Power supply connector jack

A technology of power connectors and connecting strips, which is applied to contact parts and other directions, can solve the problems of connector contact reliability, poor elasticity, and easy plastic deformation, etc., and achieve good practical value, simple structure, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

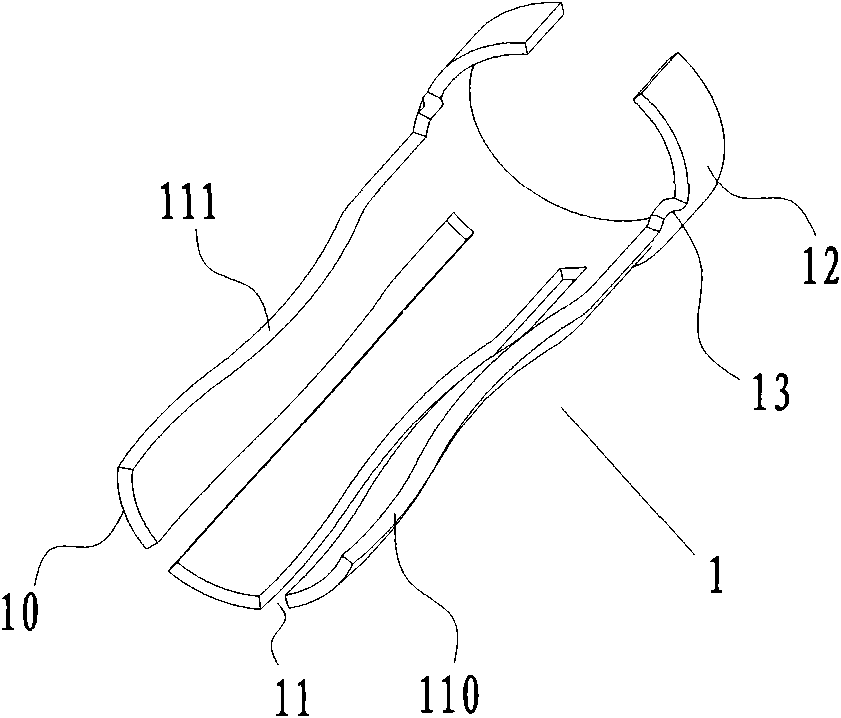

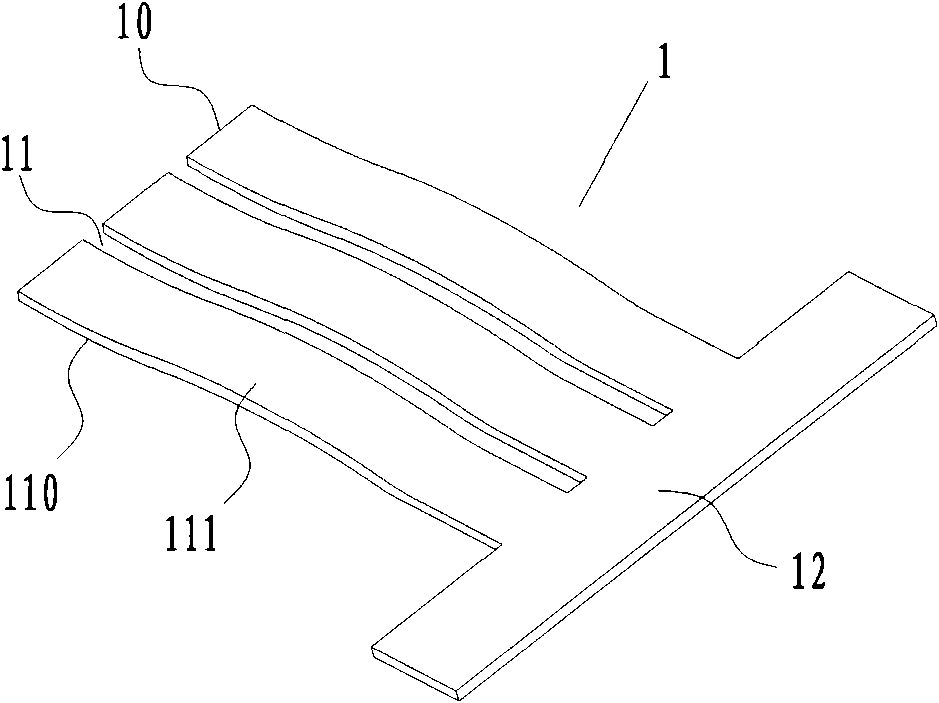

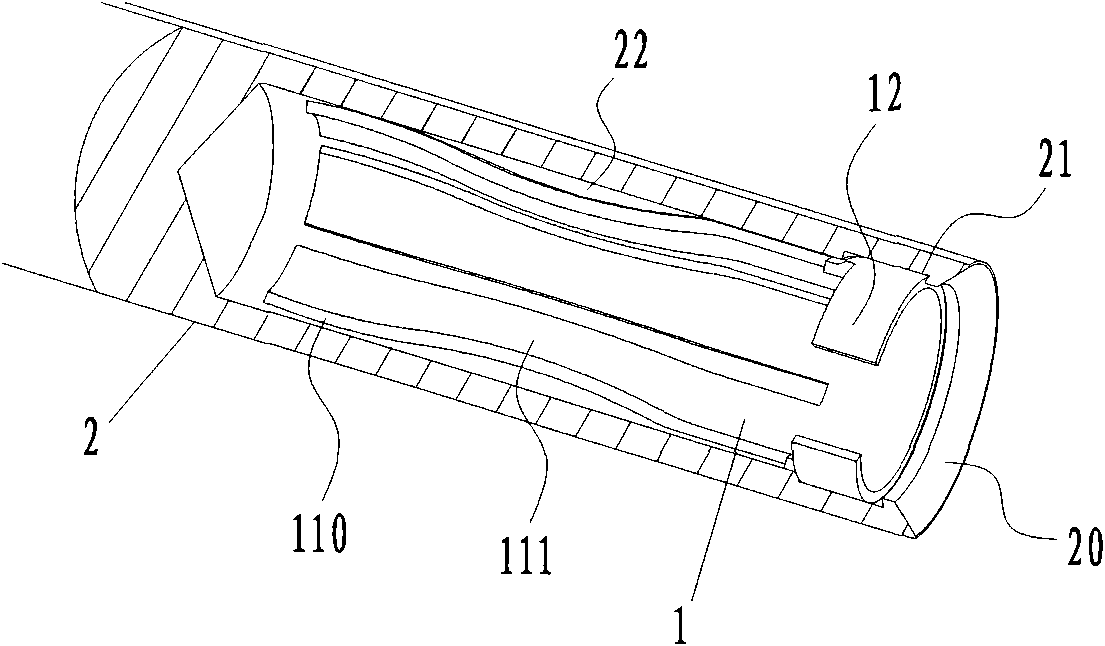

[0023] Example: such as figure 1 , figure 2 , image 3 As shown, a power connector jack, the circular hole 22 of the jack is provided with a contact ring 1, and the contact ring 1 includes at least two contact pieces 10 (in this embodiment, three contact pieces 10) extending toward the distal end. ), a narrow groove 11 is formed between the contact pieces 10, each contact piece 10 is provided with a far-end arc contact area 110 and a near-end arc contact area 111, and the tail end of the contact ring 1 connects a plurality of contact pieces by connecting strips 12 10 are connected as a whole, and in addition, the connection strip 12 is connected with the contact piece 10 through a circular arc transition area 13 .

[0024] Such as figure 2 As shown, the contact ring 1 is formed by punching and rolling a very thin copper alloy strip, and includes three contact pieces 10 protruding to the far end, and they are connected to each other by a connecting strip 12 at the proximal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com