High-thermal-conductivity electronic package composite material and preparation method thereof

A technology of electronic packaging and composite materials, which is applied in nanotechnology, circuits, electrical components, etc. for materials and surface science. Effect of electromigration failure time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

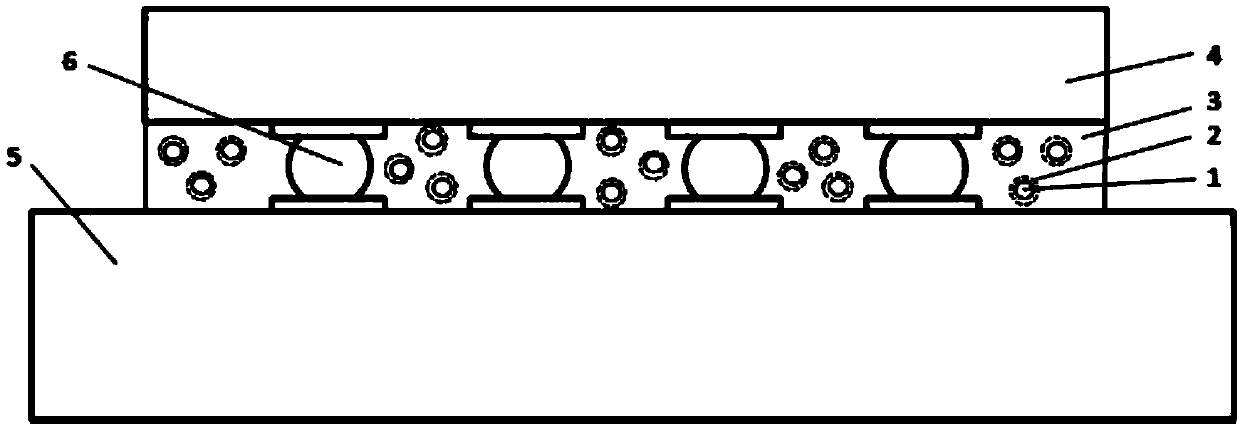

[0037] The high thermal conductivity electronic packaging composite material provided by the invention is used on the packaging filling of microelectronic chips, such as figure 1 As shown, the outer surface of the nano-copper particles 1 is covered with a silicon dioxide layer 2; the silicon dioxide layer 2 is used as an insulating layer, and its thickness is 10-100 nm; the particle size of the nano-copper particles is 50-500 nm. The nano-copper particles wrapped with the silicon dioxide layer 2 are mixed with the polymer 3 to form a high thermal conductivity electronic packaging composite material; wherein, the volume ratio of the insulating nano-particles to the polymer is 0.1-0.3. Polymers include epoxy, acrylate or phenolic resins.

[0038] Fill the electronic packaging compound material with high thermal conductivity between the chip 4 and the substrate 5. The micro bump 6 is also included between the chip 4 and the substrate 5. The micro bump 6 is the I / O connection betw...

Embodiment 2

[0041] Step 1: Weigh 2mmol copper oxalate and dissolve it in 25ml N,N-dimethylformamide solution;

[0042] Step 2: Add 1mmol polyvinylpolypyrrolidone and 1.3mmol sodium borohydride to the solution in step 1;

[0043] Step 3: After stirring for five minutes, the above mixture was heated to 85°C and kept for 3 minutes, and then filtered to obtain an orange precipitate, which is called filter residue A, and the filter residue A was washed several times with alcohol to obtain intermediate product A;

[0044]Step 4: Dissolving and dispersing the intermediate product A obtained in Step 3 in a mixed solution of 60ml of water and 40ml of ethanol to obtain a mixed solution;

[0045] Step 5: Add 1 mL of concentrated ammonia water to the mixed solution in Step 4, and then add 0.24 mmol of ethyl orthosilicate; wherein, the concentration of ammonia water is 28% by mass;

[0046] Step 6: After stirring at room temperature for 6 hours, filter to obtain filter residue B, wash filter residue ...

Embodiment 3

[0054] Step 1: Weigh 3mmol copper oxalate and dissolve it in 50ml N,N-dimethylformamide solution;

[0055] Step 2: Add 1.6mmol polyvinylpolypyrrolidone and 1.8mmol sodium borohydride to the step 1 solution;

[0056] Step 3: After stirring for five minutes, the above mixture was heated to 90°C and kept for 4 minutes, and then filtered to obtain an orange precipitate, which is called filter residue A, and the filter residue A was washed several times with alcohol to obtain intermediate product A;

[0057] Step 4: Dissolving and dispersing the intermediate product A obtained in Step 3 in a mixed solution of 75ml of water and 75ml of ethanol to obtain a mixed solution;

[0058] Step 5: Add 3 mL of concentrated ammonia water to the mixed solution in Step 4, and then add 0.3 mmol of tetraethyl orthosilicate; wherein, the concentration of ammonia water is 26% by mass;

[0059] Step 6: After stirring at room temperature for 7 hours, filter to obtain filter residue B, wash filter resi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com