Patents

Literature

36results about How to "Meet liquidity requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

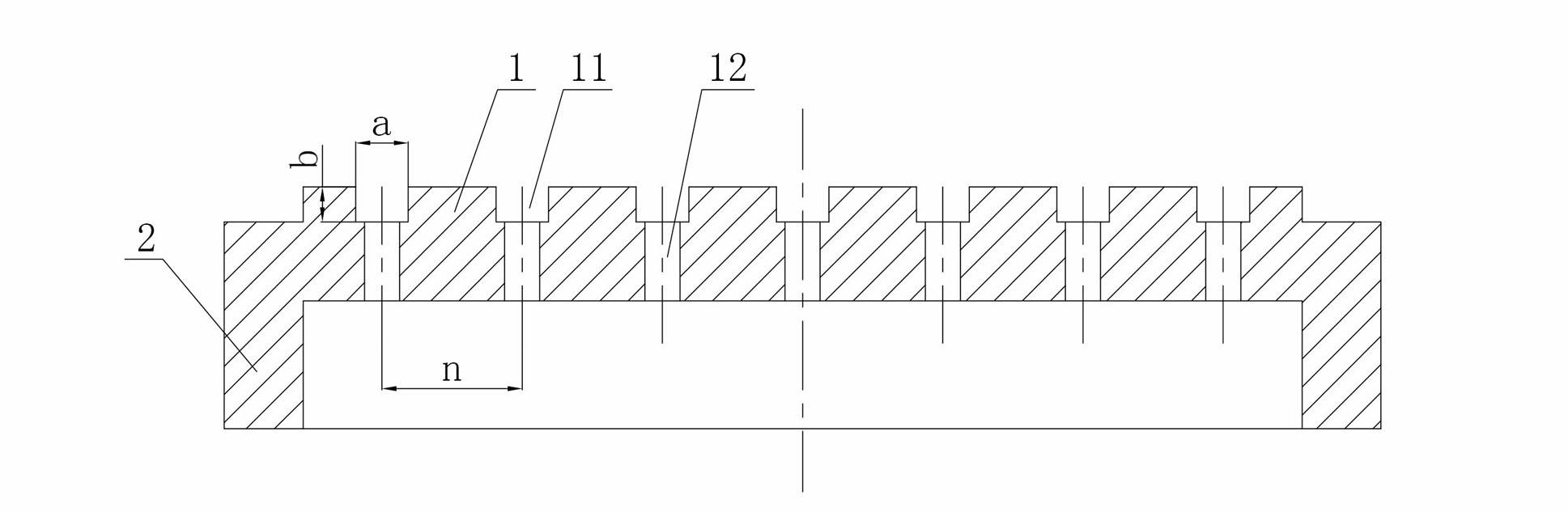

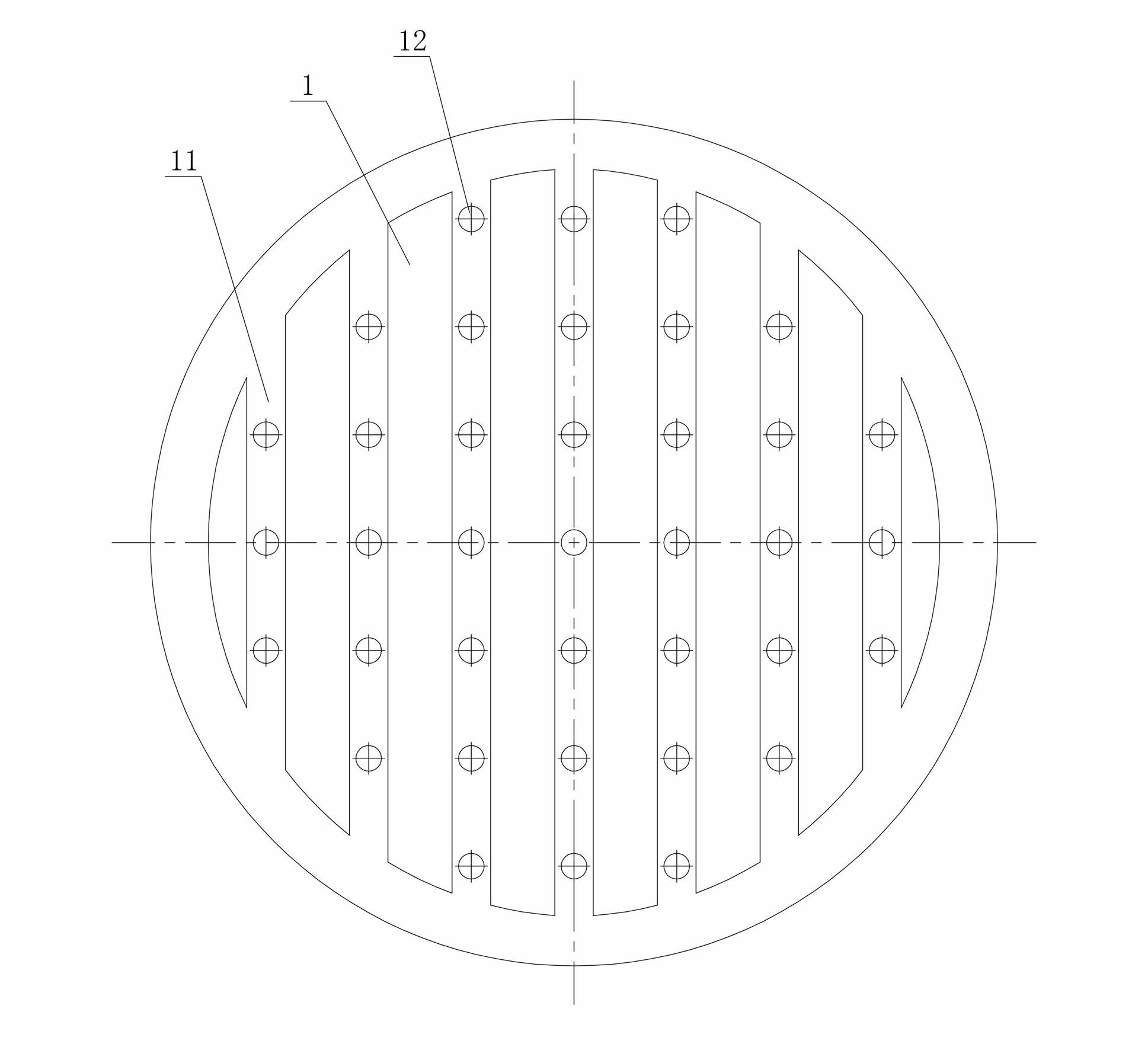

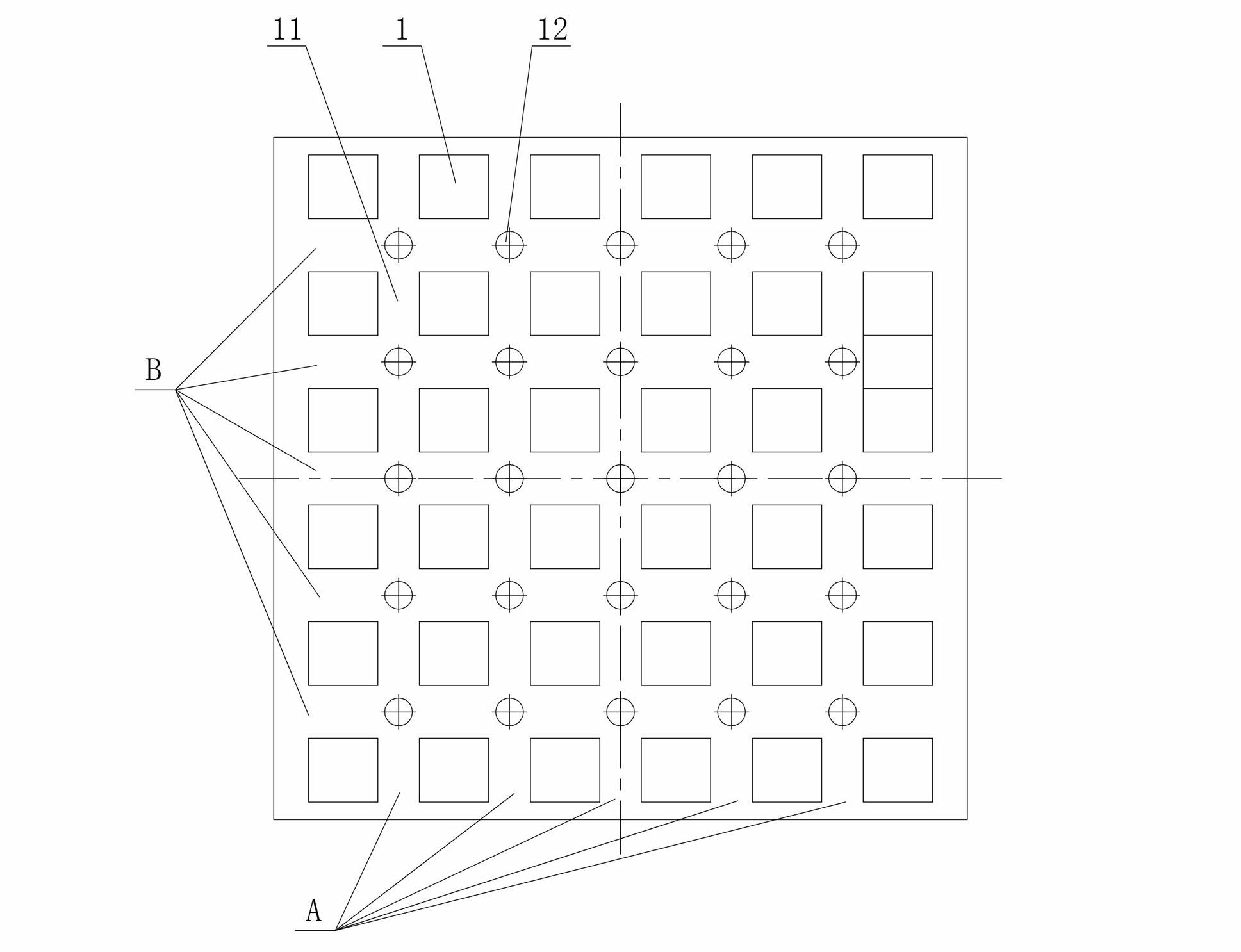

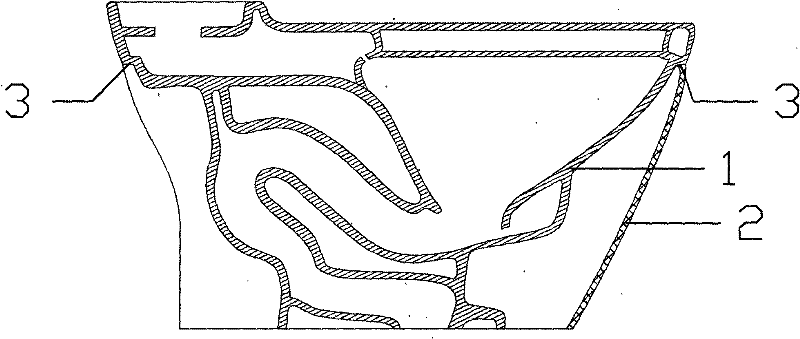

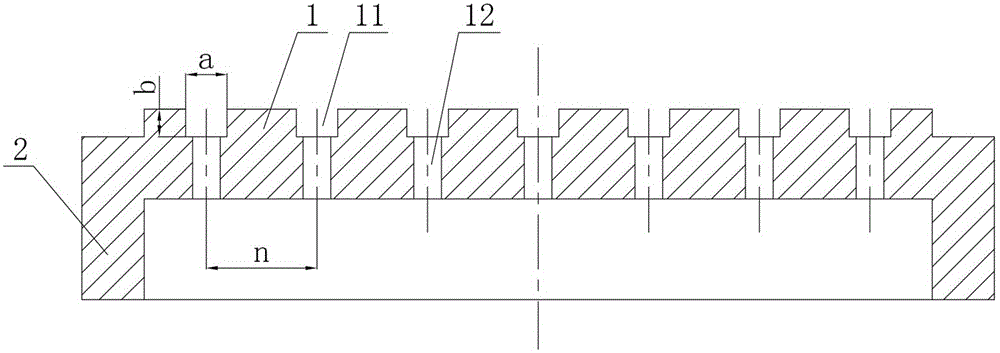

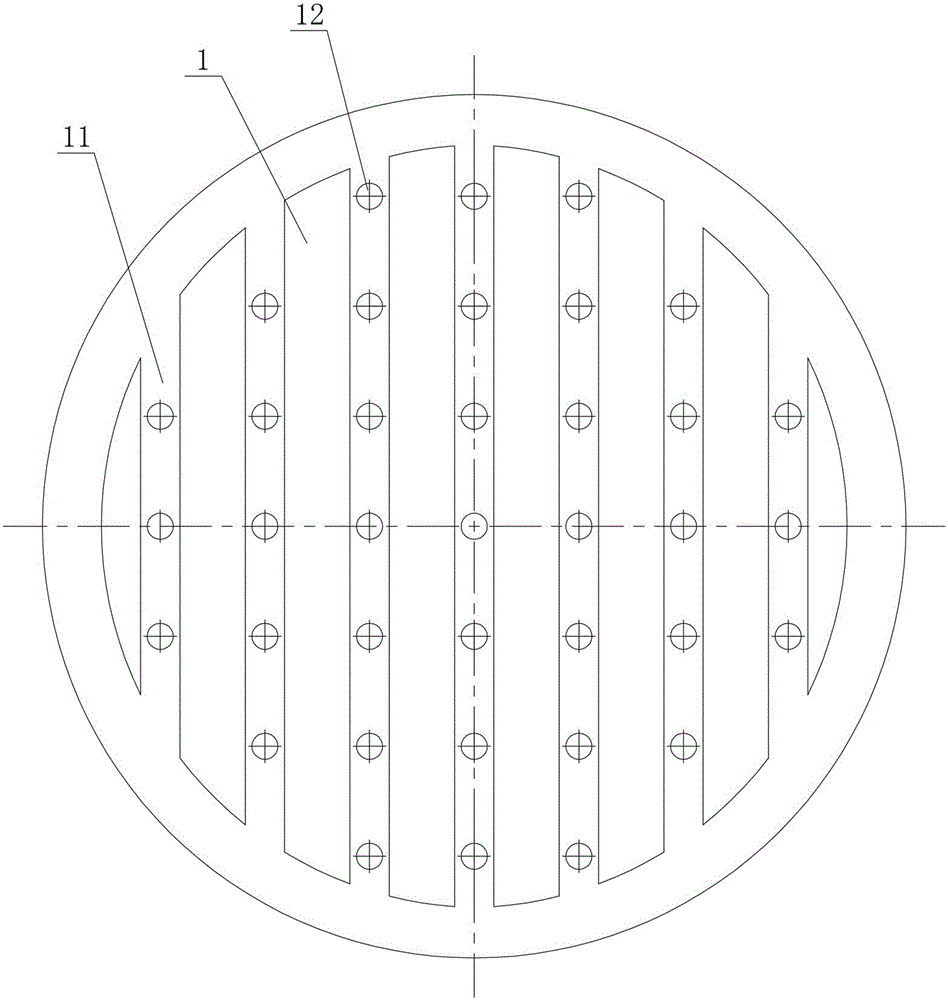

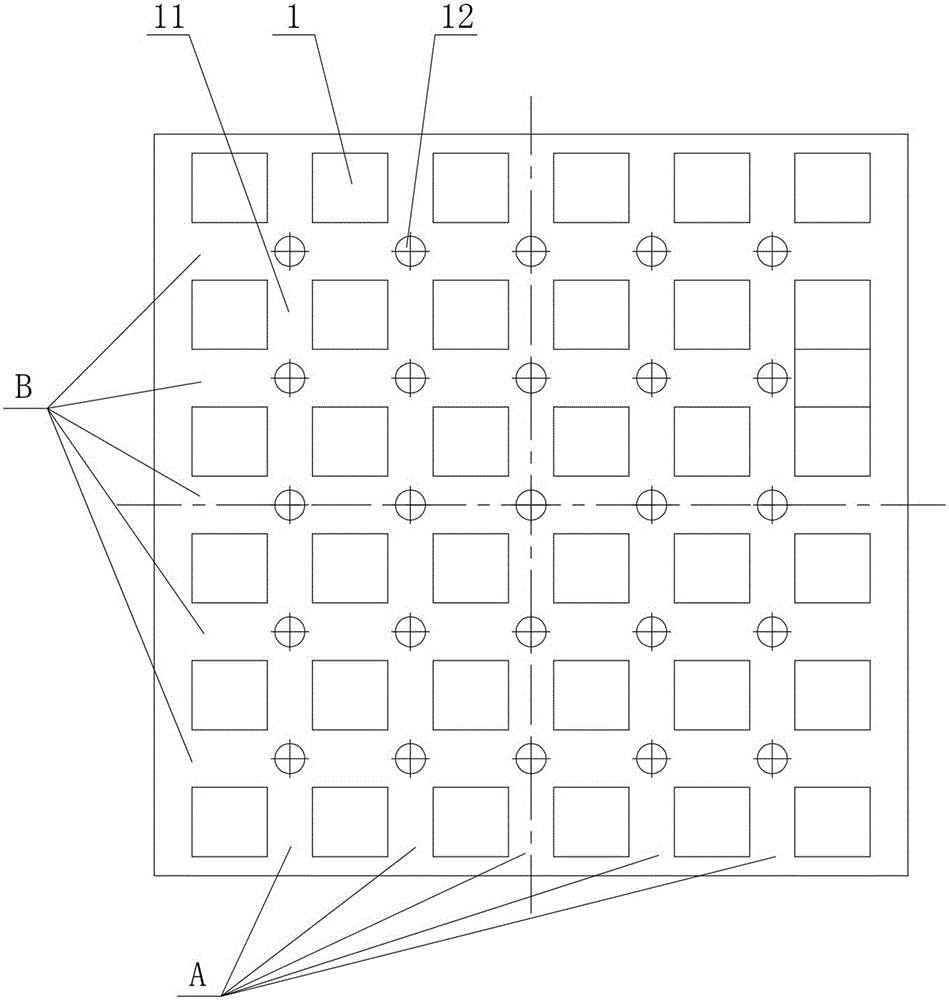

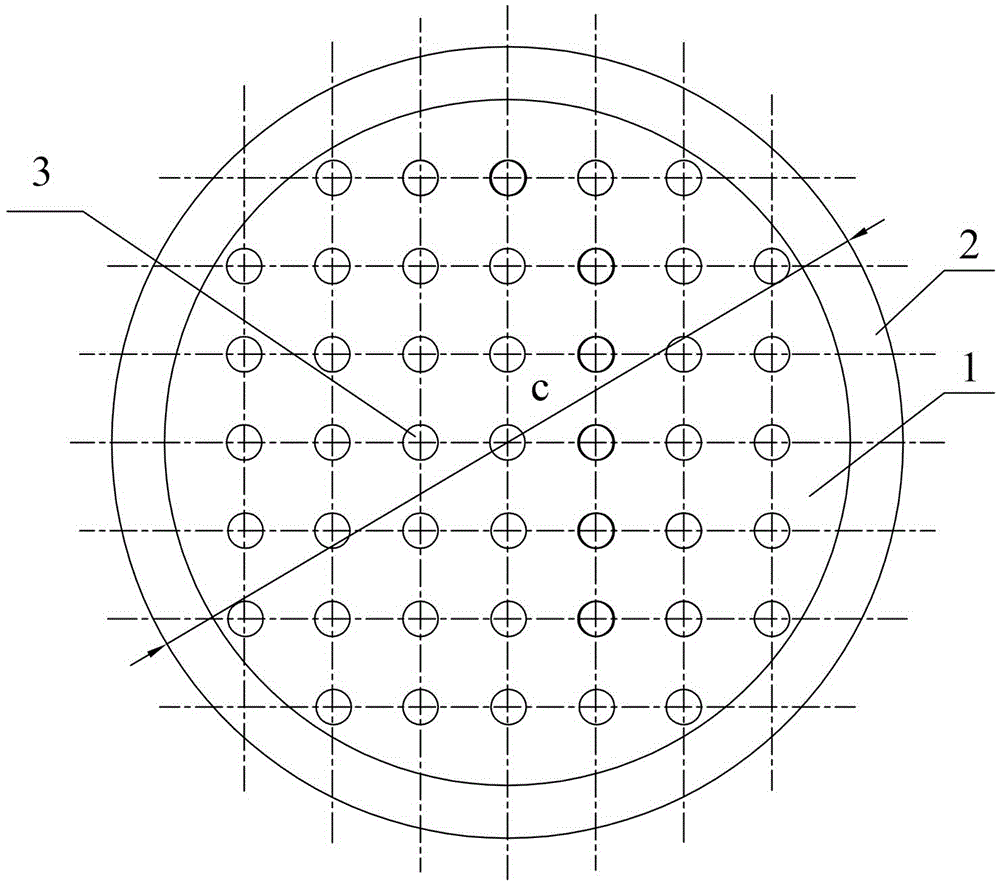

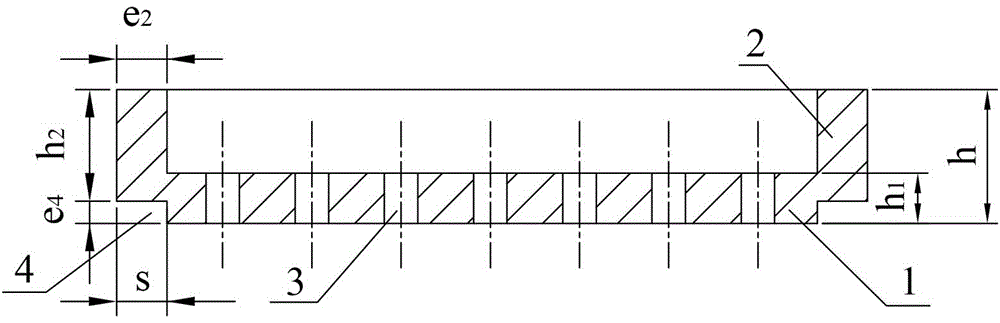

Multipurpose boat for powder metallurgical sintering and multipurpose boat unit

The invention discloses a multipurpose boat for powder metallurgical sintering, which comprises a disk-shaped graphite boat body surrounded by a side wall and a base plate, wherein a plurality of grooves for accommodating the strip-shaped powder metallurgical sintering body are formed outside the base plate of the graphite boat body. The multipurpose boat for powder metallurgical sintering has the advantages of simple structure and wide application range, and is capable of reducing the handling cost of material. The invention further discloses a multipurpose boat unit which is made by overlapping more than two boats.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Method of preparing high fluidity punching proof acrylic resin

InactiveCN101338009AImprove liquidityMeet liquidity requirementsPolymer scienceZiegler–Natta catalyst

A high fluidity anti-impact polypropylene resin process comprises the processes that propylene monomers are bulk polymerized under the existence of catalysts, the catalysts are ziegler-natta catalysts, the polymerization reaction temperature is 50 DEG C to 80 DEG C, the reaction pressure is 2.4 MPa to 6.0 MPa, and the residence time of the reactants is 0.8 to 3 hours; the reaction products are carried out the gas-phase copolymerization under the existence of ethylene, the ethylene concentration in the reaction system is controlled between 0.25 volume percent and 1.2 volume percent, the copolymerization temperature is 50 DEG C to 100 DEG C, the reaction pressure is 0.9 MPa to 2.0 MPa, and the residence time of the reactants is 0.2 to 2.5 hours; the copolymerization products and peroxides are heated, melted and blended, the heating temperature is 180 DEG C to 270 DEG C, and the melt-blending time is controlled between 10 seconds and 30 seconds. The product has the physical properties of ideal rigidness as well as impacting strength, etc. and has excellent fluidity; the melt flow rate can reach more than 30g / 10min.

