Circular device of glass-sealed multi-core microwave insulator and manufacturing method thereof

A technology of insulators and glass seals, which is applied to parts of connection devices, assembly/disassembly of contacts, coupling devices, etc. It can solve the problems of complicated and cumbersome welding processes, difficult to achieve, and takes up a lot of space, so as to simplify the assembly process , Improve integration, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

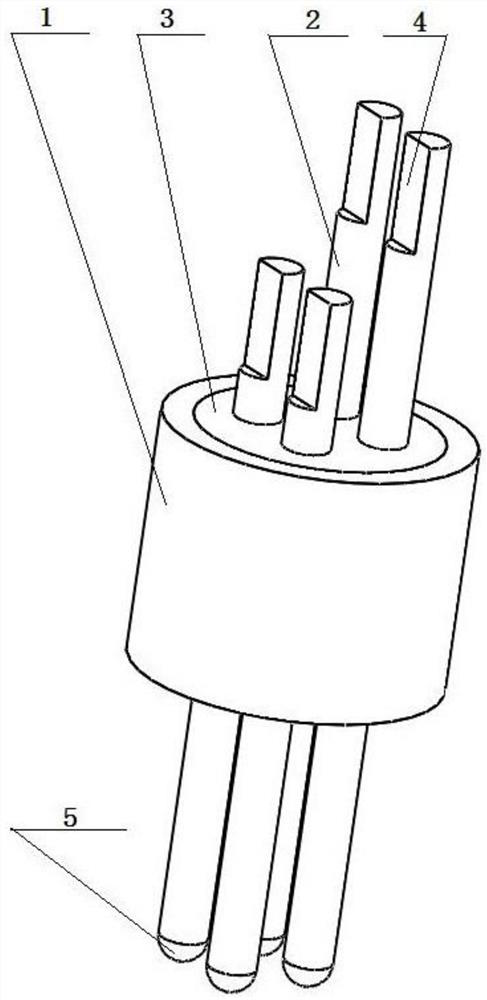

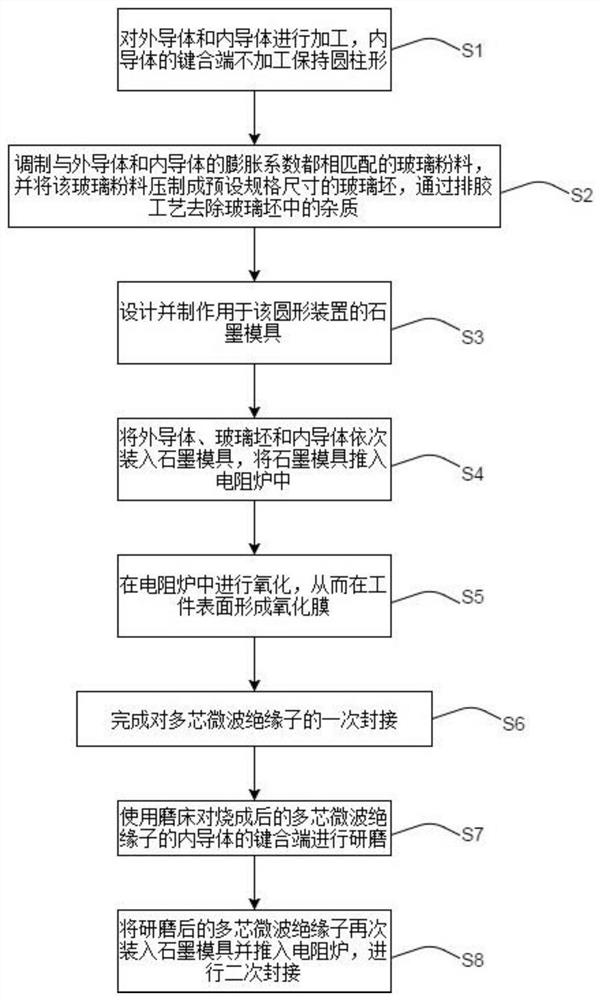

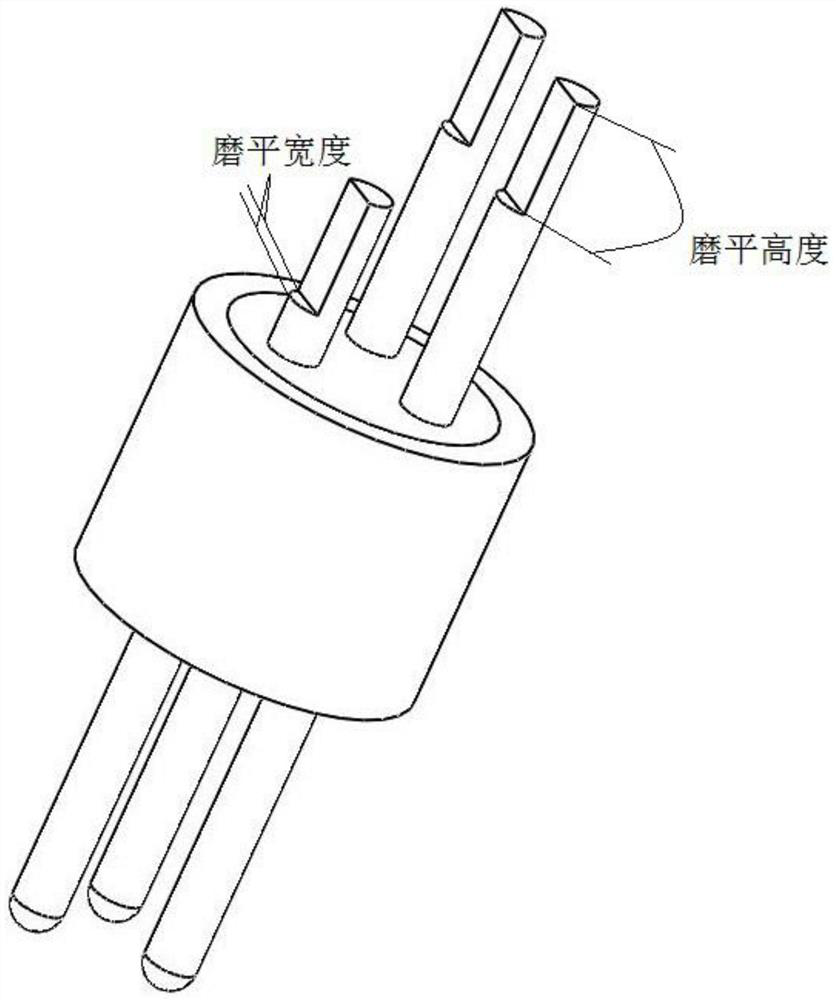

[0044] Such as image 3 As shown, it is the three-dimensional structure of a circular device with a round head glass-sealed 3-core microwave insulator. The inner diameter of the outer conductor is 2.5mm and the height is 1.6mm; the three inner conductors are evenly distributed on the insulator, and the needle diameter of the inner conductor is 0.38mm. The central moment of the inner conductor is 1.27mm, and the length of the bonding end of the inner conductor is 0.7mm. Both the outer conductor and the inner conductor are made of 4J29 Kovar alloy, the sealing glass is glass powder of model 7070, the sealing temperature is 980°C, the insulation resistance of the finished product is ≥5000MΩ, and the air leakage rate is ≤5×10 - 4 Pa.cm 3 / s.

Embodiment 2

[0046] Such as Figure 4 As shown, it is the three-dimensional structure of a circular device with a round-headed glass-sealed 7-core microwave insulator. The inner diameter of the outer conductor is 5.5mm and the height is 2.0mm; the 7 inner conductors are evenly distributed in 3 rows on the insulator, and the needle diameter of the inner conductor is 0.38mm. , the central moment of the adjacent inner conductor is 1.27mm, and the length of the bonding end of the inner conductor is 0.8mm. Both the outer conductor and inner conductor are made of 4J29 Kovar alloy, the sealing glass is glass frit BH-W / K, the sealing temperature is 960°C, the insulation resistance of the finished product is ≥5000MΩ, and the air leakage rate is ≤5×10 -4 Pa.cm 3 / s. Here, the glass frit of model BH-W / K is produced by Nippon Electric Glass Co., Ltd in Japan.

[0047] In the above embodiments, one of the two ends of the inner conductor is the bonding end, and the other end is the socket end, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Coefficient of expansion | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com