Infrared ceramic body and infrared health physiotherapy instrument thereof

A technology of infrared ceramics and physiotherapy equipment, which is applied in the field of ceramic body and health physiotherapy equipment, infrared ceramic body and its infrared health physiotherapy equipment, and can solve the problems of deviating from the basic properties of infrared physiotherapy, not being able to exert the effect of infrared health physiotherapy, and insufficient optical density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The invention provides an infrared ceramic body, which is prepared through the following steps in sequence:

[0061]One) preparing a porous grid-shaped ceramic body, the method comprises the following steps in sequence:

[0062] 1) Weigh each component according to the following mass:

[0063] Volcanic stone powder 60kg;

[0064] Labradorite powder 5kg;

[0065] Palygorskite powder 50kg;

[0066] Cordierite powder 30kg;

[0067] The particle diameter of described volcanic stone powder, labradorite powder, palygorskite powder is 150 orders;

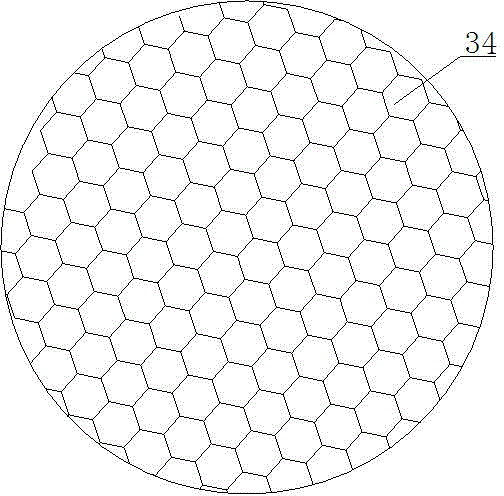

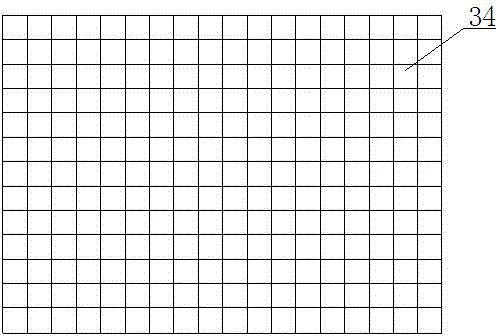

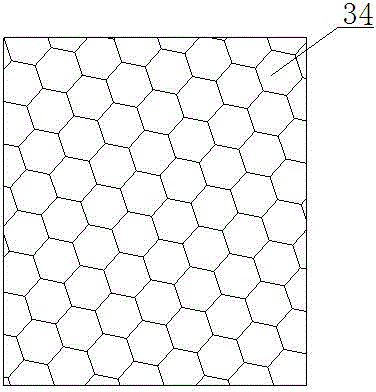

[0068] 2) Mix and grind the materials weighed in step 1) to 400 mesh, then add 20kg of binder, the binder is 5% polyvinyl alcohol, 20kg of silica powder, 5kg of irregular pore-forming fibers, After the mud is evacuated, the glue injection colloid is obtained. The glue injection colloid is formed by extrusion through the injection nozzle of the hydraulic cylinder body and the mesh forming mold. After infrared drying, it is sinte...

Embodiment 2

[0083] Another infrared ceramic body provided by the present invention is prepared through the following steps in sequence:

[0084] One) preparing a porous grid-shaped ceramic body, the method comprises the following steps in sequence:

[0085] 1) Weigh each component according to the following mass:

[0086] Volcanic stone powder 30kg;

[0087] Labradorite powder 30kg;

[0088] Palygorskite powder 30kg;

[0089] Cordierite powder 40kg;

[0090] The particle size of described volcanic stone powder, labradorite powder, palygorskite powder is 80 orders;

[0091] 2) Mix and grind the materials weighed in step 1) to 400 mesh, then add 20kg of binder, 5kg of silica powder, and 20kg of irregular pore-forming fibers. The injection nozzle of the hydraulic cylinder body and the mesh forming mold are formed by extrusion, and after infrared drying, they are sintered to 1200°C and kept warm for 9 hours to make a porous grid ceramic body; the porous grid ceramic body, the wall Thick...

Embodiment 3

[0106] The present invention provides another infrared ceramic body, which is prepared through the following steps in sequence:

[0107] One) preparing a porous grid-shaped ceramic body, the method comprises the following steps in sequence:

[0108] 1) Weigh each component according to the following mass:

[0109] Volcanic stone powder 30kg;

[0110] Labradorite powder 30kg;

[0111] Palygorskite powder 30kg;

[0112] Cordierite powder 40kg;

[0113] The particle size of described volcanic stone powder, labradorite powder, palygorskite powder is 120 orders;

[0114] 2) Mix and grind the materials weighed in step 1) to 500 mesh, then add 10kg of binder, 15kg of silica powder, and 15kg of irregular pore-forming fibers. The hydraulic cylinder body injection nozzle and the mesh forming mold are formed by extrusion, after infrared drying, sintered to 1300 ° C, and kept for 7 hours to make a porous grid ceramic body in a square shape; the porous grid ceramic body The body wall...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com