Owner:SINOPEC SHANGHAI PETROCHEMICAL CO LTD

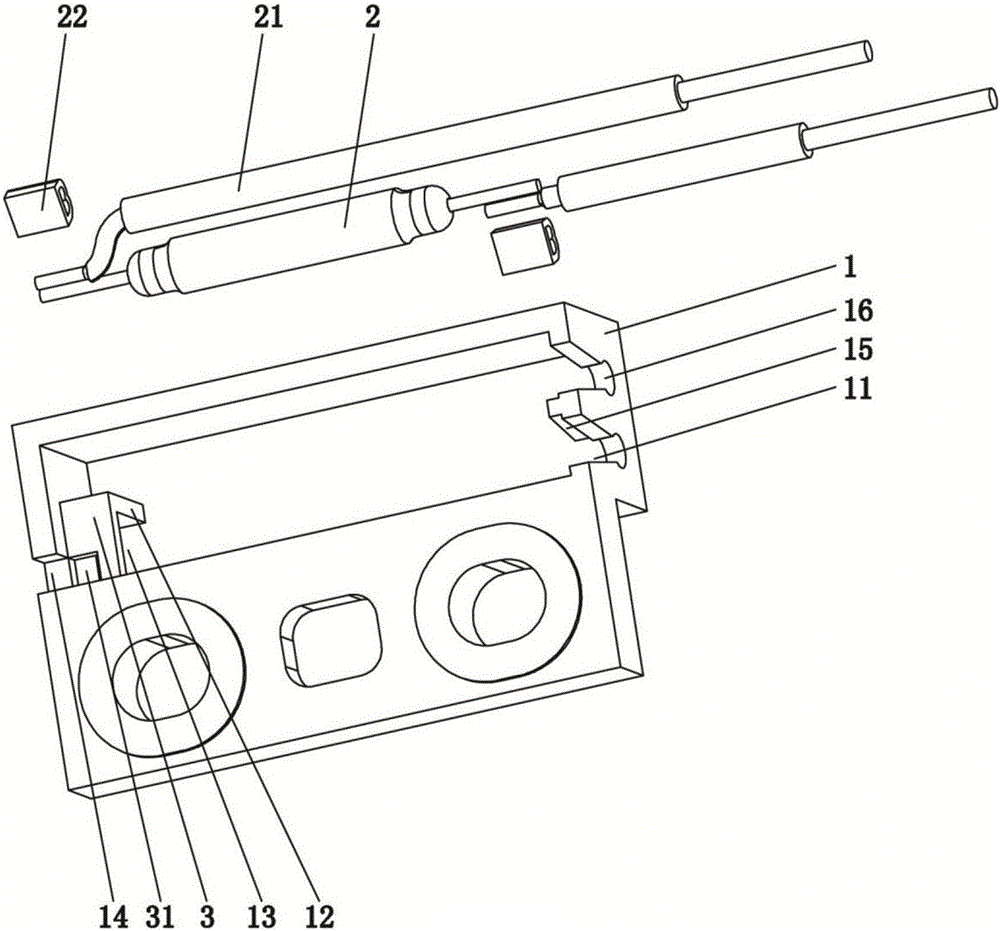

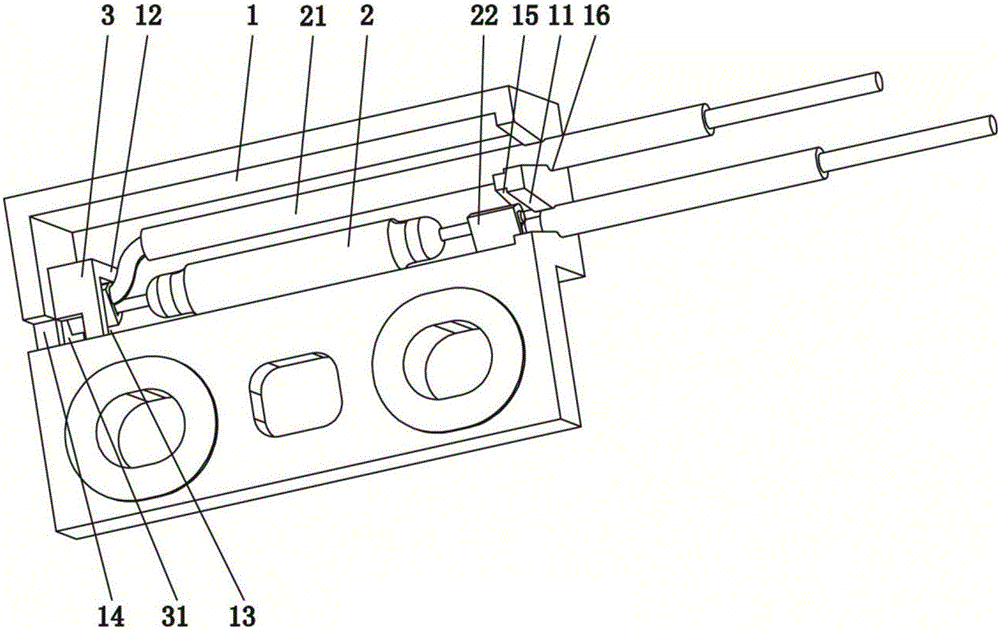

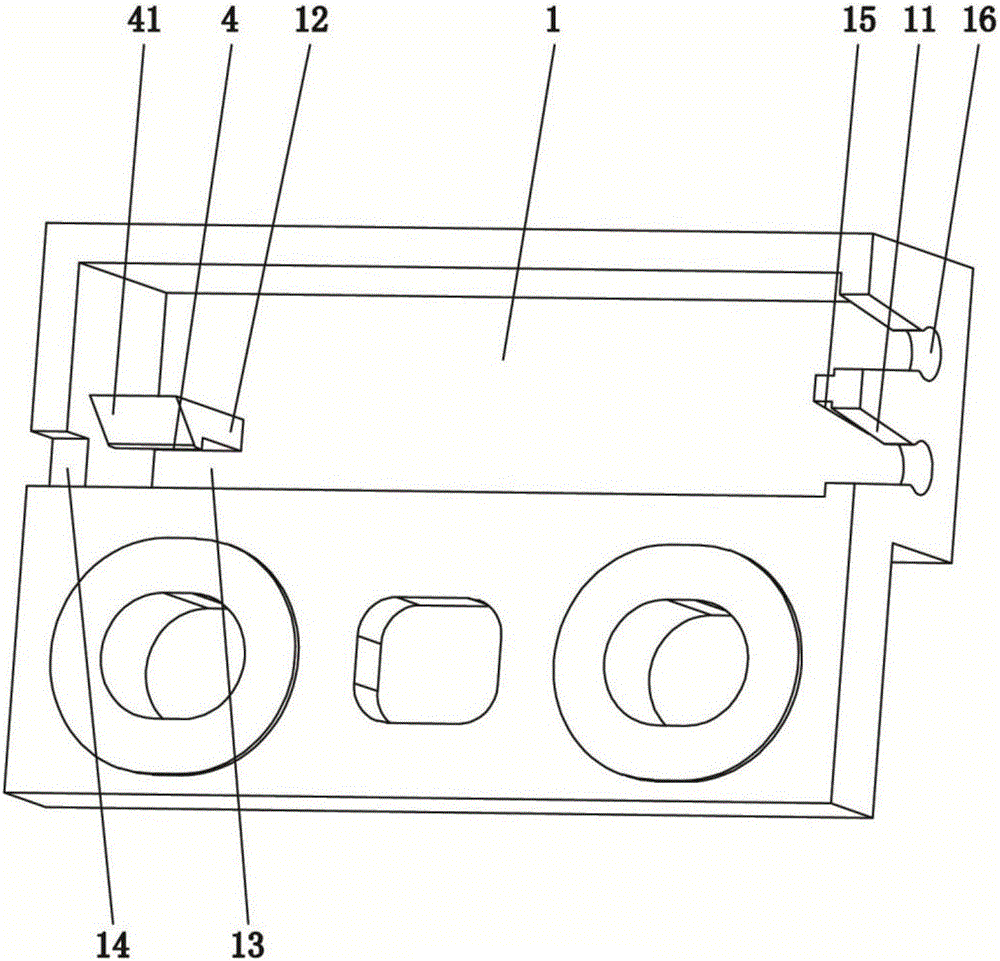

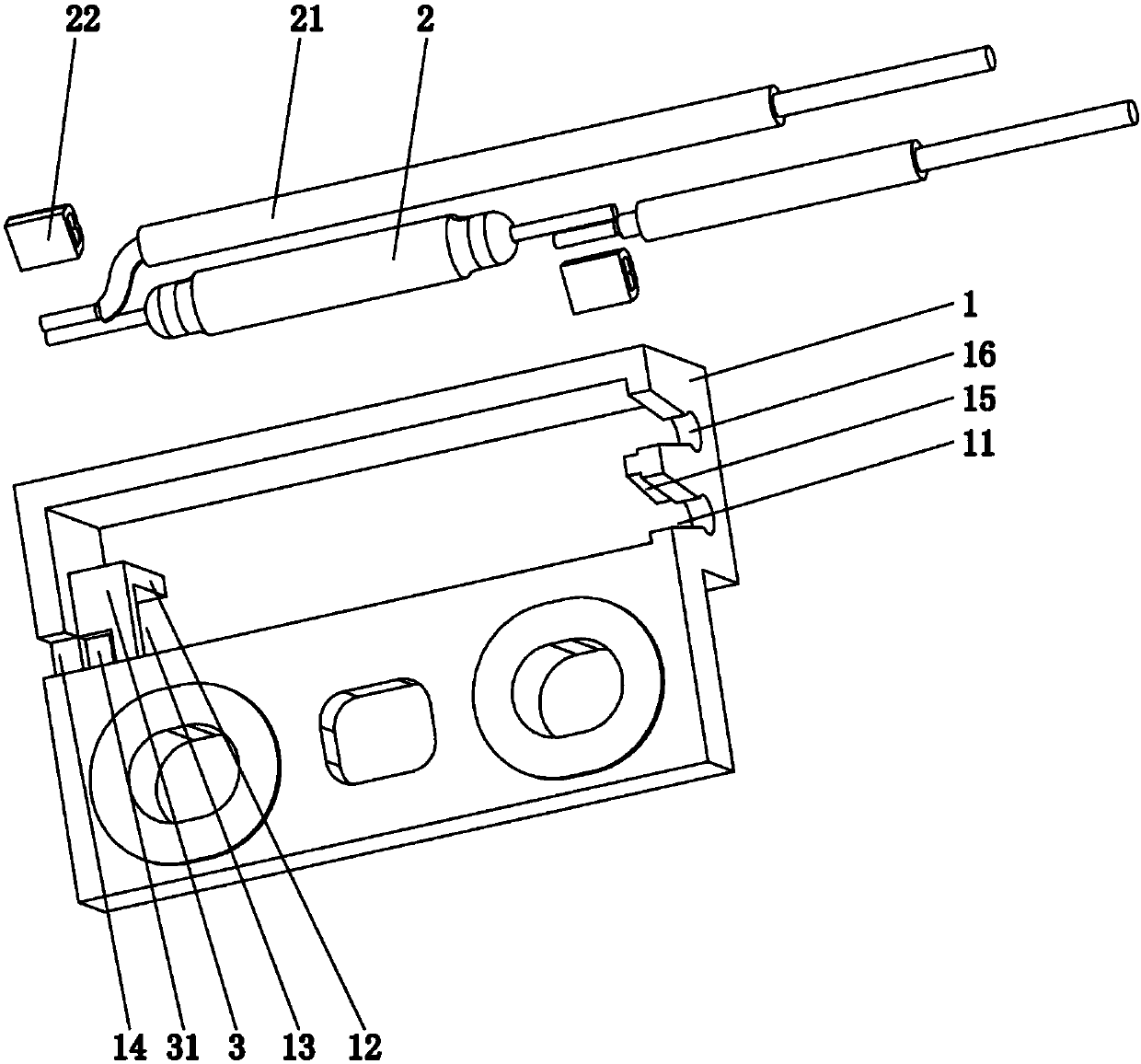

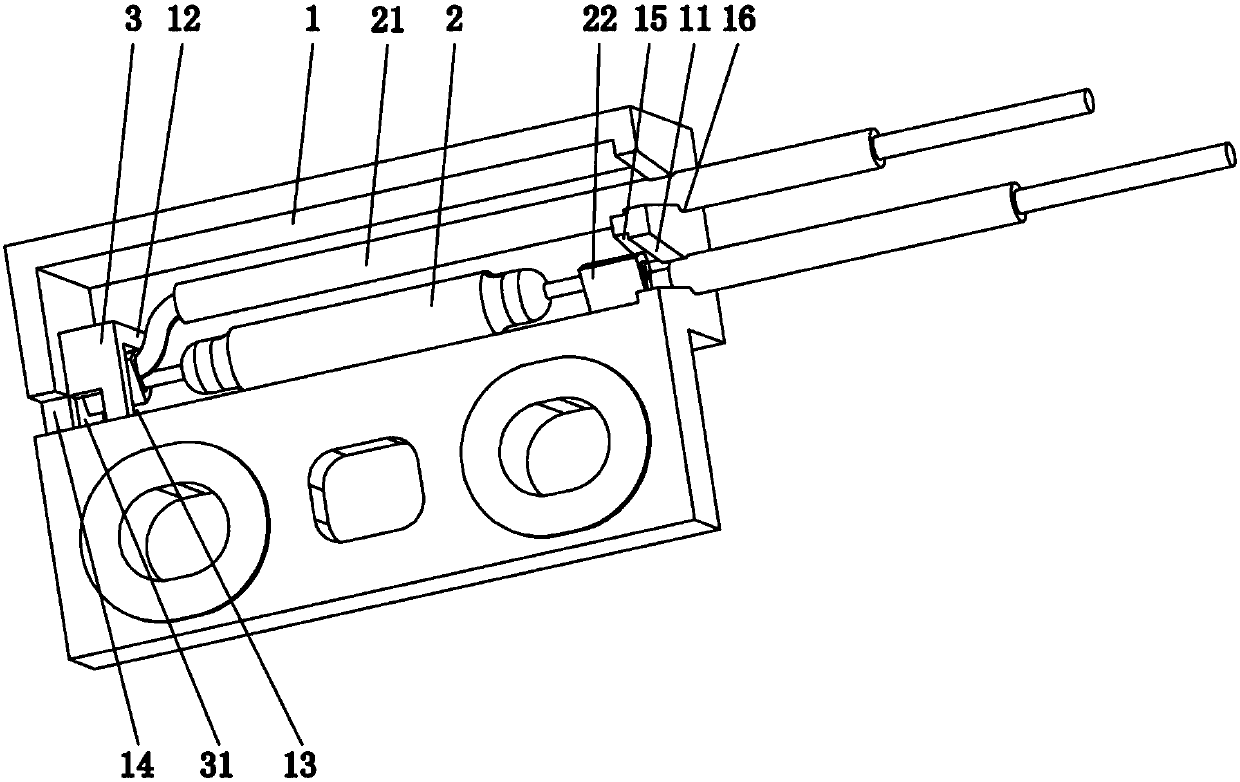

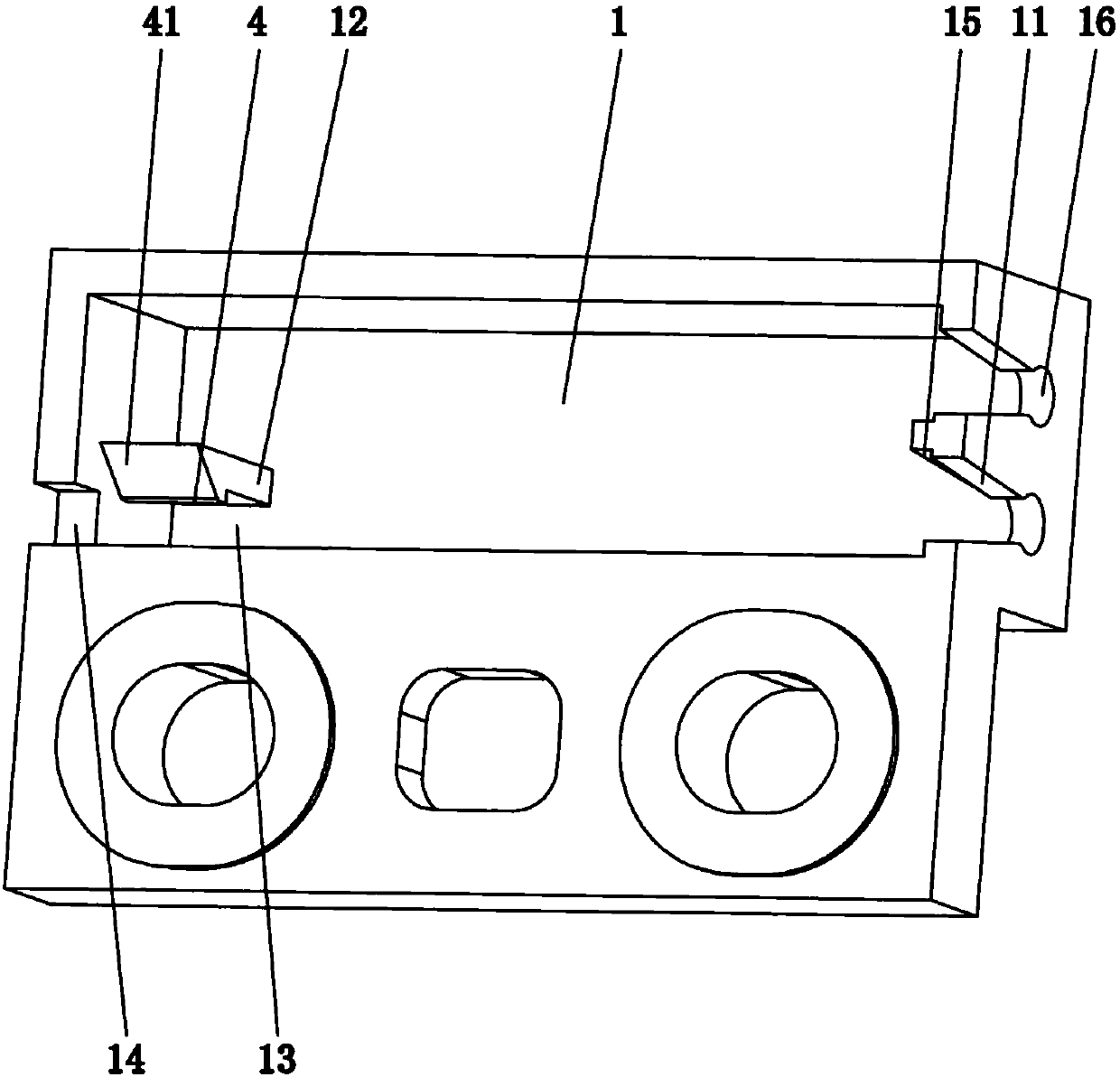

Low-pressure injection molding magnetic proximity switch

InactiveCN105845498AHigh impact strengthImprove stabilityMagnetic/electric field switchesContact electric connectionElectricityEngineering

The invention relates to the technical field of magnetic proximity switches, in particular to a low-pressure injection molding magnetic proximity switch, which comprises a plastic box, a reed switch and an inlet and outlet lead, wherein an opening is formed in the upper end of the plastic box; two threading slots are formed in the right end wall of the plastic box; a wire fixing pinch plate is arranged at the inner side of the left end wall of the plastic box; the wire fixing pinch plate is matched with the lateral wall of the plastic box to form a wire fixing opening; the inlet and outlet lead is electrically connected with two pins of the reed switch respectively; one pin of the reed switch is fixedly arranged in the wire fixing opening; and the inlet and outlet lead is transversely led out from the corresponding threading slot. The low-pressure injection molding magnetic proximity switch is reasonable in structure; one pin of the reed switch is integrally connected with the lead through a rivet; the electric connection strength is high; and the performance is stable. The rivet at one end of the reed switch is arranged in the wire fixing opening in a penetrating manner; the other end of the reed switch is limited through the positions of a wire clamping hole and a rib plate, so that the assembly position of the reed switch in an inner cavity of the plastic box is reasonable; a low-pressure injection molding process is achieved; and the impact strength and the electrical stability of the reed switch can be effectively improved.

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY

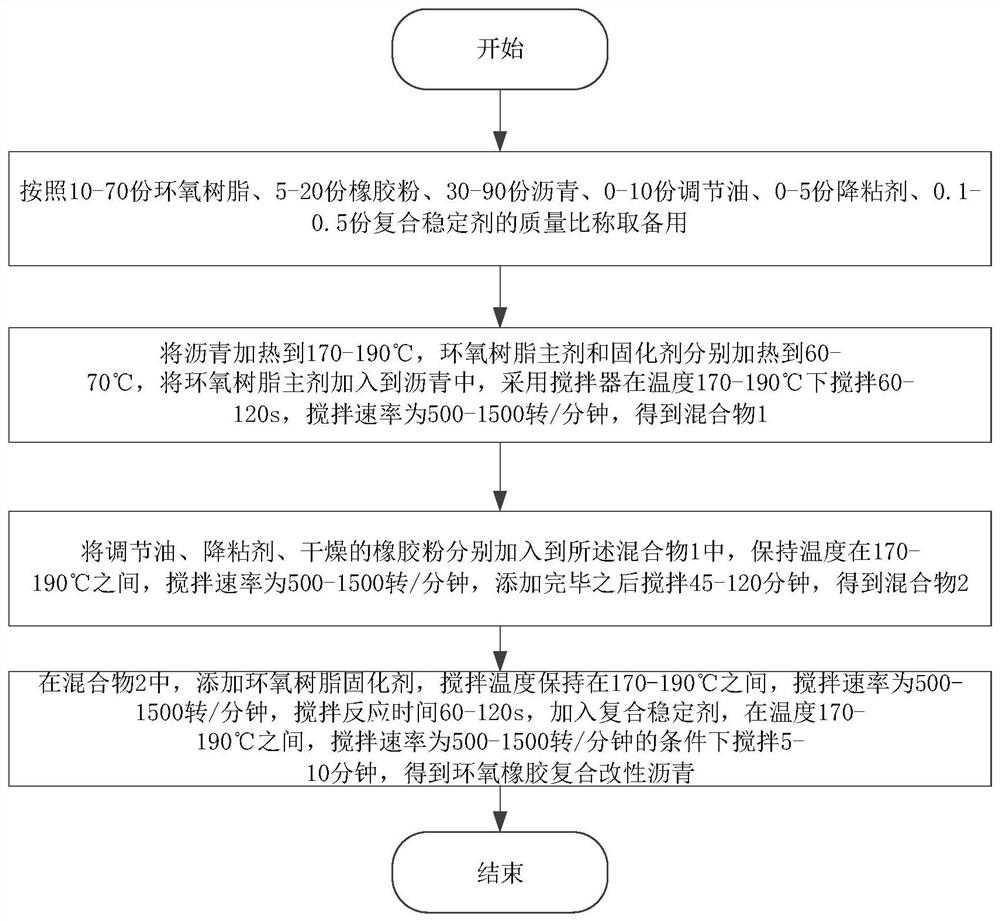

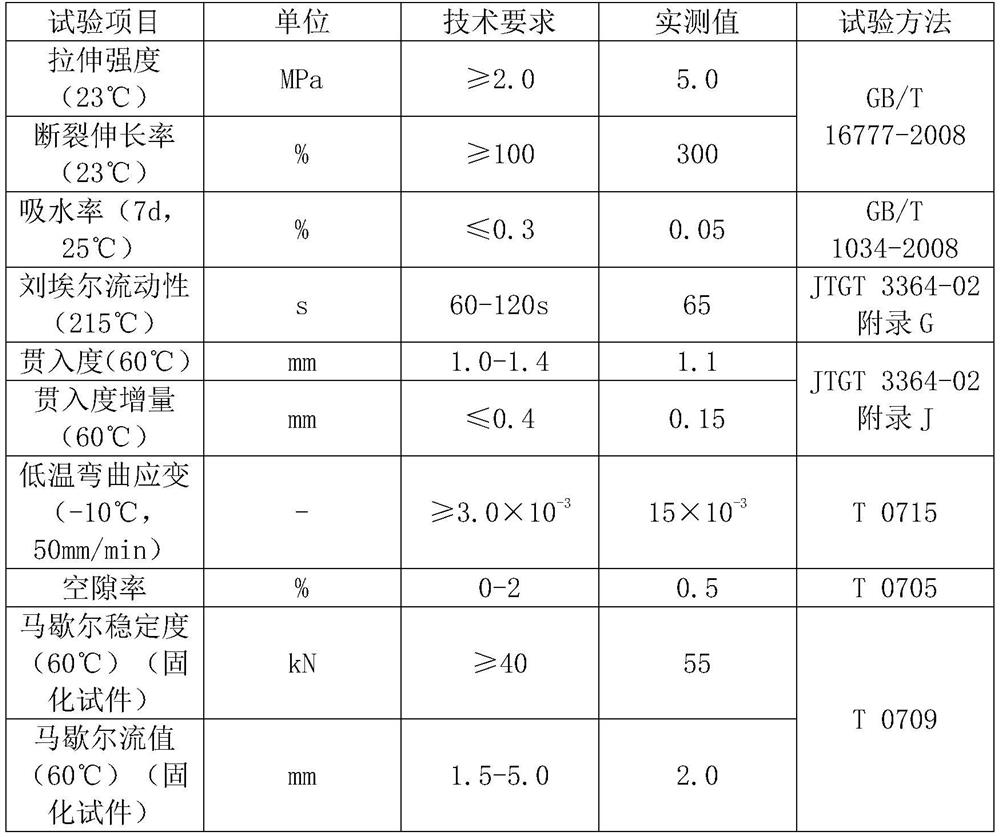

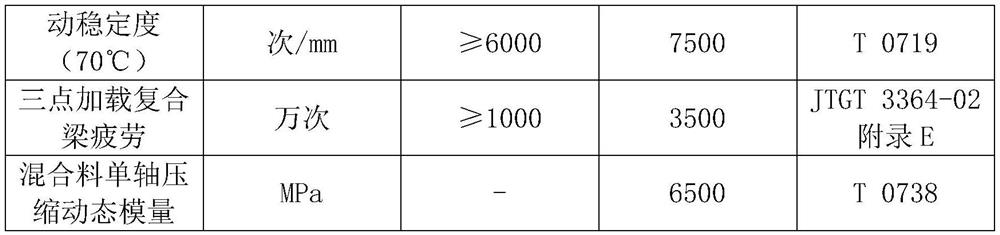

Epoxy rubber composite modified asphalt and preparation method thereof

