Nano zirconium oxide spraying powder and preparation method thereof

A technology of nano-zirconia and spraying powder, which is applied in the field of nano-ceramic materials, can solve the problems of high production cost, increased thermal conductivity, and decreased heat insulation ability, and achieve high porosity, high cohesive strength, and increased porosity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

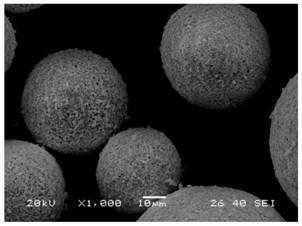

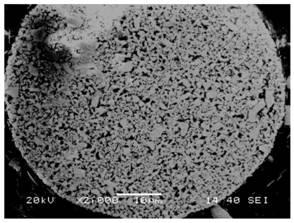

[0033] see figure 1 , figure 2 , a nano-zirconia spray powder, its preparation method comprises the following steps:

[0034] Step 1: Mix nano-YSZ powder with a grain size of 40nm and a yttrium oxide content of 7.2wt% and deionized water at a ratio of 1:3, and add a dispersant with a weight of 1% of the YSZ powder, and mix evenly to obtain a slurry;

[0035] Step 2: Grinding the slurry with a sand mill until the particle size in the slurry is less than 200nm;

[0036] Step 3: Add anionic polyacrylamide with a molecular weight of 8000 to the finely ground slurry in an amount of 0.1% of the weight of the nanometer YSZ powder, and stir until uniform at a stirring speed of 30 rpm;

[0037] Step 4: continue to add acrylic resin to the slurry, the amount added is 2% of the weight of the nanometer YSZ powder, and continue to stir at a stirring speed of 30 rpm until uniform;

[0038] Step 5: The slurry is spray-dried to obtain granulated materials; the inlet temperature during granu...

Embodiment 2

[0051] The present embodiment is a kind of nanometer zirconia spray powder, and its preparation method comprises as follows:

[0052] Step 1: Mix nano-YSZ powder with a grain size of 30nm and a yttrium oxide content of 7.5wt% and deionized water at a ratio of 1:2.5, and add a dispersant with a weight of 0.8% of the YSZ powder, and mix evenly to obtain a slurry;

[0053] Step 2: using a sand mill to grind the slurry until the particle size in the slurry is less than 100nm;

[0054] Step 3: Add anionic polyacrylamide with a molecular weight of 10,000 to the finely ground slurry in an amount of 0.18% of the weight of the nanometer YSZ powder, and stir until uniform at a stirring speed of 20 rpm;

[0055] Step 4: continue to add acrylic resin to the slurry, the amount added is 1.5% of the weight of the nanometer YSZ powder, and continue to stir at a stirring speed of 30 rpm until uniform;

[0056] Step 5: The slurry is spray-dried to obtain granulated materials; the inlet tempera...

Embodiment 3

[0064] The present embodiment is a kind of nanometer zirconia spray powder, and its preparation method comprises as follows:

[0065] Step 1: Mix nano-YSZ powder with a grain size of 80nm and a yttrium oxide content of 7.25wt% and deionized water at a ratio of 1:2, and add a dispersant with a weight of 0.5% of the YSZ powder, and mix evenly to obtain a slurry;

[0066] Step 2: Grinding the slurry with a sand mill until the particle size in the slurry is less than 300nm;

[0067] Step 3: Add anionic polyacrylamide with a molecular weight of 12,000 to the finely ground slurry in an amount of 0.06% of the weight of the nanometer YSZ powder, and stir until uniform at a stirring speed of 20 rpm;

[0068] Step 4: continue to add acrylic resin to the slurry, the amount added is 1.5% of the weight of the nanometer YSZ powder, and continue to stir at a stirring speed of 30 rpm until uniform;

[0069] Step 5: The slurry is spray-dried to obtain granulated materials; the inlet temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| bulk density | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com