Production process for disassembly forming of ceramic pedestal pan

A production process and toilet technology, applied in the field of ceramics, can solve the problems of pipeline deformation, product deformation, product molding and firing pass rate difficult to stabilize, etc., to achieve the effect of improving product quality and making molds easy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

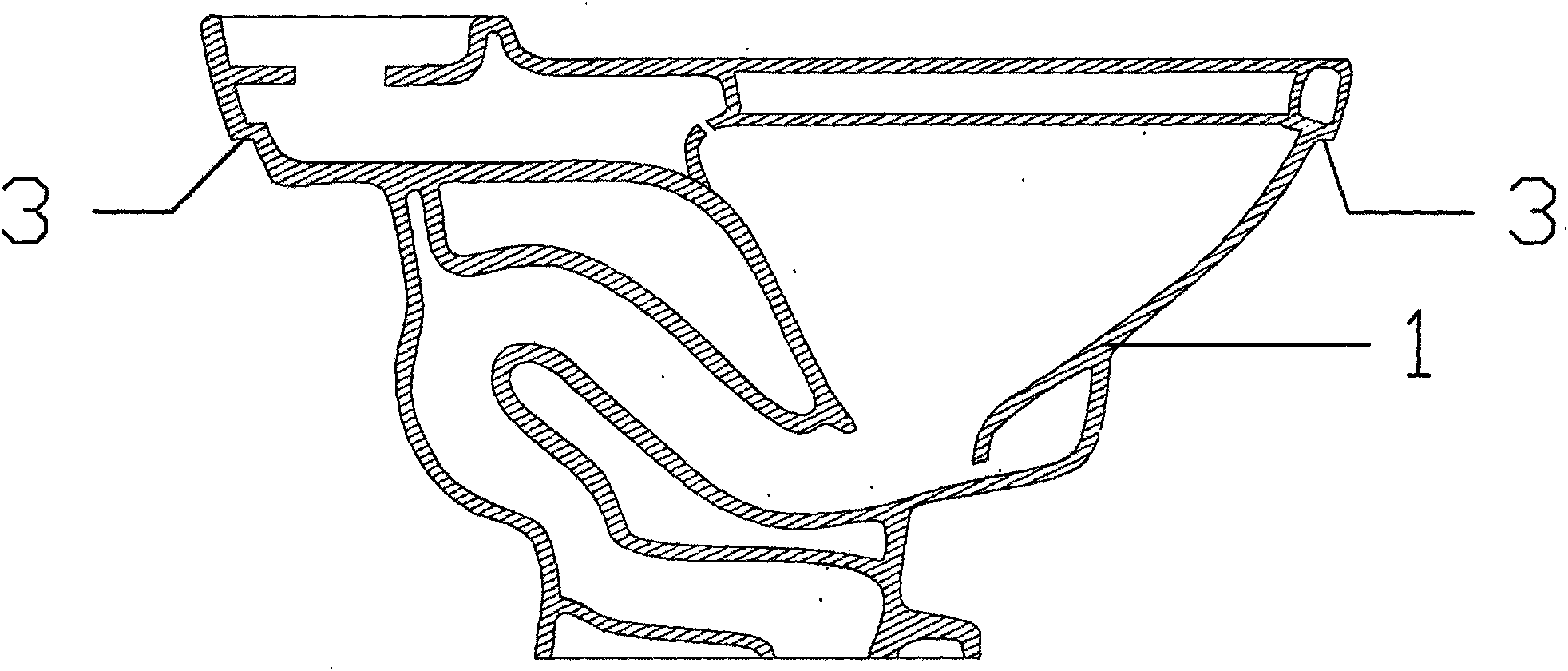

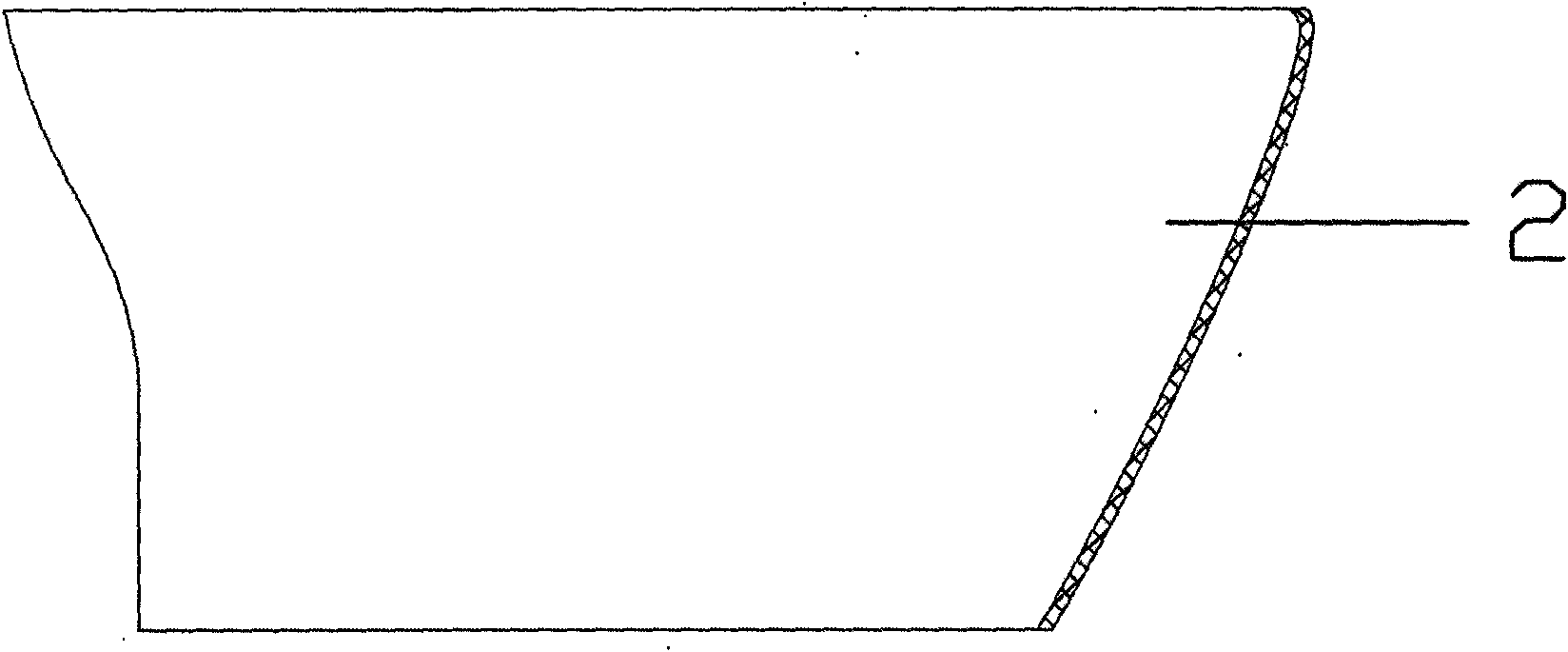

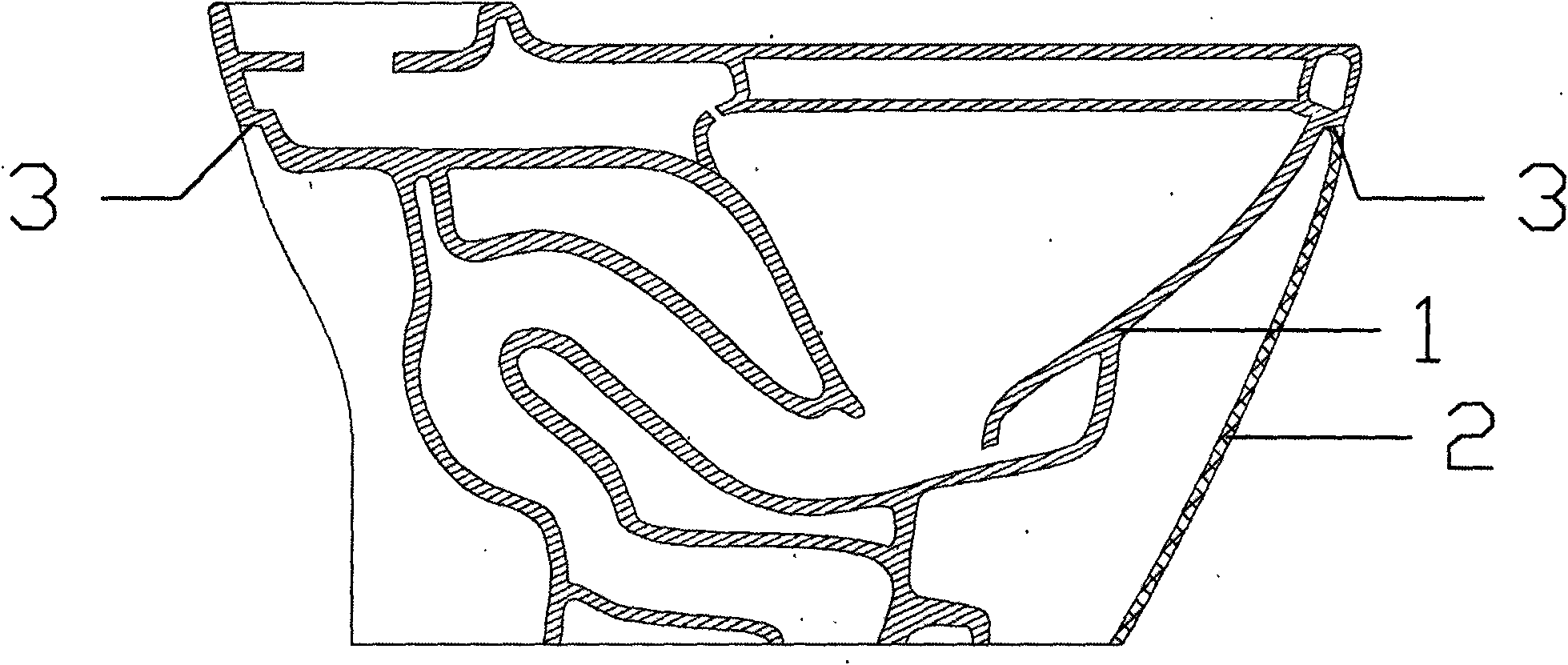

[0021] Example: such as Figure 1~3 As shown, in the present invention, the seat body 2 and the toilet body 1 of the toilet are respectively designed with molds, and a part 3 connected with the seat body 2 is reserved on the toilet body 1;

[0022] Prepare ceramic slurry according to the conventional ceramic production process. The mud used in the seat body 2 is 74 Baume, and the mud used in the toilet body 1 is 65 Baume, and then the mud is injected into the mold respectively;

[0023] The base body 2 is grouted and molded for 4 hours and then the mold is opened and naturally dried for 3 hours. The corresponding toilet body 1 is grouted and molded for 7 hours and then the mold is opened and dried for 6 hours to synchronize the moisture content of the base body 2 and the soil body of the toilet body 1 Reach 15% (that is, the toilet body 1 should be grouted 6 hours earlier than the seat body 2 to ensure the same time when the two are dried, and the green body can be bonded immediate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com