Photosensitive resin composition, dry film resist and corresponding element

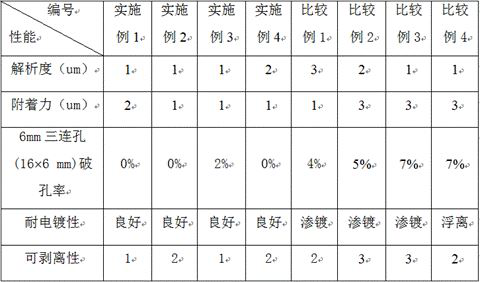

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition, dry film resist and corresponding components, and can solve problems such as inability to realize weak alkaline development, unfavorable large-scale production, lack of tin plating resistance, etc. Achieving good capping ability and high resolution, good stripping properties, and improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

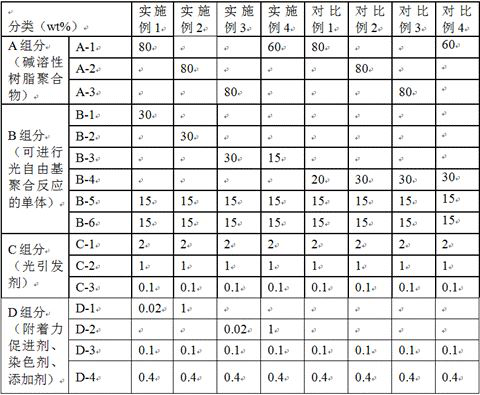

Examples

Embodiment

[0053] Alkali-soluble resin A-1: acrylic acid / methacrylic acid / methyl methacrylate / butyl acrylate / styrene=6 / 18 / 45 / 20 / 11 (weight ratio) ( M w =80000).

[0054] Alkali-soluble resin A-2: methacrylic acid / methyl methacrylate / butyl acrylate / styrene=24 / 45 / 15 / 14 (weight ratio) ( M w =101000).

[0055] Alkali-soluble resin A-3: methacrylic acid / methyl methacrylate / butyl acrylate / styrene=25 / 57 / 15 / 5 (weight ratio) ( M w =119300).

[0056] Prepare the following photopolymerizable monomers:

[0057] B-1: In the above general formula (I), R1 is H, R2 is H, o+n=6, p+m=30 (average) compound (Guangzhou Sartomer, PRO31627)

[0058] B-2: In the above general formula (I), R1 is CH 3 , R2 is CH 3 , o+n=2, p+m=24 (mean value) compound (Nippon Oil & Fat, blemmer PDBPE series)

[0059] B-3: In the above general formula (I), R1 is CH 3 , R2 is CH 3 , o+n=12, p+m=6 (average) compound (National Fine Chemicals)

[0060] B-4: Ethoxylated (30) bisphenol A dimethacrylate (Meiyuan 2301) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com