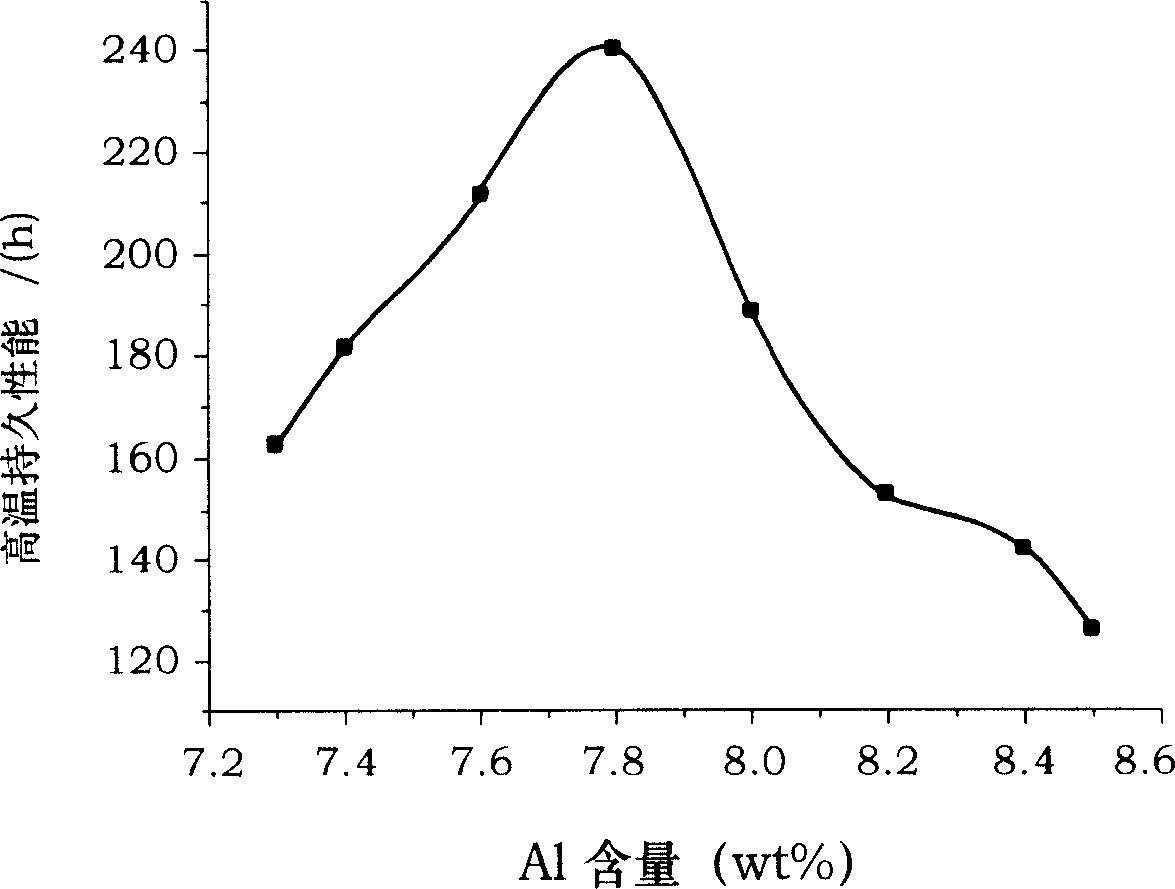

High temperature alloy material of Ni3AL based monocrystalline containing molybdenum, and praparation method

A high-temperature alloy and base single crystal technology, applied in the field of high-temperature alloy materials, can solve the problems of high density, unfavorable wide application of aero-engines, and increased alloy manufacturing costs, etc., to meet low density, good high-temperature durable strength and plasticity, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1: Preparation of Ni-7.6wt%Al-14wt%Mo single crystal superalloy

[0038] A: Bars made by smelting:

[0039] The first step, take Ni, Al, Mo elemental material by weight,

[0040] First put Ni and Mo directly into the IS65V8 vacuum induction furnace, and then add Al during the alloying period;

[0041] The second step is to pump the vacuum of the induction furnace to below 0.75Pa;

[0042] The third step is to adjust the melting temperature to 1500°C, after 25 minutes of melting time;

[0043] Then, heat the temperature in the furnace to 1558°C and keep it warm for 4 minutes;

[0044] Then, turn off the power and cool down to 1500°C, and cast alloy rods with electricity;

[0045] The alloy bar is taken out after cooling with the furnace for 12min;

[0046] B: Single crystal superalloy material

[0047] The fourth step is to put the alloy rod prepared in the third step above into the alumina crucible in the ISP05DS / SC directional single crystal growth furnac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com