Production process for converting gray black barite into white barite finished product

A production process and barite technology, applied in the direction of calcium/strontium/barium sulfate, etc., can solve problems such as inapplicability, limited application fields, and reduced density, and achieve low cost, simple and reliable process, and low energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

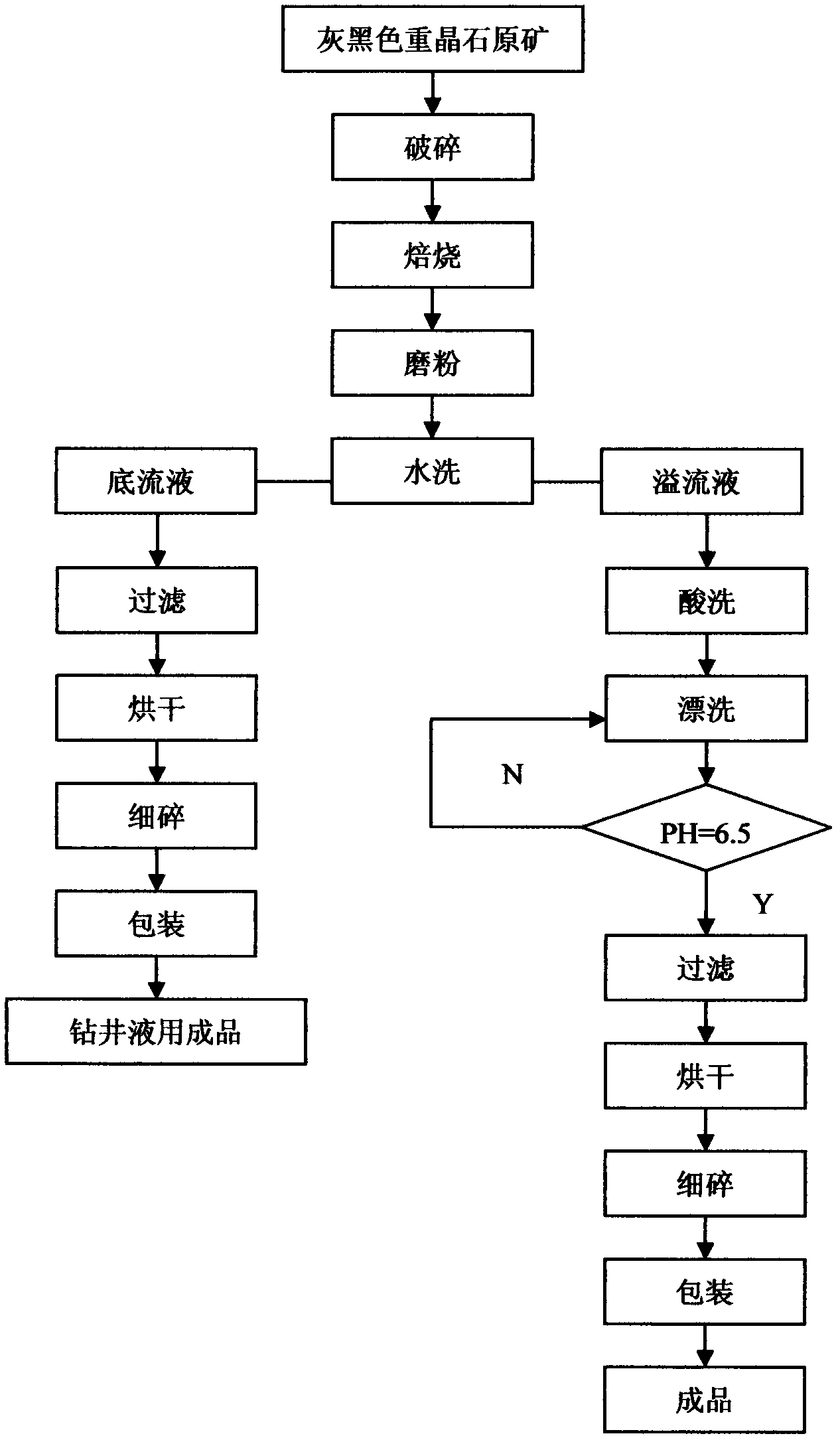

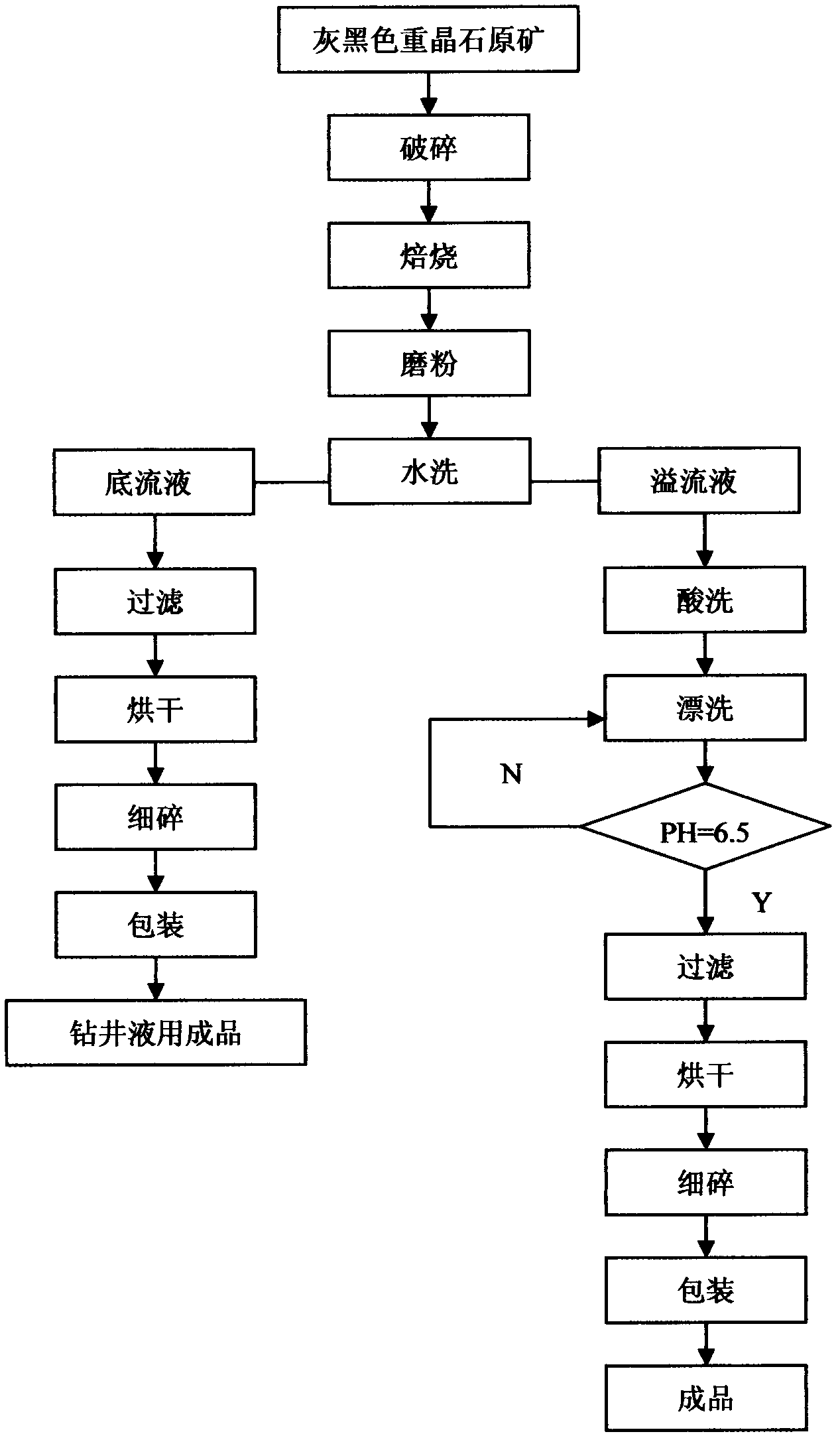

[0016] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0017] As shown in the accompanying drawings, the process flow of the present invention is: gray-black barite raw ore→crushing→roasting→milling→water washing→overflow liquid after the water washing→pickling→rinsing→filtering→drying→fine crushing→ Packaging → finished product; the washed underflow liquid → filtering → drying → crushing → packaging → finished product for drilling fluid.

[0018] As shown in the figure, in the "crushing" process, the particle size after crushing is 80mm; the roasting is weak reduction roasting at a temperature of 950°C; in the "milling" process, the raw materials are placed in Raymond Grinding in the mill, the fineness after grinding is 200 mesh; in the "washing" process, in the washing tank, the small particle size flows out through the overflow port at the upper part of the tank body, and the large particle size passes through the unde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com