiency of an acousto-optic tunable filter (AOTF). The system comprises a wavelength tunable laser, a neutral density filter, a diaphragm orifice, a beam splitting mirror, a two-dimensional electric turnplate and an energy meter. The wavelength tunable laser can generate laser beams with continuously adjustable wavelength, the laser beams after passing through the neutral density filter and the diaphragm orifice are split into two beams of lasers with fixed beam splitting ratio by the beam splitting mirror, and the energy of reflecting beams is used as reference energy; transmission beams enter the AOTF, the energy of diffracted light is received when radio-frequency drive is applied to the transmission beams, and energy with direct penetration is received when the drive is not applied to the transmission beams, thereby calculating the diffraction efficiency of the AOTF. Meanwhile, the measurement of an aperture angle can be realized by changing the angle of incident light through the two-dimensional electric turnplate. The device has the characteristics of simple principle and strong operability, can meet the requirement of testing the continuous wavelength of the AOTF and can also enhance the testing accuracy greatly by utilizing reference beams generated by the beam splitting mirror.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

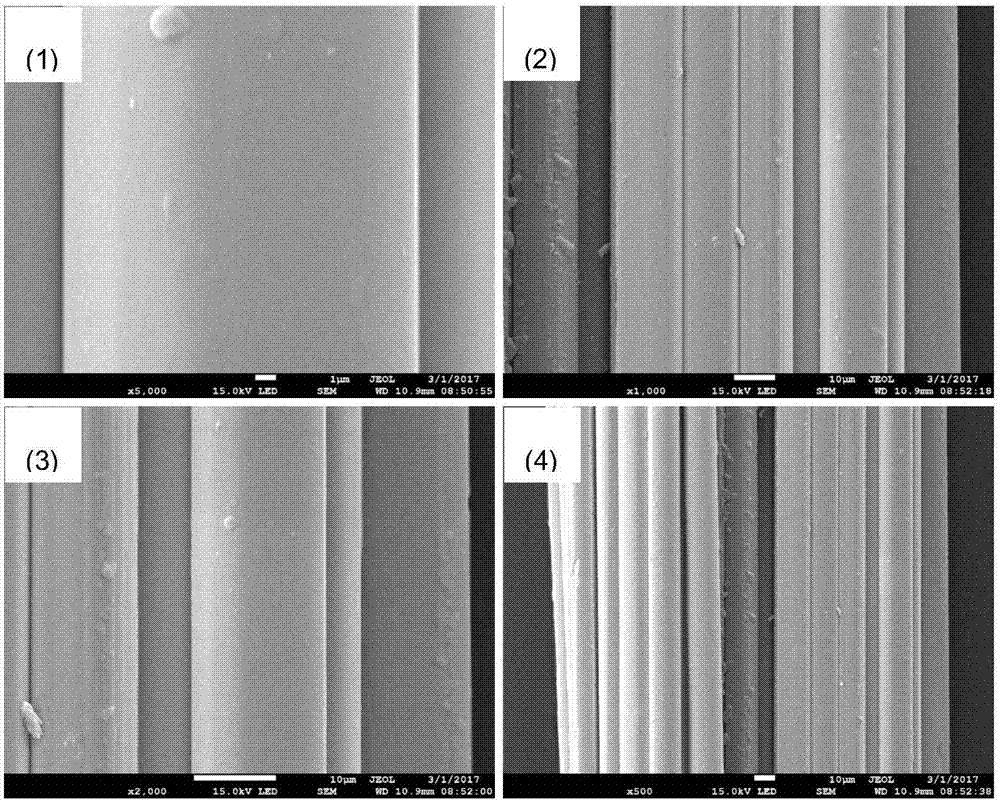

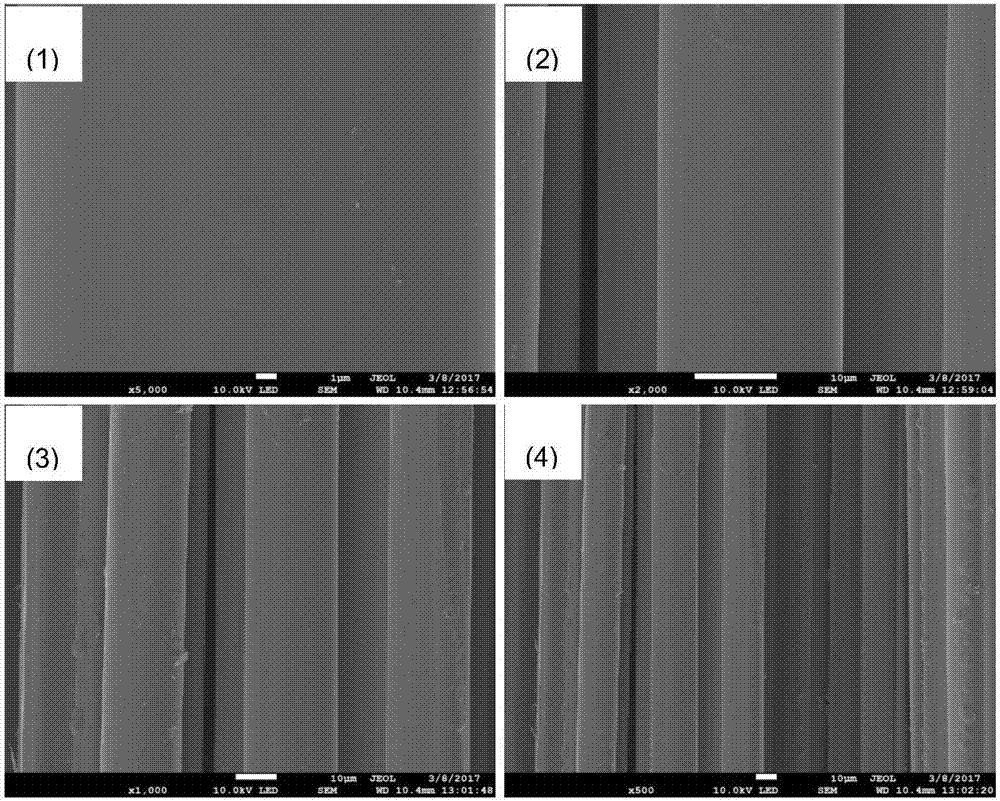

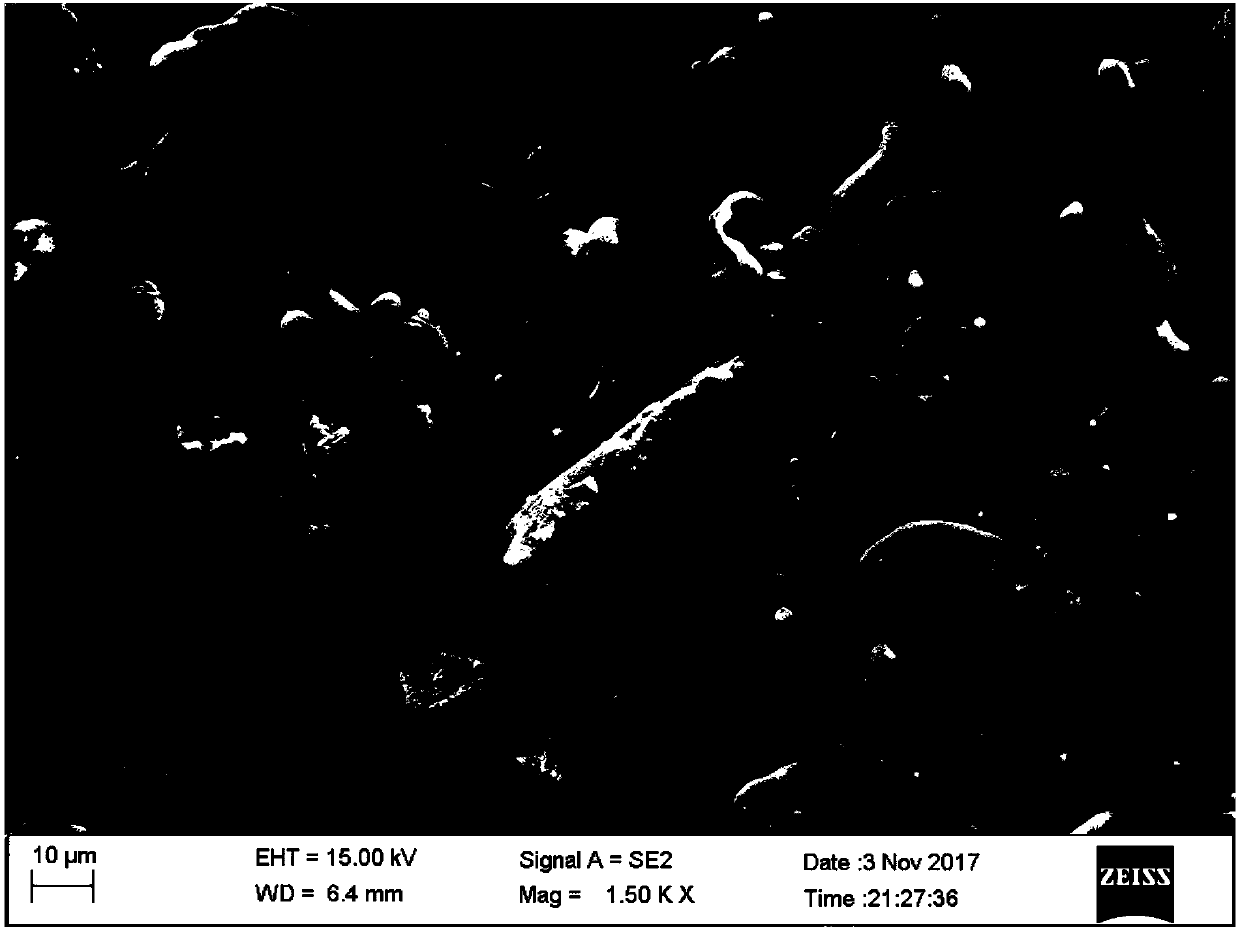

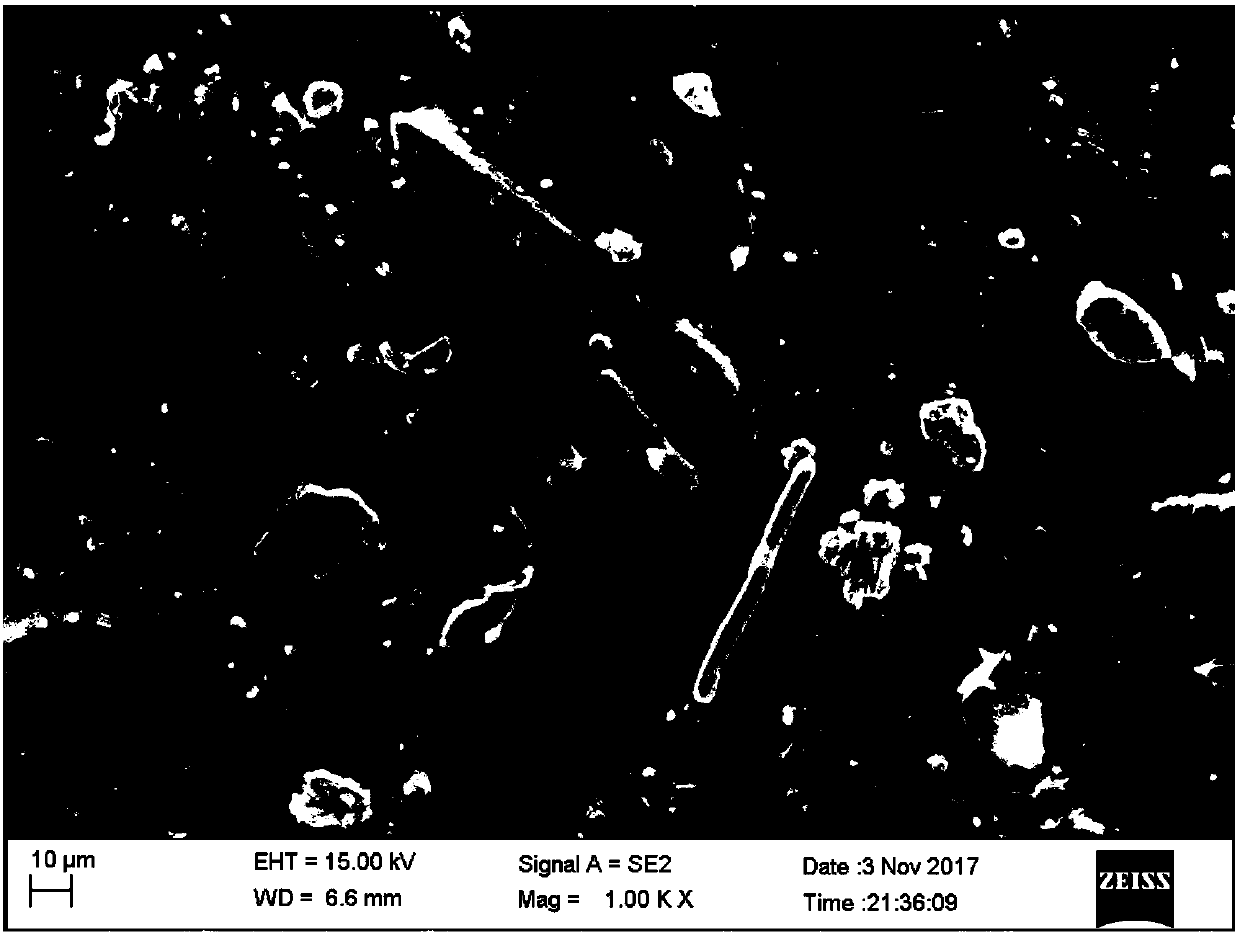

Composite and conductive polyimide/nickel fiber and preparation method thereof

The invention provides a composite and conductive polyimide / nickel fiber and a preparation method thereof and belongs to the field of electromagnetic-shielding and conductive fiber. Polyimide fiber is used as basic fiber, the surface of the polyimide fiber is supported with an ultra-thin metal layer through a surface modified ion exchange technique, then uniform precipitation of the metal nickel layer is conducted on the surface of the fiber by adopting a traditional chemical plating method, and accordingly a perfect and compact high-conductive metal nickel layer is obtained. Efficient preparation of the polyimide / nickel fiber having excellent surface metal luster, good interface caking property, high conductivity and controllable nickel layer thickness. The implementing process is simple, processizing is easy, and an application prospect is good.

Owner:BEIJING UNIV OF CHEM TECH

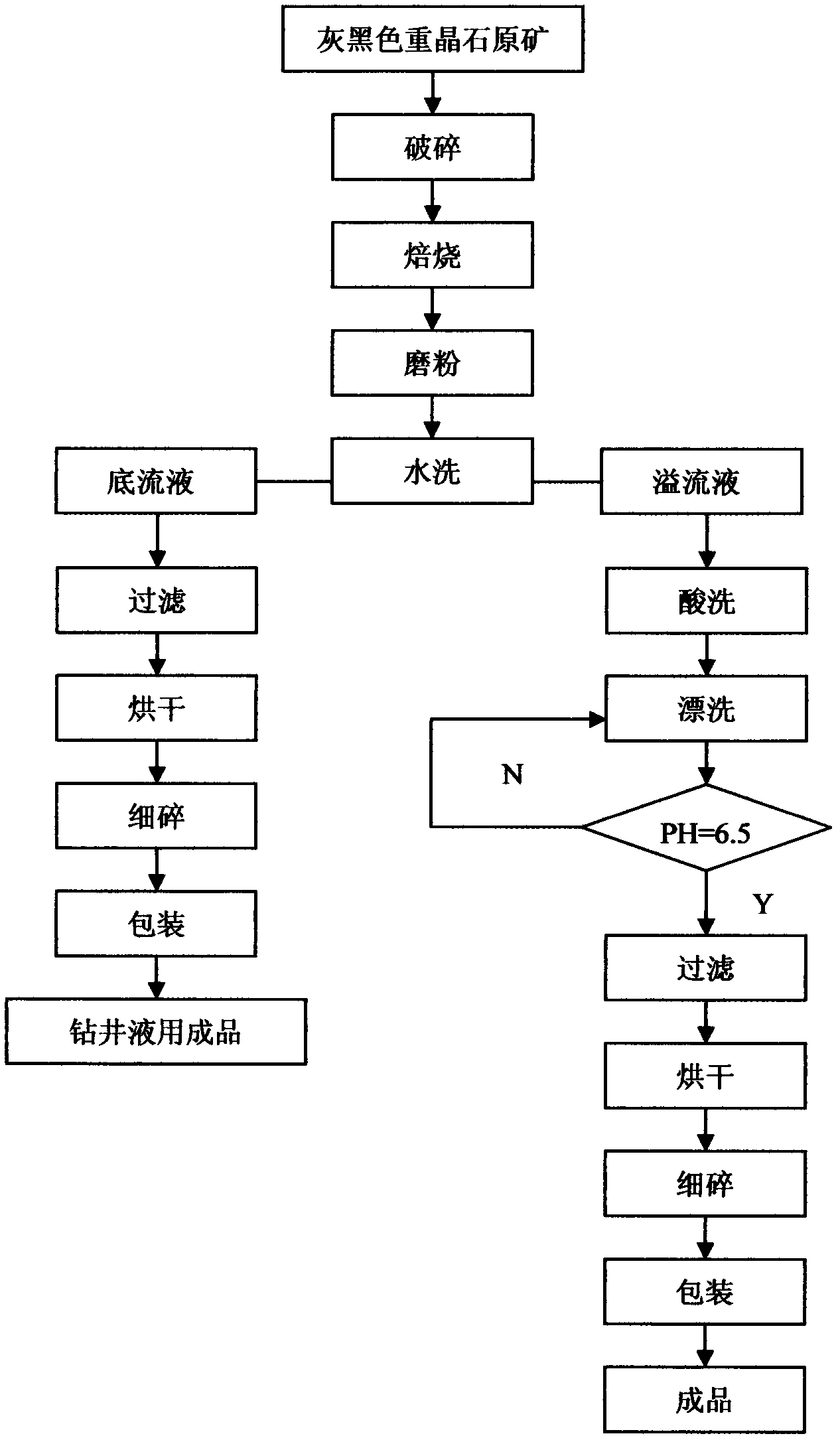

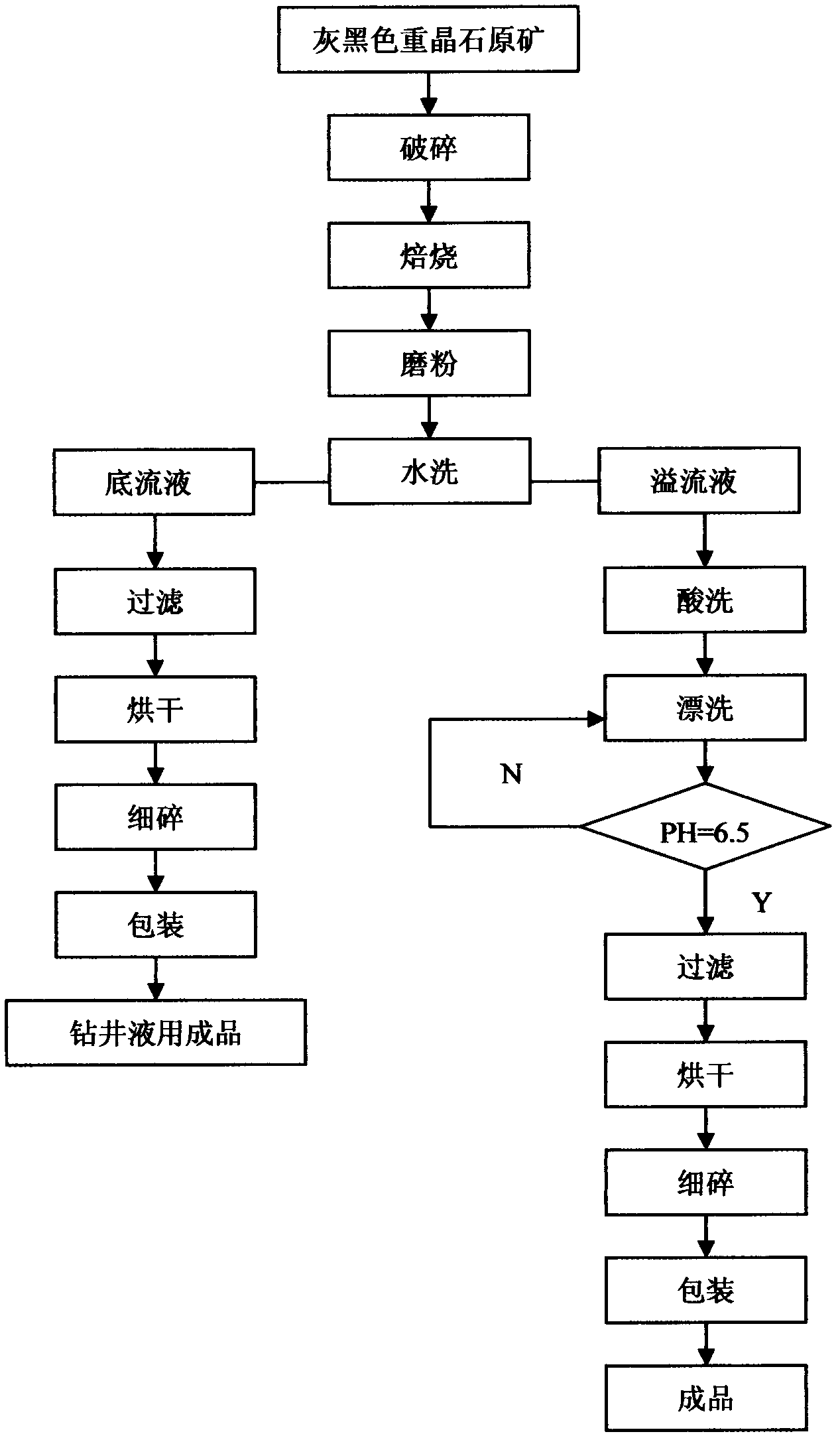

Production process for converting gray black barite into white barite finished product

InactiveCN102303890AImprove use valueHigh densityCalcium/strontium/barium sulfatesHigh densityFiltration

The invention discloses a production process for converting gray black barite into a white barite finished product. The process flow comprises: crushing black barite raw ore, roasting, grinding into powder, washing with water, pickling overflow liquid obtained after washing with water, rinsing, filtering, drying, finely breaking, packing and obtaining finished product, wherein the bottomflow liquid obtained after washing with water is filtered, the product obtained is dried and finely ground, and the ground product is packed and thus, the drilling fluid finished product is obtained. When the production process is used, gray black barite can be converted into white barite which can be directly used in paint making, coating, paper making and the like industries as a filler, the density of barite can be increased greatly, the corresponding indexes such as alkali metal content and viscous effect can be improved correspondingly, the prepared drilling fluid weighting agent can meet high-density and high-quality drilling fluid requirements, the application range of the gray black barite can be obviously expanded and the utilization value of the gray black barite can be increased.

