Vacuum channel type photocathode and preparation method thereof

A photocathode and channel technology, applied in the manufacture of light-emitting cathodes, photoemission cathodes, main electrodes of discharge tubes, etc., can solve the problems of poor stability, short life, low emission current density, etc., to reduce lattice mismatch, The effect of increasing the frequency and increasing the current emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] The present invention further provides a method for preparing a photocathode, comprising the following steps:

[0043] Use organic solvents, deionized water, acidic or alkaline solutions, etc. to clean the pollutants on the surface of the cathode substrate material;

[0044] Using epitaxial techniques such as MOCVD or MBE to grow a buffer layer on the surface of the cathode substrate material;

[0045] Using techniques such as MOCVD or MBE to alternately grow the first semiconductor material and the second semiconductor material on the buffer layer to obtain a periodic structure, and further form a surface semiconductor layer on the periodic structure to obtain a cathode emission layer;

[0046] Fabricate a vacuum channel structure on the surface of the obtained cathode emission layer using micro-nano processing technology or ion beam focused etching technology, wherein the area of the vacuum channel on the side close to the substrate is smaller than the area of the...

Embodiment 1

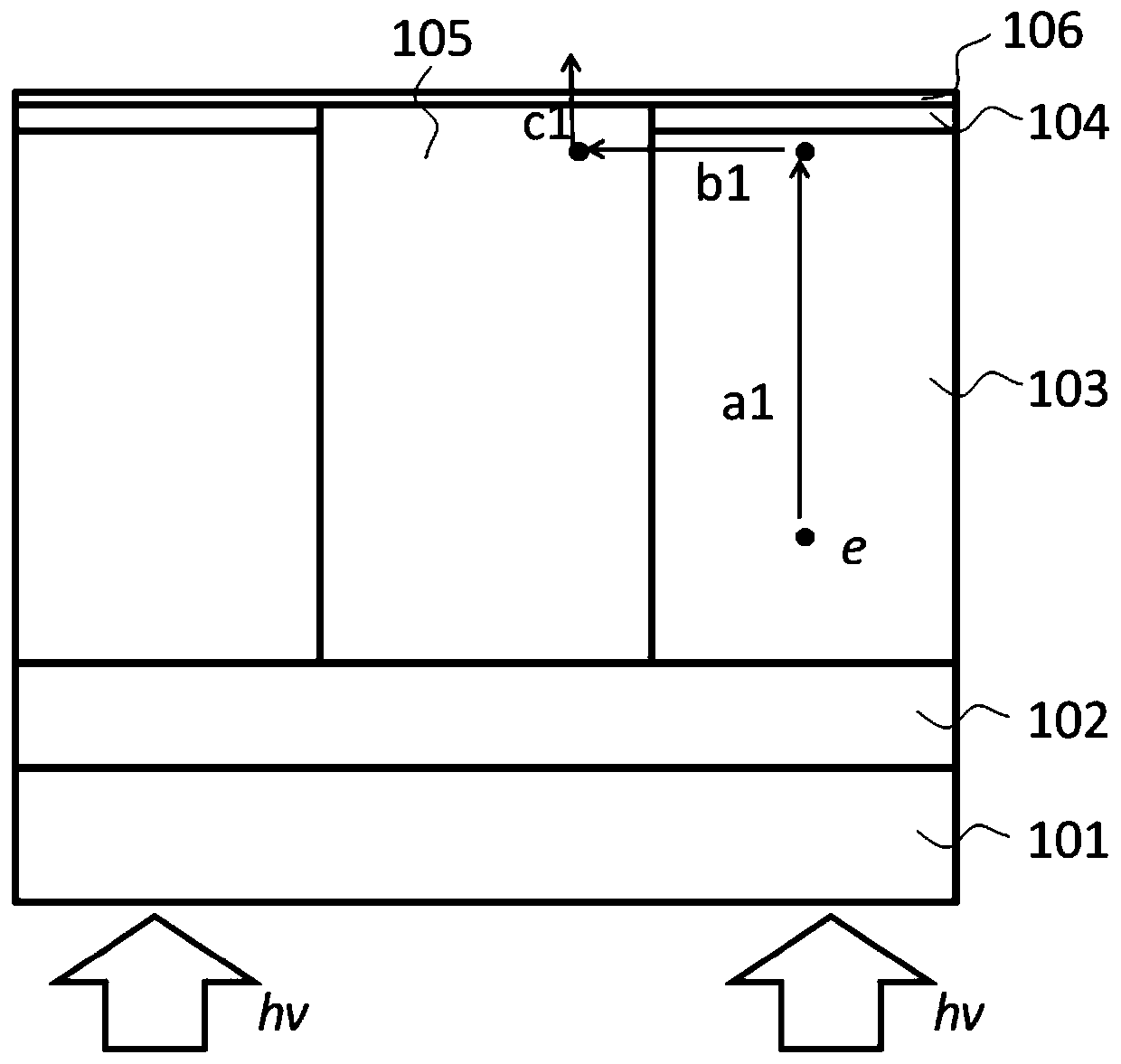

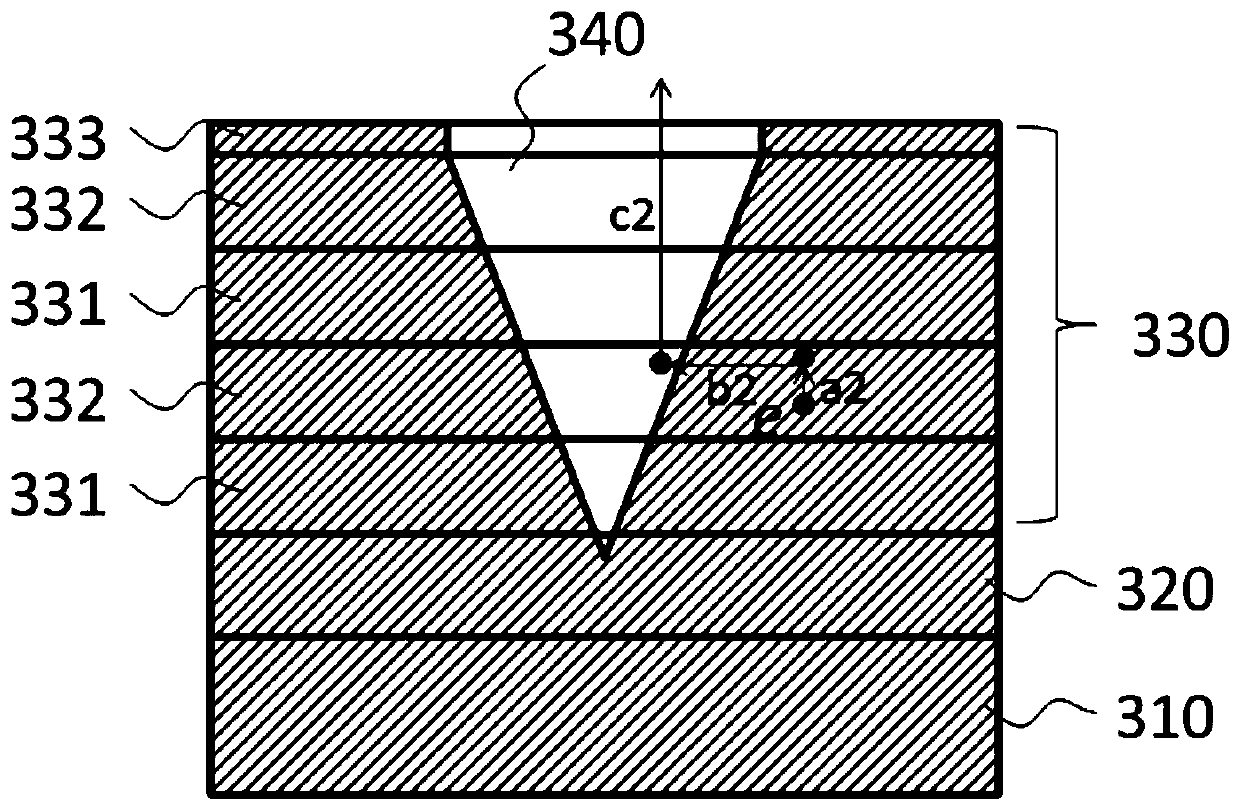

[0051] Combine below figure 2 Specifically illustrate a schematic diagram of a vacuum channel photocathode according to Embodiment 1 of the present invention, the photocathode includes a sapphire substrate, and has a GaN layer as the first semiconductor material layer, and an Al layer as the second semiconductor layer. 0.3 Ga 0.7 A cathode emitter layer with a periodic structure of N layers and an inverted conical vacuum channel.