The invention provides epoxy rubber composite modified asphalt and a preparation method thereof. The epoxy rubber composite modified asphalt comprises the following components in parts by weight: 10-70 parts of epoxy resin, 5-20 parts of rubber powder, 30-90 parts of asphalt, 0-10 parts of regulating oil, 1-5 parts of a viscosity reducer and 0.1-0.5 part of a composite stabilizer. The epoxy rubber composite modified asphalt has the remarkable technical characteristics of being adjustable in rigidity, low in viscosity in the construction process, high in viscosity and elasticity under the service condition, good in high-temperature stability, high in durability, energy-saving and environment-friendly.

Owner:JIANGYIN TAIFU ASPHALTUM

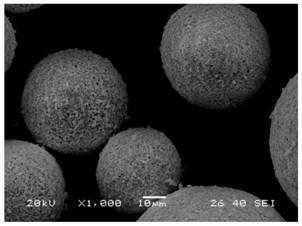

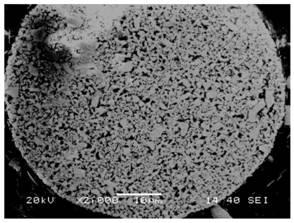

Nano zirconium oxide spraying powder and preparation method thereof

InactiveCN110451957AHigh porosityThere will be no significant decrease in cohesive strengthPorositySpray Granulation

The invention provides powder which has a non-hollow porous spherical structure and consists of nano zirconium oxide (YSZ) aggregates partially stabilized by yttrium oxide with the mass fraction of (7-8) wt%. The porosity of powder particles ranges from 40% to 70%, and the surfaces of the powder particles are of a porous rough structure. The powder is prepared by means of a conventional spray granulation process. The process comprises the steps of firstly, dispersing the nano YSZ aggregates through sand milling; then, adding a flocculant into the dispersed slurry to make the nano particles aggregated into loose flocculent aggregates so that the nano particles can be restrained from migrating to the surfaces in the spray granulation process and correspondingly formation of a hollow structure is avoided, and finally preparing the powder which has the non-hollow porous spherical structure and is high in porosity. By adopting the powder, a YSZ coating with the high porosity, high internalcohesive strength and great sintering resistance can be prepared.

Owner:苏州炻原新材料科技有限公司

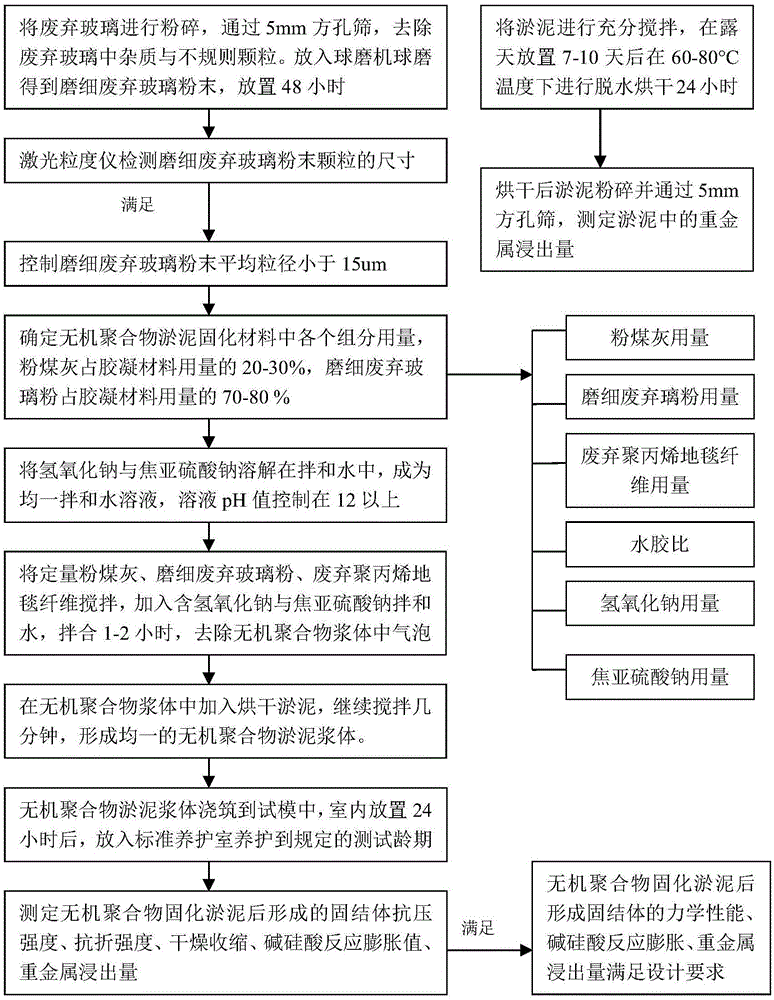

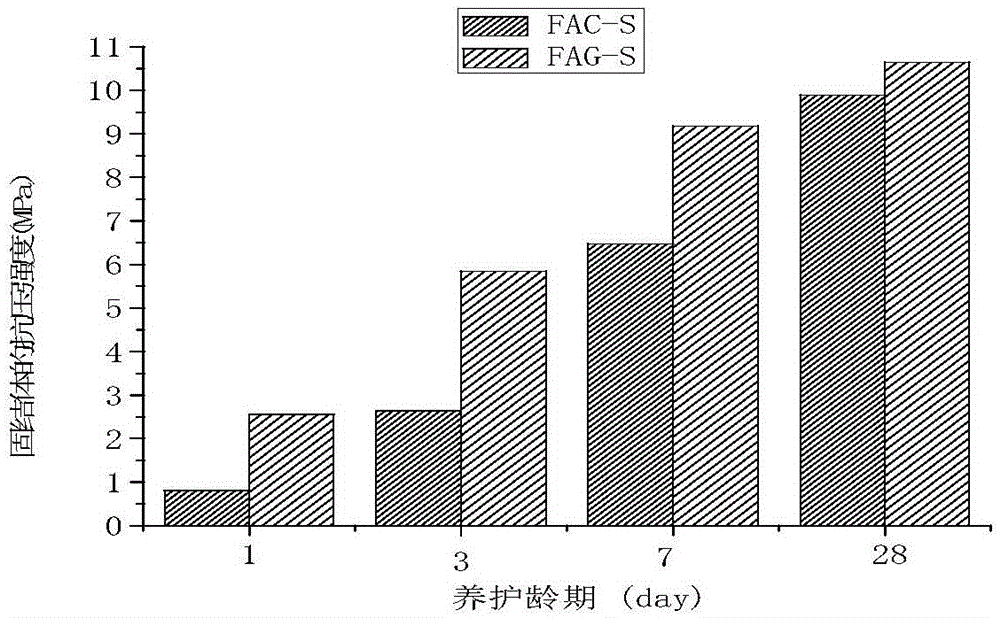

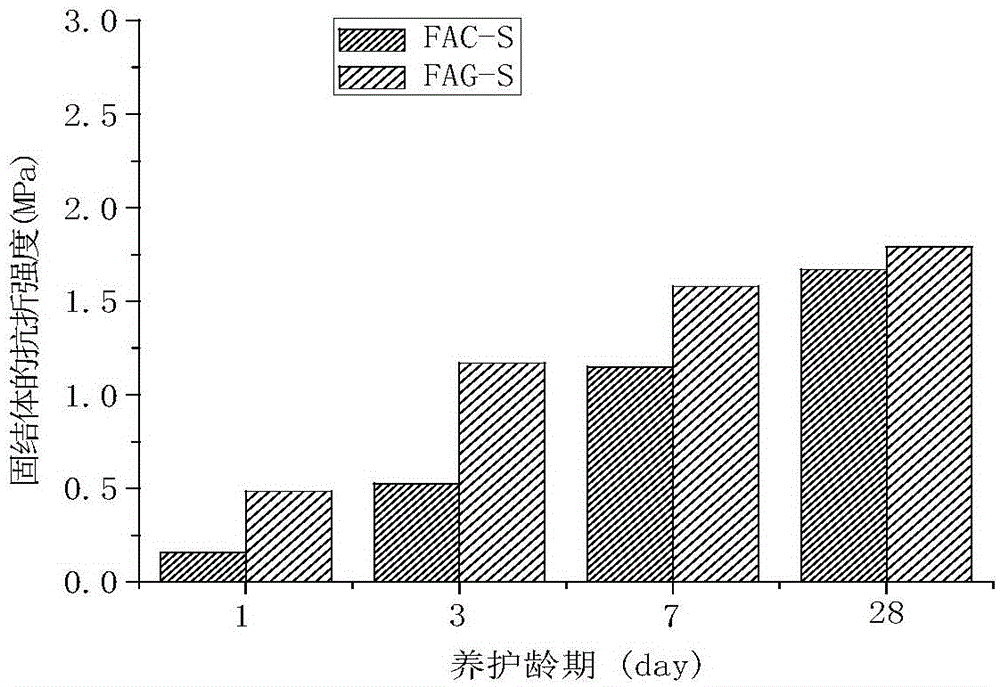

Preparation method of fly ash-waste glass powder inorganic polymer silt-solidifying material