Owner:卢长生

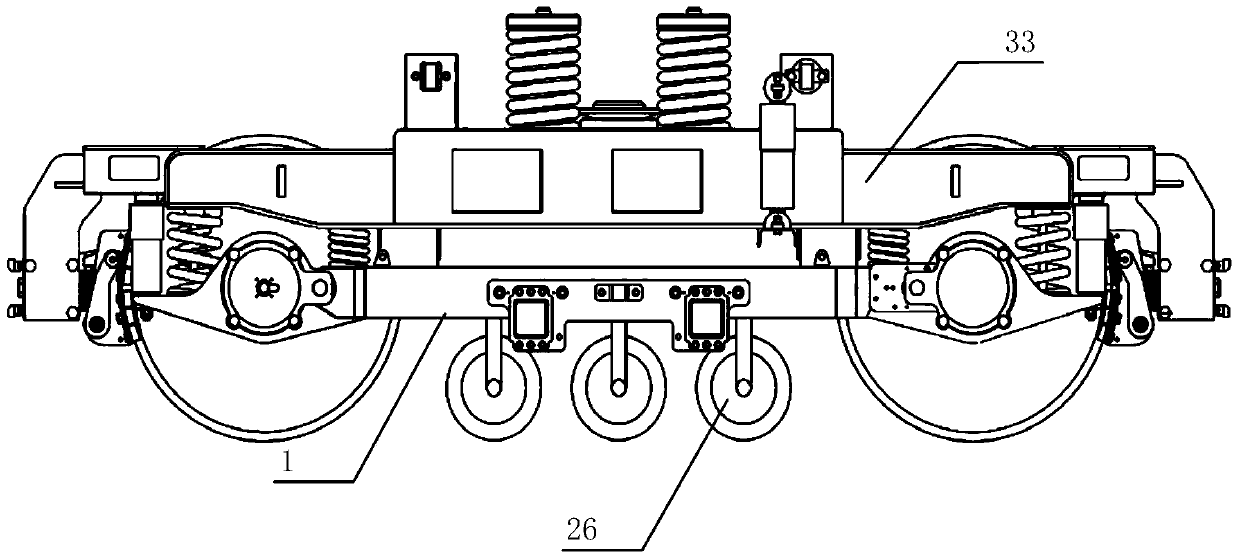

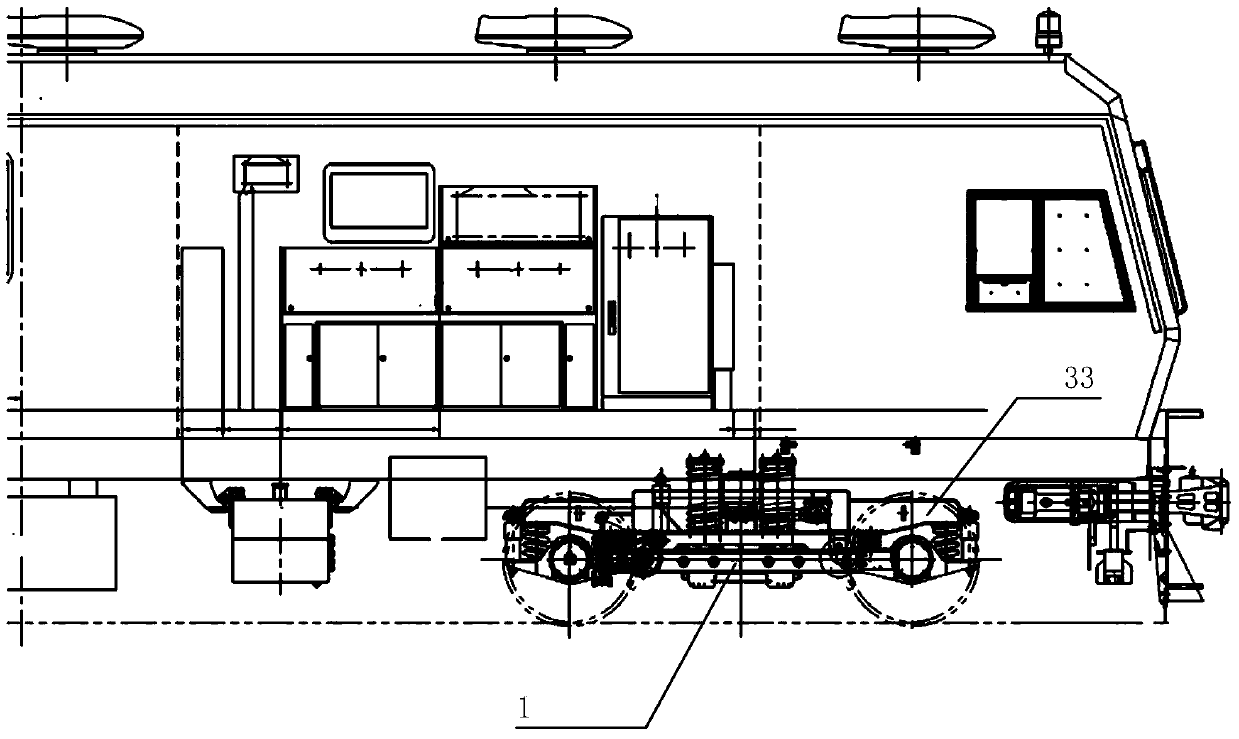

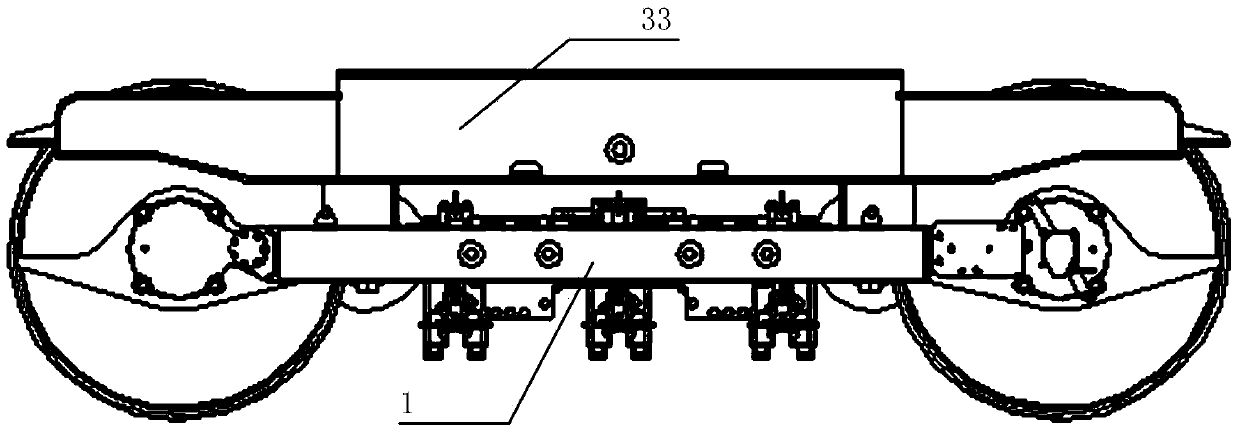

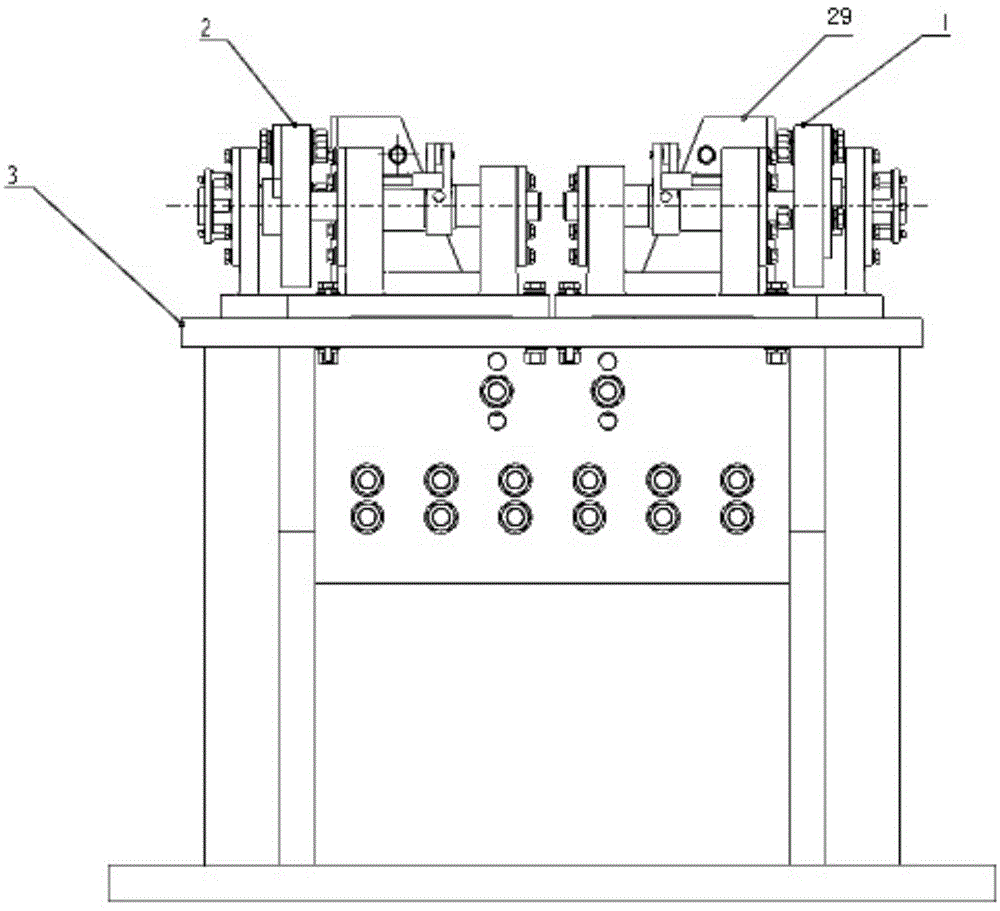

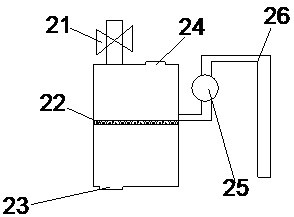

Inspection device mounted based on bogie

ActiveCN103738357AMeet the densityFulfil requirementsRailway auxillary equipmentRailway profile gaugesBogieHigh density

The invention discloses an inspection device mounted based on a bogie. The inspection device is mounted on the bogie and comprises left vertical beams, right vertical beams, two frame assemblies, transverse beams, unit fixing device assemblies, motor assemblies, inspecting wheel assemblies, and connecting plates. The left vertical beams and the right vertical beams are mutually connected to form a carrier of an inspection device body, and the frame assemblies are correspondingly mounted on the carrier along the directions of the transverse beams. The unit fixing device assemblies are movably mounted on the frame assemblies through the connecting plates, and the inspecting wheel assemblies are arranged on the unit fixing device assemblies. The motor assemblies are arranged between the frame assemblies and combinations of the unit fixing device assemblies and the connecting plates and drive the unit fixing device assemblies to move on the frame assemblies along the direction of the transverse beams. The device is compact in structure, high in adaptability and high in efficiency and accuracy, is adaptable to 0 to 80 km / h high speed operations, and current high density and high speed running organizing requirements can be met fully.

Owner:ZHUZHOU TIMES ELECTRONICS TECH CO LTD +1

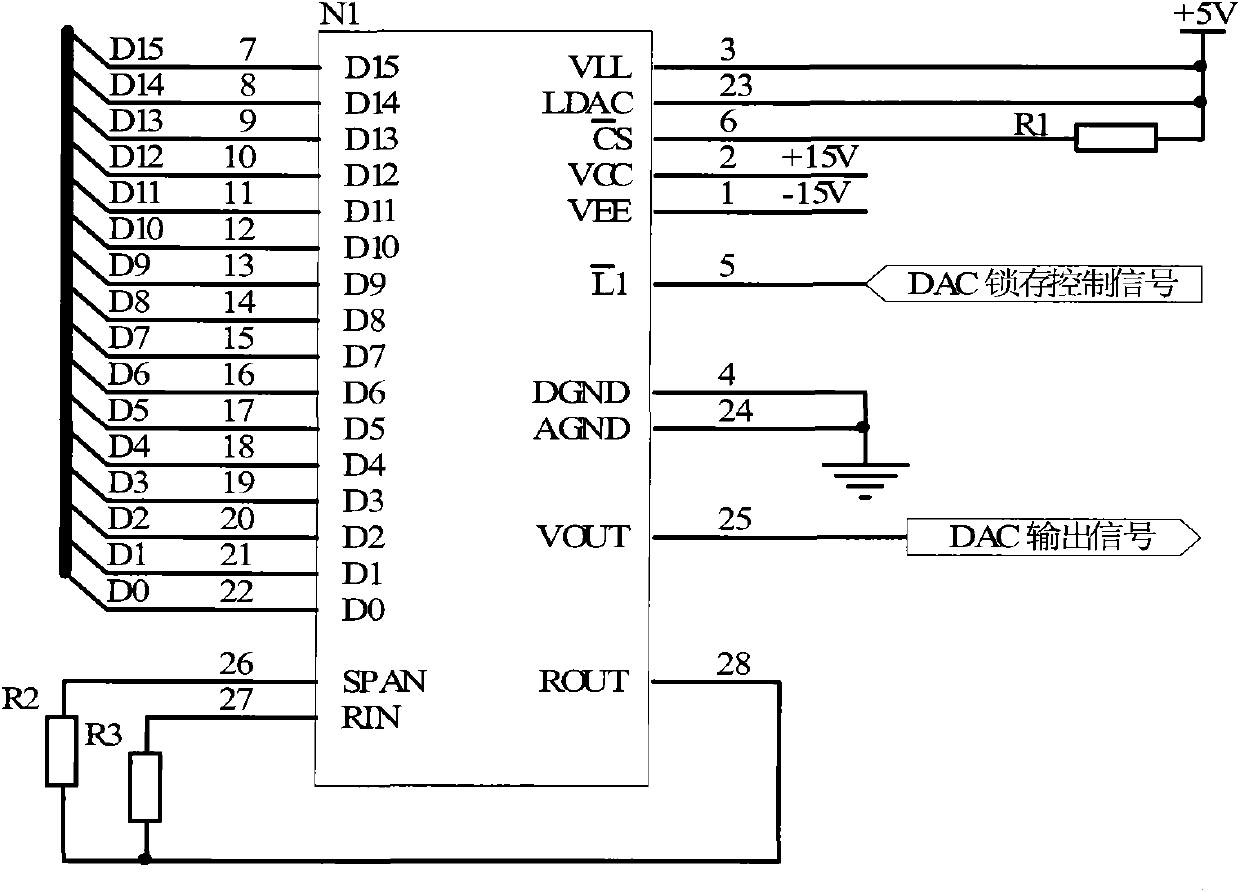

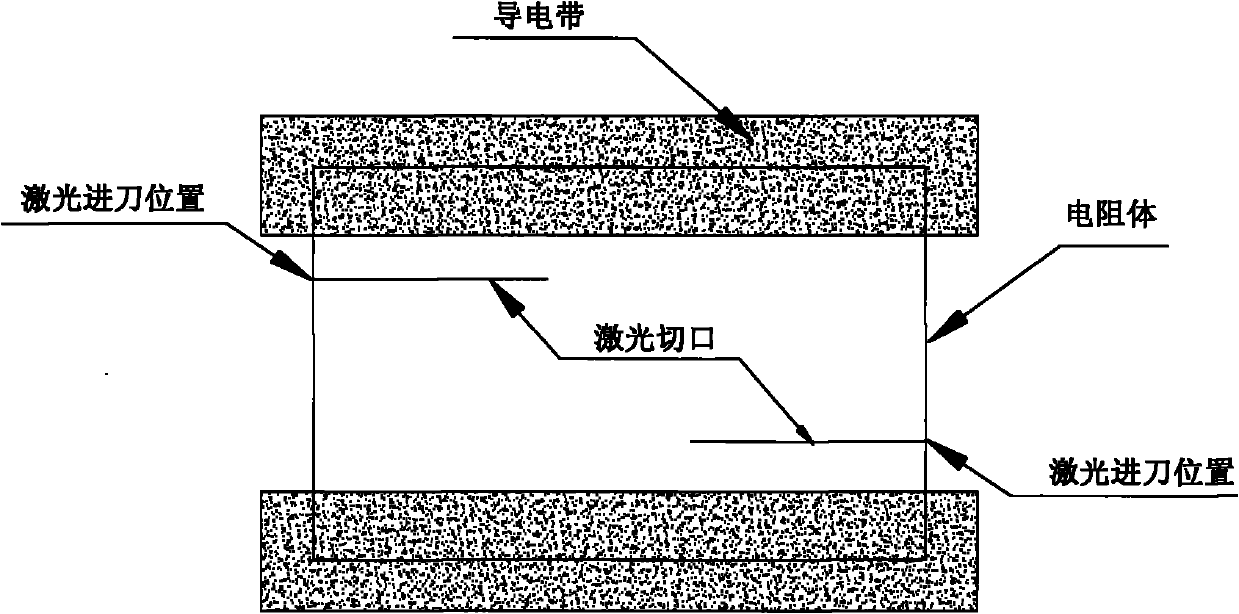

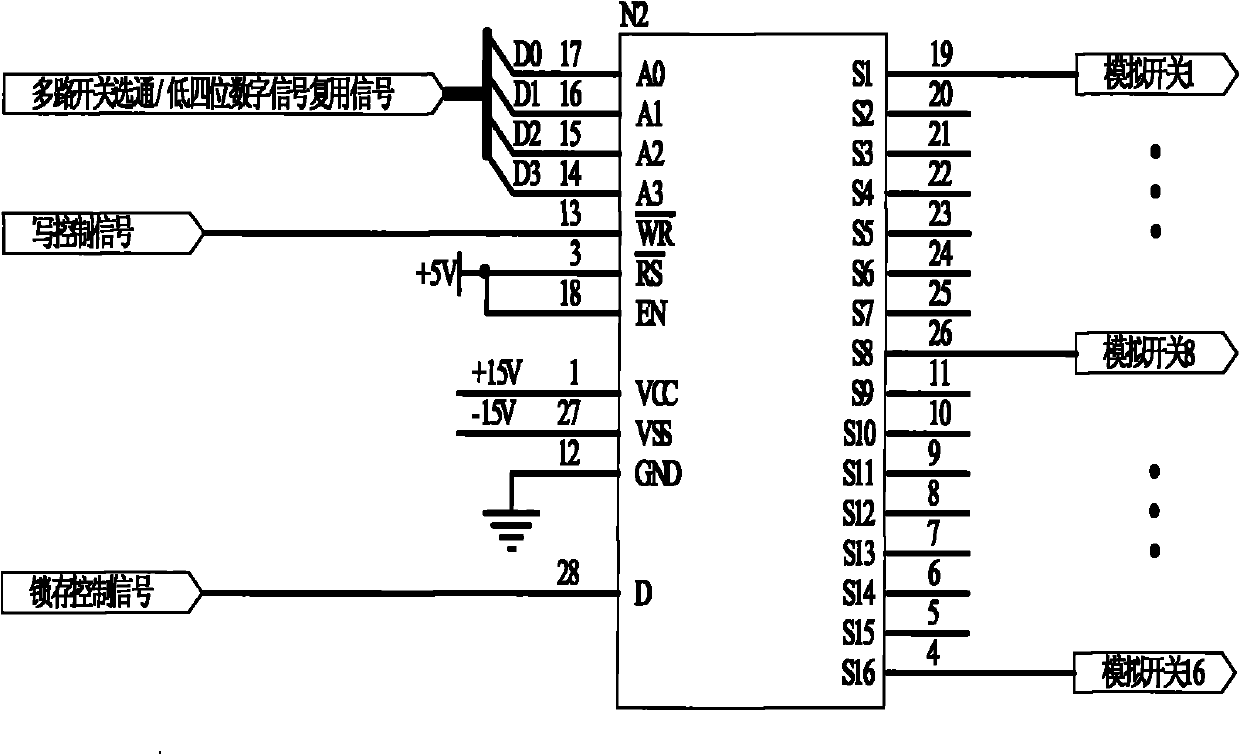

High-accuracy fine adjustment method for zero position and measuring range parameters of digital-to-analogue conversion circuit

InactiveCN101997546AMeet the densityMinimization requirementsAnalogue/digital conversion calibration/testingElectricityEngineering

The invention relates to a high-accuracy fine adjustment method for the zero position and measuring range parameters of a digital-to-analogue conversion circuit, which comprises the following steps of: connecting a thick-film resistor for realizing fine adjustment in the digital-to-analogue conversion circuit; manufacturing a laser fine adjustment special probe card connected with the thick-film resistor and an electrical detecting instrument; and presetting electrical performance parameters of the zero position and the measuring range of the circuit, inputting a digital signal source to the digital-to-analogue conversion circuit, controlling a laser beam to form a laser incision on the thick-film resistor by utilizing a programmable fine adjustment unit of a laser fine adjustment machineso as to perform active fine adjustment of the thick-film resistor, monitoring the zero position and output voltage value of full measuring range of the digital-to-analogue conversion circuit on linein real time by utilizing the electrical detecting instrument, so that the output reaches the preset electrical performance parameter values accurately to realize the high-accuracy fine adjustment ofthe zero position and measuring range of the digital-to-analogue conversion circuit. By the method, the high density and miniaturization requirements of multiple paths of digital-to-analogue conversion circuits can be met, the consistency of the output of multiple paths of digital-to-analogue conversion circuits is improved effectively, and the accuracy of the electrical performance parameters offrameworks of like products can be improved simultaneously and effectively.

