Preparation method of fly ash-waste glass powder inorganic polymer silt-solidifying material

An inorganic polymer, waste glass technology, applied in solid waste management, sustainable waste treatment, climate sustainability, etc., can solve problems such as large drying shrinkage, easy cracking, and slow development of consolidated strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

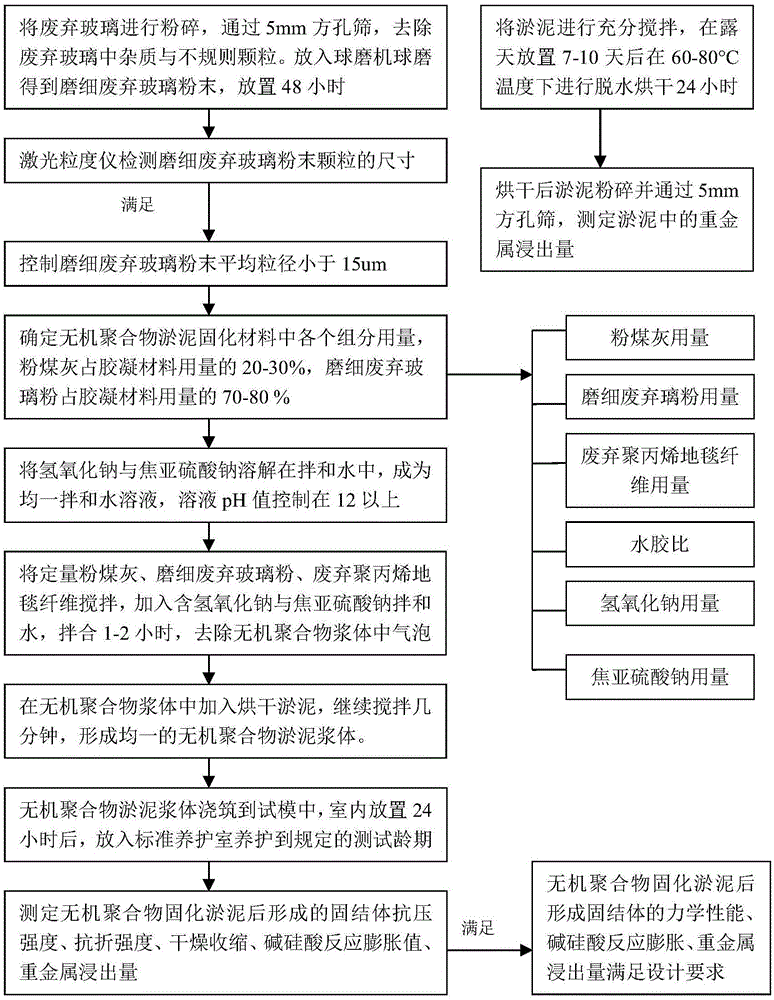

[0026] The preparation method of fly ash-waste glass powder inorganic polymer sludge solidification material comprises the following steps:

[0027] 1. Pretreatment of sludge

[0028] After fully stirring the sludge obtained from sewage treatment plants, river dredging and reclamation projects, place it in the open air with a roof for 7-10 days, dehydrate and dry it at 60-80°C, crush it and pass it through a 5mm square hole sieve to remove the sludge various impurities. The treated sludge was taken to determine the leaching amount of heavy metals in the sludge according to the American Environmental Protection Summer Toxic Characteristic Leaching Method (TCLP, EPAMethod1311).

[0029] 2. Preparation of fly ash-waste glass powder inorganic polymer sludge solidification material

[0030] 2.1. Raw materials

[0031] Sorting, cleaning, drying, and crushing waste white glass beverage bottles and passing through a 5mm square hole sieve to remove impurities and irregular particles...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com