The invention discloses a preparation method of fly ash-waste glass powder inorganic polymer silt-solidifying material. The preparation method includes: mixing fly ash with pretreated waste glass powder; adding sodium hydroxide and sodium pyrosulfite composite excitant solution; preparing the fly ash-waste glass powder inorganic polymer silt-solidifying material to solidify silt. By using this inorganic polymer to solidify silt, on one hand, the defect that the preparation process of traditional fly ash-waste glass powder inorganic polymer silt-solidifying material needs a great amount of cement for use is overcome, and environmental impact by the emission of industrial dust and greenhouse gases such as CO2 generated in cement production is decreased; on the other hand, the fly ash and waste glass powder solid wastes are used to prepare the silt-solidifying material, the industrial wastes such as the fly ash and the waste glass powder are fully recycled and are massively consumed, and the problem that a traditional backfilling method requires massive land and causes severe pollution to the surroundings while disposing these solid wastes is avoided.

Owner:内蒙古宇翼环保科技开发有限责任公司

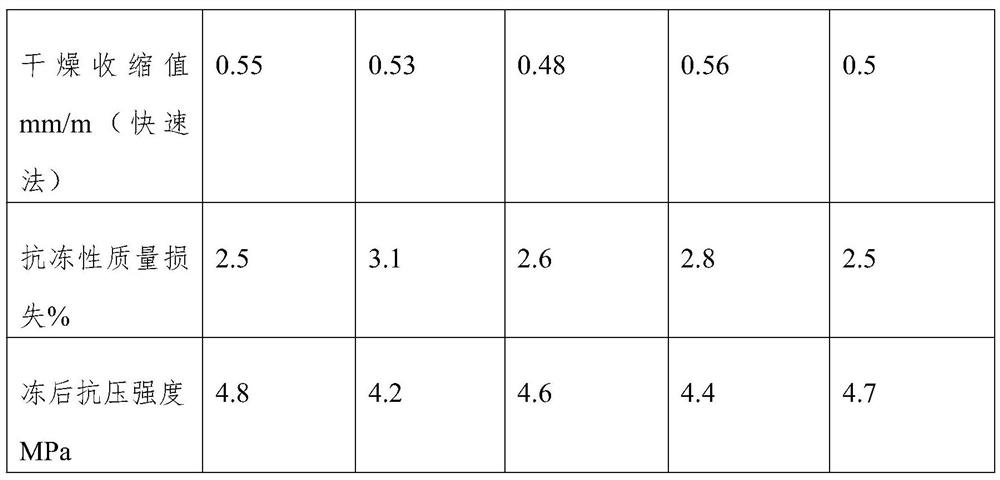

Preparation method of autoclaved aerated concrete slab

The invention relates to the technical field of construction, in particular to a preparation method of an autoclaved aerated concrete slab. The preparation method of the autoclaved aerated concrete slab comprises the steps of slurry preparation, pouring, statical stop, cutting and autoclaved curing; and the slurry comprises the following ingredients in parts by weight: 4 to 7 parts of fried gypsumpowder, 8 to 12 parts of lime, 8 to 12 parts of cement, 45 to 55 parts of a siliceous material, 13 to 19 parts of phosphorus-containing waste residue, and 0.06 to 0.09 part of a gas former; accordingto the invention, the ingredients are reasonably prepared and the process is controlled, so that the internal and appearance quality of the product is improved, the use amounts of the lime and the cement are controlled to directly reduce the production cost, the static-stopping time is shortened to improve the production efficiency, and the use amounts of solid waste gypsum,fly ash, phosphorus slag and the like are increased.

Owner:GUIZHOU KAILIN PHOSPHOGYPSUM INTEGRATION UTILIZATION +1

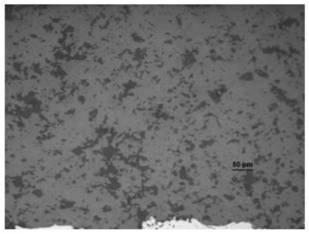

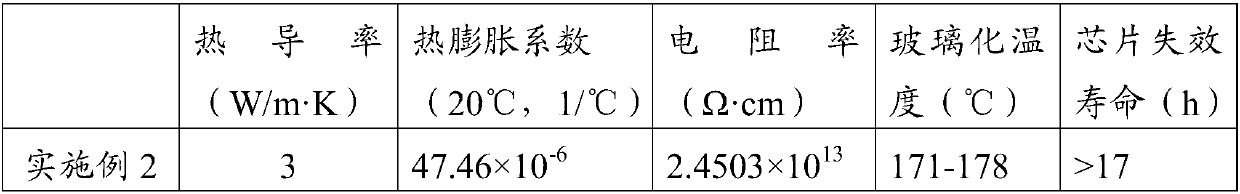

High-thermal-conductivity electronic package composite material and preparation method thereof

ActiveCN109659281AGood size controlUniform shapeMaterial nanotechnologyTransportation and packagingVitrificationNanoparticle

The present invention provides a high-thermal-conductivity electronic package composite material and a preparation method thereof. The composite material is composed of insulating nano-particles and apolymer which have a volume ratio of 0.1 to 0.3. The insulating nano-particles are nano copper particles coated with a silicon dioxide insulating layer having a thickness of 10 to 100 nm. The nano copper particles each have a particle diameter of 50 to 500 nm. The preparation method comprises the steps of: preparing insulating nano copper particles; and then mixing the insulating nano copper particles with the polymer to form the high-thermal-conductivity electronic package composite material. The composite material provided by the invention can meet the requirements of the package filling for thermal conductivity and fluidity while satisfying the package insulation. The nano composite filling can significantly improve the heat dissipation performance of a device, reduce a thermal expansion coefficient, increase glass transition temperature, and greatly prolongs the electromigration failure time.

Owner:CENT SOUTH UNIV

High-performance automobile die casting aluminum alloy material and preparation method thereof

The invention discloses a high-performance automobile die casting aluminum alloy material and a preparation method thereof. The high-performance automobile die casting aluminum alloy material comprises the following components of, by mass, 8%-9% of Si, 0.5%-0.8% of Fe, Cu 3.2%-3.8% of Cu, 0.15%-0.40% of Mn, less than or equal to 0.3% of Mg, less than or equal to 1.5% of Zn, 0.008%-0.02% of Sr, less than or equal to 0.05% of other single impurity element, less than or equal to 0.15% of impurity element total amount, and 84.2%-88.1% of Al. The preparation method of the high-performance automobile die casting aluminum alloy material comprises the following steps of material preparation, smelting, alloying, cooling and component adjustment, refining, standing and modification. According to thehigh-performance automobile die casting aluminum alloy material and the preparation method thereof, the composition proportion of the aluminum alloy material is optimized, so that die casting production is facilitated, sufficient strength is achieved so as to meet load requirements of an automobile die casting, and wide applicability is achieved.

Owner:南通众福新材料科技有限公司

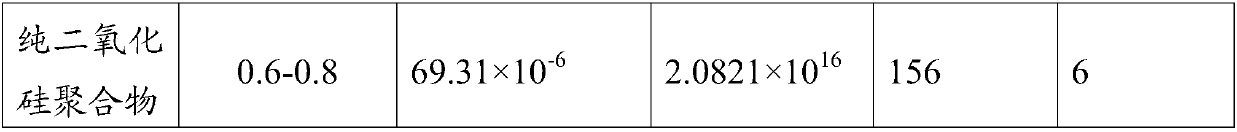

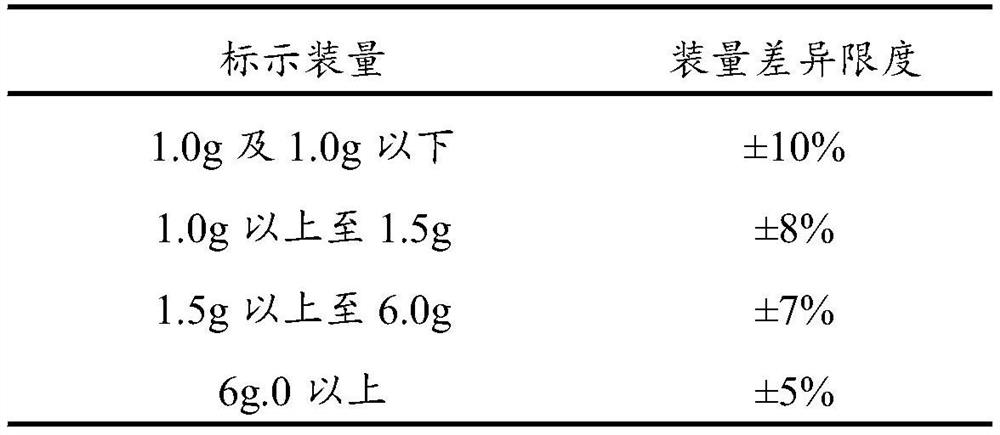

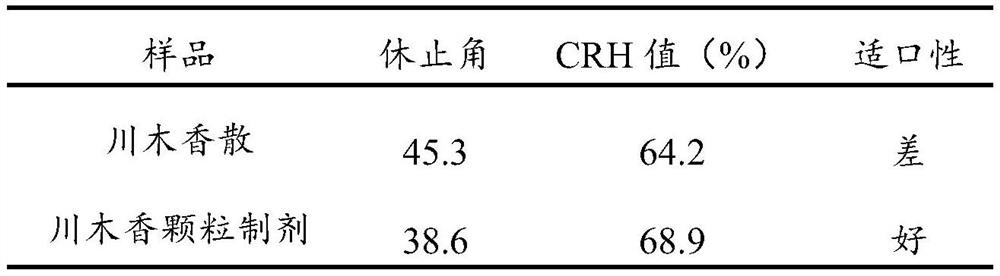

Formula granules containing fiber Mongolian medicine powder and preparation method thereof

ActiveCN112999171AEnsure safetyGuaranteed validityPharmaceutical non-active ingredientsGranular deliveryFormularyPharmacy medicine

The invention provides fiber-containing Mongolian medicine powder formula granules and a preparation method thereof, and belongs to the technical field of Mongolian medicine preparations, and the mass ratio of fiber Mongolian medicine, powdered sugar and starch slurry in the fiber-containing Mongolian medicine powder formula granules is (73-77): (18-22): (45-55); the mass percentage content of the fiber Mongolian medicine in the fiber Mongolian medicine powder formula granules is 74.8%-75.1%. The fiber-containing Mongolian medicine powder formula granules provided by the invention are prepared by taking traditional single fiber-containing Mongolian medicine decoction parts as raw materials through the steps of crushing, adding auxiliary materials, granulating and the like. The Mongolian medicine single decoction parts are processed into the novel formula granules by applying a modern pharmacy method aiming at the purpose of not changing the medicine material basis in national medicine research and development, and the quality controllability and stability of the Mongolian medicine decoction parts are comprehensively improved on the premise of completely retaining the traditional attributes and clinical medication habits of the Mongolian medicine, so that the safety and effectiveness of the Mongolian medicine are guaranteed.

Owner:那生桑 +2

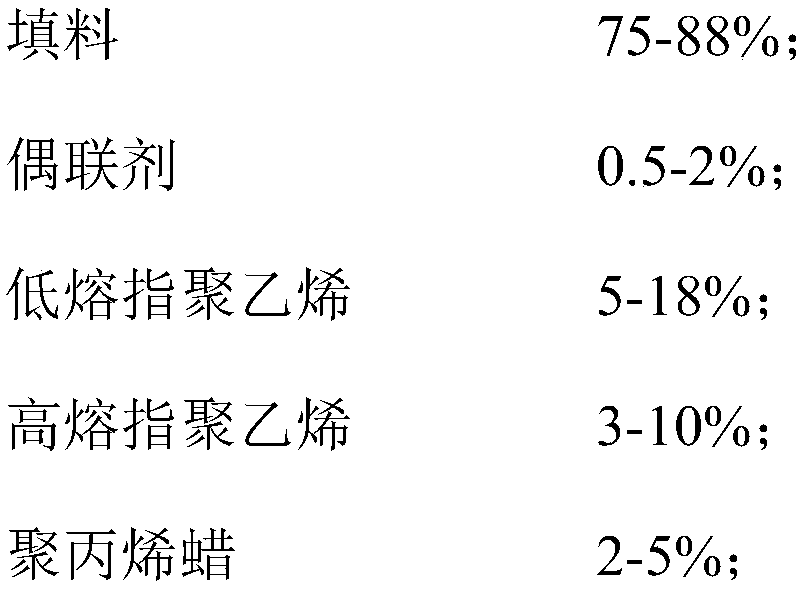

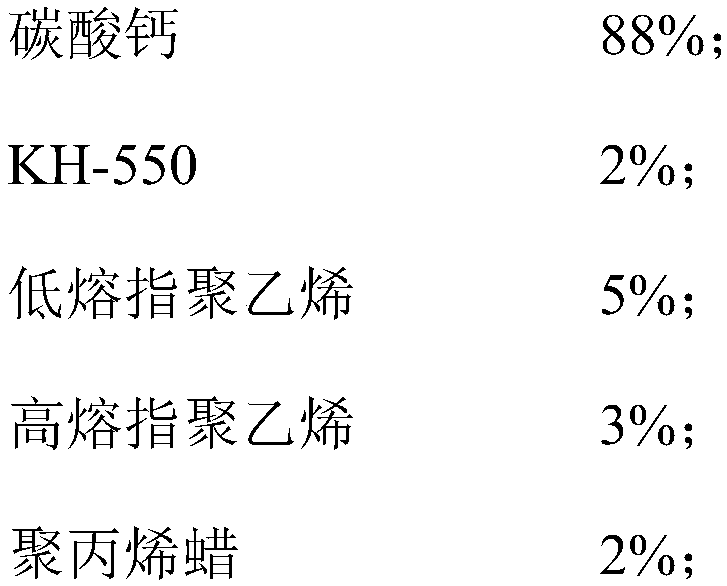

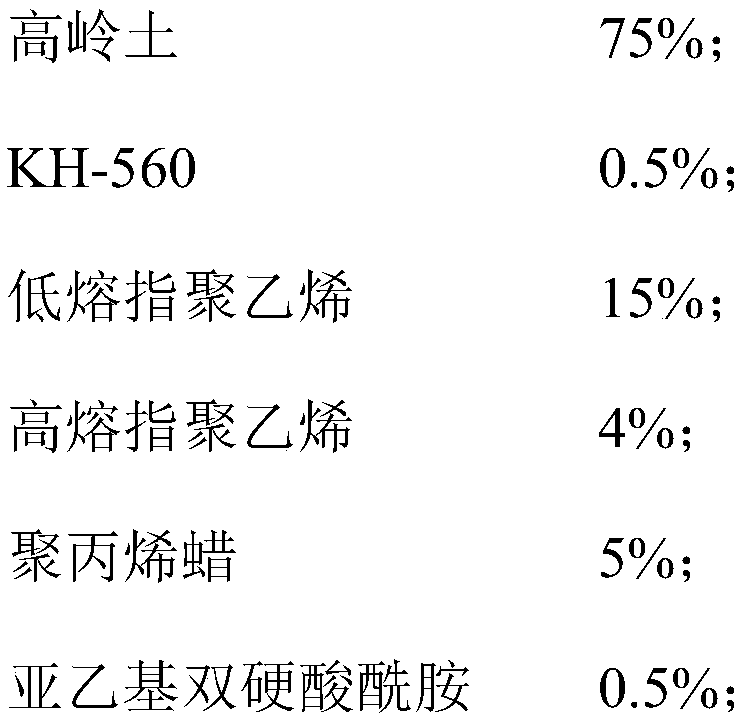

Filling master batch and preparation method and application thereof and polypropylene drawing material containing filling master batch

ActiveCN109135008AImprove mechanical propertiesMeet liquidity requirementsMonocomponent polyolefin artificial filamentArtifical filament manufactureWaxPolymer science

The invention provides a filling master batch and a preparation method and application thereof and a polypropylene drawing material containing the filling master batch. The filling master batch is prepared from, by weight, 75%-88% of filler, 0.5%-2% of coupling agent, 5%-20% of low-melt-flow-index polyethylene, 3%-10% of high-melt-flow-index polyethylene and 2%-5% of polypropylene wax. The preparation method of the filling master batch comprises the steps that the filler and the coupling agent are mixed and react firstly, then the mixture is mixed with the other components, and then extrudingis carried out. The filling master batch has good high temperature resisting performance, can be used as the filling master batch of the polypropylene drawing material, the mechanical performance of the polypropylene drawing material is improved, and the fuming problem in the polypropylene drawing production process is relieved.