Owner:SUZHOU R&D CENT OF NO 214 RES INST OF CHINA NORTH IND GRP

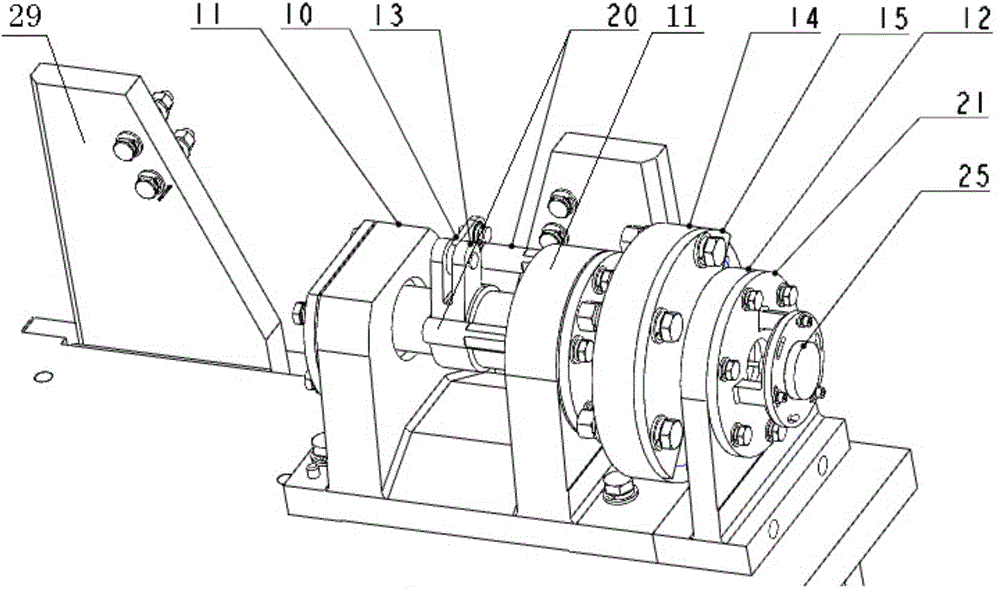

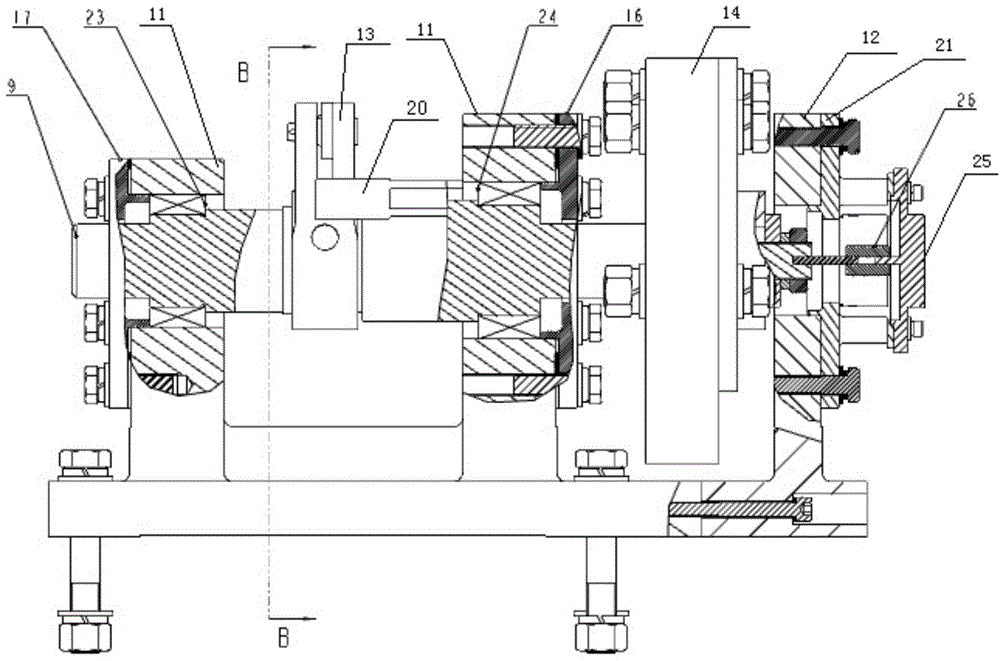

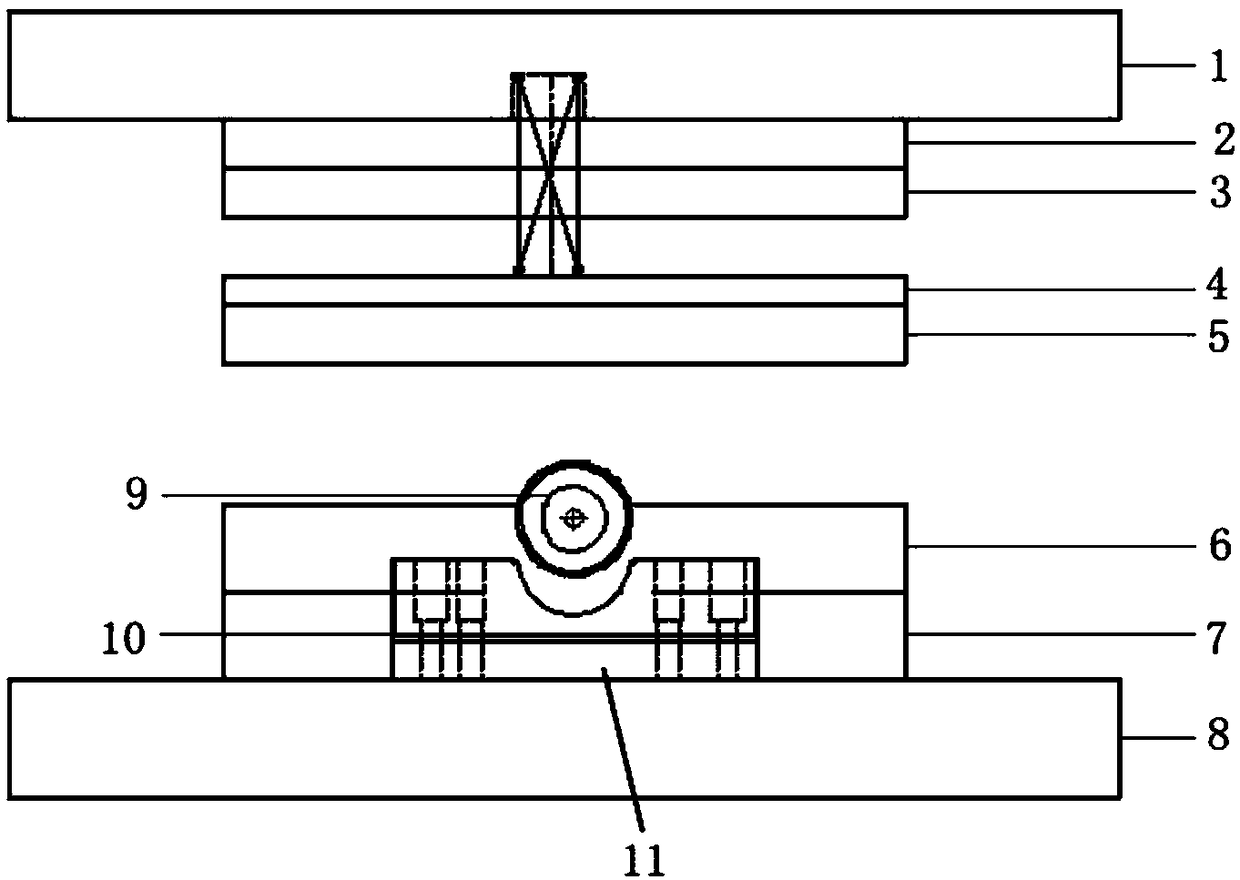

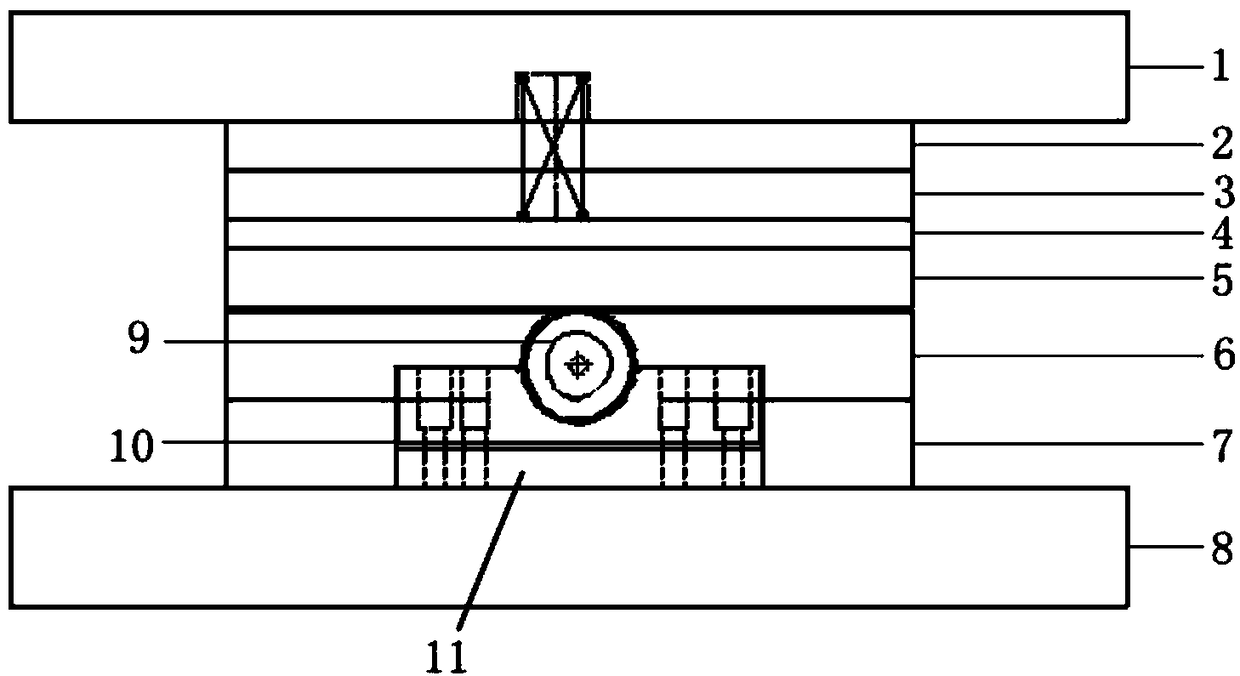

Adjustable-rigidity double-air-rudder equivalent load simulation device

ActiveCN105628349AEasy to assemble and disassembleMeet the densityMachine part testingVacuum pumpingSpatial structure

The invention belongs to the field of a servo mechanism, relates to an adjustable-rigidity double-air-rudder equivalent load simulation device, and specifically relates to an adjustable-rigidity double-air-rudder equivalent load simulation device for acceptance inspection of electro-hydraulic servo mechanism. The device comprises a right-end inertia assembly, a left-end inertia assembly, a base and an elastic support ear assembly; and the right-end inertia assembly and the left-end inertia assembly are symmetrically fixed on the base, and the elastic support ear assembly is fixed to a side face of the base. The device has the advantages of two-position integration and the small space structure, a load characteristic is guaranteed to be stable and reliable in a long term, and assembly and disassembly of a to-be-detected product, filling of a servo mechanism, vacuum pumping and other operation are convenient to perform; the rotational inertia, the inertia moment and the load rigidity parameter are adjustable; and, when the device does not work, a swinging scope of a rocker arm can be limited through a limited rod, and then the object of protection of n angle displacement sensor is achieved.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

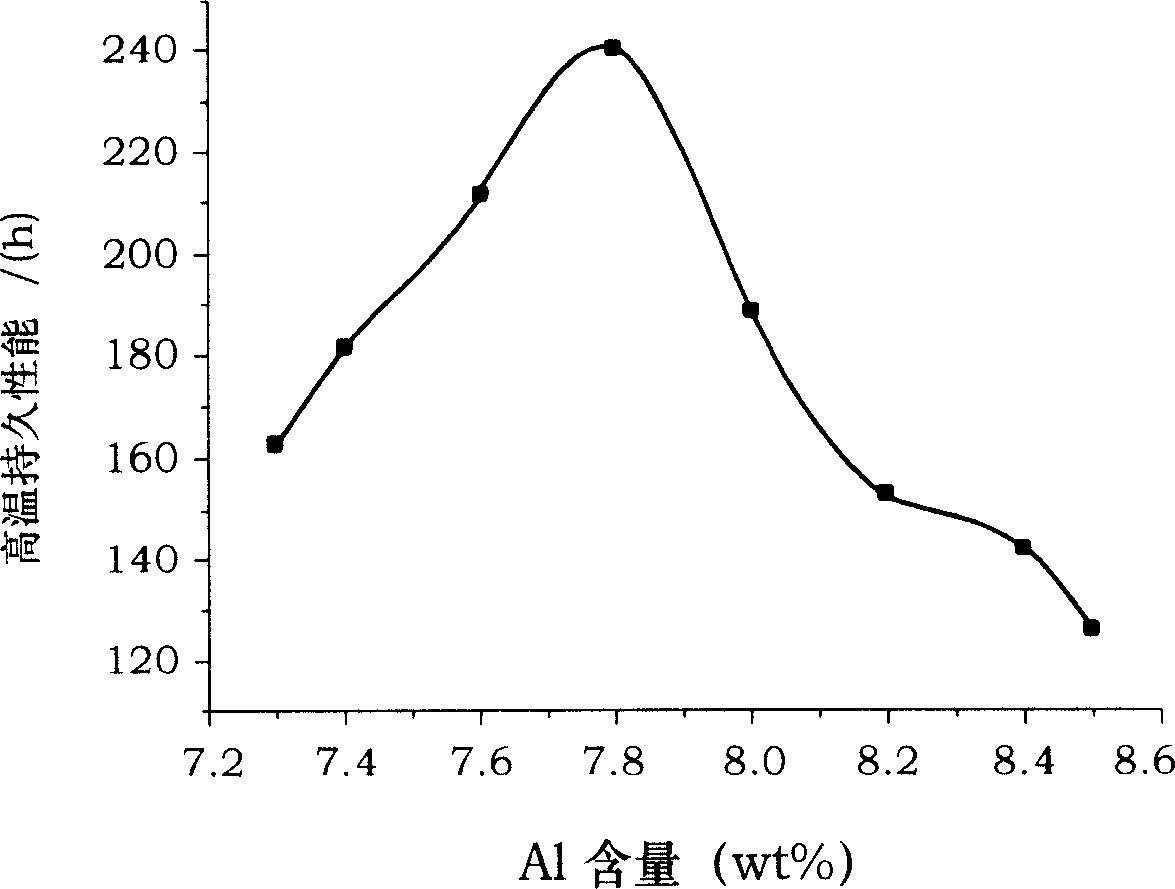

High temperature alloy material of Ni3AL based monocrystalline containing molybdenum, and praparation method

This invention discloses a Mo-containing Ni3Al-based single crystal high-temperature alloy material, which is composed of: Ni 7.3-8.5 wt.5, Al 13.5-15 wt. % and Mo. The Mo-containing Ni3Al-based single crystal high-temperature alloy material has a density of 7.8-7.9 g / cm3, which can satisfy the requirements of low density and high push weight ratio of aviation gas turbine engines. The alloy material also has excellent high-temperature strength and plasticity and high stress conditions, and the high-temperature tolerance can reach 239.35 h at 1100 deg.C under 130 MPa.

Owner:BEIHANG UNIV

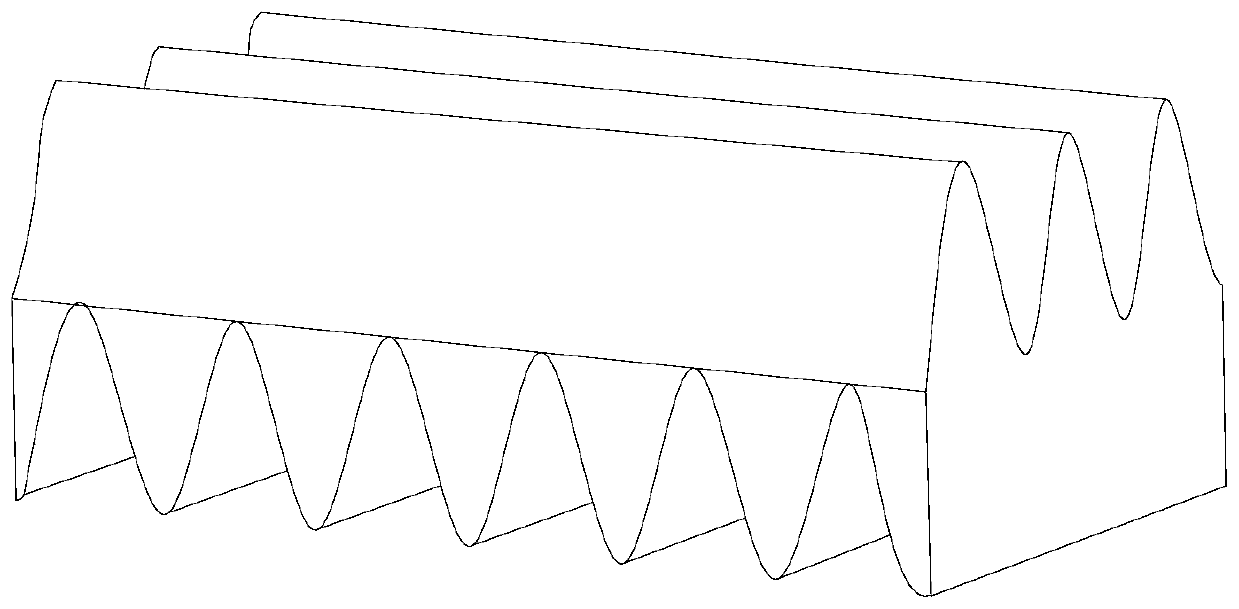

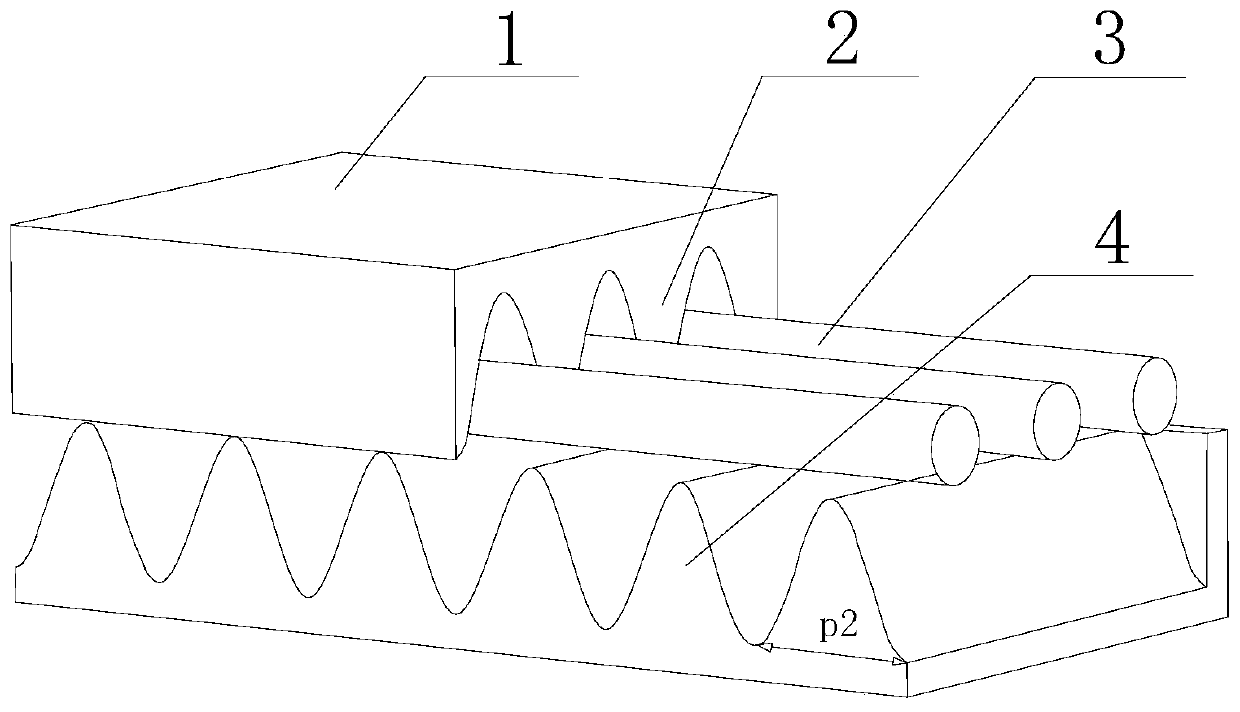

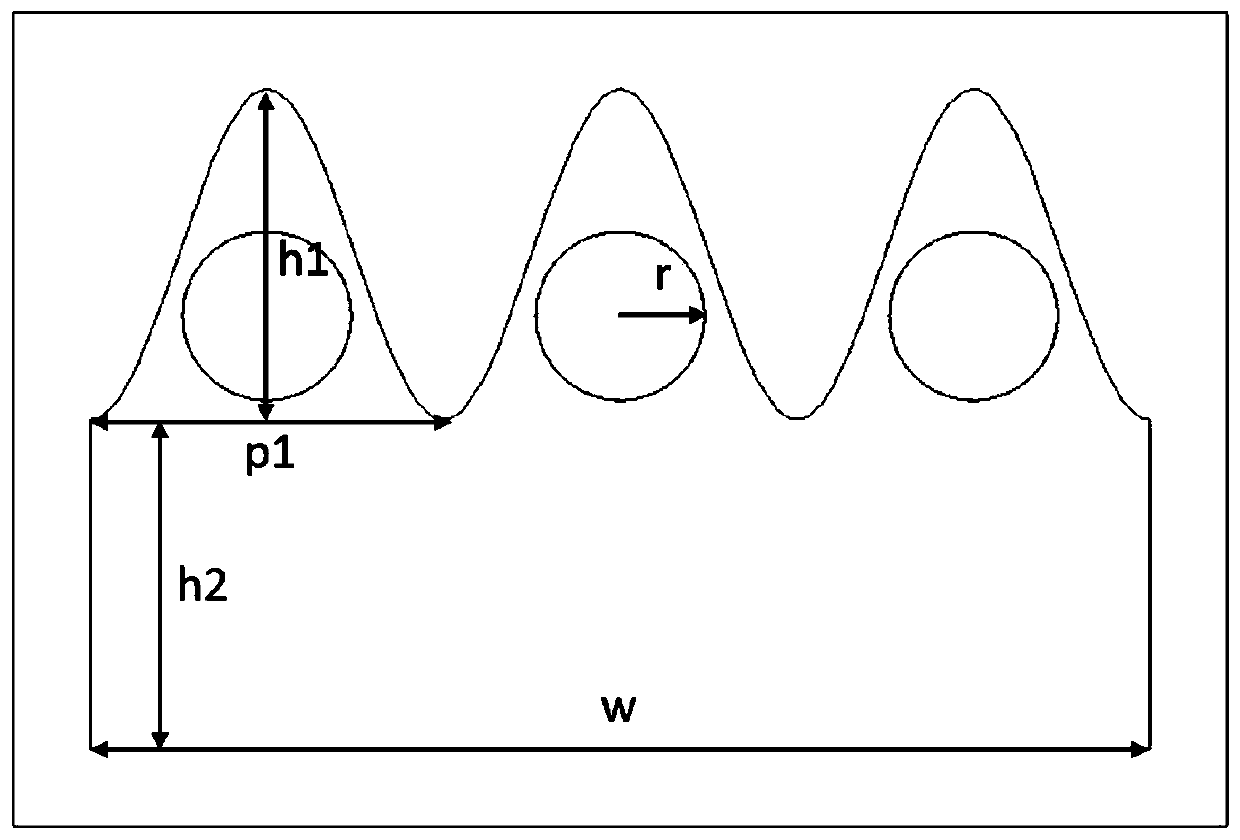

Multi-electron-beam-channel slow-wave structure with trigonometric function contour

InactiveCN110752131ARealize long-distance transmissionImprove interchangeabilityTransit-tube circuit elementsWave structureParticle physics

The invention discloses a multi-electron-beam-channel slow-wave structure with a trigonometric function contour, and belongs to the technical field of electric vacuum devices. The structure is composed of a cuboid shell, a plurality of cosine grid teeth distributed at the upper part in the shell and a plurality of sine grid teeth distributed at the lower part in the shell, wherein an electron beamchannel is formed between every two adjacent cosine grid teeth, circular electron beams are arranged in the electron beam channels, and the part between two adjacent sine grid teeth serves as a high-frequency system so as to jointly form the multi-electron-beam-channel slow-wave structure. The multi-electron-beam-channel slow-wave structure with the trigonometric function contour provided by theinvention is suitable for working in high-order space harmonics, and can meet requirements of the terahertz wave band. Meanwhile, the structure is provided with the natural circular electron beam channels, can achieve long-distance transmission under the condition that the electron beam current density is not reduced, and can effectively conduct beam-wave interaction.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

