Epoxy rubber composite modified asphalt and preparation method thereof

A technology of composite modified asphalt and epoxy rubber, which is applied in the direction of building components, building insulation materials, buildings, etc., and can solve the problems of not having elastic modulus adjustable function, not having high elasticity and high viscosity characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

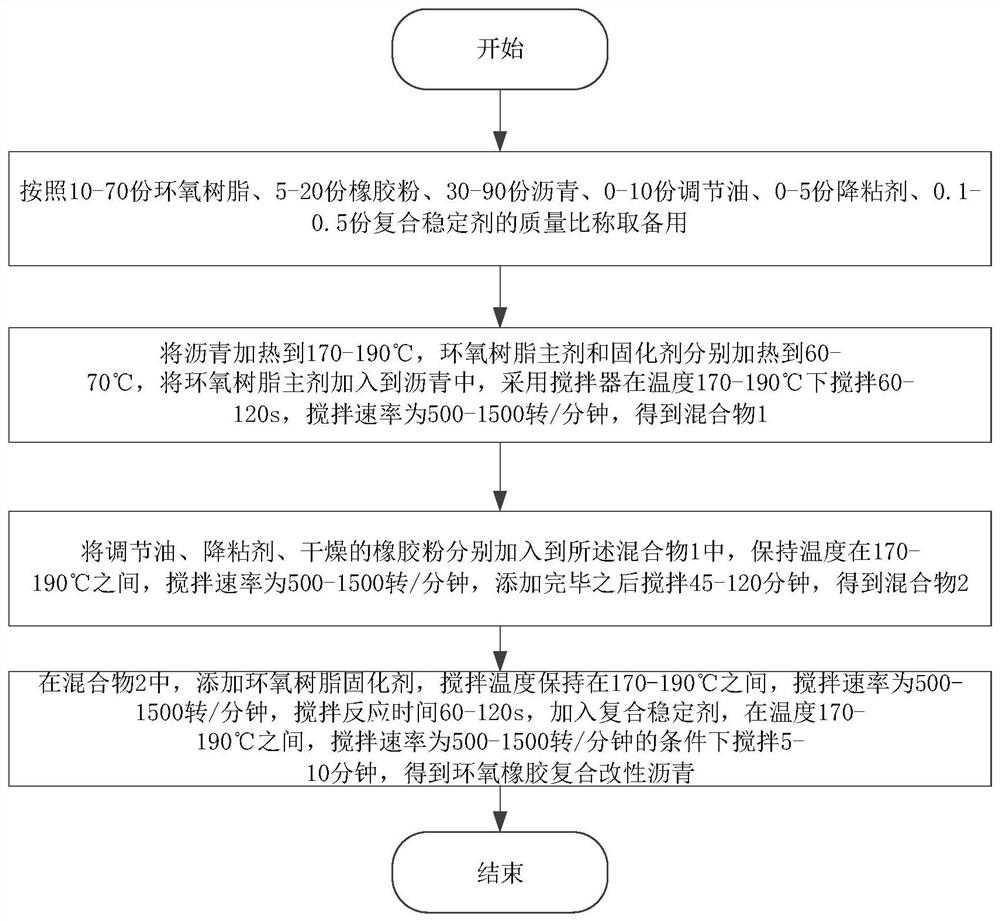

[0033] The present invention also provides a kind of preparation method of epoxy rubber composite modified asphalt, specifically divided into the following steps:

[0034] Step 1, taking base asphalt, epoxy asphalt main agent, epoxy asphalt curing agent, rubber powder, regulating oil, viscosity reducer, composite stabilizer by weighing according to the mass ratio described in the claim;

[0035] Step 2: Heat the base asphalt to 170-190°C, heat the epoxy resin main agent and curing agent to 60-70°C respectively, then add the epoxy resin main agent to the base asphalt, and use a stirrer at a temperature of 170-190°C Stirring at ℃ for 60-120s at a stirring rate of 500-1500 rpm to obtain mixture 1;

[0036] Step 3, add the adjusting oil, viscosity reducer, and dry rubber powder to the mixture 1 in the above step 2 respectively, keep the temperature between 170-190°C, and the stirring speed is 500-1500 rpm, after the addition is complete Stir for 45-120 minutes to obtain mixture 2...