Owner:GUANGDONG SUNION CHEM & PLASTIC

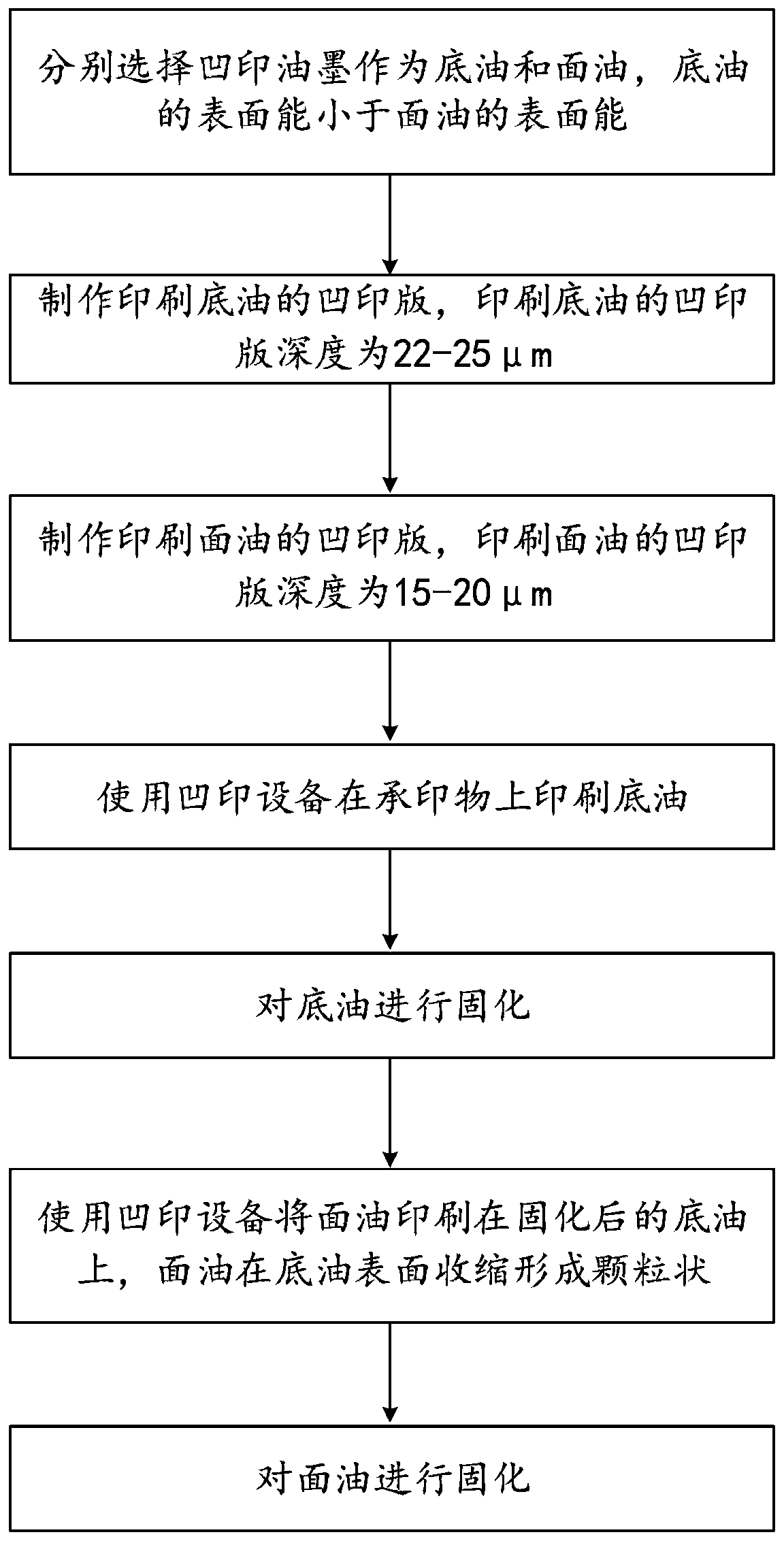

Method for achieving great impression effect through gravure device

InactiveCN111301017AMeet liquidity requirementsSolve difficult registration problemsOther printing apparatusPrinting after-treatmentProcess engineeringBase oil

The invention discloses a method for achieving a great impression effect through a gravure device. The method comprises the following steps that firstly, gravure ink with the surface energy of 20-29 dyn / cm is selected to serve as base oil, gravure ink with the surface energy of 30-45 dyn / cm is selected to serve as surface oil, and a proper bottom oil gravure depth and a proper surface oil gravuredepth are selected; secondly, the bottom oil is printed on a printed material and cured; and finally, the surface oil is painted on the surface of the cured bottom oil and is cured. In the method, thegravure ink with the proper surface energy is selected to serve as the bottom oil and the surface oil, so that the surface oil can retract into particles on the bottom oil to achieve the great impression silk screen surface simulation effect while the requirement of gravure for fluidity of the ink is met. The properly selected gravure depths can meet surface effect requirements of different products. The idle gravure capacity is fully utilized, and the production efficiency is improved by 30% compared with that of an offset printing mode.

Owner:CHONGQING HONGJIN PRINTING

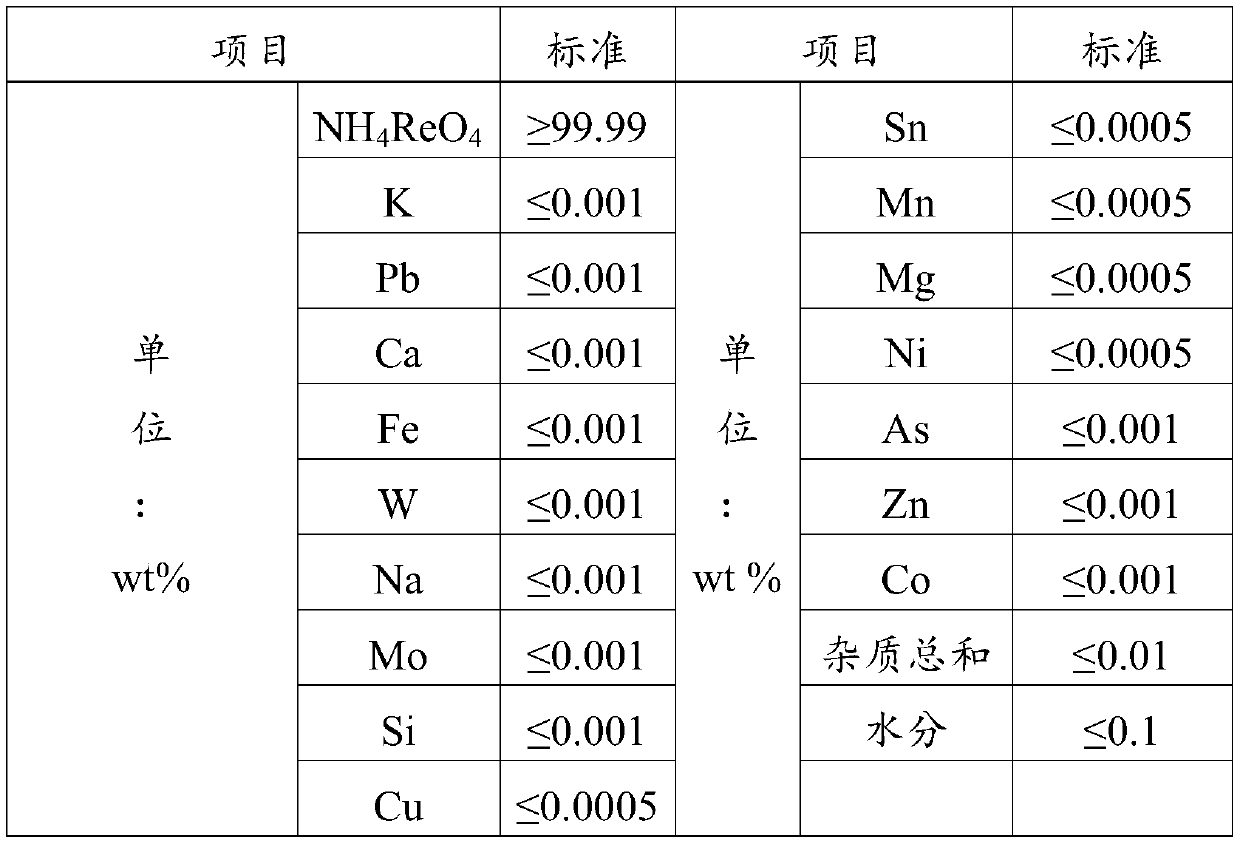

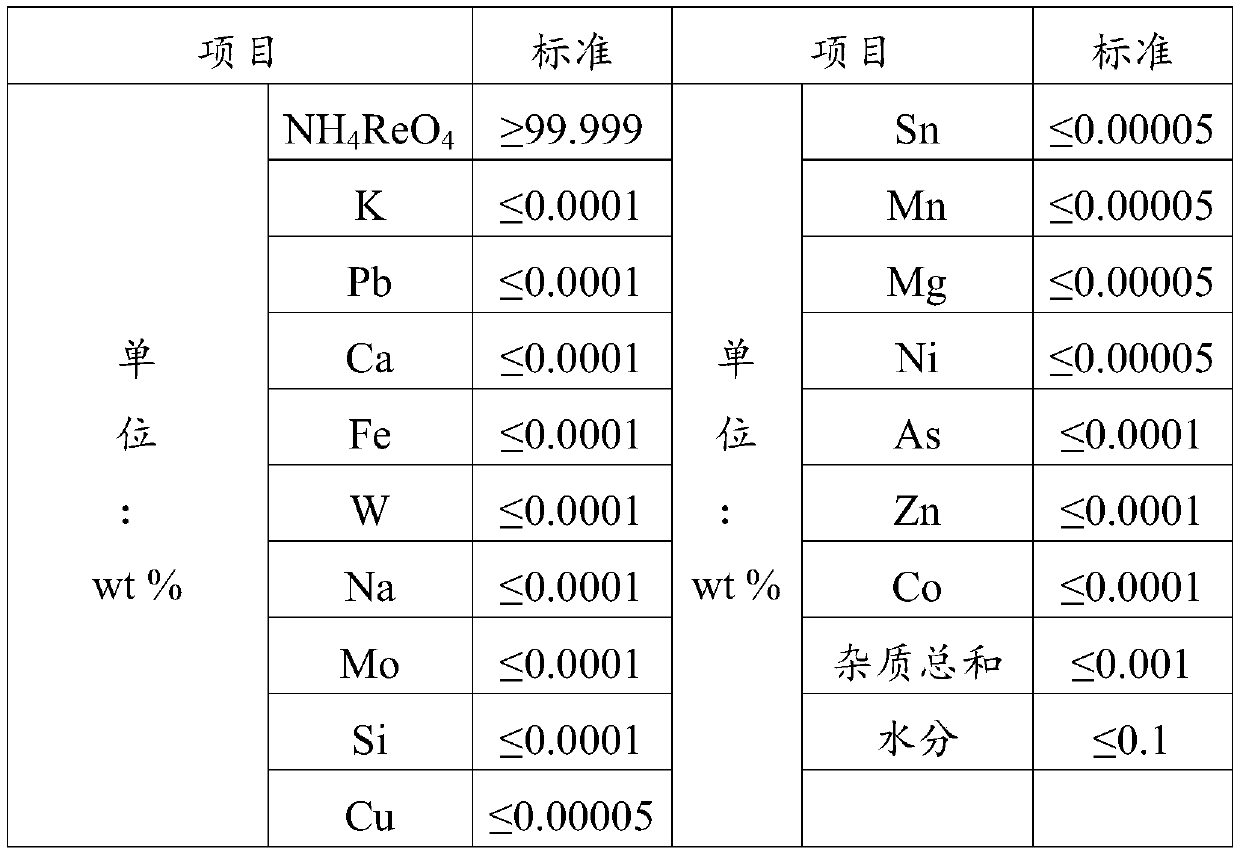

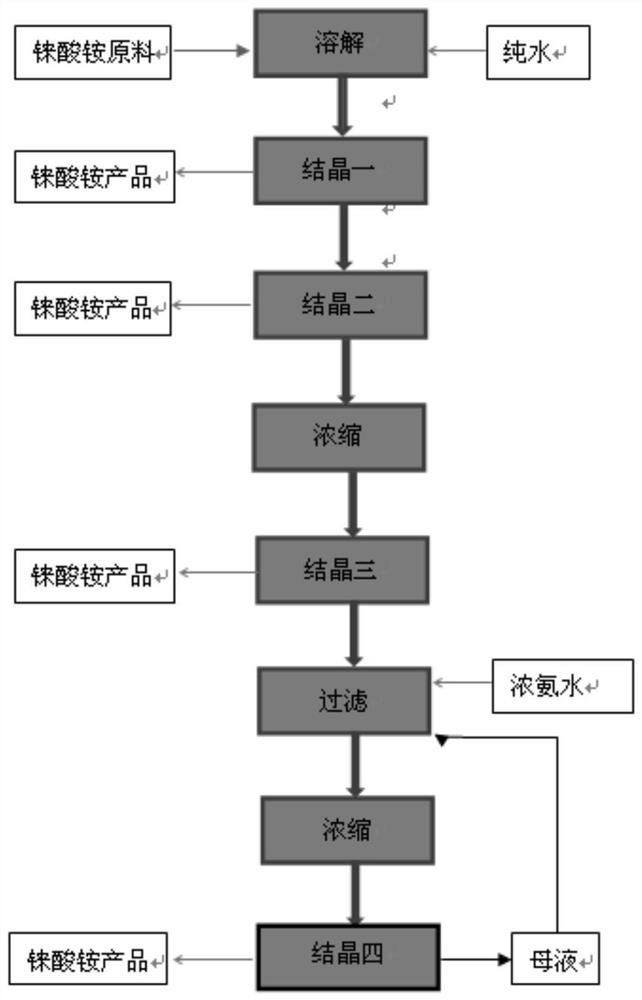

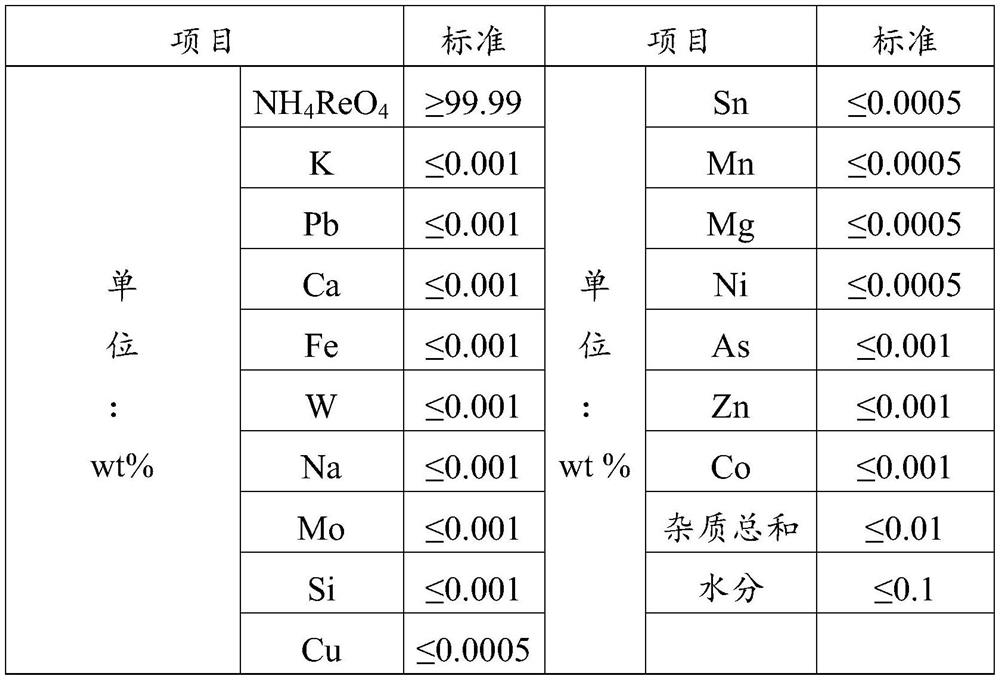

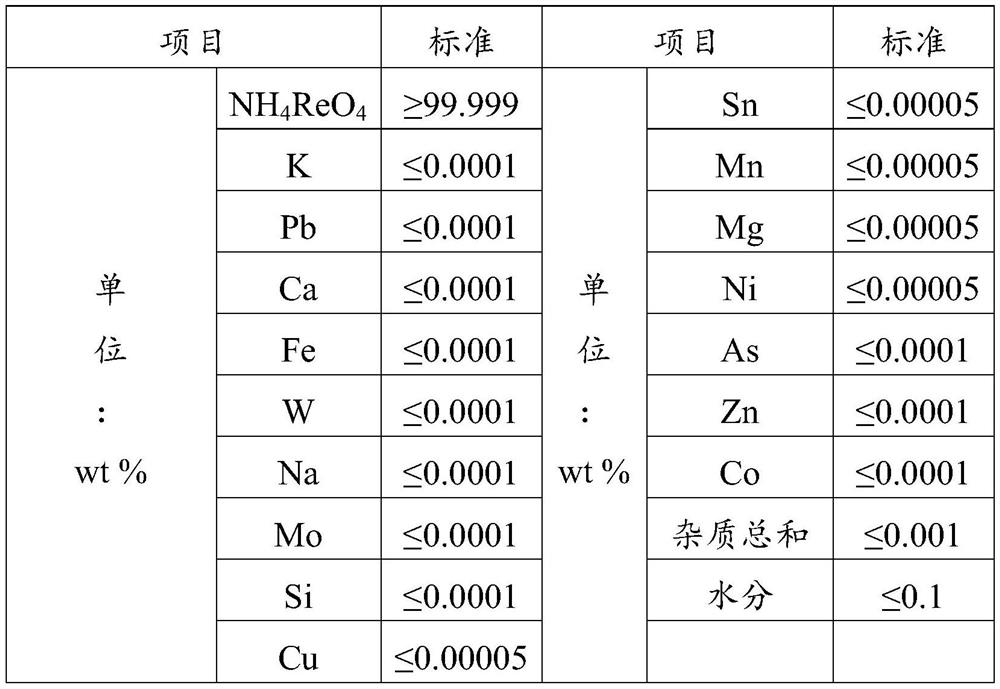

Method for preparing ultra-pure ammonium rhenate crystals with controllable particle sizes

ActiveCN110527854AHigh purityMeet liquidity requirementsProcess efficiency improvementCrystallization temperatureHydrometallurgy

The invention provides a method for preparing the ultra-pure ammonium rhenate crystals with the controllable particle sizes, and belongs to the technical field of hydrometallurgy. According to the invention, the recrystallization treatment is carried out on an aqueous solution of the ammonium rhenate crude product by using a multi-step crystallization method, meanwhile, the crystallization temperature nodes are controlled to be 35-45 DEG C, 0-5 DEG C and 20-40 DEG C, so that the ultra-pure ammonium rhenate crystal with the purity being greater than or equal to 99.999% can be prepared, and theyield of the ultra-pure ammonium rhenate crystal can reach 90% or above. Meanwhile, the consistency of the particle sizes of the obtained ultra-pure ammonium rhenate crystals is ensured, and the grainsize of the crystal can be adjusted by adjusting the crystallization concentration, temperature, time, crystallization times and the like of the ammonium rhenate solution, so that the requirements ofdifferent purposes on the flowability of the ammonium rhenate crystal can be met. The method is suitable for the industrial continuous production, and can realize the high-efficiency and low-energy-consumption large-scale production of the ammonium rhenate crystals with ultrahigh purity and controllable particle sizes.