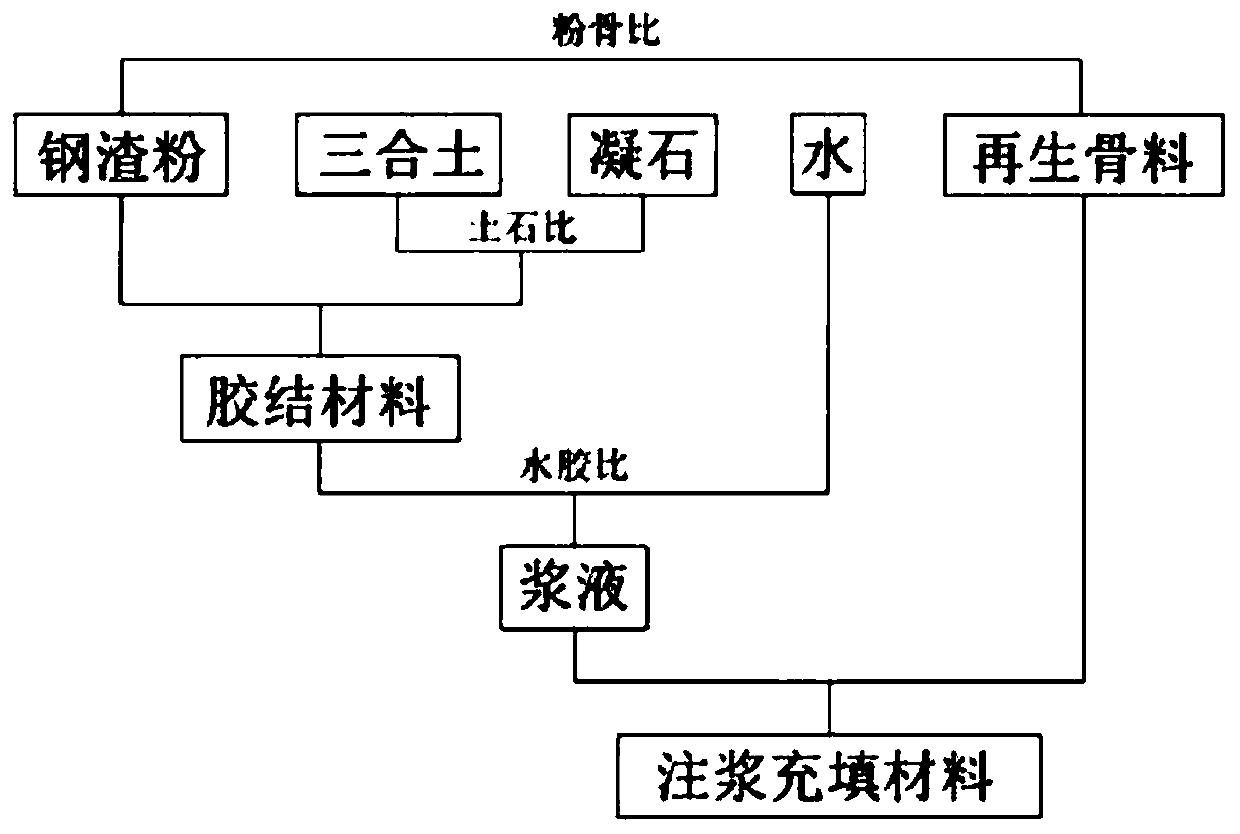

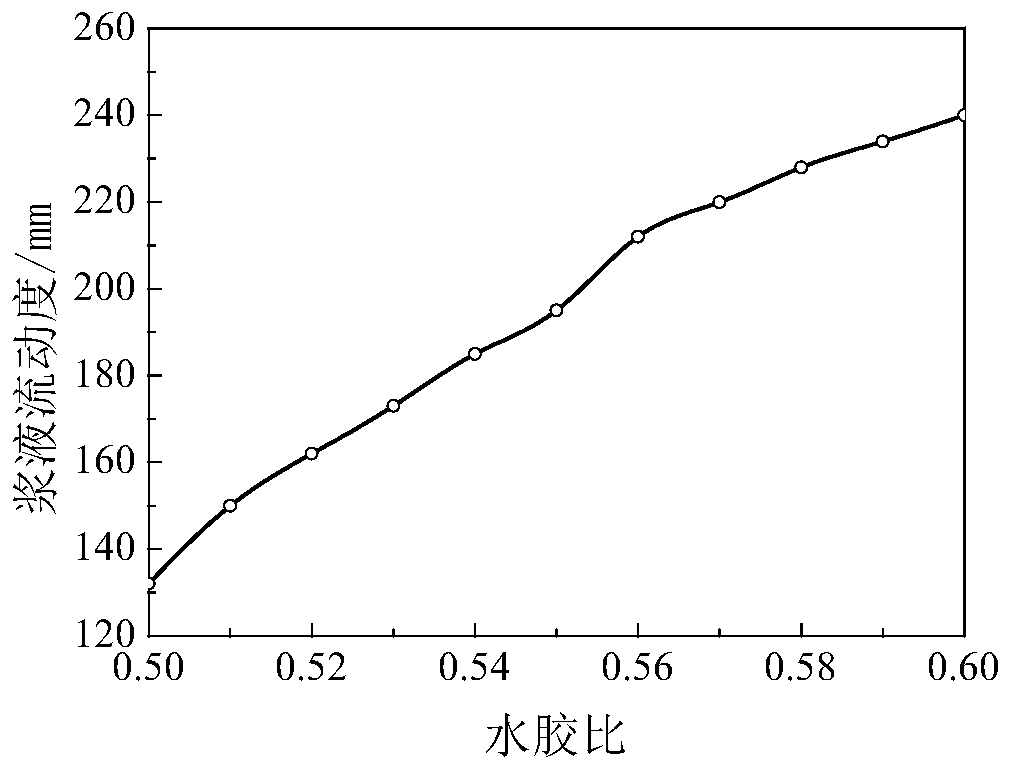

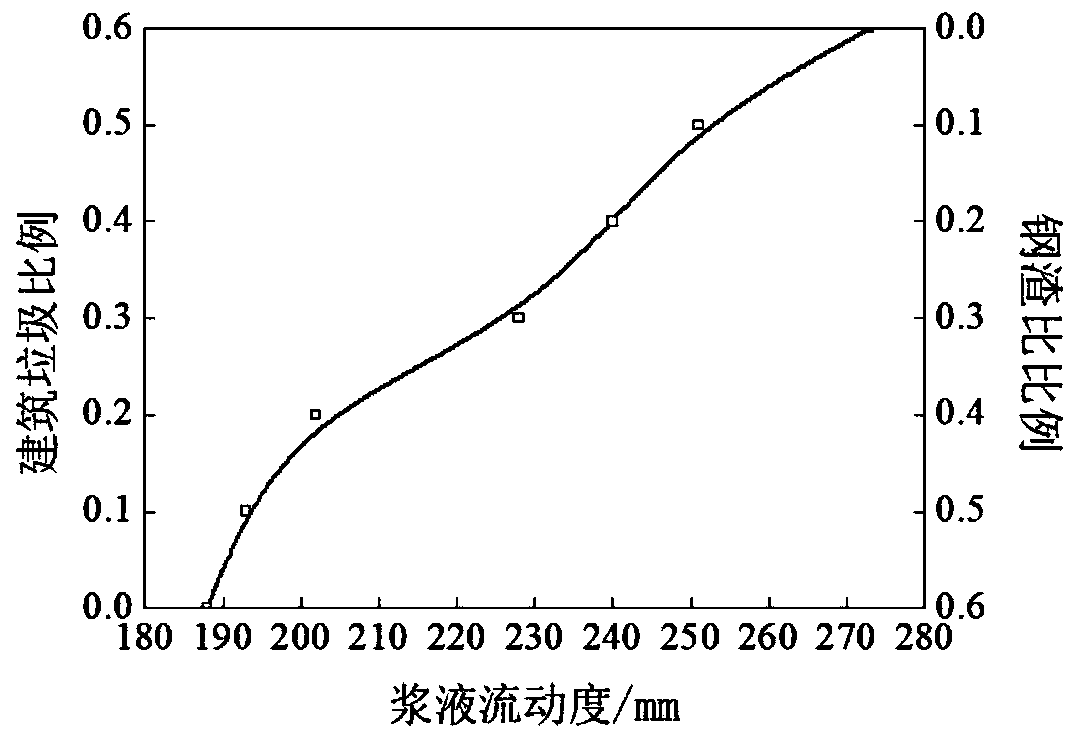

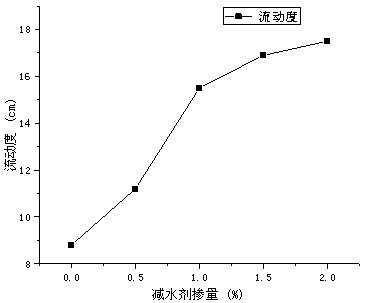

Method for preparing grouting and filling material by utilizing industrial solid waste

The invention discloses a method for preparing a grouting and filling material by utilizing industrial solid waste. The method comprises the following specific steps: determination of raw materials ofthe grouting and filling material: selecting building waste recycled aggregates, steel slag powder, glued stone and concrete as the raw materials; respectively determining proportions of required cementing materials to water through measurement, determining the proportion of the required building waste recycled aggregates to the steel slag powder, and determining the proportion of the required concrete to the glued stone; mixing and preparing of a filling material: preparing the grouting and filling material according to the determined proportions of the cementing materials to the water, thedetermined proportion of the building waste recycled aggregates to the steel slag powder and the determined proportion of the concrete to the glued stone. According to the method disclosed by the invention, not only the problem of urban environment pollution can be reduced, but also the problems of source and cost of the grouting and filling material can also be solved, and meanwhile, the fluidityand the compression strength of the grouting and filling material both can accord with requirements.

Owner:XUZHOU UNIV OF TECH

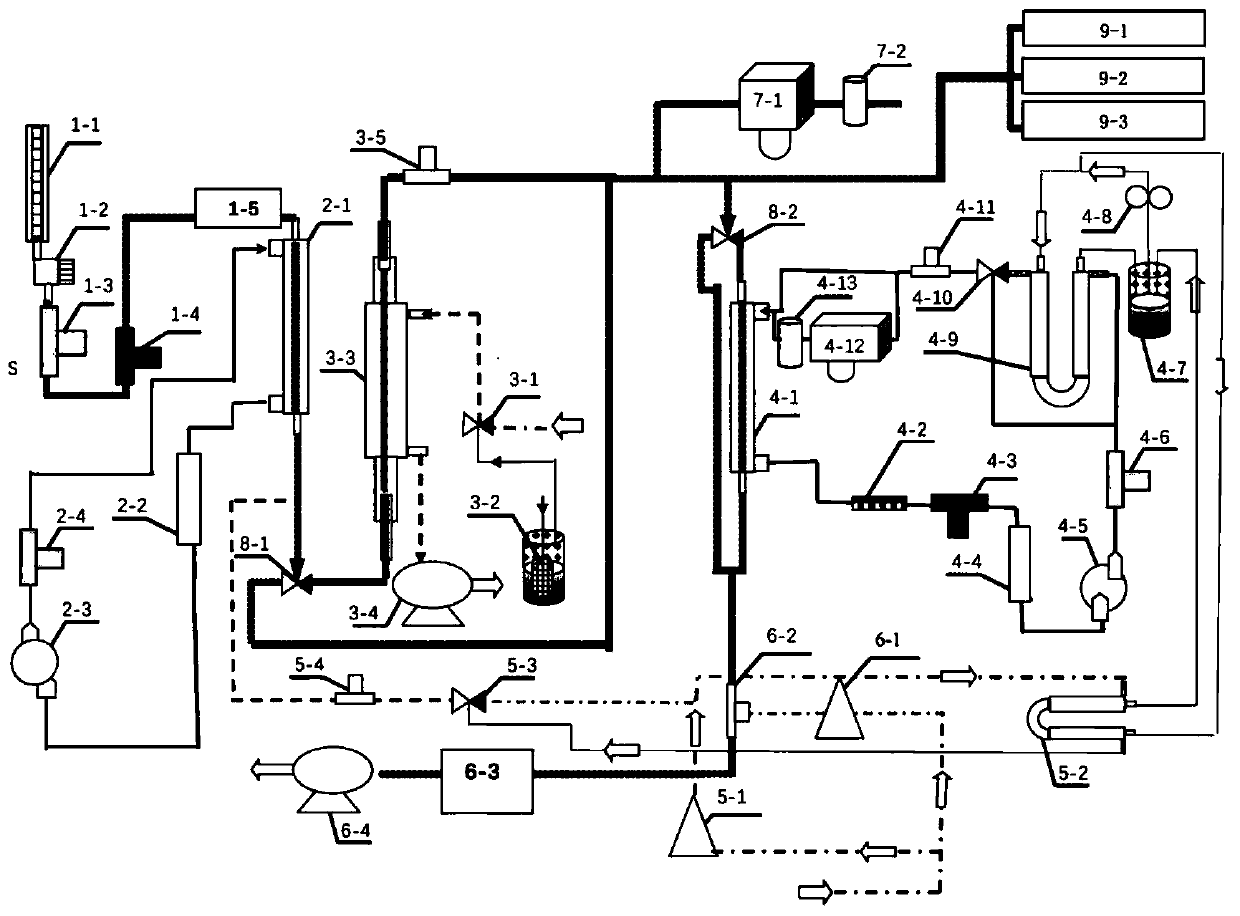

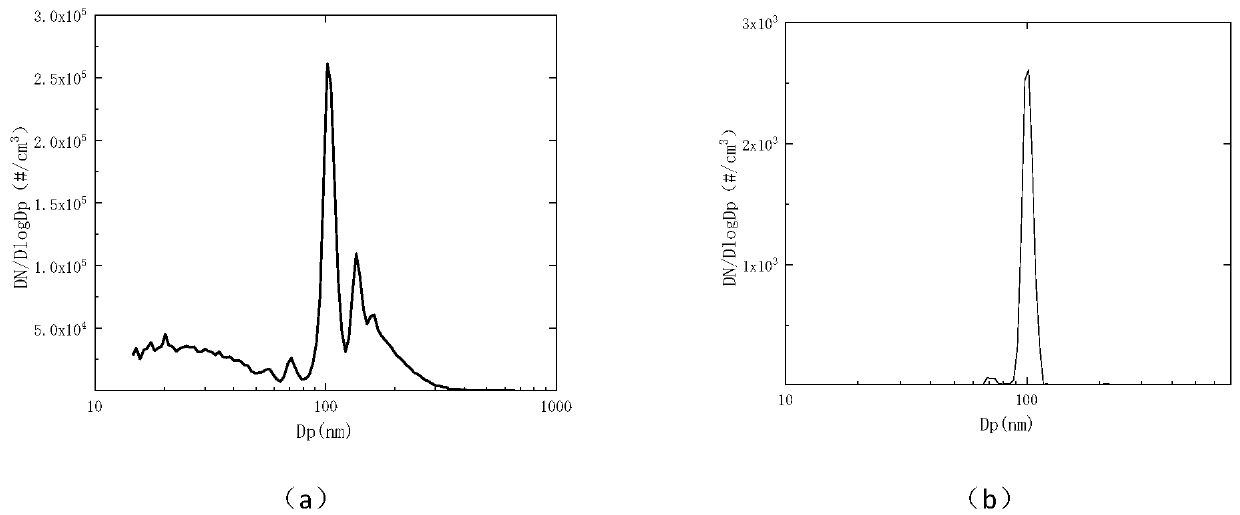

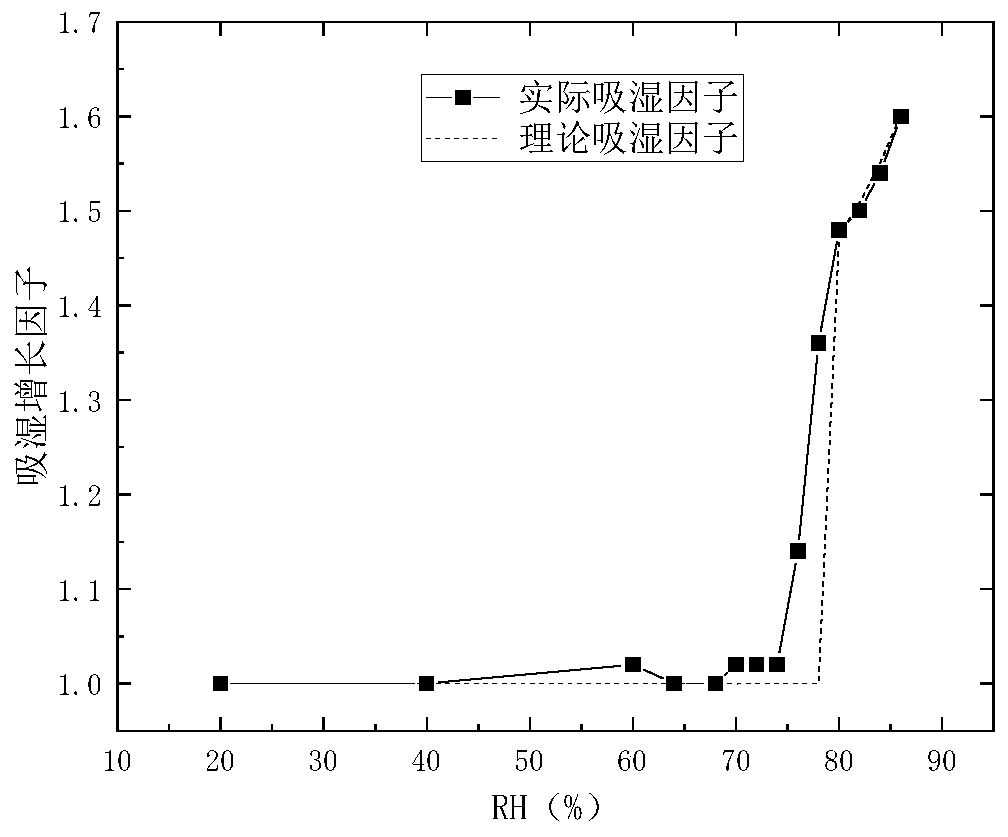

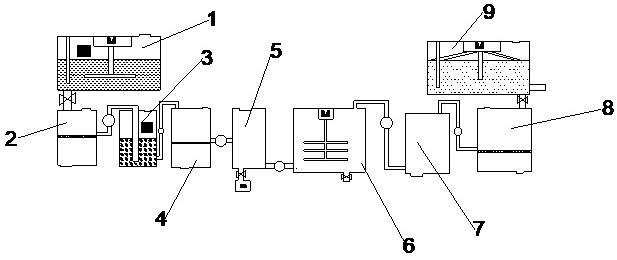

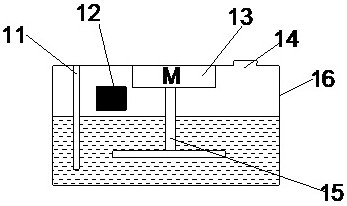

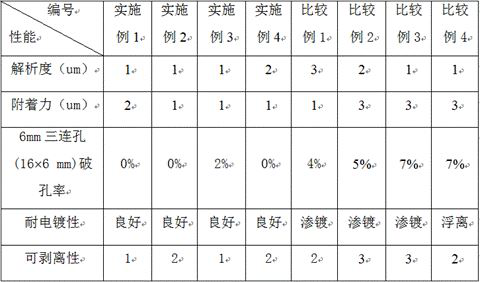

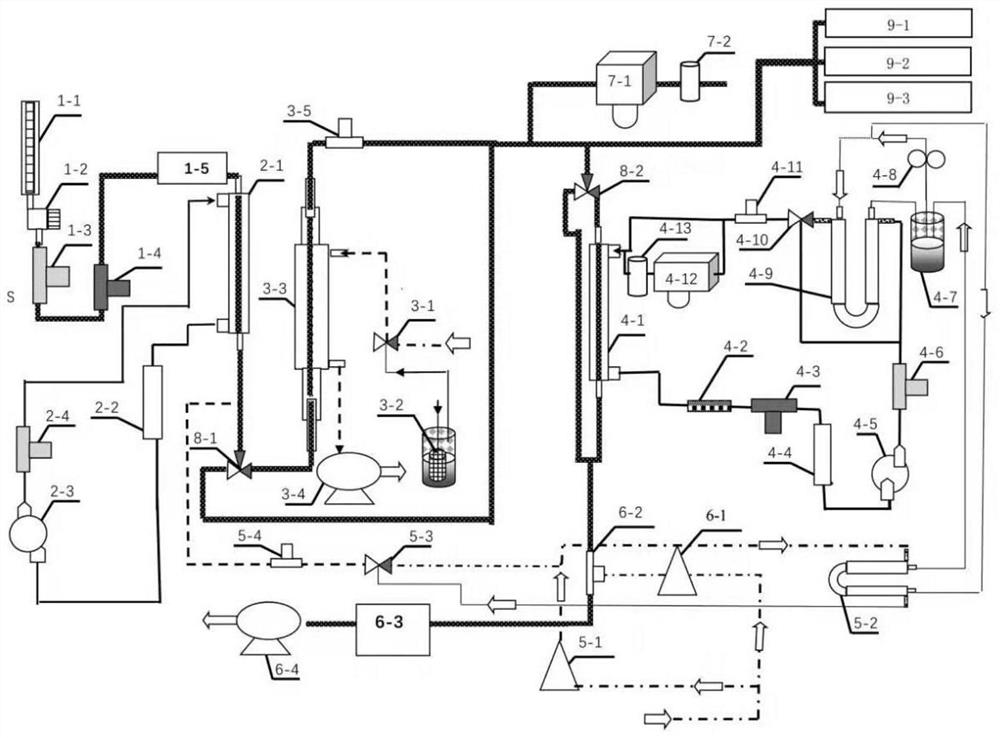

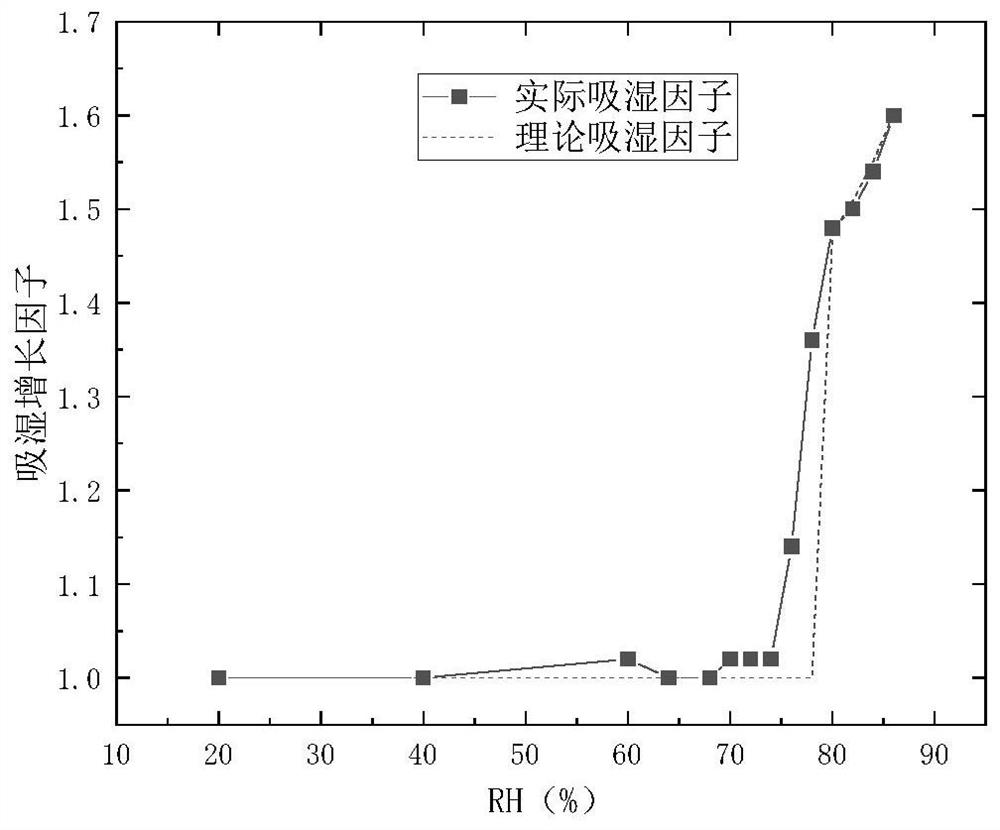

Aerosol moisture absorption characteristic comprehensive measuring instrument

InactiveCN111122392AHigh trafficMeet the optical characteristicsParticle size analysisIndividual particle analysisParticulatesControl system

The invention discloses an aerosol moisture absorption characteristic comprehensive measuring instrument, which comprises an aerosol pretreatment system, a first particle screening system, a humidifying system, a second particle screening system, a diluting and humidifying system, a condensed particle counting system, a compressed air system, a temperature and humidity monitoring and calibrating system, a parameter measuring system and a signal acquisition and control system. By means of the aerosol moisture absorption characteristic comprehensive measuring instrument, the humidification flowis large, humidification is fast, the measurement precision is high, and self-correction can be achieved.

Owner:BEIHANG UNIV +1

Method for reinforcing silicone rubber by applying liquid crystal polymer microfibrillation

The invention belongs to the field of silicone rubber reinforcement and in particular relates to a method for reinforcing silicone rubber by applying liquid crystal polymer microfibrillation. Ingredients of a composite material comprise high temperature vulcanized silicone rubber, white carbon black and liquid crystal polymers. A preparation method comprises the following steps: firstly preparingmaterials according to the ingredients, uniformly mixing on a mixer by adopting a melting and heat mixing method, and then vulcanizing, so that the silicone rubber-based composite material is obtained. the method provided by the invention has the advantages that the liquid crystal polymers can be fibrillated into a fibrous structure in a processing process, anchoring effect is achieved, mechanicalproperties of the silicone rubber-based composite material are improved, and the development requirement that the future silicone rubber-based composite material gives consideration to flame retardance, heat resistance, low density and high strength at the same time.

Owner:NORTHEASTERN UNIV

Infrared ceramic body and infrared health physiotherapy instrument thereof

InactiveCN104609877AMeet the densityMeet infrared optical densityLight therapyCeramicwareFiberHydraulic cylinder

The invention discloses an infrared ceramic body and an infrared health physiotherapy instrument thereof and aims at providing an infrared ceramic body with the physiotherapy grade infrared effect and an infrared health physiotherapy instrument containing the infrared ceramic body. The infrared health physiotherapy instrument accords with the human body needs and is convenient to use. A preparation method of the infrared ceramic body comprises the following steps: weighing the components, mixing, grinding, then adding an adhesive, silica powder and irregular pore-forming fibers, smelting into sludge, vacuumizing to obtain a glue injection colloid, forming by virtue of an injection nozzle of a hydraulic cylinder and a reticular forming die in an extrusion mode, carrying out infrared drying, sintering until the temperature is 1200-1500 DEG C, and keeping the temperature for 2-9h to prepare a porous grid ceramic body; jet milling a material until the size is 600-2000 meshes, adding the adhesive and silica, and mixing into a slurry liquid; and cooling the porous grid ceramic body to the normal temperature, rapidly immersing the porous grid ceramic body into the slurry liquid with the temperature to be 80-100 DEG C, detaining for 60-300 seconds, enabling the infrared slurry to fill into the porous grid ceramic body, drying, carrying out secondary low-temperature sintering at the temperature of 600-900 DEG C, and keeping the temperature for 3-6h. The invention belongs to the technical field of health equipment.

