Ganoderma lucidum spore powder tablet and preparation method thereof

A technology of spore powder tablet and Ganoderma lucidum spore powder is applied in the directions of food ingredients as anticaking agents, food ingredients as viscosity modifiers, food ingredients functions, etc. It can improve the sensory properties and palatability, enhance the fluidity and compressibility, and increase the fluidity and compressibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

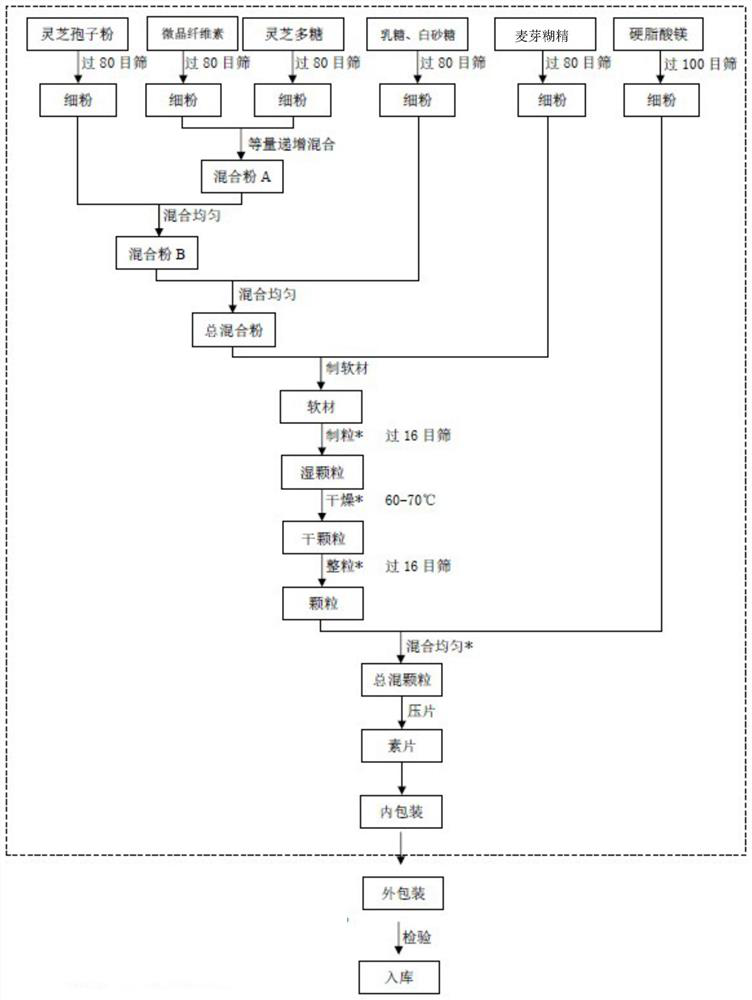

[0039] The formulation and preparation process of the present invention is used to prepare a Ganoderma lucidum spore powder tablet, which is specifically as follows.

[0040] The ganoderma lucidum spore powder tablets were prepared according to the following steps as shown in Table 1.

[0041] (1) Mix: According to the formulation shown in Table 1, in accordance with the equal amount of mixing principle, Ganoderma lucidum spore powder, Ganoderma lucidum polysaccharide or iron dendrobium polysaccharide, microcrystalline cellulose, lactose and white sugar powder, mixed preparation to obtain total mixed powder;

[0042] (2) Software: Machine dextrin is mixed into the total mixing powder and add a suitable amount of adhesive to form a soft material;

[0043] (3) Genuine: Make the soft material over 16 mesh screens into wet particles;

[0044] (4) Dry: Dry the wet particles at 60-70 ° C to give dry particles;

[0045] (5) Whole particles: After the dry particles have a 16-mesh screen, ...

Embodiment 2

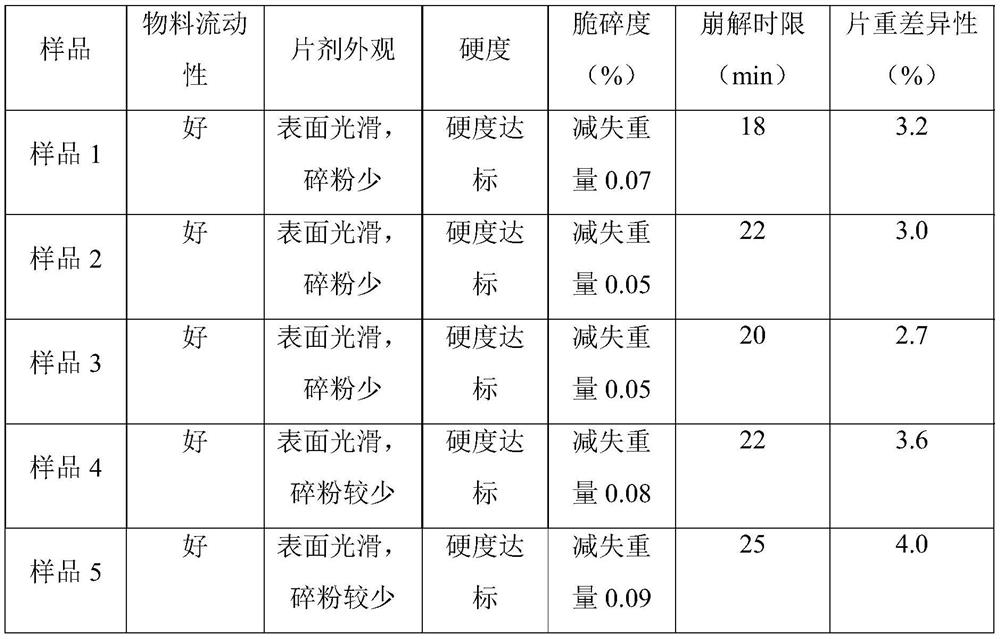

[0057] Taking the granulation of material fluidity, tablets appearance, hardness, fragmenesis, disintegration, and weight differences in detection indicators, and analyzes the five samples prepared, as shown in Table 2.

[0058] Table 2 Analysis of the results of Ganoderma lucidum spore powder tablets

[0059]

Embodiment 3

[0061] According to the formulation of the sample 3, the process verification was performed, ie, according to the sample 3 formulation ratio, respectively, the corresponding raw members were uniform, and the mixture was mixed, sieved, using 60% ethanol solution as a binder, and then 16 mesh sample screen Drying under the conditions of granulation, 60 ° C, after 16 mesh sample sieve granules, the finished product is obtained. Among them, the amount of the raw material (excluding the binder) is 25 g, 50 pieces, and a theoretical film weight of 0.5 g / sheet, and 3 batches were carried out.

[0062] The three batches of Ganoderma lucidum spore powder under this condition were dark brown, uniform, smooth and complete. Ganoderma lucidum spore powder tablet preparation process verification test results See Table 3, the re-obtained Ganoderma lucidum spore powder is shown in Table 4.

[0063] Table 3 Ganoderma lucidum spore powder tablet preparation process verification test

[0064] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com