Owner:昆明先导新材料科技有限责任公司

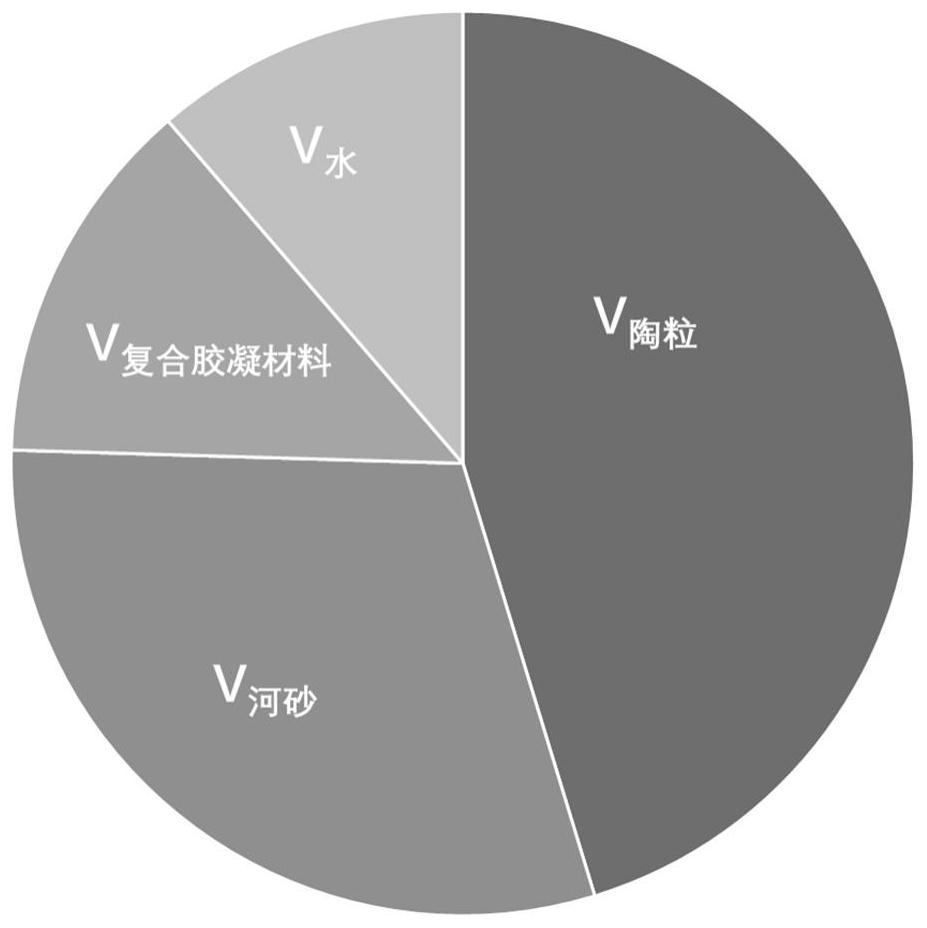

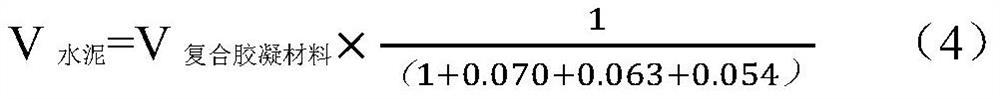

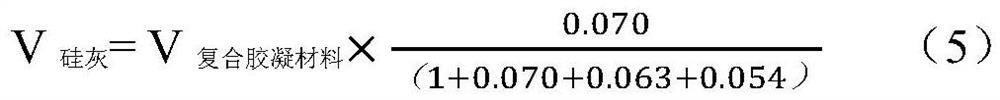

Design method of mix proportion of LC50-LC80 light high-strength silicate ceramsite concrete

ActiveCN110981333AHas the effect of energy saving and emission reductionReduce accumulationSurface layering apparatusCement mixing apparatusPhysical chemistryExpanded clay aggregate

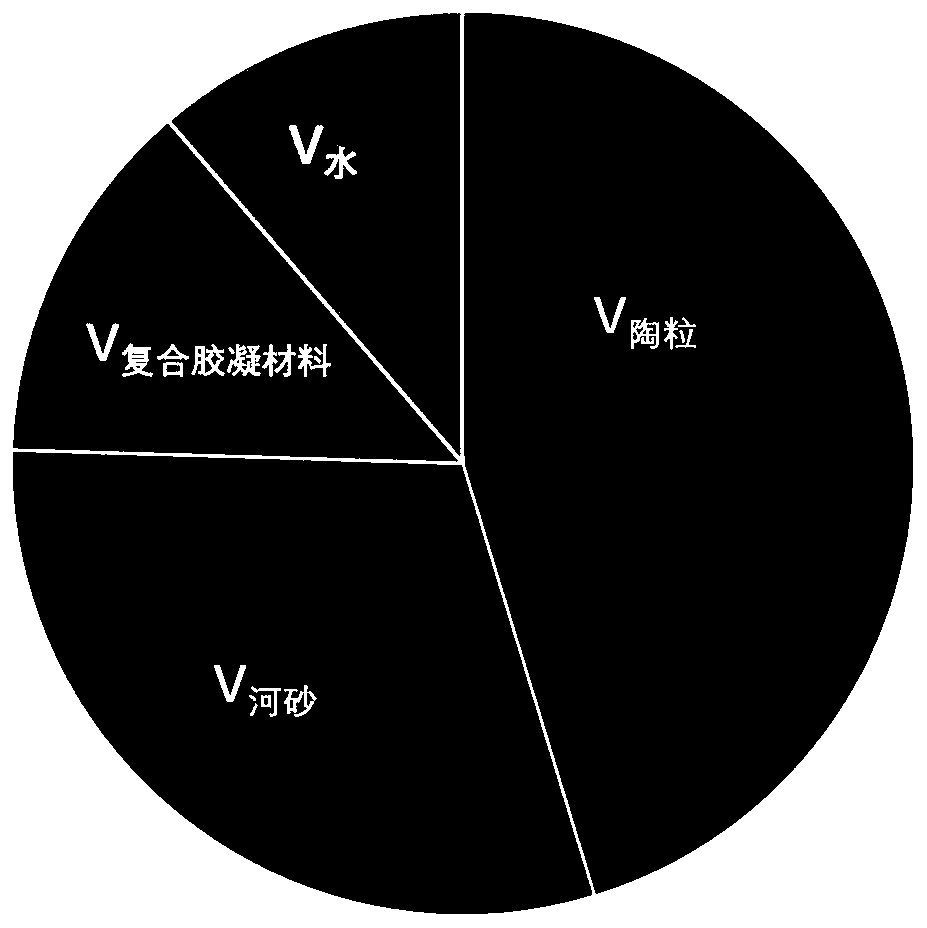

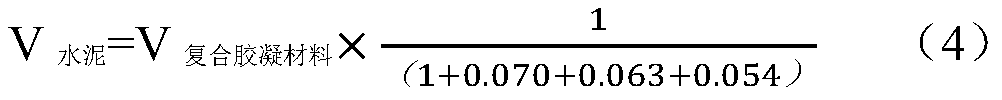

The invention discloses a design method of mix proportion of LC50-LC80 lightweight high-strength silicate ceramsite concrete, and belongs to the technical field of concrete preparation. The absolute volume fractions of components of each cubic meter of silicate ceramsite concrete are determined by an absolute volume fraction linear method as follows: composite cementing material absolute volume fraction is V composite cementing material, shell silicate ceramsite absolute volume fraction is V ceramsite, water absolute volume fraction is V water, and river sand absolute volume fraction is V river sand, wherein the V composite cementing material is composed of V cement, V silica fume, V fly ash and V slag. The design method of the mix proportion of the silicate ceramsite concrete is simple, practical, effective and accurate, and has important theoretical significance and practical value for promoting the application of silicate concrete in high-rise buildings and long-span bridges.

Owner:NANJING UNIV OF SCI & TECH +1

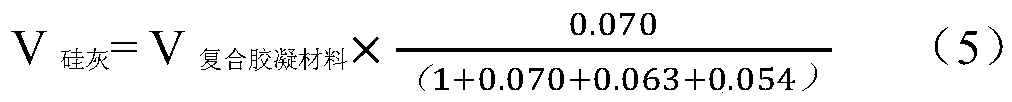

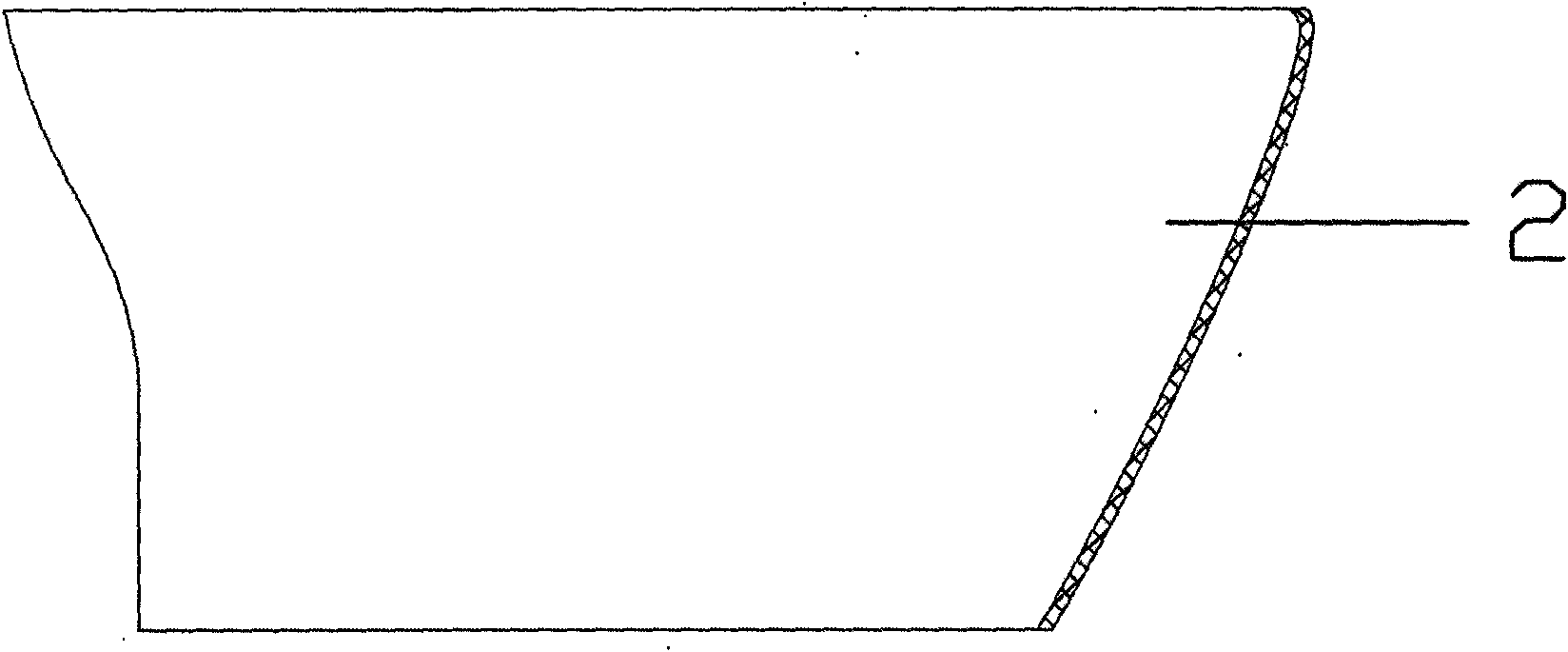

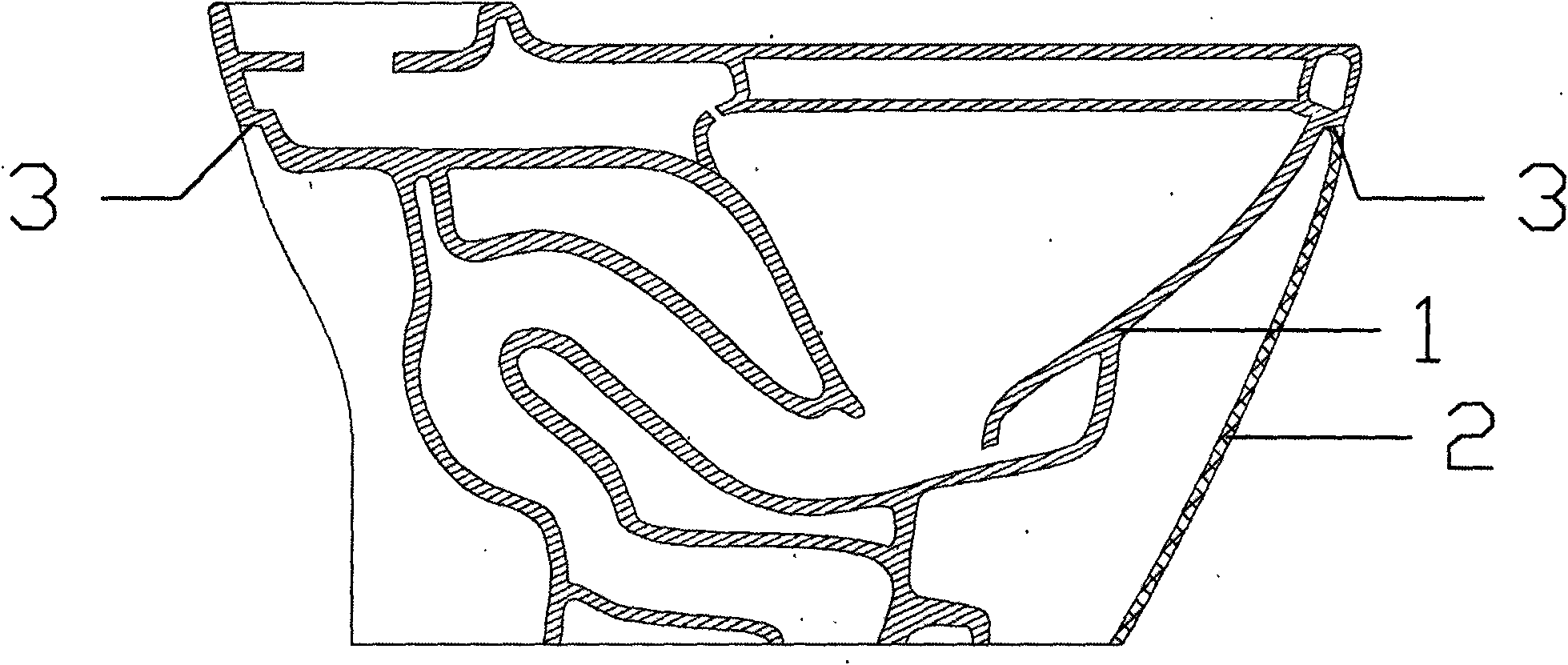

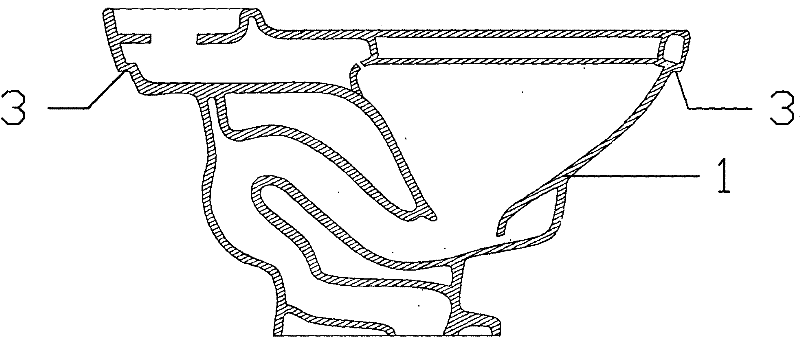

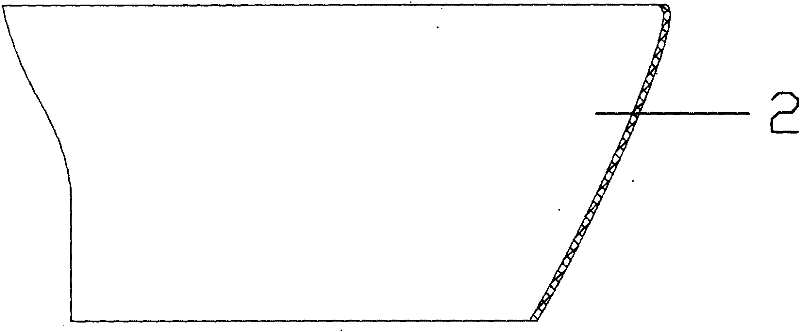

Production process for disassembly forming of ceramic pedestal pan

ActiveCN101786886AEasy to manufactureMeet liquidity requirementsClaywaresWater savingEnergy conservation

The invention discloses a production process for disassembly forming of a ceramic pedestal pan, which comprises the following process steps of: mould design; slip casting; die sinking and drying; billet adhesion; and glazing and sintering. The product qualification rate of the ceramic pedestal pan produced by the process can reach over 85 percent; and the pollution discharge and water conservation of the product meet and even exceed the standard of national water-saving products.

Owner:潮州市亚陶瓷业有限公司

High-brightness finishing printing silica gel for silk screen printing and preparation method of high-brightness finishing printing silica gel

The invention discloses high-brightness finishing printing silica gel for silk screen printing. The high-brightness finishing printing silica gel is prepared from the following raw materials in parts by mass: 10 to 15 parts of a high-brightness finishing printing silica gel component A and 1 to 3 parts of a high-brightness finishing printing silica gel component B. The invention further discloses a preparation method of the high-brightness finishing printing silica gel for the silk screen printing. According to the high-brightness finishing printing silica gel and the preparation method thereof, the defects of the general bright finishing gel are overcome; the high-brightness finishing gel with an outstanding brightness effect, high debubbling effect, urgent baking resistance, and zero hard spots and bubbles on a baked product is prepared; the finishing gel can be used for large-pattern printing finishing, to meet the requirement for the flowability, and also used for small-pattern finishing, to meet the requirement for avoiding smudging of a fillet.

Owner:东莞市科多有机硅材料有限公司

Production process for disassembly forming of ceramic pedestal pan

ActiveCN101786886BEasy to manufactureMeet liquidity requirementsClaywaresWater savingEnergy conservation

The invention discloses a production process for disassembly forming of a ceramic pedestal pan, which comprises the following process steps of: mould design; slip casting; die sinking and drying; billet adhesion; and glazing and sintering. The product qualification rate of the ceramic pedestal pan produced by the process can reach over 85 percent; and the pollution discharge and water conservation of the product meet and even exceed the standard of national water-saving products.