[0052] Specifically, the vacuum channel photocathode includes a sapphire substrate 310 on which Al 0.3 Ga 0.7 The N layer is used as a buffer layer 320 , and a cathode emission layer 330 is formed on the buffer layer, including a periodic structure of alternately arranged first semiconductor materials 331 and second semiconductor materials 332 and a surface semiconductor layer 333 . The thickness of the first semiconductor layer GaN layer is 35nm, the second semiconductor layer Al 0.3 Ga 0.7 The thickness of the N layer is 65 nm, the first sem...

Embodiment 2

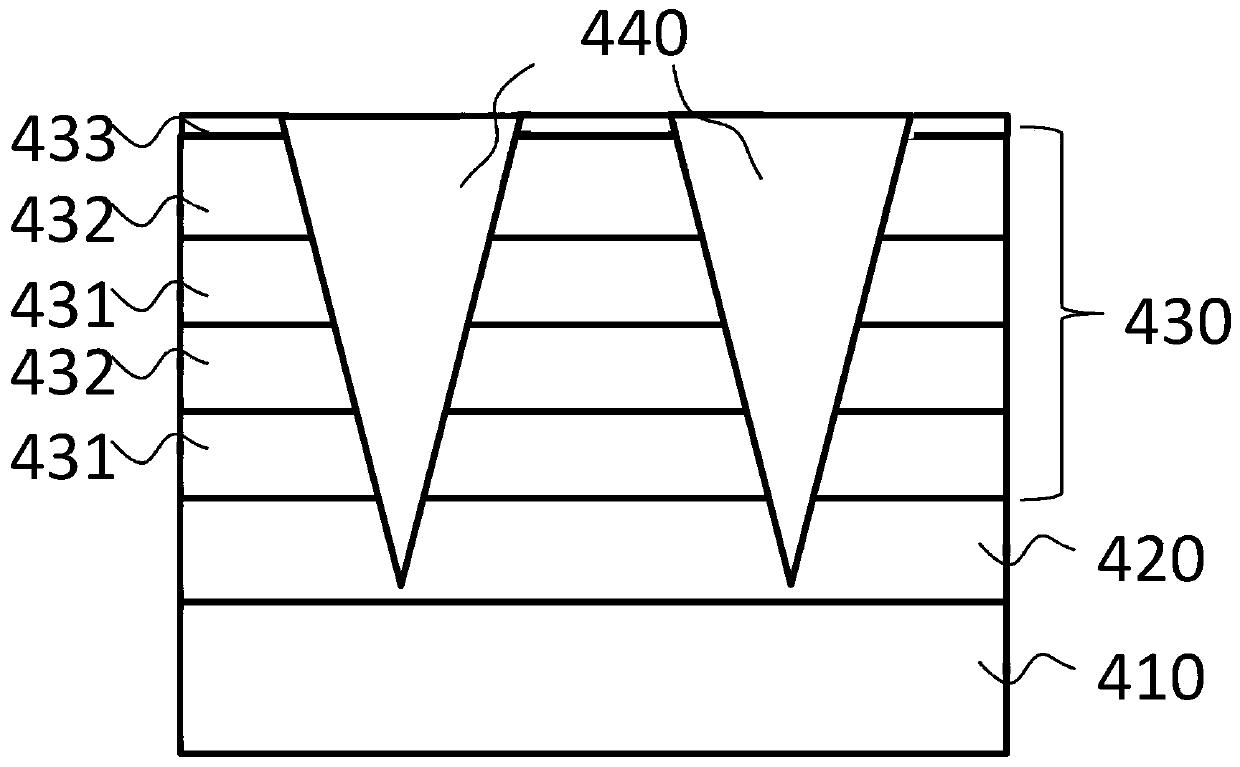

[0061] image 3 According to the strip-shaped vacuum channel type photocathode according to the embodiment 2 of the present invention, the photocathode comprises a GaAs substrate, and has a GaAs layer as a first semiconductor layer, a second semiconductor layer Al 0.55 Ga 0.45 Cathode emitter layer with periodic structure of As layer and two vacuum channels.

[0062] Specifically, the vacuum channel photocathode includes a GaAs substrate layer 410, an Al 0.55 Ga 0.45 As buffer layer 420, a cathode emission layer 430 formed on the buffer layer, including alternately arranged first semiconductor material layers GaAs layers 431 and second semiconductor material layers Al 0.55 Ga 0.45 As layer 432, each Al 0.55 Ga 0.45 The thicknesses of the As layer and the GaAs layer are 50nm and 60nm respectively, the cycle number T of the two crystals is 8; the thickness of the surface GaAs layer 433 is 50nm. The vacuum channel structure is a strip structure, the width of the vacuum cha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com