Owner:GUANGZHOU BAIYUXIN BIOCHEM TECH

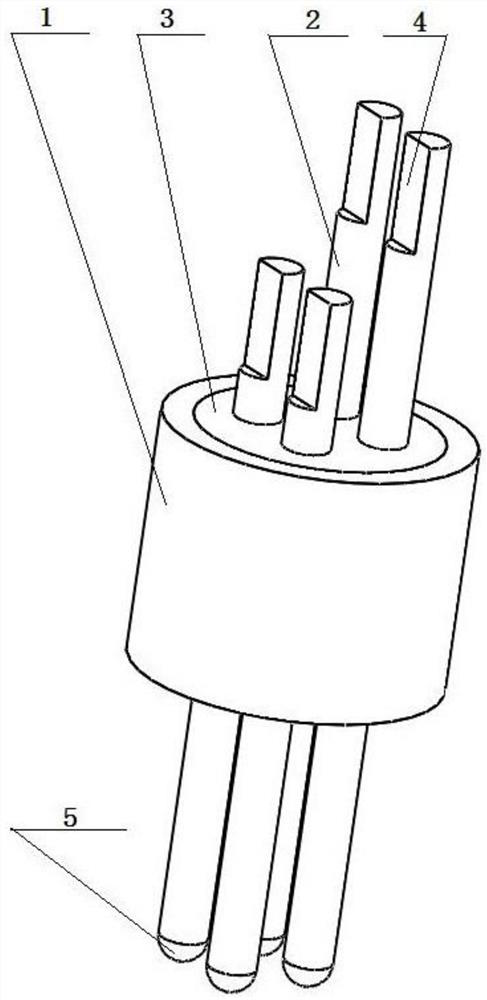

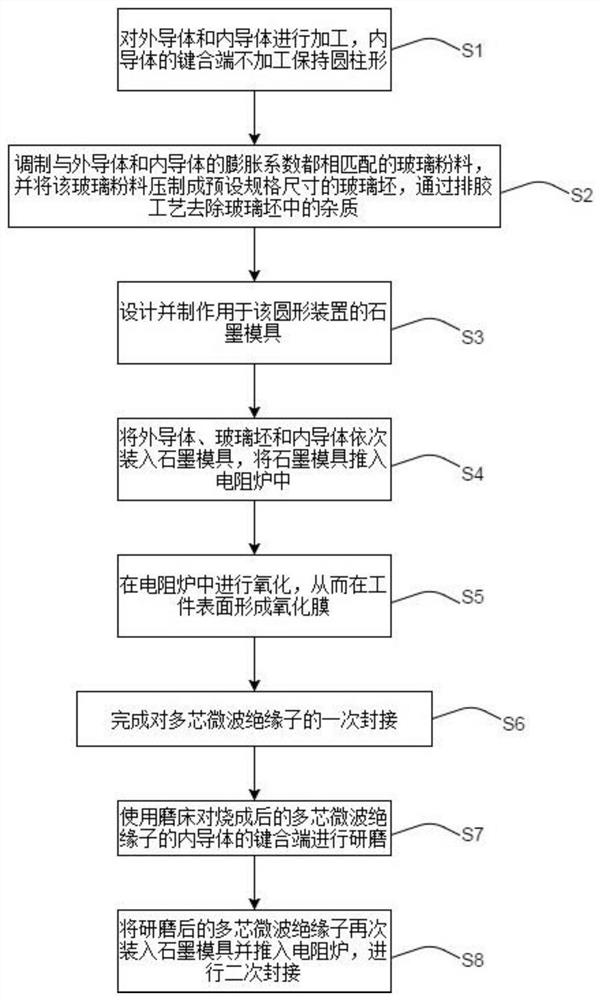

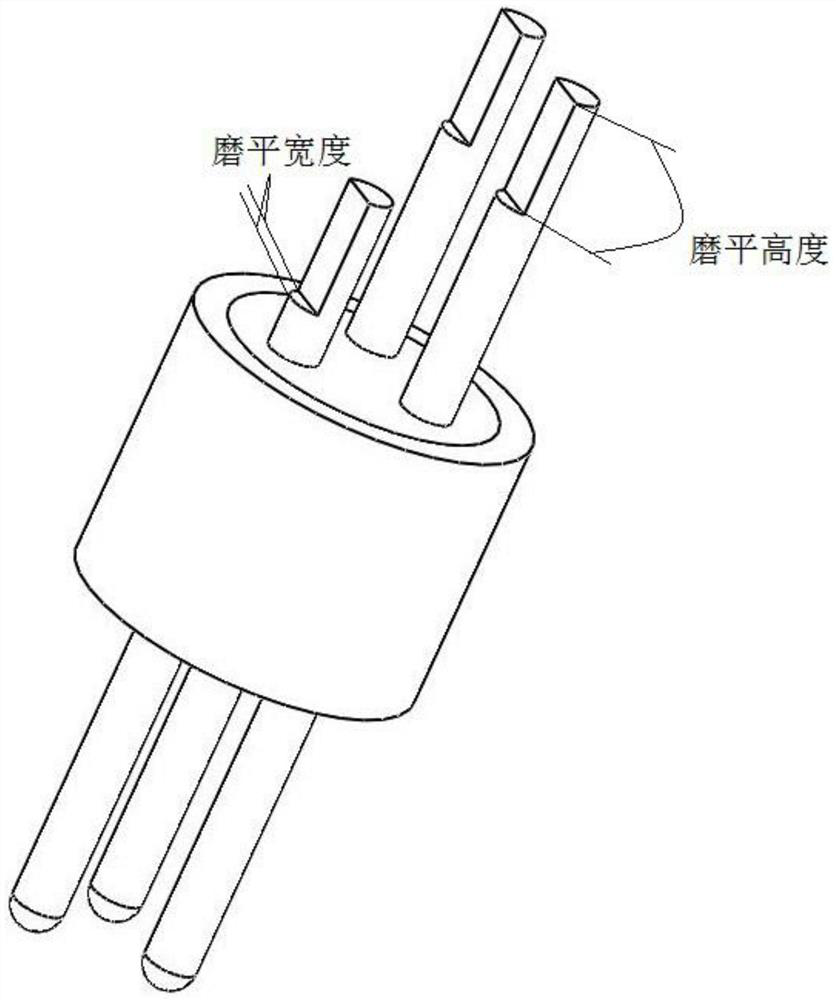

Circular device of glass-sealed multi-core microwave insulator and manufacturing method thereof

PendingCN112332140AMeet reliabilityMeet the densityContact member manufacturingContact member assembly/disassemblyAerospaceMicrowave

The invention discloses a circular device of a glass-sealed multi-core microwave insulator and a manufacturing method of the circular device, relates to the technical field of microwave devices, and solves the technical problems of low integration level, large size and heavy weight of the microwave insulator. The circular device comprises an outer conductor, an inner conductor and an insulator, wherein the insulator is a glass cylinder; N through holes are formed in the glass cylinder by 2-4 rows; the center distances between any two adjacent through holes are equal, and an inner conductor penetrates through the insulator from the through holes. Compared with the prior art, the integration degree is improved, the occupied space is smaller, the weight is lighter, the development requirements of aerospace and military radars for high reliability, high density, miniaturization and light weight are met, meanwhile, the cost is reduced, and the assembly process is simplified.

Owner:SOUTHEAST UNIV

Technology and apparatus for producing aluminum alloy substrate printed circuit board

ActiveCN107858625AImprove cooling effectImprove stabilityMolten spray coatingPrinted circuit manufactureInsulation layerCeramic coating

The invention discloses a technology and an apparatus for producing an aluminum alloy substrate printed circuit board. The production technology comprises the following steps: performing arc sprayingto form an aluminum coating, used as a primer layer, on the surface of an aluminum alloy substrate; spraying a ceramic coating on the aluminum coating by using a plasma spraying method; performing vacuum infiltration to complete the pore sealing of the ceramic coating; spraying a water-soluble ceramic coating on the surface of the ceramic coating, and baking the water-soluble ceramic coating to form a ceramic film layer on the ceramic surface to complete the production of a ceramic insulation layer; and arranging wires on the ceramic insulation layer through using laser. The production apparatus comprises a driving belt, a first heating furnace, an arc spraying device, a plasma spraying device, a vacuum furnace, a water-soluble ceramic spraying device, a second heating furnace and a laser.The technology and the apparatus realize the production of the aluminum alloy substrate ceramic circuit board having the advantages of high heat dissipation performance, excellent electrical performance, good electromagnetic shielding performance, flexible processing modes and large-scale production, have a high stability and a high reliability, can be used in harsh environments, and improve theapplication range of the aluminum alloy circuit board.

Owner:WUHAN HGLASER ENG CO LTD

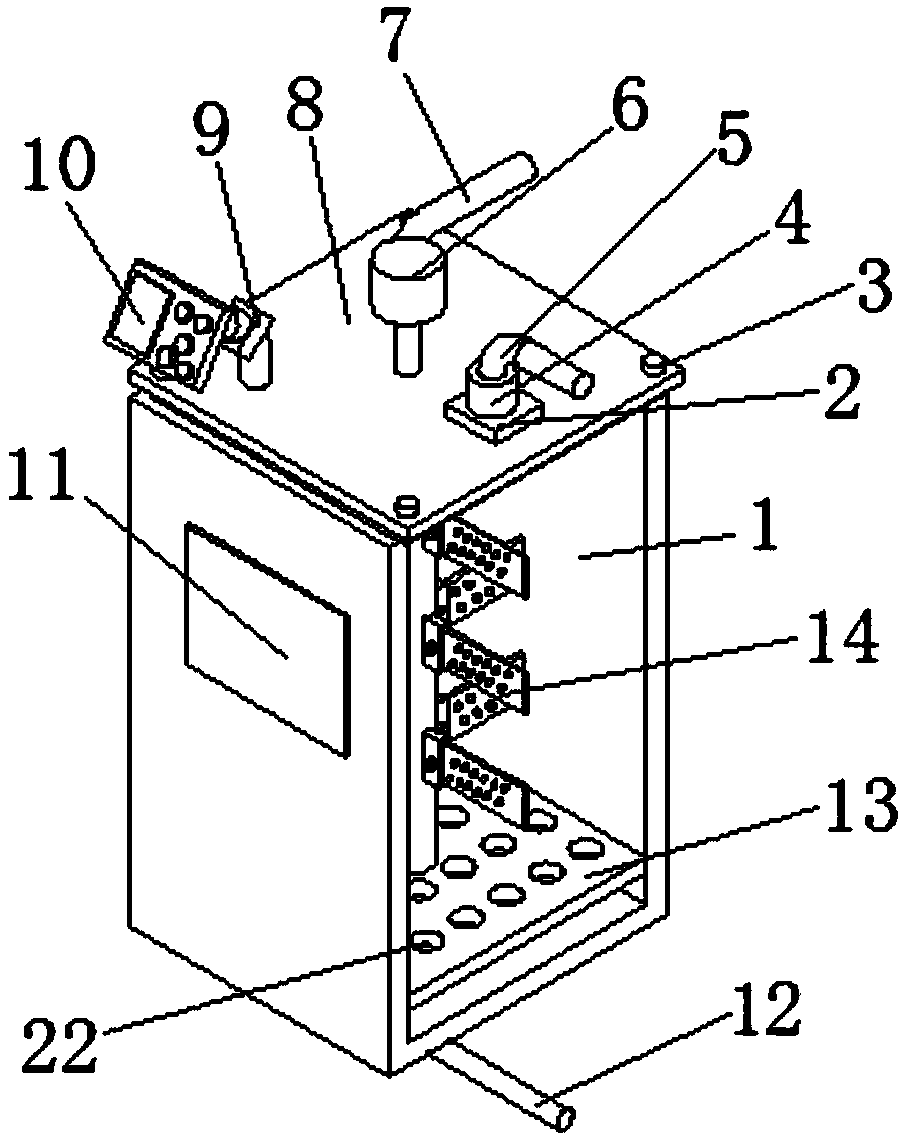

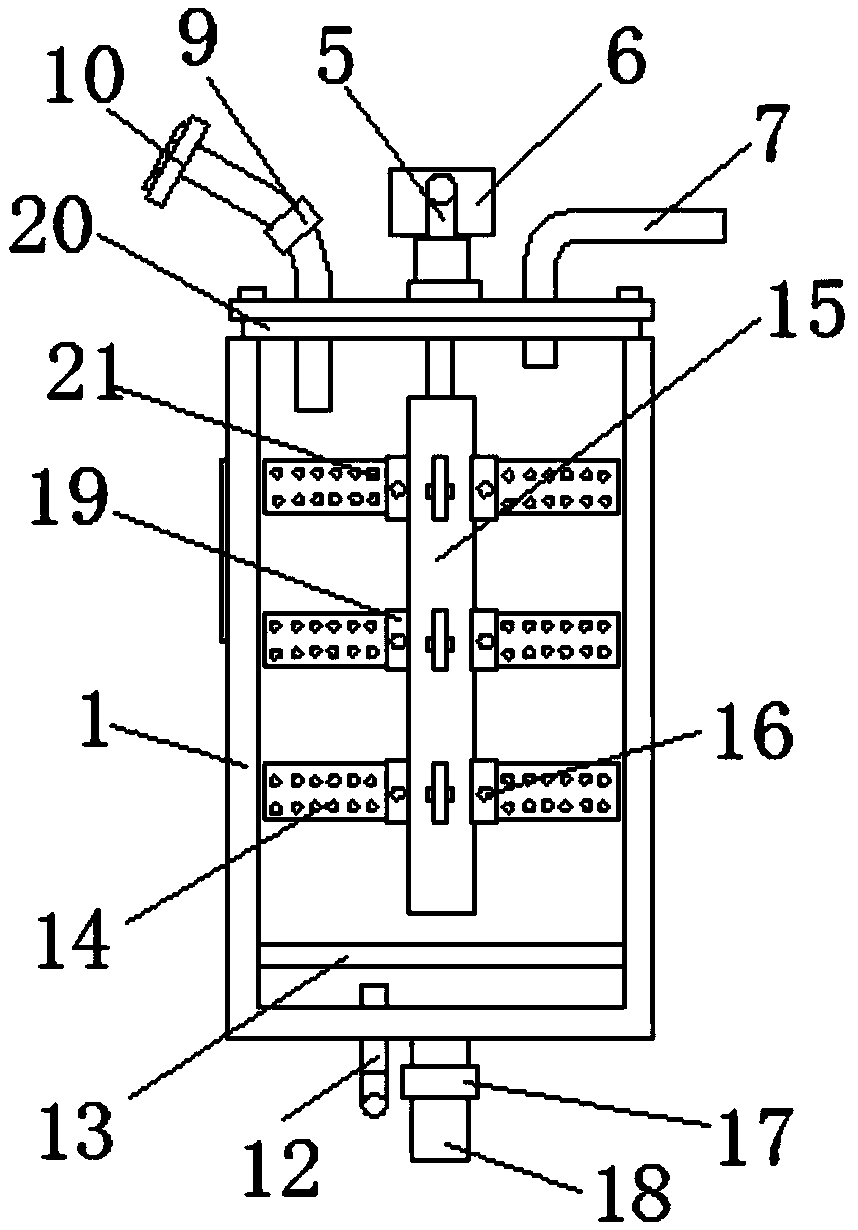

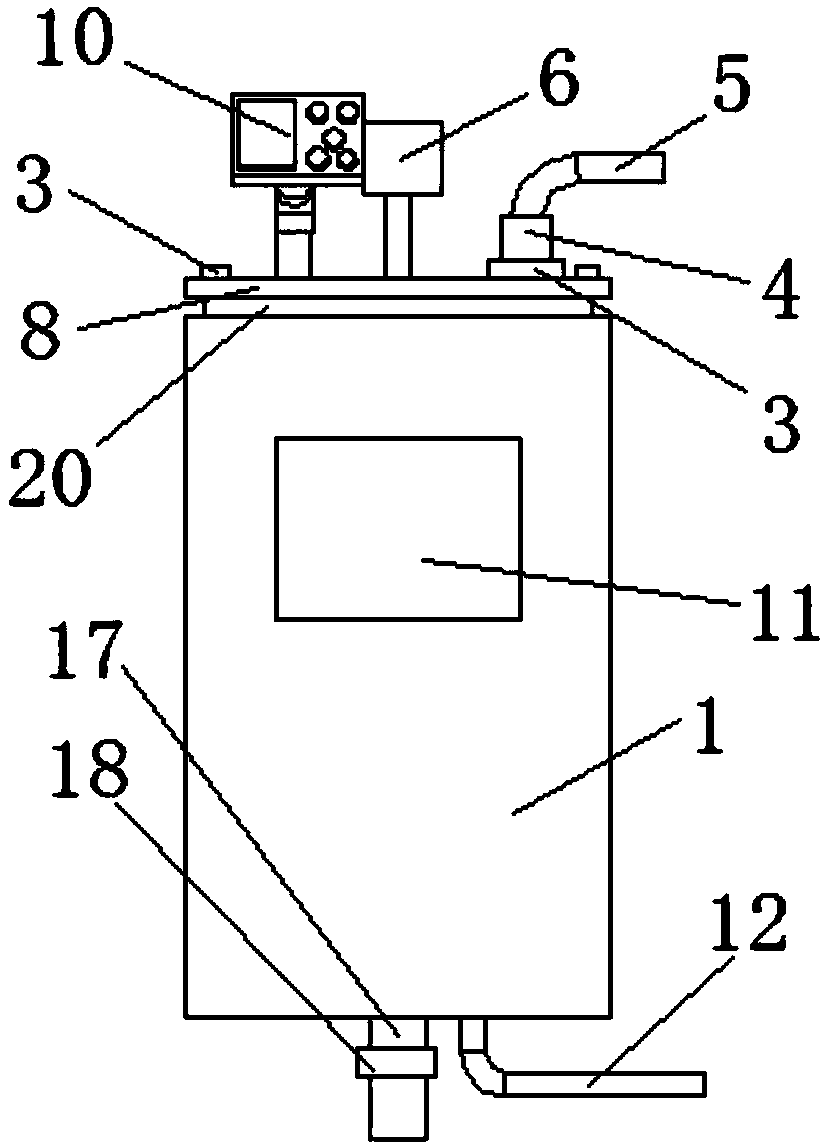

Bioloreactor centrifugal lifting agitator

InactiveCN108144487AMeet the requirements of volume enlargementLow costRotary stirring mixersTransportation and packagingEngineeringSingle chip

The invention discloses a bioreactor centrifugal lifting agitator, comprising a box body, wherein a first baffle is arranged on the upper surface of the box body, and the four corners of the upper surface of the first baffle are respectively provided with first screws; the four first screws penetrate through the first baffle to be connected with the box body, and a motor is arranged in the middleof the upper surface of the first baffle; a PH tester is arranged at the left side of the upper surface of the first baffle, and the test end of the PH tester penetrates through the first baffle and extends to the inside of the box body, and the upper surface of the PH tester is connected with a bent fixing column; the other end of the bent fixing column is fixedly connected with a single-chip microcomputer, and an L-shaped air outlet pipe is arranged at the right side of the upper surface of the box body; one end of the L-shaped air outlet pipe penetrates through the first baffle and extendsto the inside of the box body, and a bent liquid inlet pipeline is arranged at the front side of the upper surface of the box body. The bioreactor centrifugal lifting agitator disclosed by the invention has the advantages that the cost is low, the equipment is simple, the agitating performance is high, the efficiency is high, the product effect is remarkable, the requirements that the carrier density is increased, and the volume of the bioreactor is enlarged can be met, and the convenience is brought to use.