Owner:潮州市亚陶瓷业有限公司

Nano-zirconia spray powder and production method thereof

ActiveCN110668812AHigh porosityThere will be no significant decrease in cohesive strengthSpray GranulationNanoparticle

The invention provides non-hollow porous spherical-structure powder composed of aggregate of nanometer yttria-partially stabilized zirconia (YSZ) with a mass fraction of 7 wt% to 8 wt%. The porosity of powder particles is 40% to 70%, and surfaces are of porous rough structures. The powder is produced by adopting a conventional spray granulation technology: firstly, nanometer YSZ aggregate is dispersed by adopting sanding, and then a flocculating agent is added into dispersed slurry to make nanometer particles aggregate, so as to form the loose flocculent aggregate, so that surface migration ofthe nanometer particles in the spray granulation process is inhibited, a hollow structure is avoided, and finally, the non-hollow porous spherical-structure powder with high porosity is produced. Byadopting the powder, a YSZ coating with high porosity, high cohesion strength and sintering resistance can be produced.

Owner:苏州炻原新材料科技有限公司

Methanol diesel oil and preparation method thereof

The invention discloses methanol diesel oil and a preparation method thereof. The methanol diesel oil is prepared from, by weight, 23-27 parts of 200 # solvent oil, 28-32 parts of common first-vacuumdiesel oil, 15-17 parts of methyl tertiary butyl ether, 26-32 parts of coal tar, 28-34 parts of aviation kerosene and 15-18 parts of methanol. The preparation method of the methanol diesel oil comprises the following steps that 1, the methyl tertiary butyl ether and the methanol are weighed according to the proportion respectively, the weighed methyl tertiary butyl ether and the methanol are mixedand uniformly stirred, and a methanol-based mixed solution is further prepared; 2, the 200 # solvent oil, the common first-vacuum diesel oil, the coal tar and the aviation kerosene are weighed respectively according to the proportion, the weighed 200 # solvent oil, the common first-vacuum diesel oil, the coal tar and the aviation kerosene are sequentially added into the methanol-based mixed solution obtained in step 1 and stirred evenly, and the methanol diesel oil is obtained. The prepared methanol diesel oil is good in stability, free of layering and good in combustion performance.

Owner:河南妙天新能源研究院有限公司

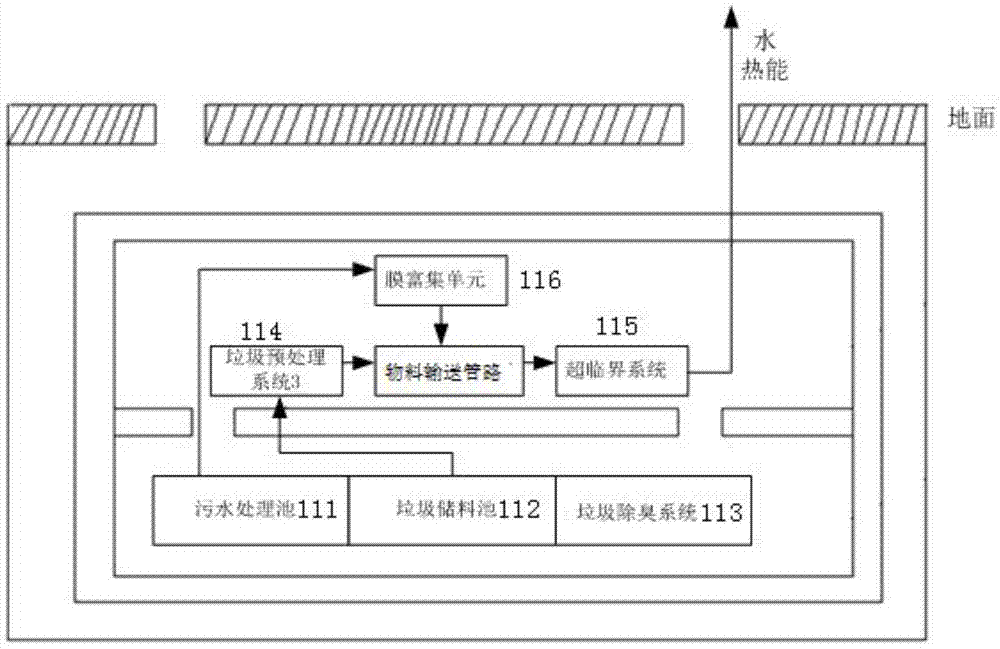

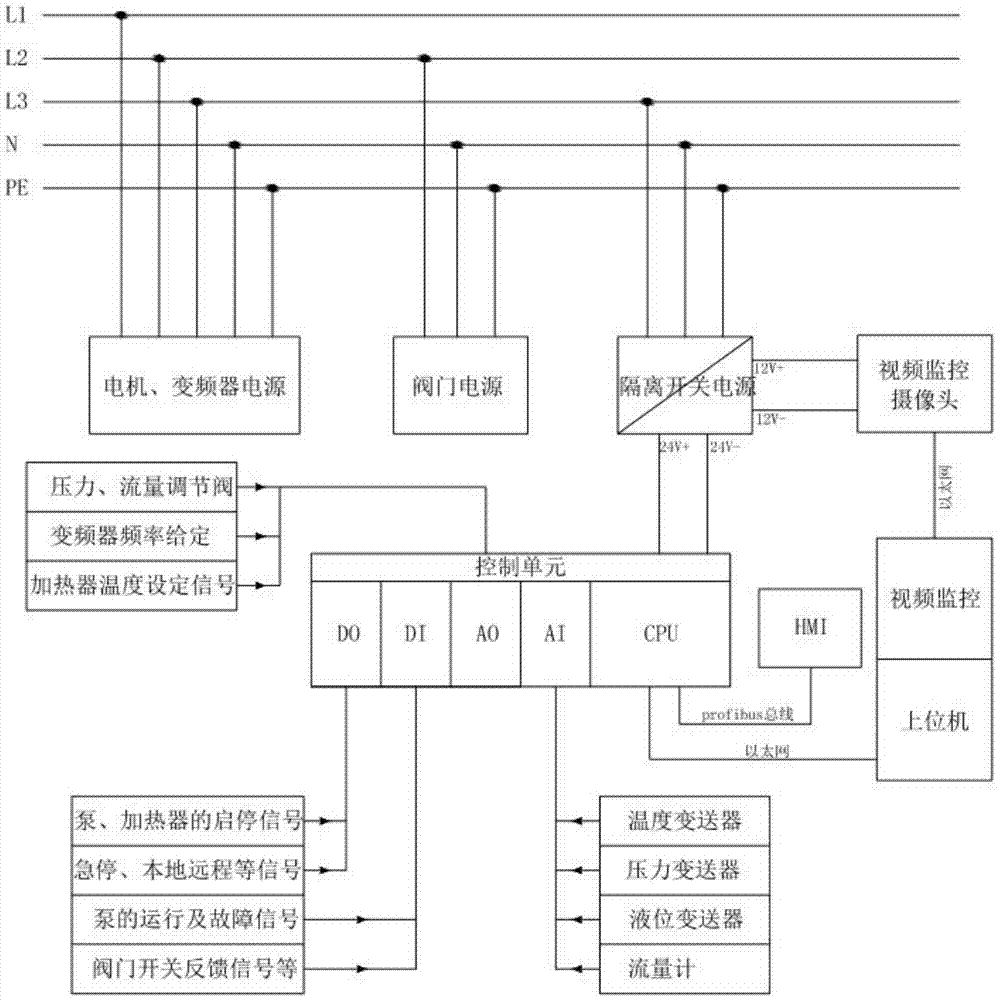

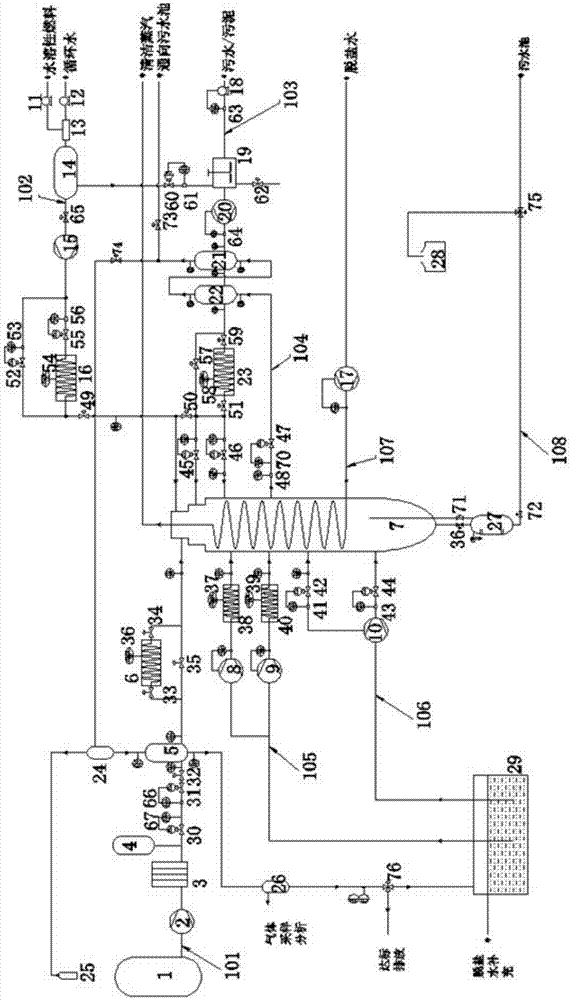

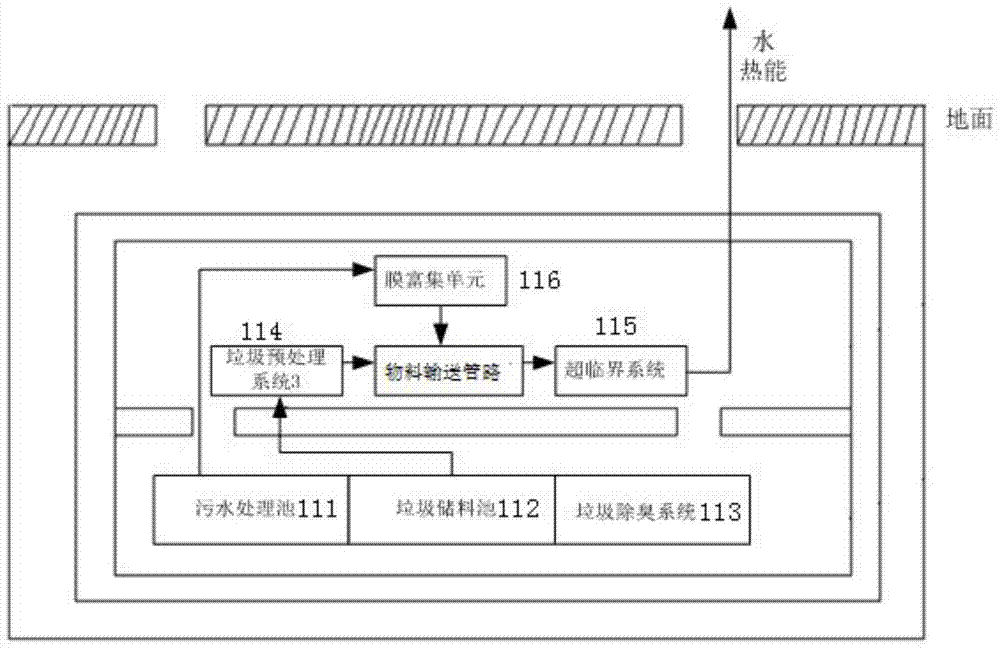

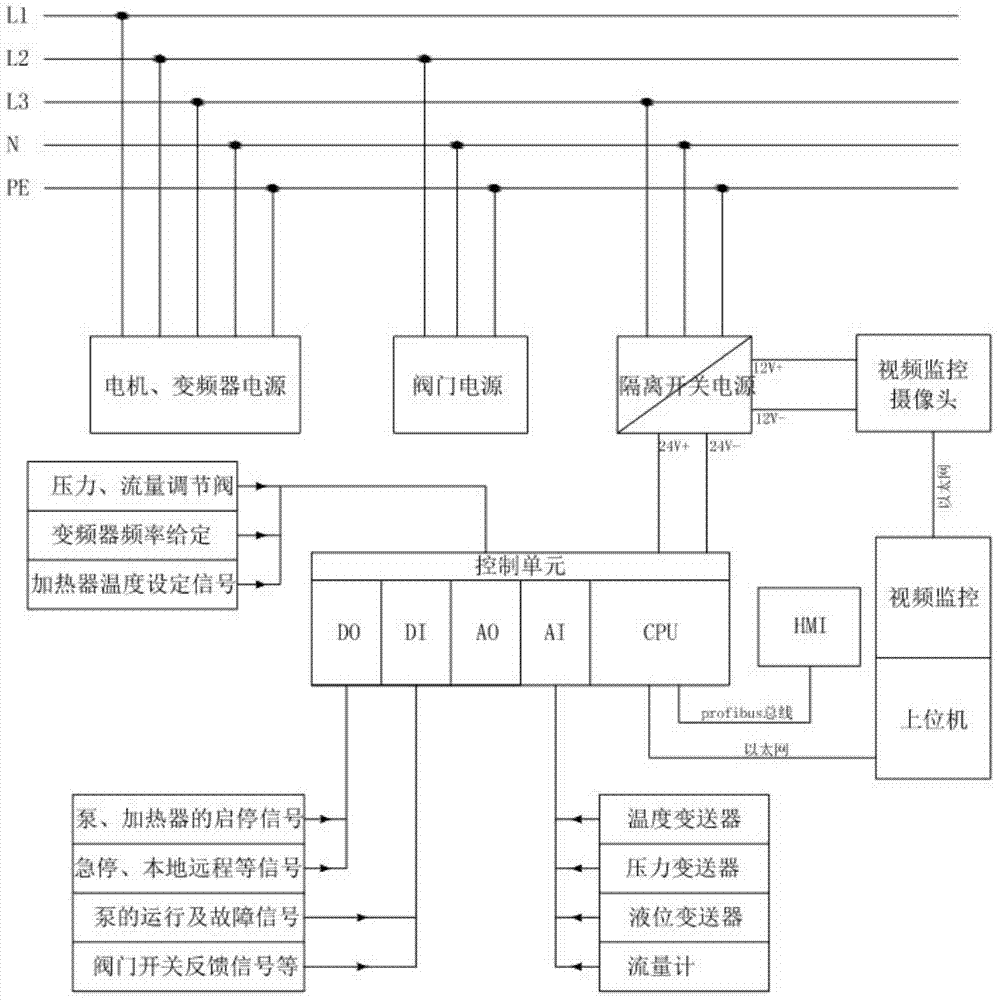

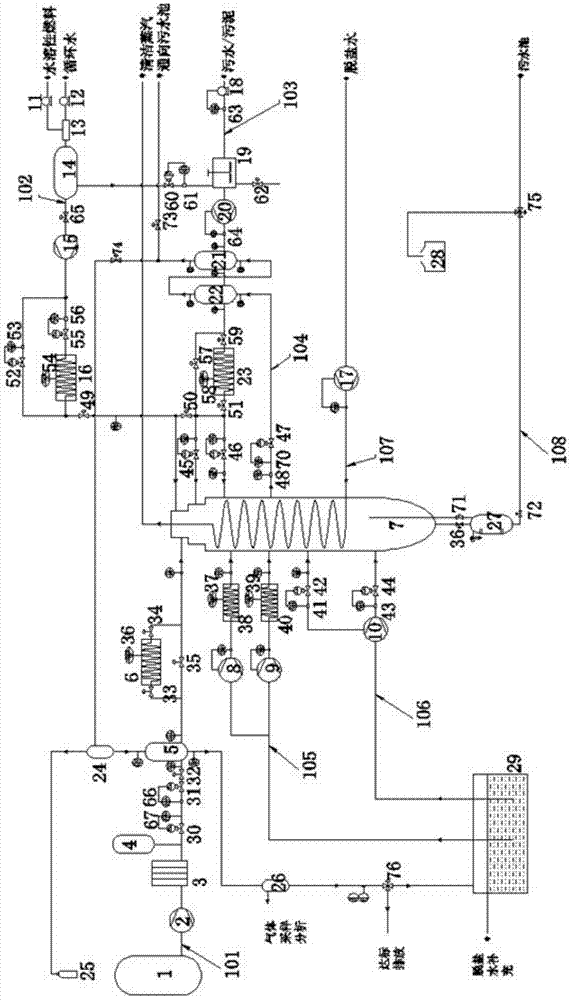

Community full underground type resource cyclic utilization system for sewage and solid trash

InactiveCN105439320AGuaranteed temperature fieldAvoid instabilityTransportation and packagingSolid waste disposalElectricityControl system

The invention relates to a community full underground type resource cyclic utilization system for sewage and solid trash. The community full underground type resource cyclic utilization system is characterized by comprising a membrane enrichment unit, a trash pretreatment system and a supercritical reaction system which are arranged on the first floor underground, a sewage treatment pool and a trash storage pool which are arranged on the second floor underground, and a control system arranged in a ground central control room; the control system comprises sensors, on-site execution parts, a controller and an upper computer; the on-site execution part is electrically connected with the controller; the sensor, the controller and the upper computer are in signal connection; the sensors and the on-site execution parts are arranged on an oxidizing agent conveying pipeline, a fuel conveying pipeline, a material conveying pipeline, a reactor, a gas-stage product discharge unit and a liquid-stage product discharge unit. The community full underground type resource cyclic utilization system can treat sewage and solid trash at the same time, solid trash is not treated through incineration any more, pollutant discharge is reduced, the control processes such as start, stop, emergency stop, temperature regulation and pressure regulation of the system are achieved through a control unit, and data generated when the system runs can be effectively collected, stored and analyzed.

Owner:王冰

Design method of mix proportion of lc50~lc80 light weight high strength silicate ceramsite concrete

ActiveCN110981333BHas the effect of energy saving and emission reductionReduce accumulationSurface layering apparatusCement mixing apparatusPhysical chemistryExpanded clay aggregate

The invention discloses a design method for the mix ratio of LC50-LC80 lightweight high-strength silicate ceramsite concrete, which belongs to the technical field of concrete preparation. The present invention uses the absolute volume fraction linear method to determine the absolute volume fraction of each component of silicate ceramsite concrete per cubic meter: the absolute volume fraction of composite cementitious material V 复合胶凝材料 , shell silicate ceramsite absolute volume fraction V 陶粒 , the absolute volume fraction of water V 水 and river sand absolute volume fraction V 河砂 . where V 复合胶凝材料 by V 水泥 , V 硅灰 , V 粉煤灰 and V 矿渣 composition. The invention is a simple, practical, effective and accurate design method of the mix ratio of the silicate ceramsite concrete, and has important theoretical significance and practical value for promoting the application of the silicate concrete in high-rise buildings and long-span bridges.

Owner:NANJING UNIV OF SCI & TECH +1

Multipurpose boat and multipurpose boat set for powder metallurgy sintering

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Autoclaved aerated concrete block and preparation method thereof

The invention relates to the technical field of a concrete block, in particular to an autoclaved aerated concrete block and a preparation method thereof. The autoclaved aerated concrete block is prepared by mixing calcium materials, siliceous materials, stir-fried plaster, a gas forming agent and phosphorus-containing waste slag and sequentially performing casting, still standing, cutting and autoclaved caring. Through the reasonable proportioning and process control, the internal and external quality of the product are improved; the consumption of lime and cement is reduced; the production cost is directly reduced; the still standing time is shortened; the production efficiency is improved.