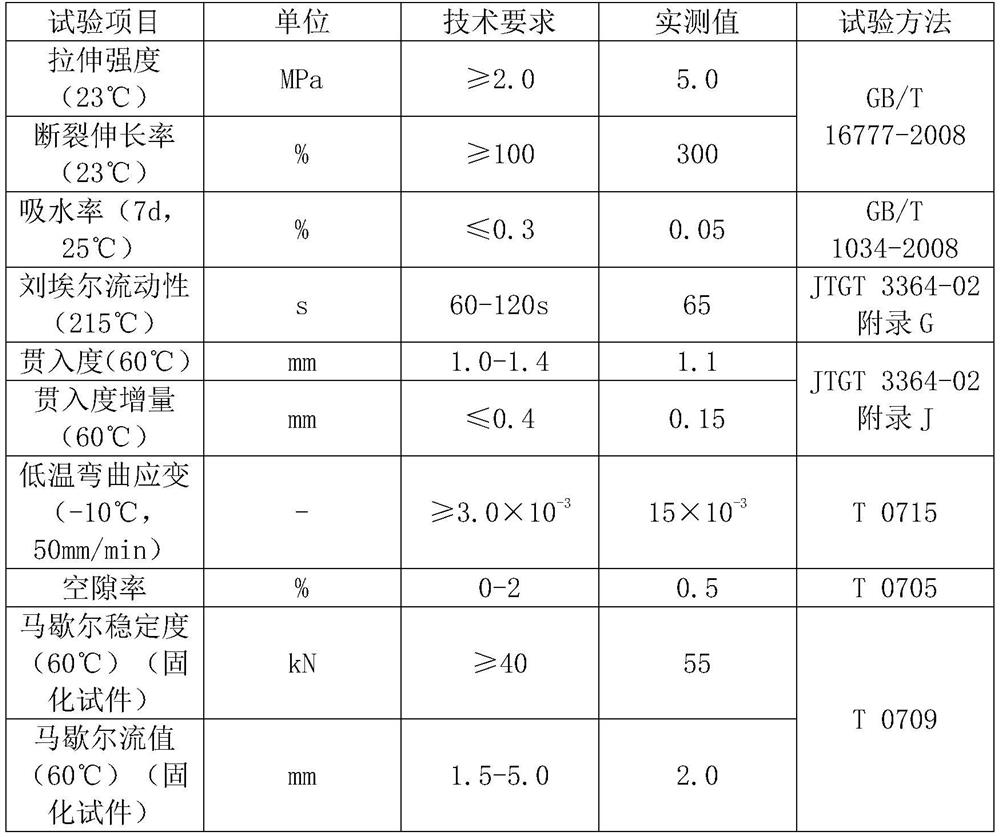

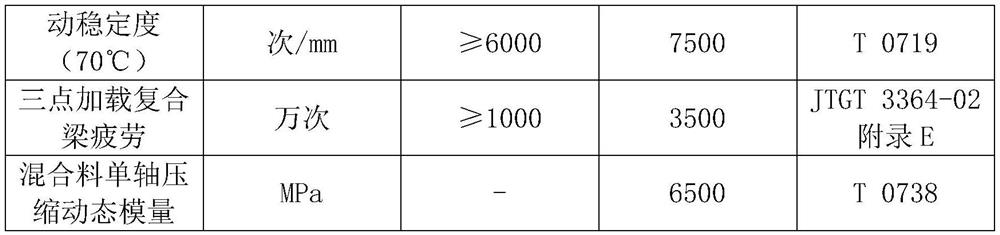

Embodiment 1

[0039] According to the epoxy resin: asphalt mass ratio of 40:60, epoxy resin main agent: curing agent mass ratio of 3:1, weigh 60 parts of base asphalt, 30 parts of epoxy resin main agent, and 10 parts of curing agent. Heat base asphalt to 180°C, epoxy resin main agent and curing agent to 65°C, then add epoxy resin main agent to base asphalt, use a stirrer to stir at 180°C for 90s, stirring speed at 1000 rpm, mixture 1 was obtained. Then add 5 parts of regulating oil, 3 parts of viscosity reducing agent, and 10 parts of dry rubber powder into the above mixture 1 respectively, keep the temperature at 180°C, and stir at a speed of 1000 rpm, and stir for 60 minutes after the addition to obtain the mixture 2. Then add 10 parts of curing agent, keep the stirring temperature between 180°C, the stirring rate is 1000 rpm, and the stirring reaction time is 90s, then add 0.2 parts of composite stabilizer, at a temperature of 180°C, the stirring rate is 1000 rpm Under the condition of...

Embodiment 2

[0045] According to the epoxy resin: asphalt mass ratio of 30:70, epoxy resin main agent: curing agent mass ratio of 3:1, weigh 60 parts of base asphalt, 30 parts of epoxy resin main agent, and 10 parts of curing agent. Heat base asphalt to 180°C, epoxy resin main agent and curing agent to 65°C, then add epoxy resin main agent to base asphalt, use a stirrer to stir at 180°C for 90s, stirring speed at 1000 rpm, mixture 1 was obtained. Then add 5 parts of regulating oil, 3 parts of viscosity reducing agent, and 10 parts of dry rubber powder into the above mixture 1 respectively, keep the temperature at 180°C, and stir at a speed of 1000 rpm, and stir for 60 minutes after the addition to obtain the mixture 2. Then add 10 parts of curing agent, keep the stirring temperature between 180°C, the stirring rate is 1000 rpm, and the stirring reaction time is 90s, then add 0.2 parts of composite stabilizer, at a temperature of 180°C, the stirring rate is 1000 rpm Under the condition of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com