Owner:成都汇鲤科技有限公司

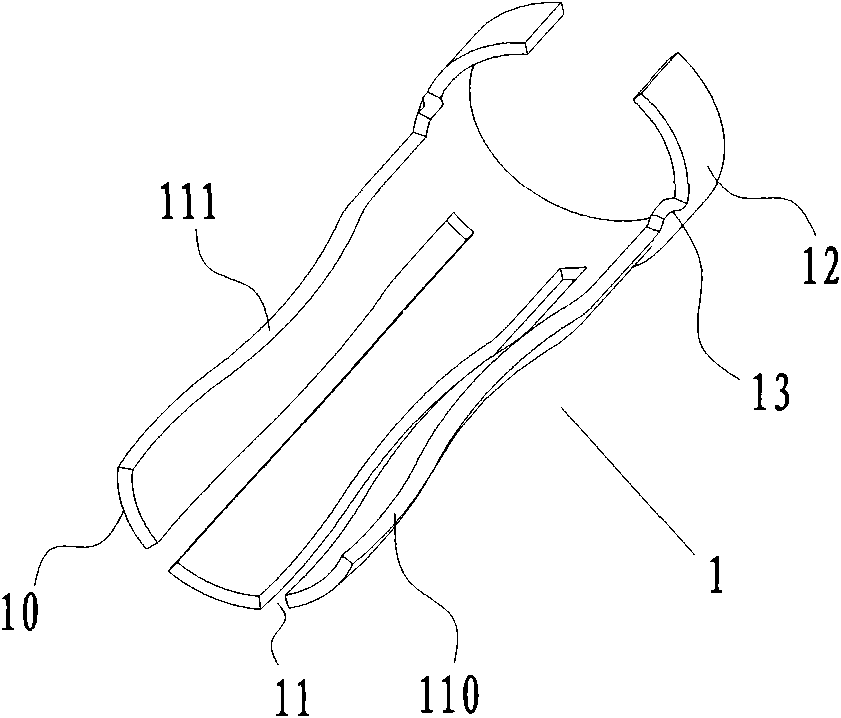

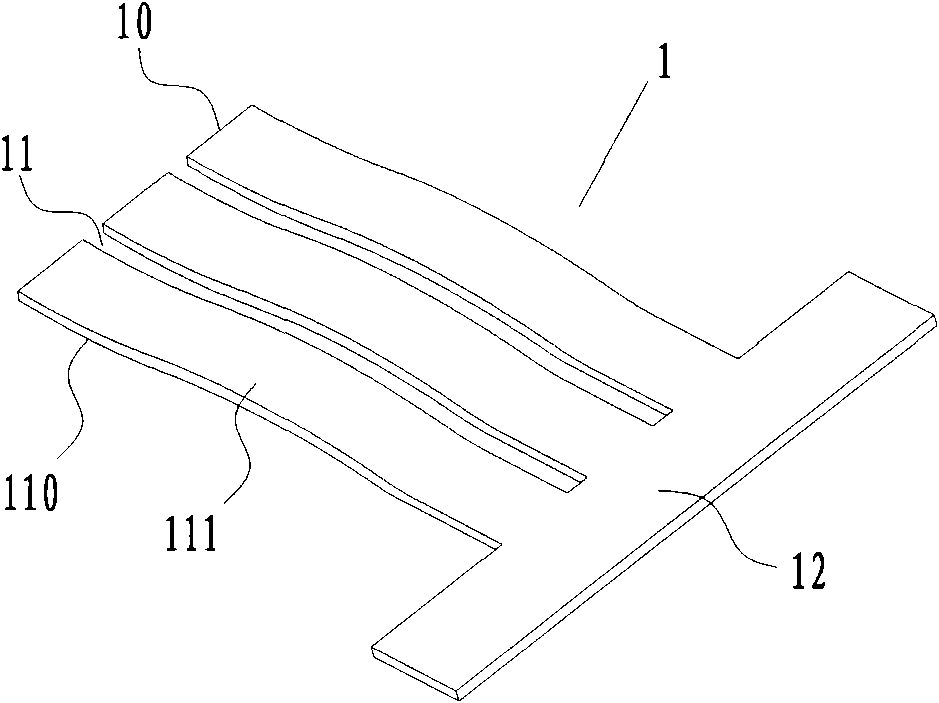

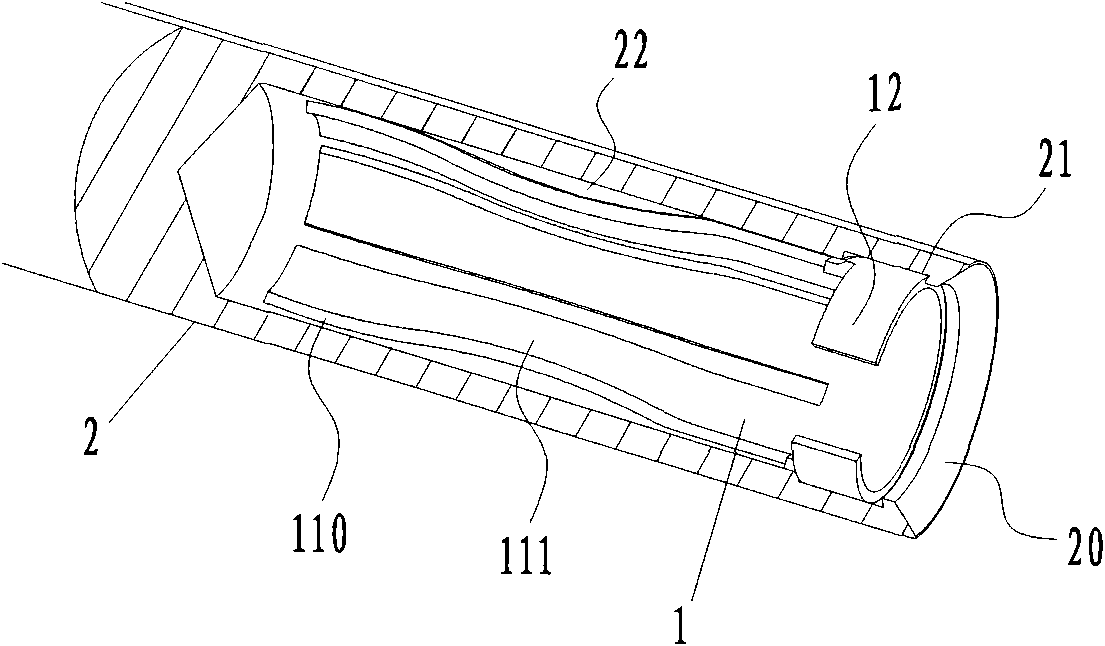

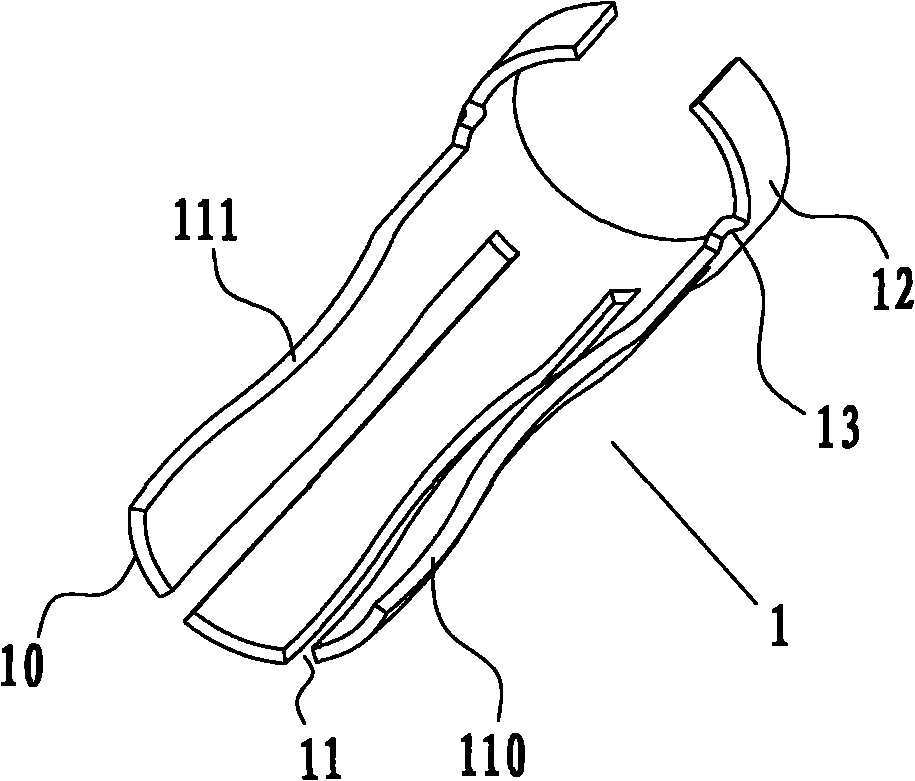

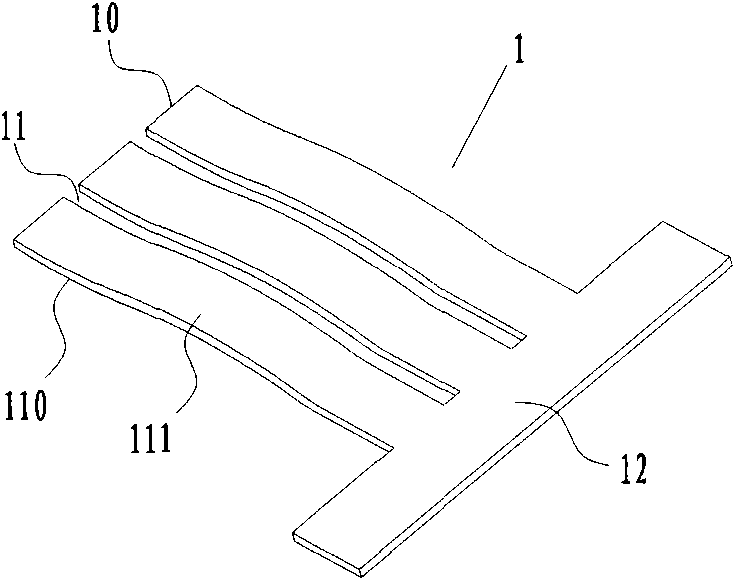

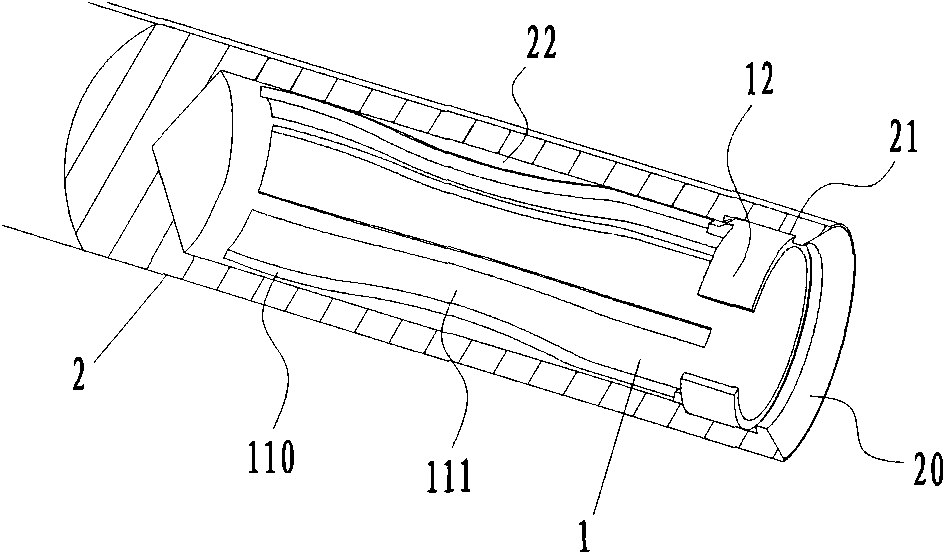

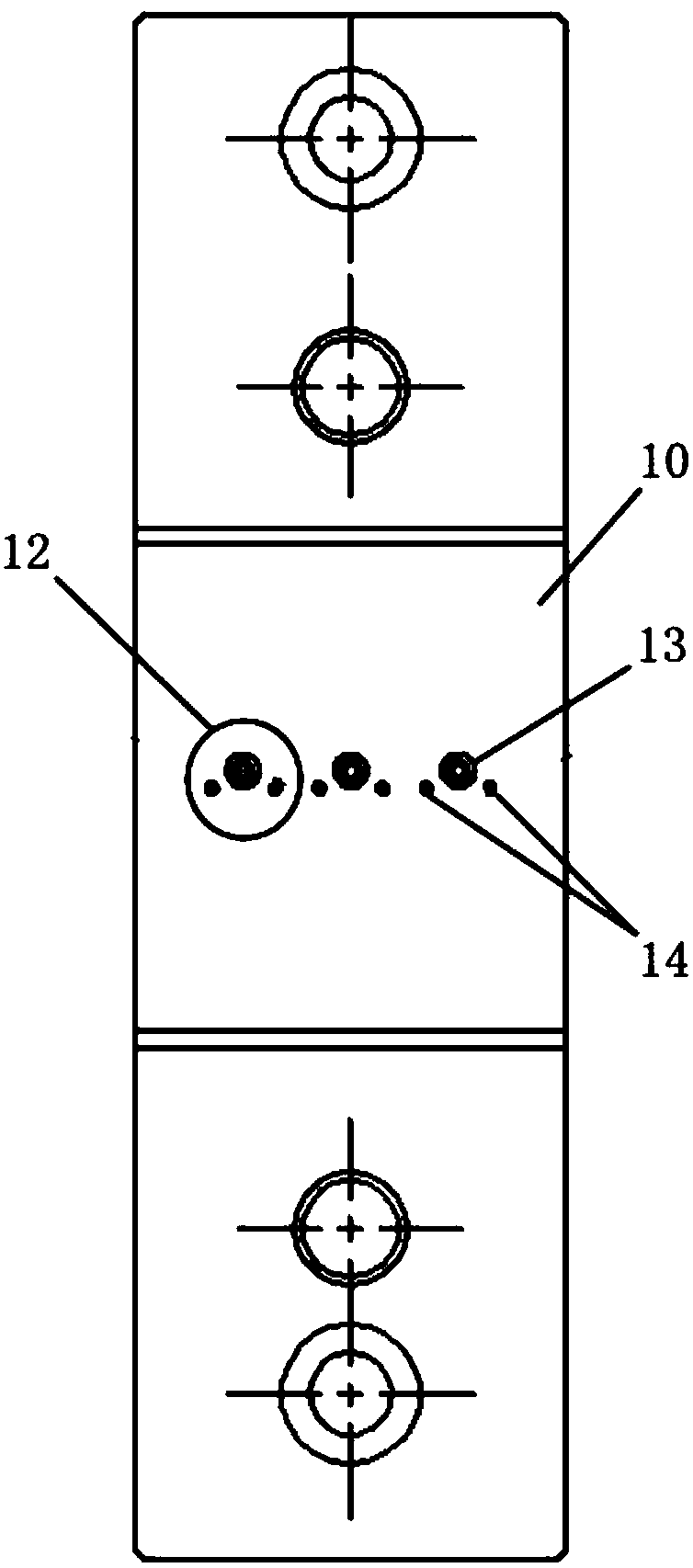

Power supply connector jack

The invention discloses a power supply connector jack. A contact ring (1) is arranged in a round hole (22) of the jack (2). The contact ring (1) comprises at least two contact chips (10) extending to remote ends. A narrow groove (11) is formed between the contact chips (10). Each of the contact chips (10) is provided with a remote end arc contact region (110) slightly protruding outwardly, and a near end arc contact region (111) slightly retracting inwardly. The tail end of the contact ring (1) connects a plurality of contact chips (10) into a whole through a connecting strip (12). A groove (21) is formed at the front part of the round hole (22). The connecting strip (12) is inserted into the groove (21). The contact ring (1) is a semi-sealing cylindrical structure having an axial opening. The connecting strip (12) and the contact chips (10) are connected through a section of arc transition region (13). The power supply connector jack is capable of meeting the requirements on high density and miniaturization of the power supply connector, can be produced on a large scale, has an excellent practical value, and is reliable in contact and low in cost.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

Contact spring coil in power connector

InactiveCN102097697AOvercoming the problem of poor elasticitySimple structureCoupling contact membersPunchingHigh density

The invention discloses a contact spring coil in a power connector, which comprises at least two contact sheets (10) extending to a distal end, wherein a narrow groove (11) is formed between the contact sheets (10), each contact sheet (10) is provided with a distal end circular arc contact region (110) protruding outwards slightly and a proximal end circular arc contact region (111) retracting inwards slightly, and a tail end of the contact spring coil (1) connects a plurality of contact sheets (10) into a whole via a connecting strip (12). The contact spring coil (1) is an axially opened semi-closed cylindrical structure. The connecting strip (12) is connected with the contact sheets (10) via a circular arc transition region (13). The contact spring coil (1) is a thin elastic copper alloy formed by punching and circle curling. The contact spring coil is used in a jack of the power connector in order to be reliably connected with a pin in cooperation with the jack, can meet the requirements of the power connector on high density and miniaturization, and is reliable in contact, low in cost, capable of mass production and great in practical value.

Owner:SUZHOU HUAZHAN SPACE APPLIANCE

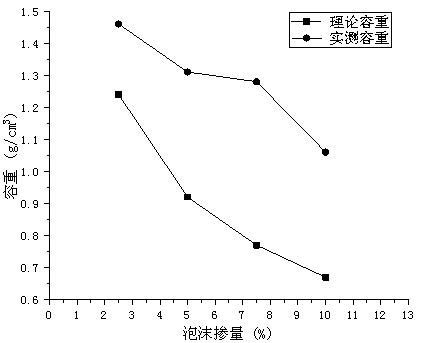

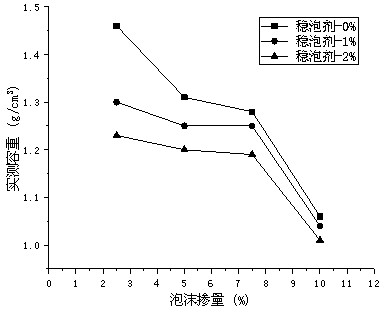

Light cement soil for deep foundation treatment and preparation method thereof

The invention discloses light cement soil for deep foundation treatment and a preparation method thereof. Foam and cement slurry are mixed in a stirring manner by using a surfactant foaming agent forfoaming treatment to introduce the foam, so that the volume weight of the cement soil is reduced. Meanwhile, due to the increase of the pores, the compactness and strength of the cement soil are reduced; by adding silicon powder and metakaolin, the cementing performance of the cement curing agent is improved, so that the strength of the light cement soil is improved; the fluidity of the light cement soil is improved by adding polycarboxylic acid; the stability of foam is improved by adding the foam stabilizer, so that the product is prevented from defoaming under pressure when being applied todeep foundation treatment, the cement soil meets the requirements of strength, volume weight and fluidity in practical engineering, and the research and development of a light cement soil material are realized.

Owner:SOUTHEAST UNIV

Preparation system of stem cell exosome compound preparation for improving premature ovarian failure

ActiveCN114134040AImprove production efficiencyIncrease expansionBioreactor/fermenter combinationsBiological substance pretreatmentsMesenchymal stem cellStem cell culture

The invention relates to a preparation system of a stem cell exosome compound preparation for improving premature ovarian failure, which comprises an endometrial stem cell exosome culture device, an umbilical cord mesenchymal stem cell single-cell suspension culture device, an umbilical cord mesenchymal stem cell single-cell suspension culture device and a stem cell exosome preparation device, the culture medium is used for culturing umbilical cord mesenchymal stem cells from the second generation to the sixth generation into umbilical cord mesenchymal stem cell single-cell suspension; the stem cell exosome compound preparation device is used for mixing the umbilical cord mesenchymal stem cell single-cell suspension and the endometrial stem cell exosome to form a stem cell exosome compound preparation; and the central control unit is used for adjusting each device parameter according to the endometrial stem cell exosome protein content, so that the generated endometrial stem cell exosome protein content meets a preset standard.

Owner:SINO AMERICAN BIOTECH INC

Holeless riveting die and holeless riveting product

The invention relates to a holeless riveting die. The holeless riveting die comprises an upper die base, an upper cushion plate, an upper clamping plate, a stop plate, an upper stripping plate, a lower die plate, a lower cushion plate and a lower die base, all of which are sequentially stacked from top to bottom. A core bar is arranged in the lower die plate. A forming block is arranged between the lower die plate and the lower cushion plate. Convex point structures are arranged at the bottom end of a semicircular groove in the forming block. The multiple convex point structures are arranged and are arranged in a linear array manner. The linear array direction of the convex point structures is parallel to the axis of the semicircular groove of the forming block. Each convex point structurecomprises a first convex point and second convex points. The invention further relates to a holeless riveting product formed through riveting machining of the above holeless riveting die. The riveting die is used for riveting a seam position of a cylindrical product, riveting is conducted without rivets or holes, thick or irregular protrusions can be prevented from existing at the seam position,and the high precision or roundness requirement of the product is met.

Owner:苏州弘能精密模具有限公司

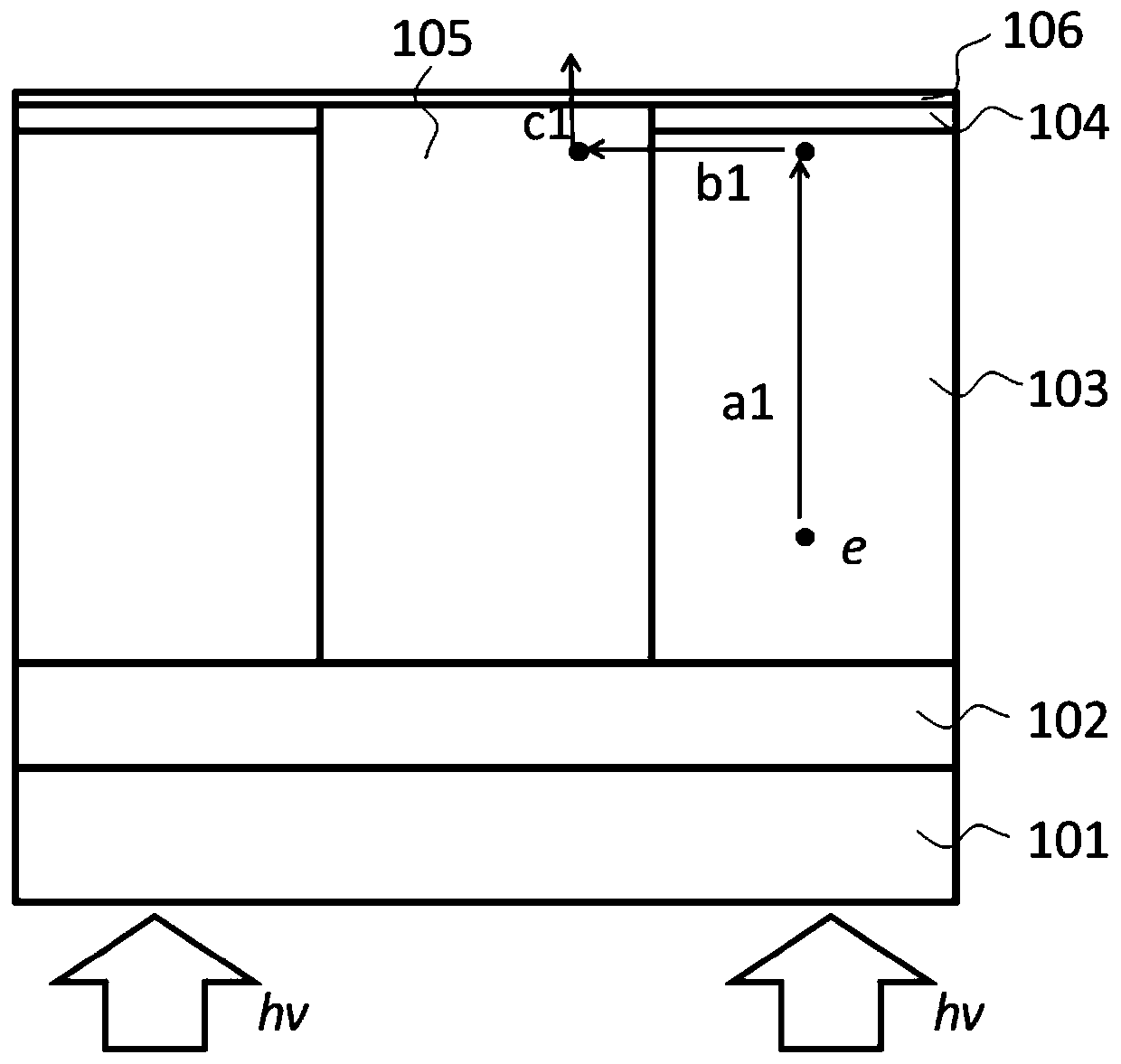

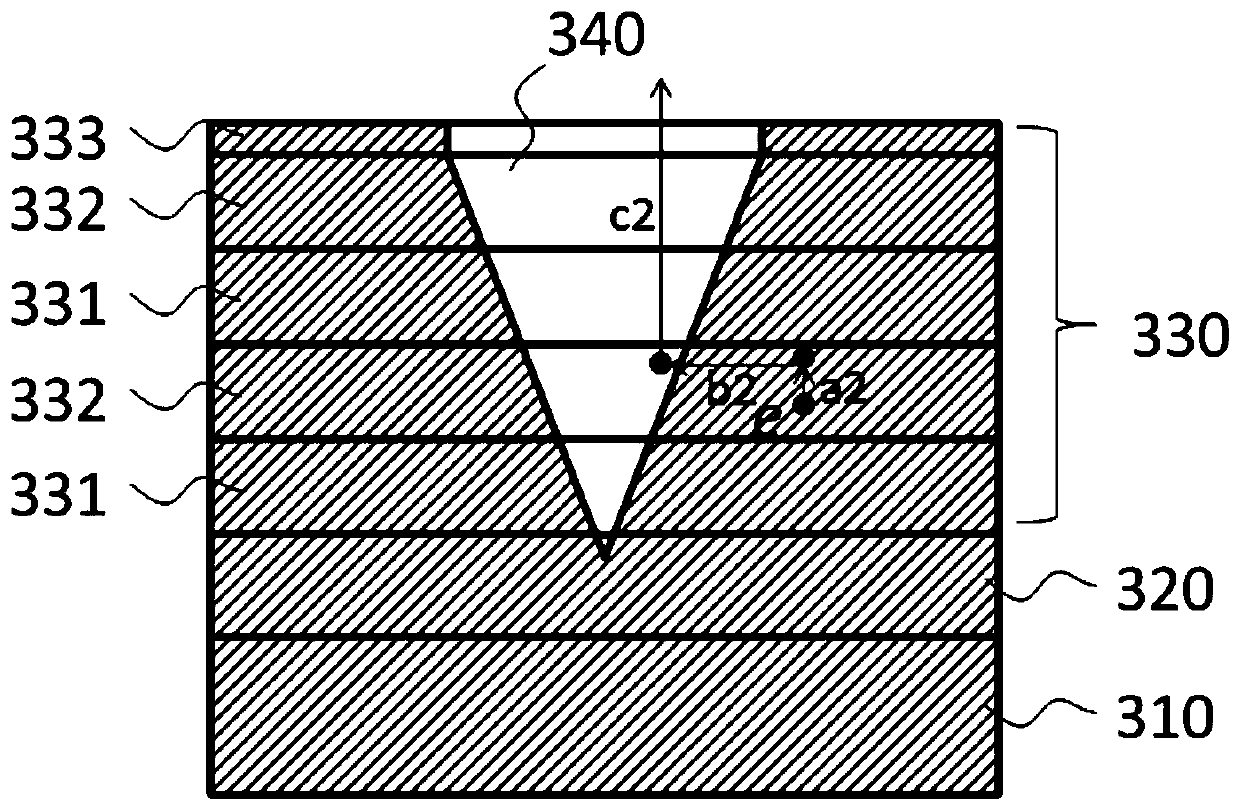

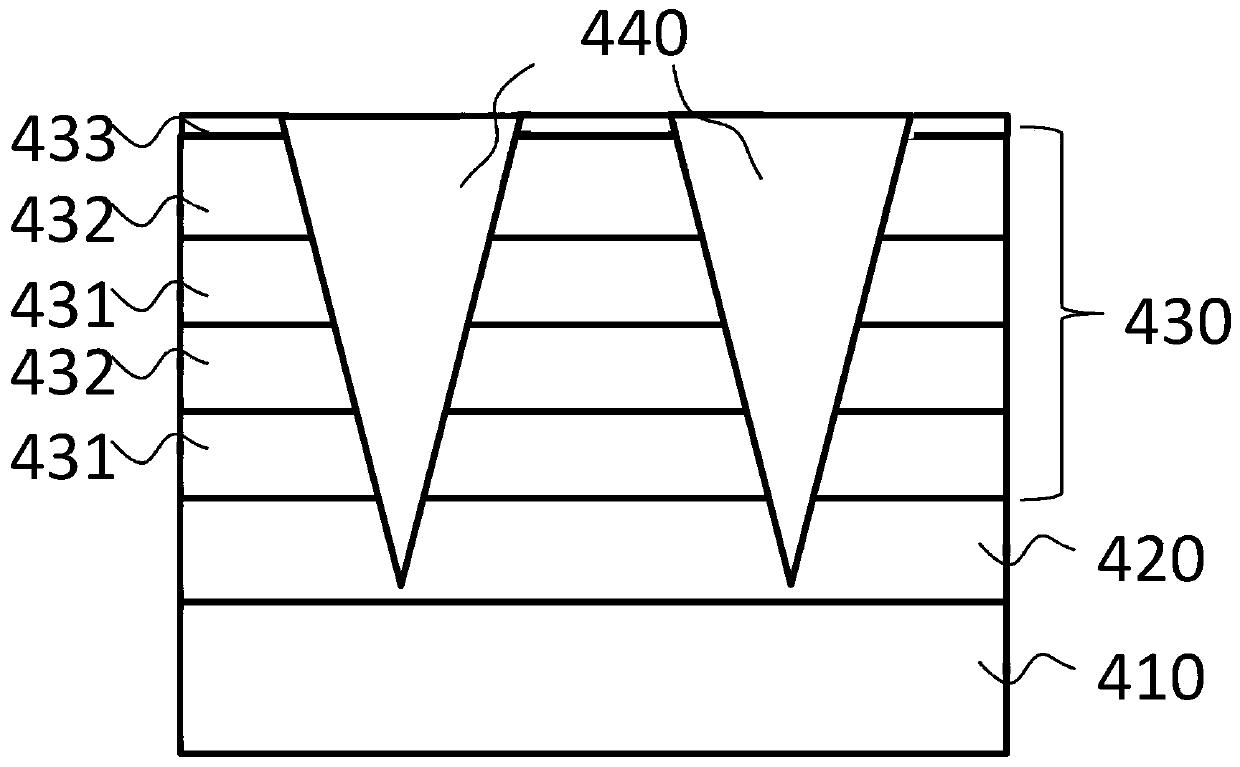

Vacuum channel type photocathode and preparation method thereof

PendingCN111370276AIncrease current emission intensityIncrease the launch areaPhoto-emissive cathodesPhoto-emissive cathodes manufactureSemiconductor materialsPhotocathode

The invention discloses a vacuum channel type photocathode and a preparation method thereof. The vacuum channel type photocathode comprises a substrate and a cathode emission layer formed on the substrate, wherein the cathode emission layer comprises first semiconductor material layers and second semiconductor material layers which are periodically and alternately arranged, and a channel formed inthe cathode emission layer, and the area of the side, close to the substrate, of the channel is smaller than that of the surface of the cathode emission layer. The photocathode provided by the invention can generate high emission current density and effectively shorten the response time of the cathode, so that the photocathode has the capability of emitting terahertz frequency electronic pulses,and can be applied to optical modulation vacuum microwave devices, free electron lasers, light sources and the like.