Owner:贵州美可斯建筑工程技术有限公司 +1

High gloss cover printing silica gel for screen printing and preparation method thereof

Owner:东莞市科多有机硅材料有限公司

A method for preparing ultra-high-purity ammonium rhenate crystals with controllable particle size

ActiveCN110527854BHigh purityMeet liquidity requirementsProcess efficiency improvementCrystallization temperatureUltra high purity

The invention provides a method for preparing ultra-high-purity ammonium rhenate crystals with controllable particle size, which belongs to the technical field of hydrometallurgy. The present invention adopts multiple fractional crystallization methods to recrystallize the aqueous solution of ammonium rhenate crude product, and at the same time controls the crystallization temperature nodes to be 35-45°C, 0-5°C and 20-40°C, not only can obtain the purity ≥ 99.999% Ultra-high-purity ammonium rhenate crystals, and the yield of ultra-high-purity ammonium rhenate crystals can reach more than 90%; at the same time, it ensures the consistency of the obtained ultra-high-purity ammonium rhenate crystals; The crystallization concentration, temperature, time and number of crystallization of the ammonium solution are used to adjust the crystal particle size, which can meet the fluidity requirements of ammonium rhenate crystals for different purposes; it is suitable for industrial continuous production, and can realize large-scale production with high efficiency and low energy consumption. Ammonium rhenate crystals with high purity and controlled particle size.

Owner:昆明先导新材料科技有限责任公司

A resource recycling system for all underground sewage and solid waste in a residential area

InactiveCN105439320BMobility is not strictly limitedUnlimited mobilitySolid waste disposalTransportation and packagingLiquid productElectrical connection

The invention relates to a resource recycling system for all underground sewage and solid waste in a residential area, which is characterized in that it includes a membrane enrichment unit, a garbage pretreatment system, and a supercritical reaction system arranged under the ground. The sewage treatment pool, garbage storage pool on the second floor, and the control system installed in the central control room on the ground. The control system includes sensors, on-site execution components, controllers, and upper computers. The on-site execution components are electrically connected to the controller. Sensors, controllers Signal connection with the host computer; sensors and on-site execution components are set on the oxidant delivery pipeline, fuel delivery pipeline, material delivery pipeline, reactor, gaseous product discharge unit, and liquid product discharge unit. The invention can treat sewage and solid waste at the same time, so that solid waste is no longer treated by incineration, reducing pollutant discharge, and realizes the control process of system start, stop, emergency stop process, temperature adjustment and pressure adjustment through the control unit, and the system runs The generated data can be effectively collected, stored and analyzed.

Owner:王冰

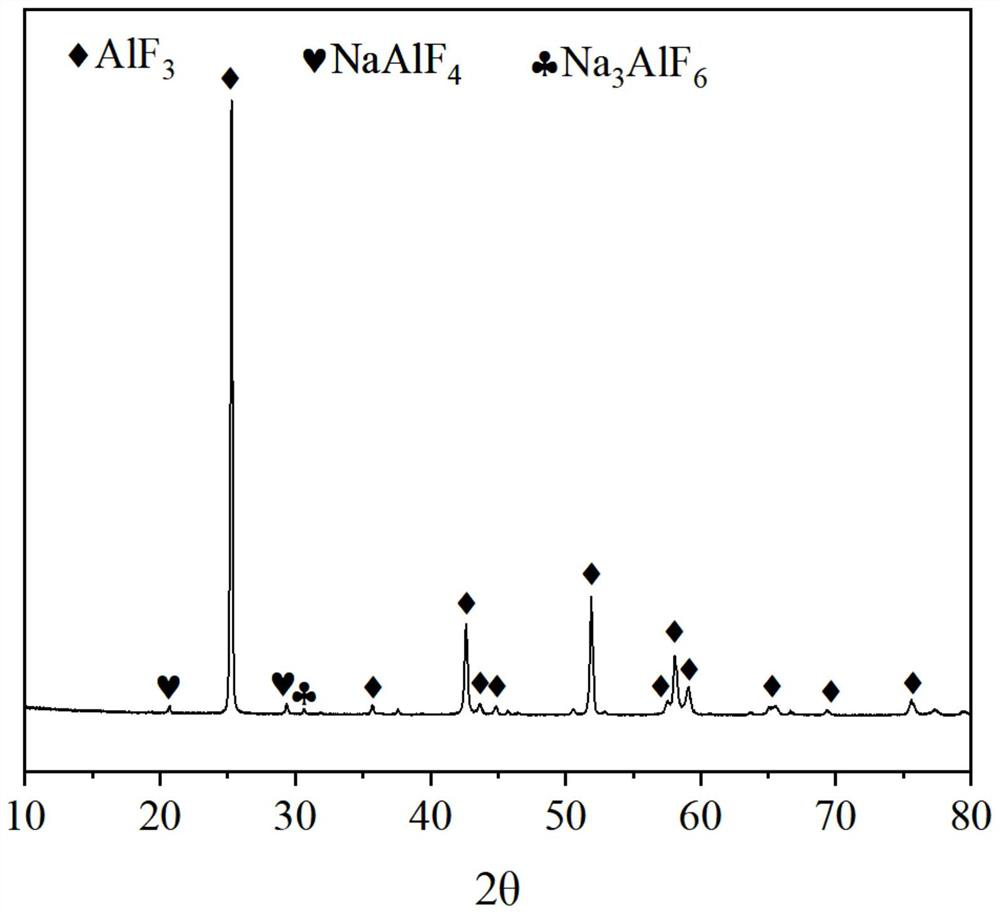

A kind of method for treating fluorine-containing waste electrolyte

ActiveCN113149052BHigh purityHigh recovery rateAlkali metal sulfites/sulfates preparation formSulfate/bisulfate preparationAluminum fluorideAluminium electrolysis

The invention discloses a method for efficiently treating fluorine-containing waste electrolyte. Additives and reaction aids are added to the waste electrolyte, mixed uniformly and ground to less than 0.355mm, roasted, cooled at a specific rate and then crushed and washed to obtain an aluminum fluoride product , the filtrate is concentrated to further extract other by-products. The present invention reduces the primary crystal temperature of the system by adding a reaction assistant, so that the reaction is carried out in a molten state, the mass transfer efficiency is high, the reaction conversion rate is high, and the effective aluminum fluoride content in the product is high; at the same time, the holding time and cooling rate are further controlled, The aluminum fluoride grains produced by the reaction grow up, and the obtained aluminum fluoride has good fluidity, which is well compatible with the current automatic feeding equipment of industrial aluminum electrolytic cells, and realizes the green and sustainable development of the electrolytic aluminum industry.

Owner:CENT SOUTH UNIV +1

A low pressure injection molding magnetic proximity switch

InactiveCN105845498BHigh impact strengthImprove stabilityMagnetic/electric field switchesContact electric connectionInjection mouldingElectrical stability

Owner:FOSHAN CHUANDONG MAGNETOELECTRICITY

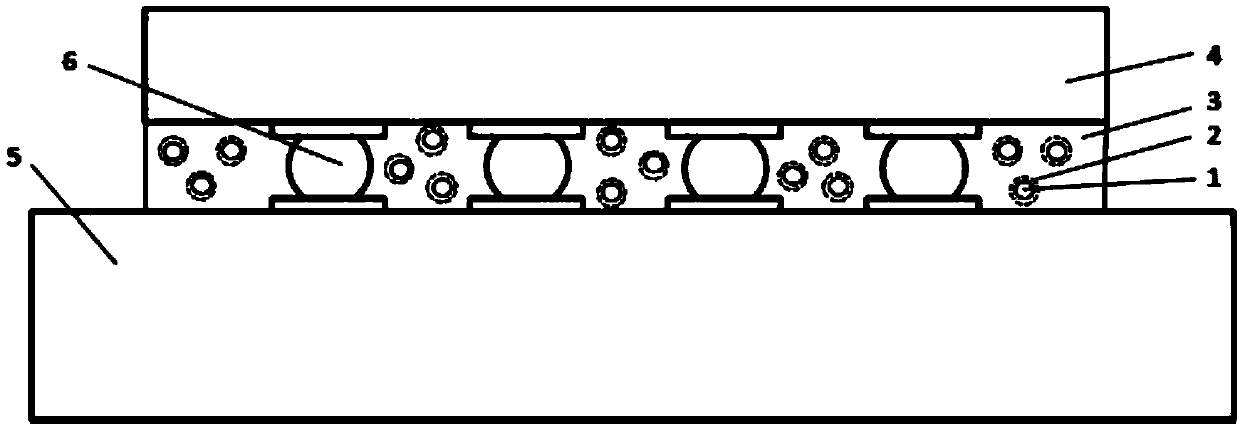

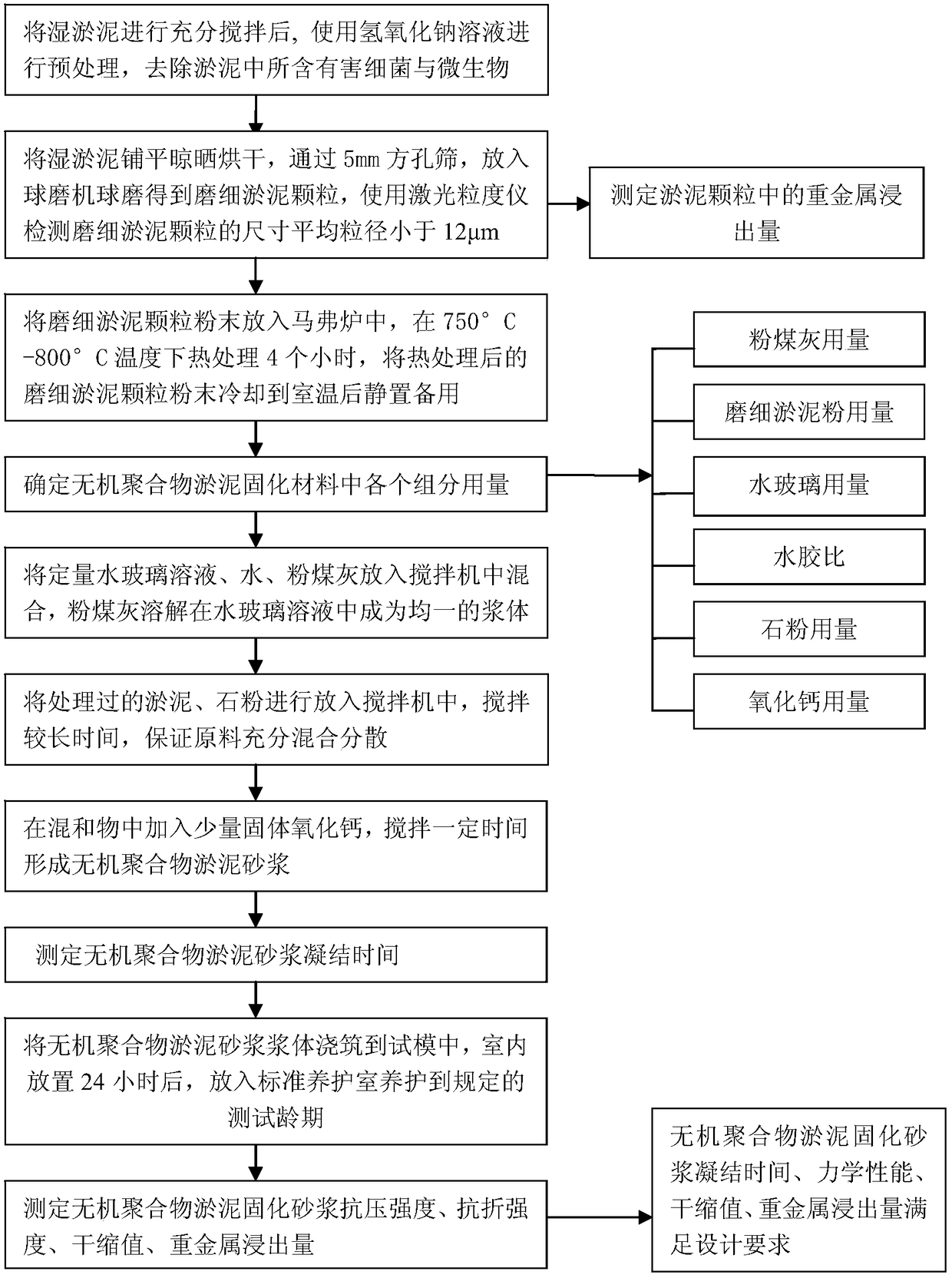

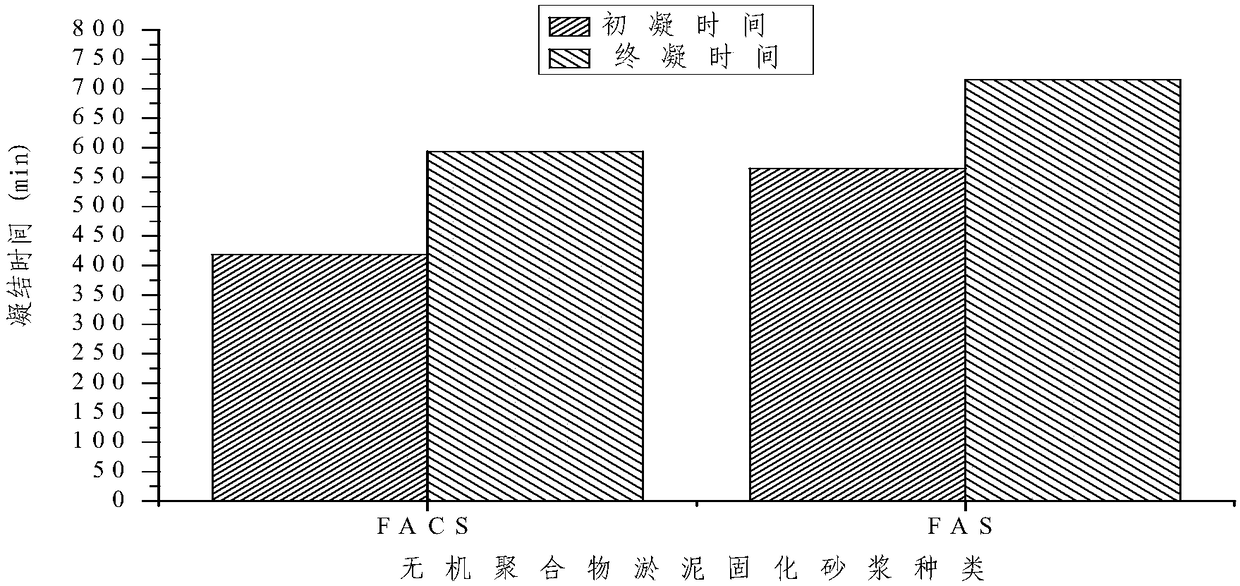

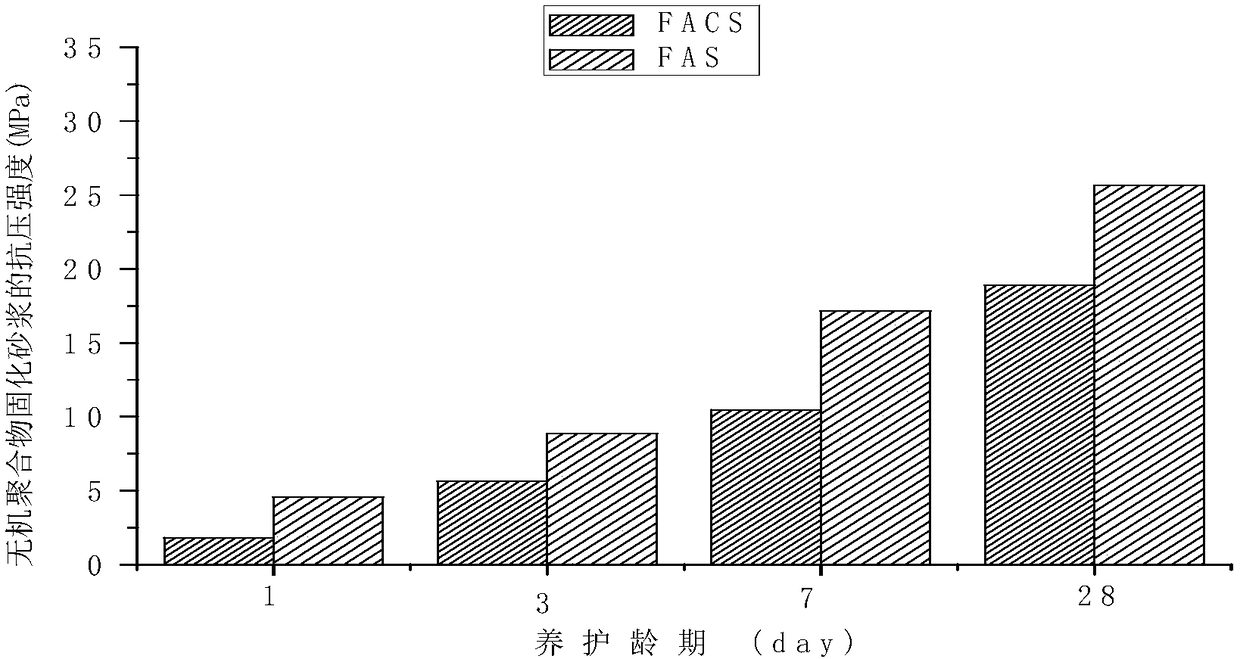

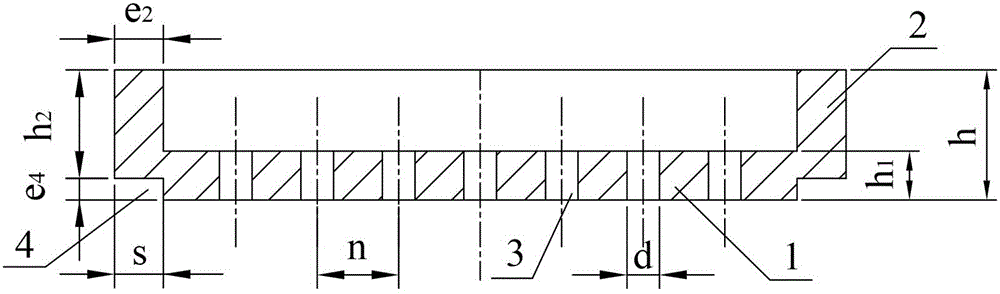

A kind of inorganic polymer sludge solidification mortar and preparation method thereof

ActiveCN106082926BLow costShorten the setting timeSolid waste managementHydration reactionSoluble glass

Owner:HOHAI UNIV

Graphite boat and graphite boat group for hard alloy sintering technology

The invention discloses a graphite boat for hard alloy sintering, which comprises a disc-shaped graphite boat body enclosed by a side wall and a bottom plate, wherein a plurality of through holes are uniformly arranged on the bottom plate. The graphite boat for the hard alloy sintering has the advantages of simple structure, convenient manufacture, uniform distribution of the intensity of the interior atmosphere, and quality stability enhancement of the product. The invention also discloses a graphite boat group formed by overlying more than two graphite boats for the hard alloy sintering in a layer-upon-layer mode, wherein a step arranged at the bottom edge of the bottom plate of the upper layer of the graphite boat is arranged on the side wall of the adjacent lower layer of the graphiteboat.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com