A hot cathode having a three-dimensional structure surface and a preparation method thereof

A three-dimensional structure, hot cathode technology, applied in the manufacture of thermionic cathodes, solid thermionic cathodes of discharge tubes, main electrodes of discharge tubes, etc., can solve the problem of small improvement in cathode performance, achieve strong ion bombardment resistance, and stable emission , high consistency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] In the prior art, the scandate cathode has relatively poor stability in emitting electron beams and weak resistance to ion bombardment, and the electron emission capability of the cathode is seriously damaged and difficult to recover after being ignited. In high-performance microwave devices, barium tungsten cathodes or film-coated barium tungsten cathodes are generally still used. Usually, the emission current intensity of the barium tungsten cathode or film-coated barium tungsten cathode is increased by increasing the cathode emission current density, but there are several existing methods for increasing the cathode emission current density, which improve the performance of the cathode relatively little. In view of the above problems, the present invention provides a hot cathode capable of effectively increasing the emission current intensity of the cathode and a preparation method thereof, and the specific technical solutions are as follows.

[0035] In one aspect, t...

Embodiment 1

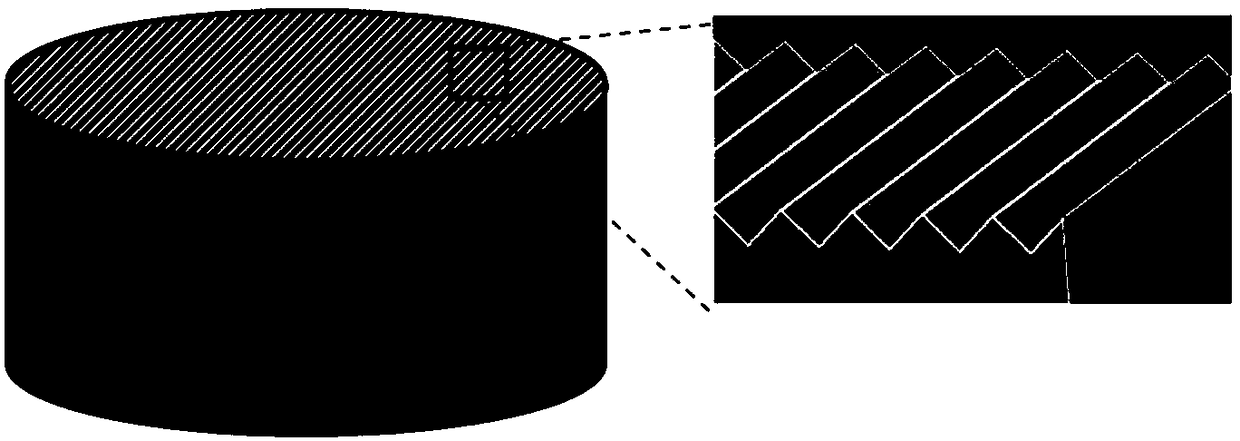

[0051] This embodiment provides a hot cathode with a three-dimensional structure surface and a preparation method thereof. The hot cathode with a three-dimensional structure surface is composed of a porous tungsten base impregnated with aluminate and a precious metal film formed on the surface of the porous tungsten base. The emission surface of the porous tungsten base is grooved to form a regularly arranged concave structure. The porosity of the porous tungsten matrix is 25%, and the aluminates BaO, CaO and Al 2 o 3 The mixing ratios are 66%, 11%, 23%. The concave structure on the surface of the porous tungsten substrate is a number of periodically arranged V-shaped channels, the channels are arranged in one direction, the width of the upper part of the channel is 5 μm, the channel depth is 5 μm, and the channel spacing is 5 μm; the precious metal is osmium , thickness 0.5 μm.

[0052] The preparation method of the hot cathode is as follows:

[0053] In the first step,...

Embodiment 2

[0060] This embodiment provides a hot cathode with a three-dimensional structure surface and its preparation method. The hot cathode is composed of a porous tungsten base impregnated with aluminate and a precious metal film formed on the surface of the porous tungsten base, wherein the porous tungsten The emitting surface of the base is grooved to form a regularly arranged concave structure.

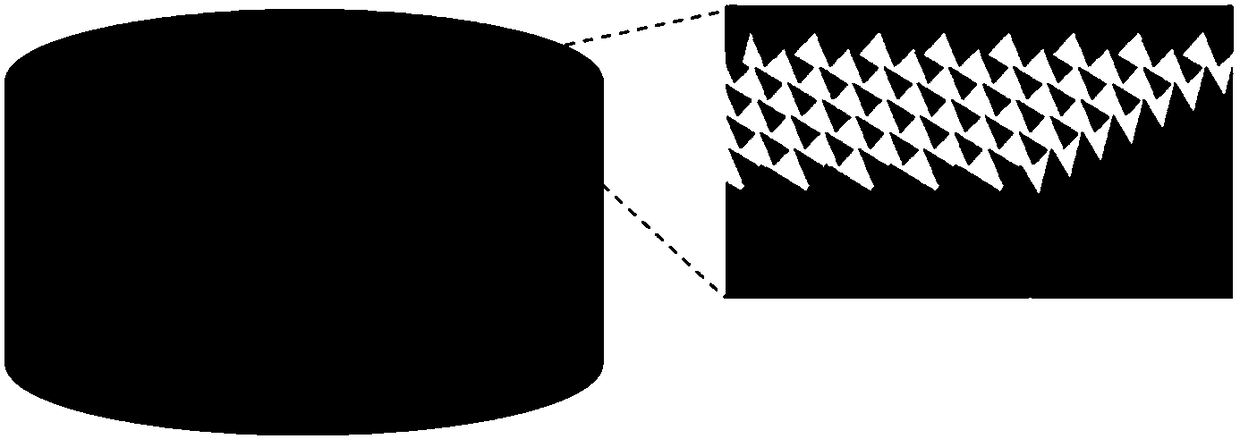

[0061] Porous tungsten base with 25% porosity, aluminates BaO, CaO and Al 2 o 3 The mixing weight percentages are 66%, 11%, 23%. The channel structure on the porous tungsten-based surface is a number of V-shaped channels arranged periodically and regularly. The channels are periodic structures in the orthogonal direction. The width of the upper part of the channel is 35 μm, the channel depth is 100 μm, and the channel spacing is 50 μm; Osmium, thickness 2μm.

[0062] A hot cathode with a three-dimensional structured surface is prepared as follows:

[0063] In the first step, aluminat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com