Owner:NO 12 RES INST OF CETC

Stepless speed changing reducer and driving joint used for bio-robot

ActiveCN111775178APrecise infinitely variable speed functionLarge power adjustable rangeJointsArmsReduction driveEngineering

The invention provides a stepless speed changing reducer and a driving joint used for a bio-robot. The reducer comprises a first grade sun gear, a first grade planet gear, a first grade annular gear,a second grade planet gear, a second grade annular gear, a planet carrier and a friction type clutch; the first grade planet gear is outwardly engaged with the sun gear; the first grade planet gear isinwardly engaged with the first grade annular gear; the first grade planet gear is supported on a supporting shaft of the planet carrier; a first bearing is arranged between the first grade planet gear and the supporting shaft; the second grade planet gear is inwardly engaged with the second grade annular gear; the second grade planet gear rotates synchronously with the first grade planet gear; the friction type clutch comprises a friction sheet and a pressurizing part; the friction sheet is positioned on one side of the peripheral wall of the first grade annular gear; and the pressurizing part is used for exerting pressure on the friction sheet to generate friction force between the friction sheet and the peripheral wall. The reducer has a wide range of power adjustment, is light, convenient and tight in structure, is highly reliable, and meets specific requirements of the bio-robot.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

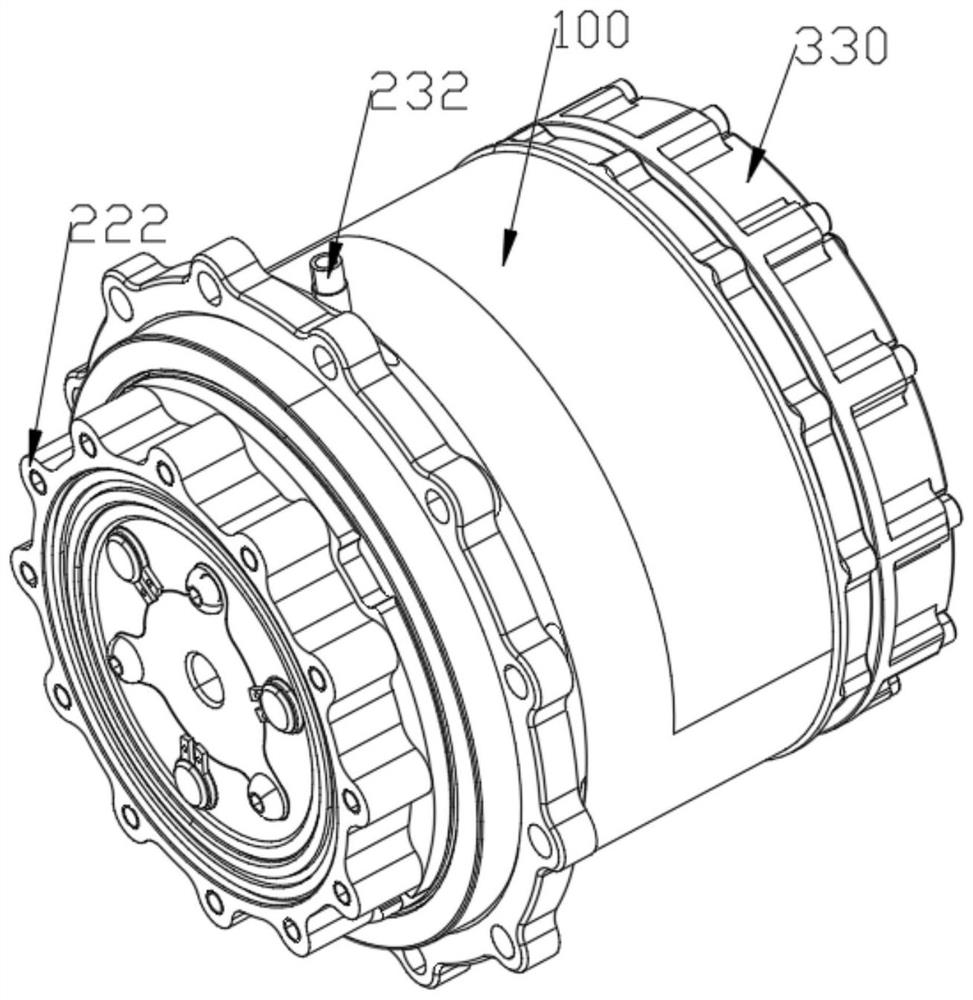

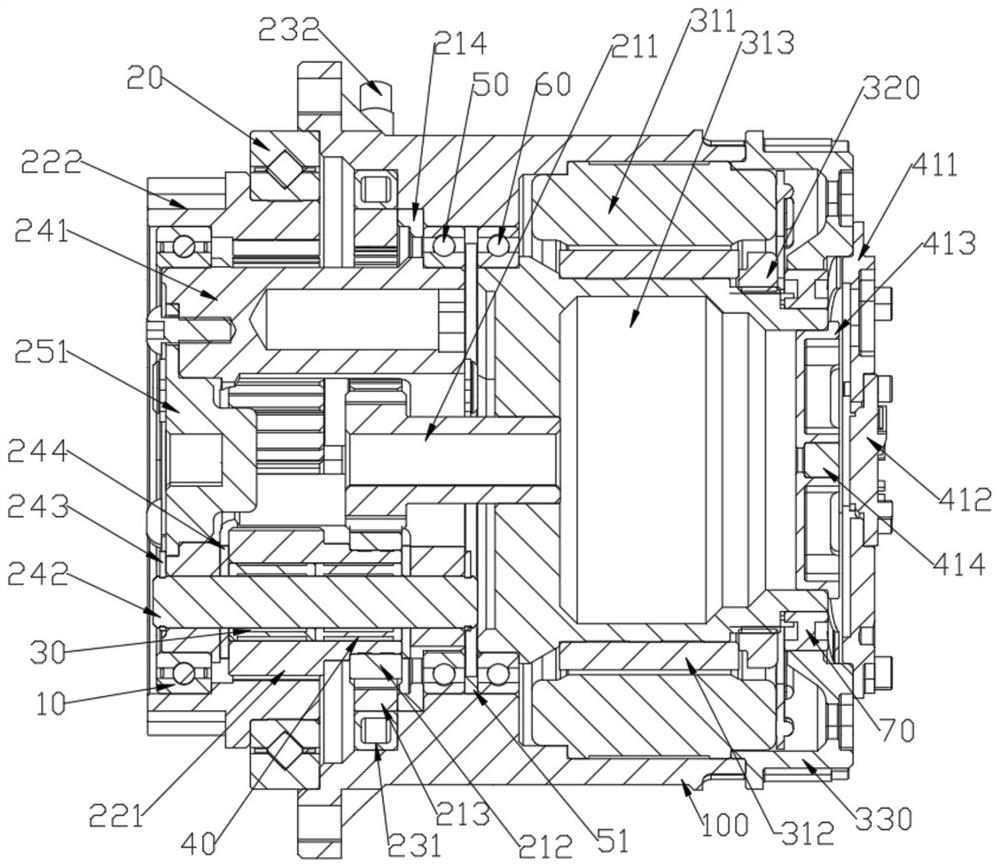

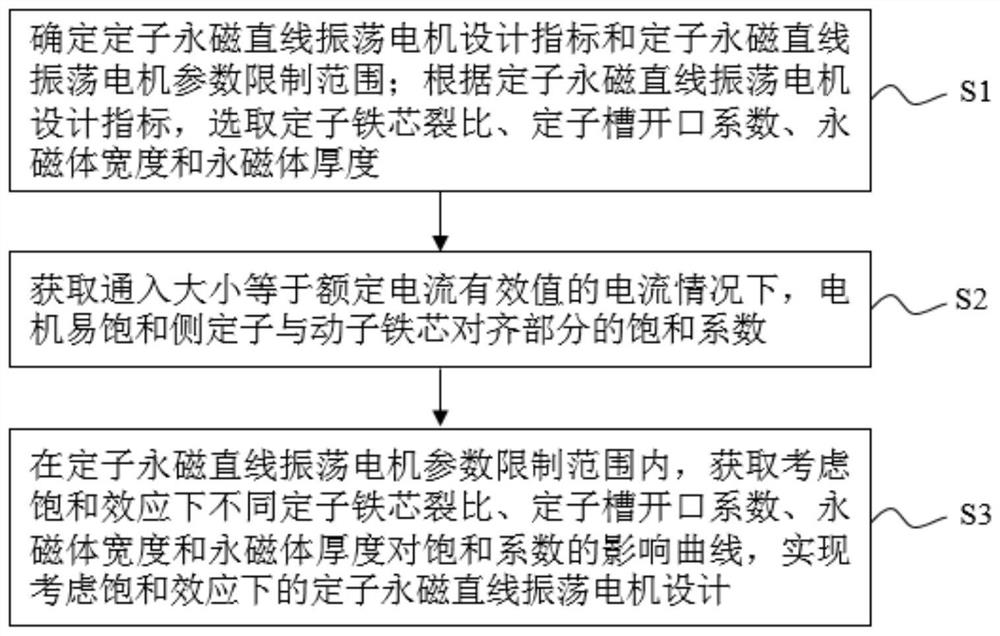

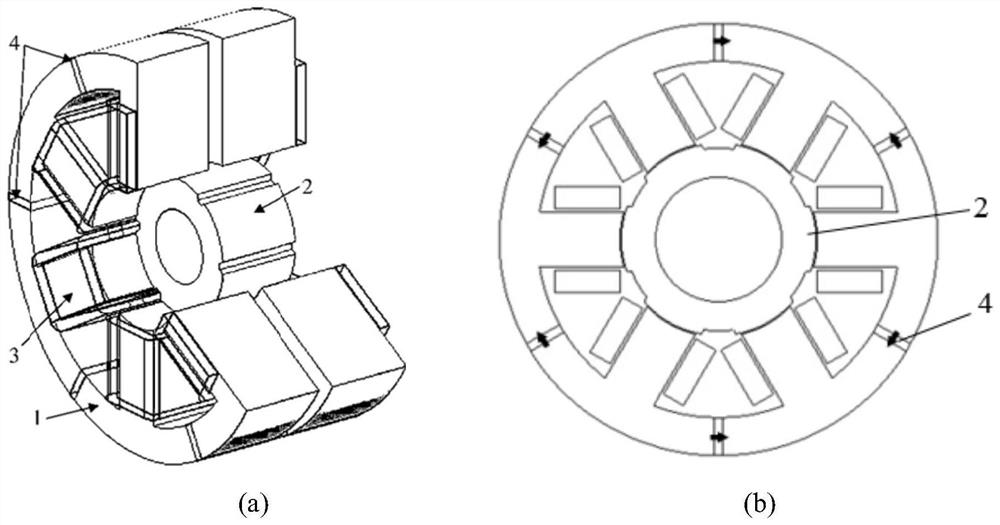

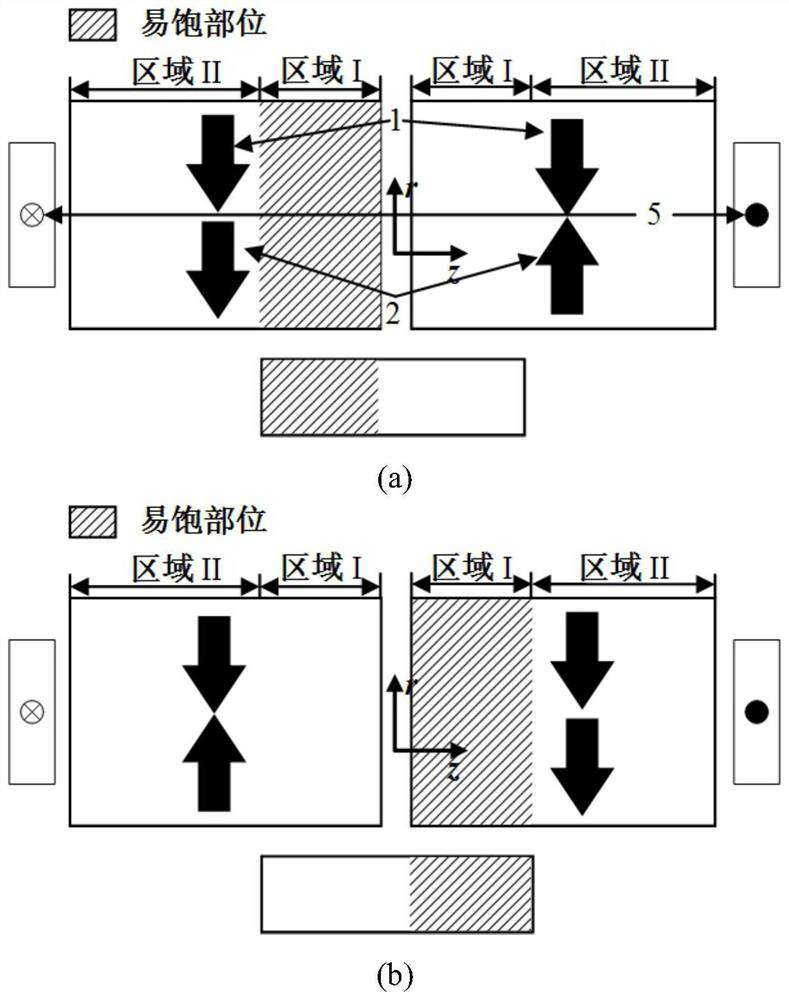

Stator permanent magnet linear oscillation motor design method and system considering saturation effect

PendingCN114709999APrecise design sizePrecise characteristicsElectric machinesMagnetic circuit stationary partsElectric machineEngineering

The invention discloses a stator permanent magnet linear oscillation motor design method and system considering a saturation effect, and the method comprises the steps: determining a design index and a parameter limiting range of a stator permanent magnet linear oscillation motor, and calculating a rated current effective value of the motor under a specific size parameter according to the efficiency and copper loss limitation; calculating the saturation coefficient and the electromagnetic thrust of the aligning part of the stator and the rotor iron core on the easy-to-saturate side of the motor by combining a no-load and load nonlinear equivalent magnetic circuit model; and judging whether the performance parameters such as the saturation degree of the iron core and the electromagnetic thrust meet the requirements or not through the design indexes corresponding to the specific application, if not, updating the size parameters, and recalculating the saturation coefficient and the output thrust until the design requirements are met. According to the method, the problems that a traditional sub-domain analysis method cannot process the saturation problem and a three-dimensional finite element method is low in calculation efficiency can be solved, the relation between the asymmetric iron core saturation effect of the stator and design size parameters is quantitatively described, and size design and output characteristic evaluation of the stator permanent magnet linear oscillation motor are completed.

Owner:GUANGXI UNIV +1

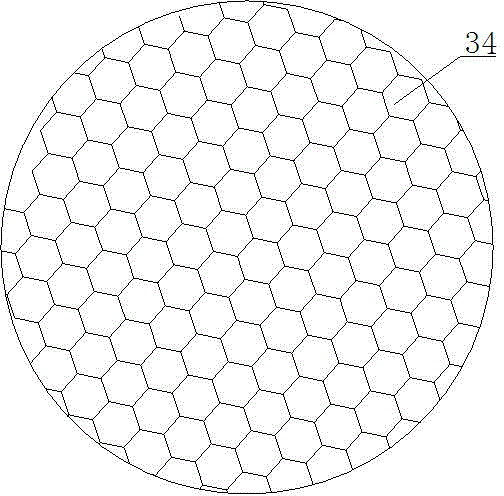

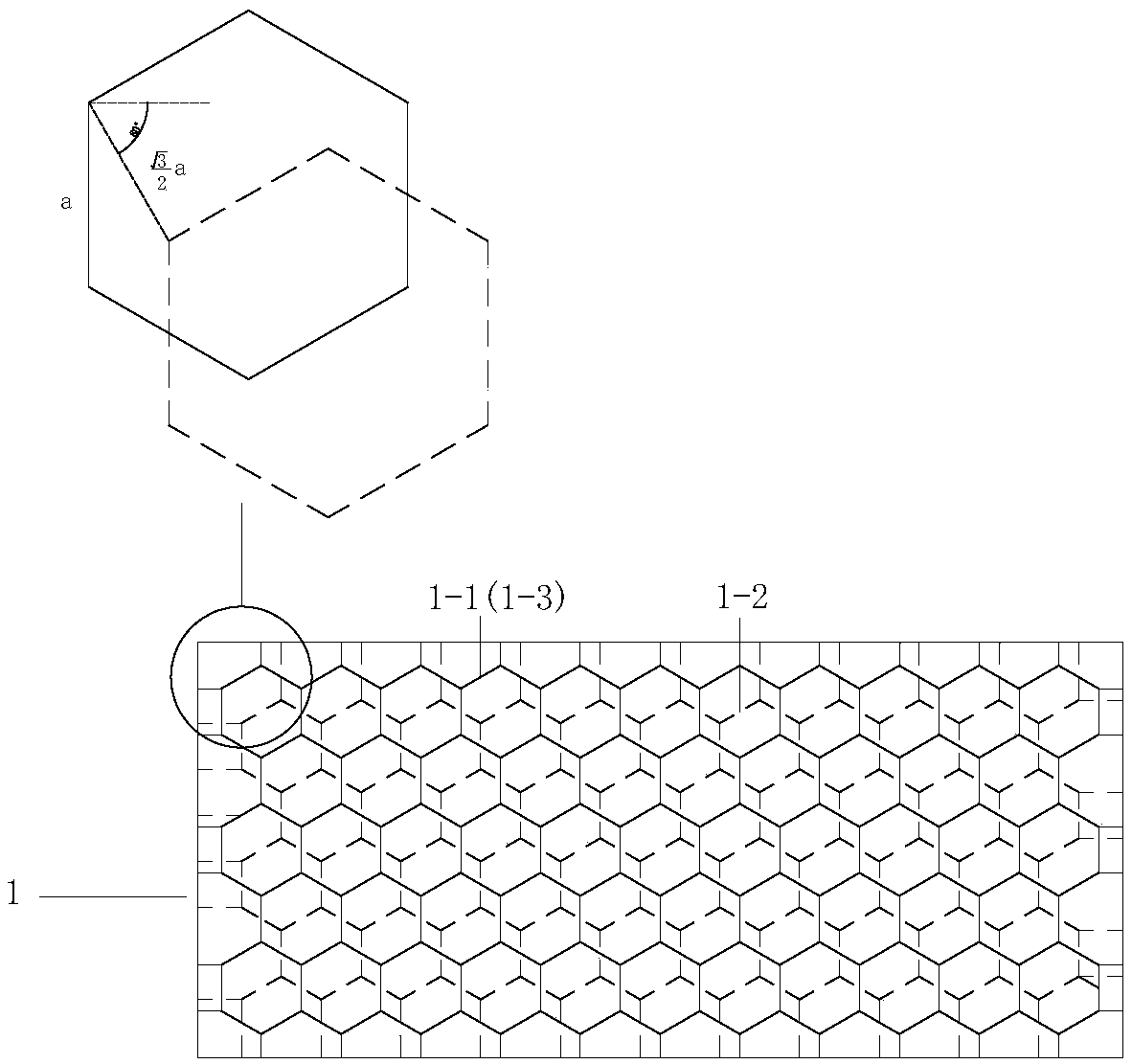

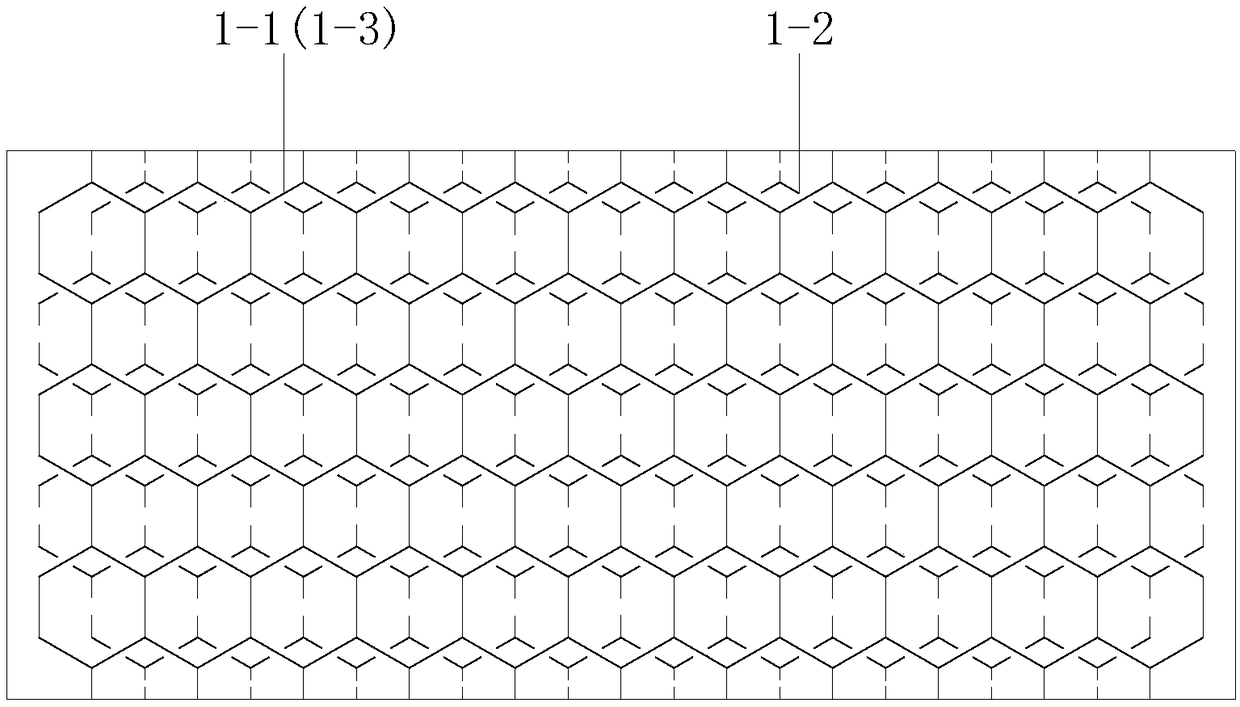

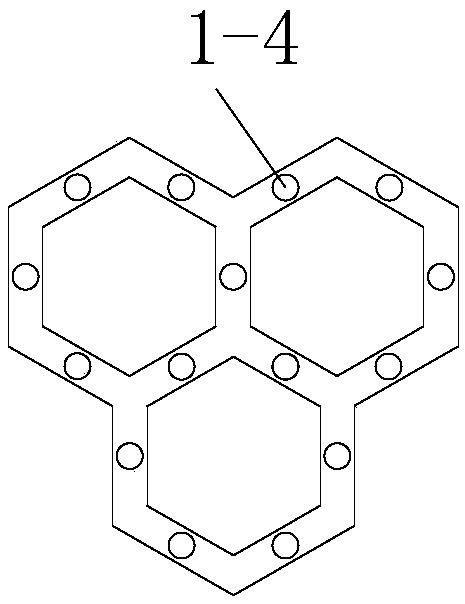

Side plate of foil generating machine and foil generating machine

ActiveCN109355683AImprove stabilityLow densityElectroforming processesEngineeringMechanical engineering

The invention relates to a side plate of a foil generating machine and the foil generating machine. The side plate comprises a first frame (1-1), a second frame (1-2) and a third frame (1-3), whereinthe first frame (1-1), the second frame (1-2) and the third frame (1-3) each include an frame outside and a plurality of regular hexagonal unit structural bodies inside, and the intersecting positionsof the regular hexagonal unit structural bodies of the three frames are connected through "insert tubes-threaded tubes". By using the side plate of the foil generating machine and the foil generatingmachine, the influence of external environmental temperature fluctuations on the temperature of a foil generating machine solution can be reduced.

Owner:江西省江铜铜箔科技股份有限公司

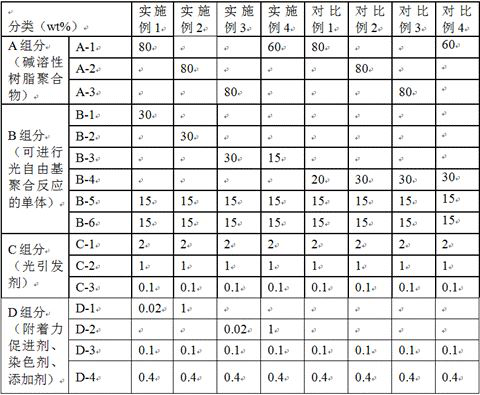

Photosensitive resin composition, dry film resist and corresponding element

PendingCN111856881AImprove featuresGood CapabilityConductive material chemical/electrolytical removalPhotosensitive materials for photomechanical apparatusPolymer scienceSide chain

The invention relates to a photosensitive resin composition, a preparation method, a dry film resist and a corresponding element, and belongs to the technical field of preparation of circuit printingelements. The photosensitive resin composition comprises 50-70% of alkali-soluble resin, 30-50% of a photo-free radical polymerization monomer, 0.1-5% of a photoinitiator and 0.01-1% of an adhesion promoter; and the side chain of alkali-soluble resin molecules has an aromatic group or alicyclic hydrocarbon structure. The dry film resist prepared from the photosensitive resin composition has high electroplating resistance and peelable characteristics, and the photosensitive resin composition has high hole covering capability and high resolution.

Owner:HANGZHOU FIRST ELECTRONIC MATERIAL CO LTD

A comprehensive measuring instrument for aerosol hygroscopic properties

InactiveCN111122392BHigh trafficMeet the optical characteristicsParticle size analysisIndividual particle analysisParticulatesControl system

The invention discloses a comprehensive measurement instrument for aerosol hygroscopic properties, comprising an aerosol pretreatment system, a first particle screening system, a humidification system, a second particle screening system, a dilution humidification system, a condensed particle counting system, a compressed air system, and a temperature control system. Humidity monitoring and calibration system, parameter measurement system, signal acquisition and control system. Through the technical scheme of the invention, the humidification flow rate is large, the humidification is fast, the measurement precision is high, and self-correction is possible.

Owner:BEIHANG UNIV +1

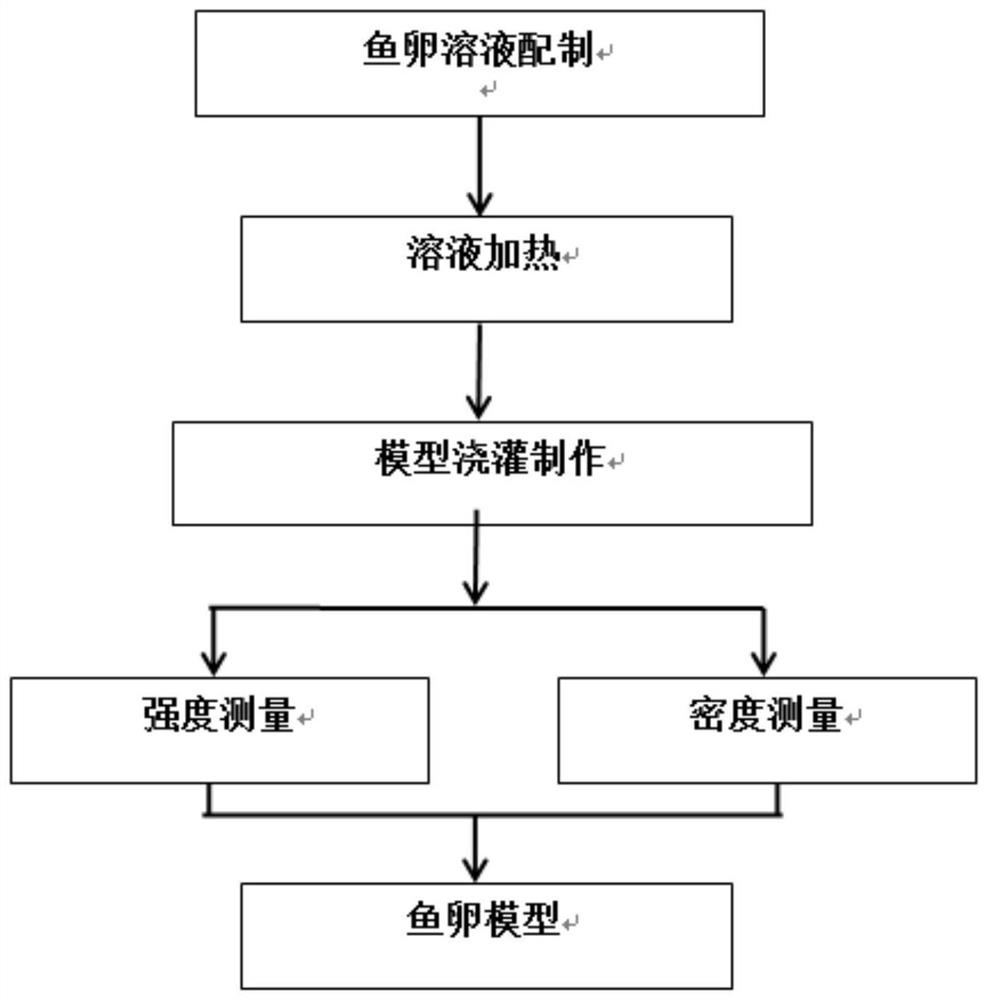

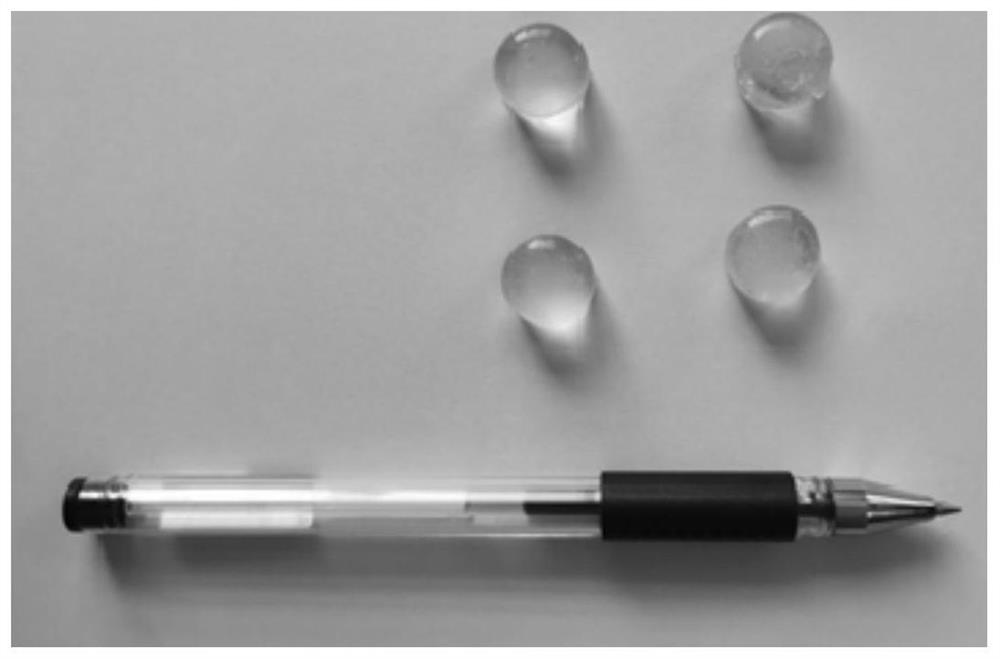

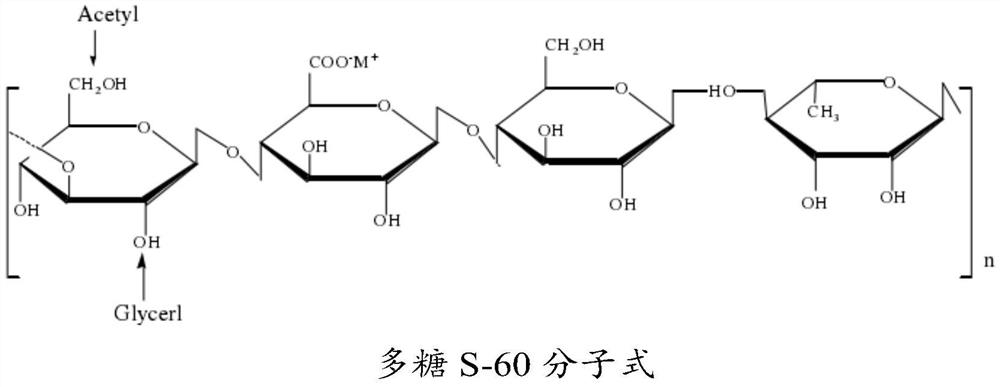

Preparation method and application of fish egg model

The application relates to the field of research on the movement of fish eggs in the wild, and in particular to a preparation method and application of a physical model of fish eggs. The method comprises mixing polysaccharides S-60, (C 12 H 18 O 9 ) n and (C 6 H 7 O 6 Na) n The mixed aqueous solution is heated to 95-100 ℃, and then poured into the mold and cooled to make a fish egg model. The three materials selected are non-toxic and harmless, and can be degraded. The input in the field river experiment will not affect the ecological environment at all. In the present application, the above two substances are blended in a certain proportion to enhance the gel strength and at the same time have better properties similar to fish eggs. join (C 6 H 7 O 6 Na) n It can not only improve the water solubility of the model so that it can be decomposed in a reasonable time to avoid being eaten by wild fish, but also improve the physical strength of the model to make it more reliable and stable to withstand the scouring of water. This fish egg model controls the density, durability and tensile strength of the model by selecting the amount of addition and the heating method.

Owner:CHONGQING JIAOTONG UNIVERSITY

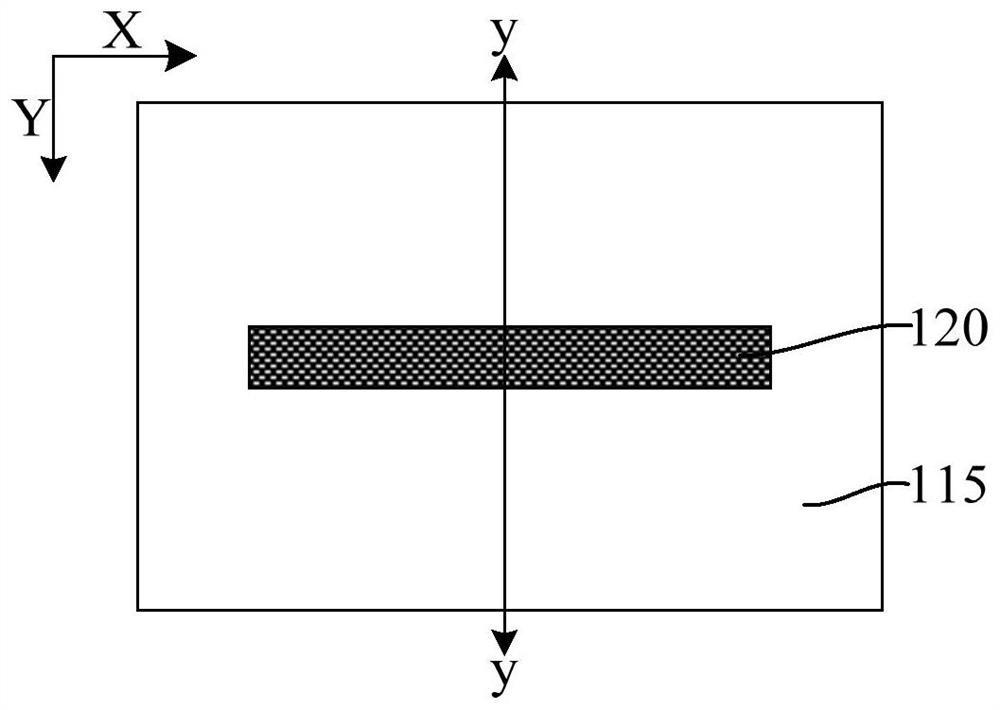

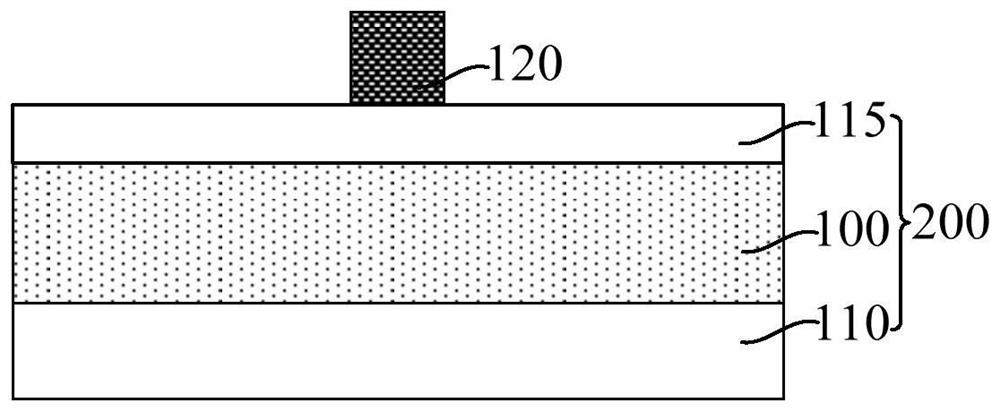

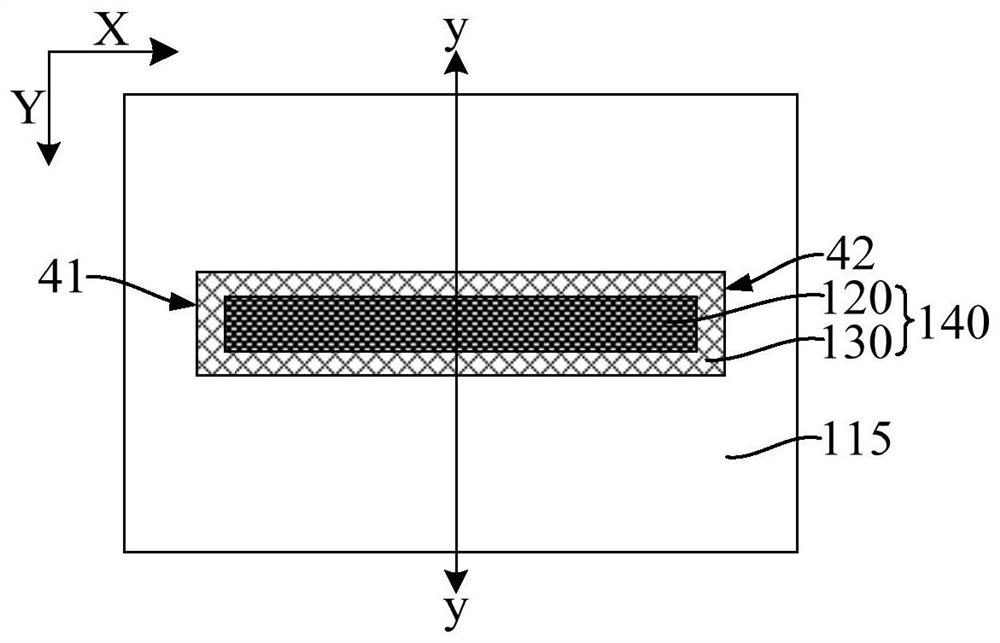

Formation method of semiconductor structure

PendingCN114388431ASmall sizeMeet the densitySolid-state devicesSemiconductor/solid-state device manufacturingGraphicsSemiconductor structure

A method for forming a semiconductor structure comprises the following steps: providing a substrate which comprises a target layer for forming a target pattern; forming a core layer extending along a first direction on the substrate, wherein a direction perpendicular to the first direction is a second direction; forming a side wall on the side wall of the core layer, wherein the core layer and the side wall located on the side wall of the core layer form a graphic structure layer; forming a sacrificial layer crossing the graphic structure layer in the second direction on the substrate, wherein the sacrificial layer at least covers part of the top and part of the side wall of the graphic structure layer; forming a flat layer on the substrate exposed by the sacrificial layer and the graphic structure layer; the sacrificial layer is removed, first grooves are formed in the flat layer, and the first grooves are located in the two sides of the pattern structure layer; the core layer is removed, so that a second groove is defined by the side walls; and etching the target layer below the first groove and the second groove by taking the flat layer and the side wall as masks to form a target pattern. The embodiment of the invention is beneficial to further compressing the pitch between the target patterns.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

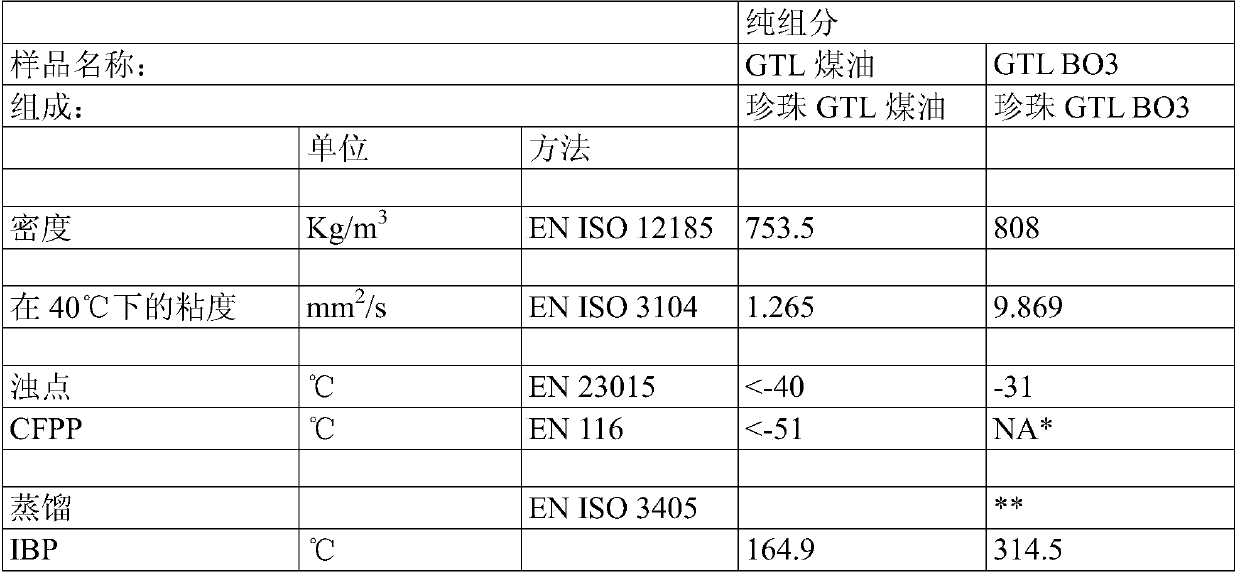

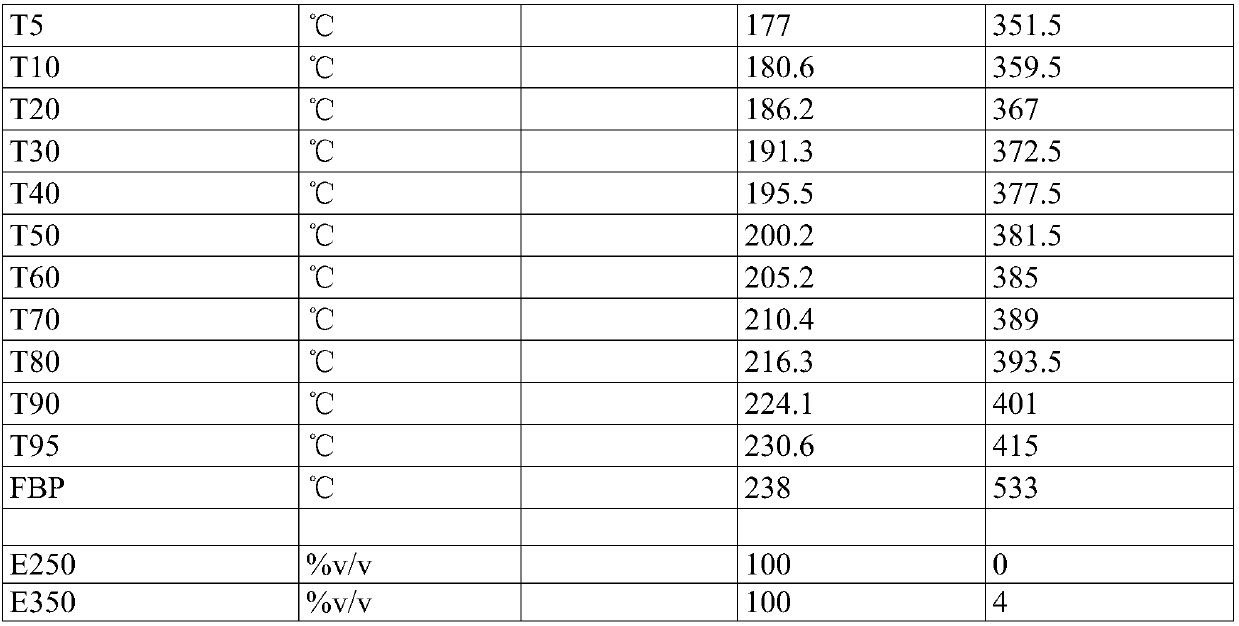

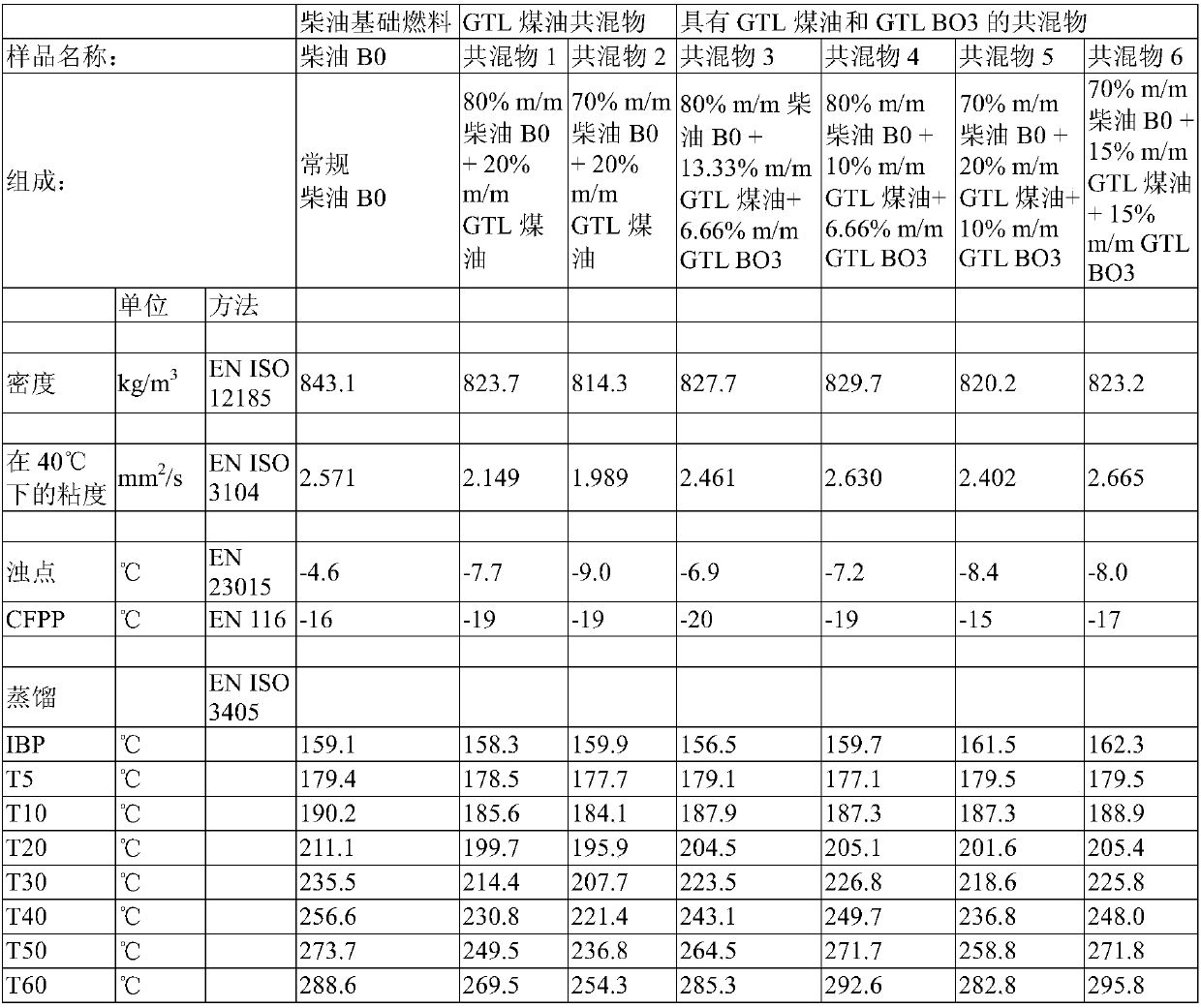

Fuel composition

ActiveCN107922861AImproved cloud pointImproved cold flow propertiesLiquid carbonaceous fuelsMachines/enginesKeroseneVolumetric Mass Density

Diesel fuel composition suitable for use in an internal combustion engine comprising: (a) 2 mass% to 30 mass% of kerosene having a kinematic viscosity at 40 DEG C of 1.5 mm<2> / s or less and a densityof 810 kg / m<3> or less; (b) 2 mass% to 20 mass% of Fischer-Tropsch derived base oil having a kinematic viscosity at 40 DEG C of 7.5 mm<2> / s or greater and a density of 790 kg / m<3> or greater; and (c)diesel base fuel. The diesel fuel composition of the present invention provides improved cold flow properties while simultaneously maintaining other properties such as viscosity and density within diesel fuel specification requirements.

Owner:SHELL INT RES MAATSCHAPPIJ BV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com