A method for preparing ultra-high-purity ammonium rhenate crystals with controllable particle size

A technology of ammonium rhenate and crystals, which is applied in the field of purification parameters of ultra-high-purity ammonium rhenate crystals and control of crystal growth process, which can solve the problems of cumbersome process flow, long time period, and no control of crystal growth process, etc., and achieve low energy consumption , the effect of high efficiency energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

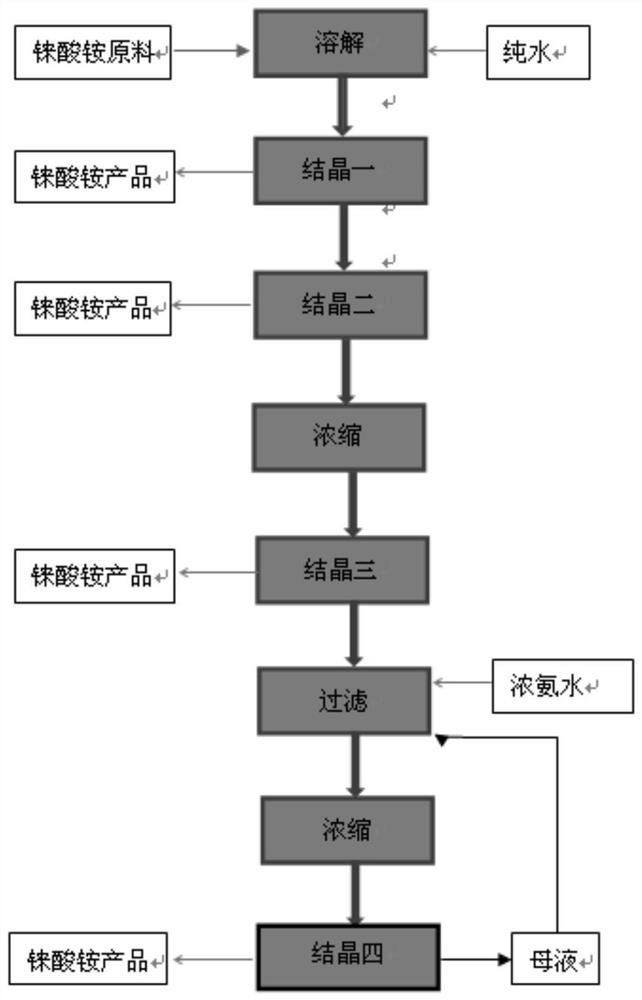

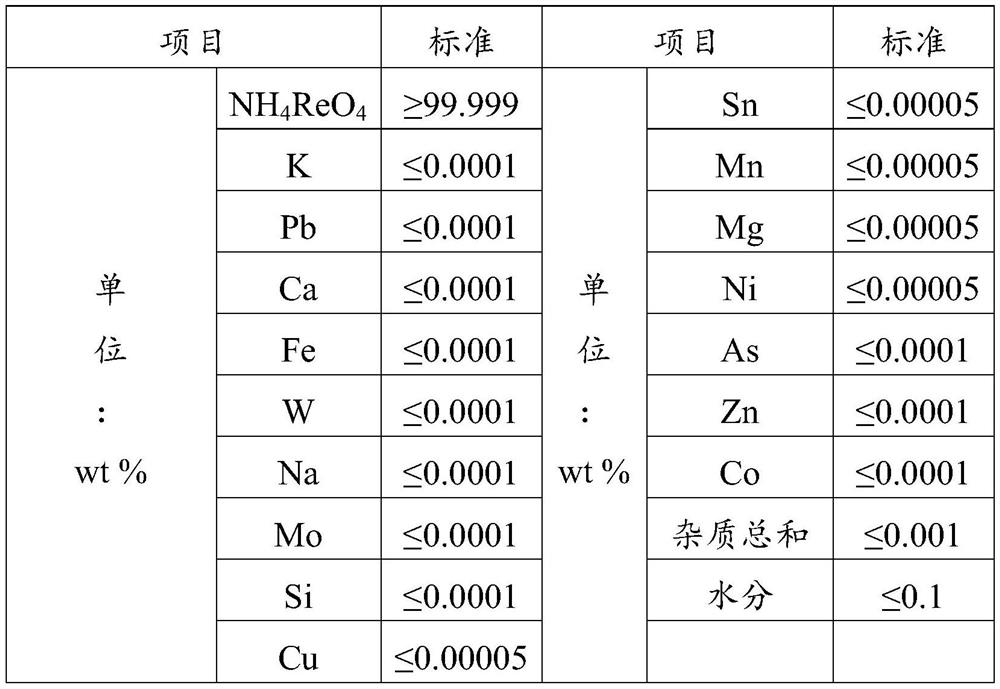

[0032] A kind of embodiment of the method for the ultra-high-purity ammonium rhenate crystal that the present invention prepares particle size controllable, it comprises the following steps:

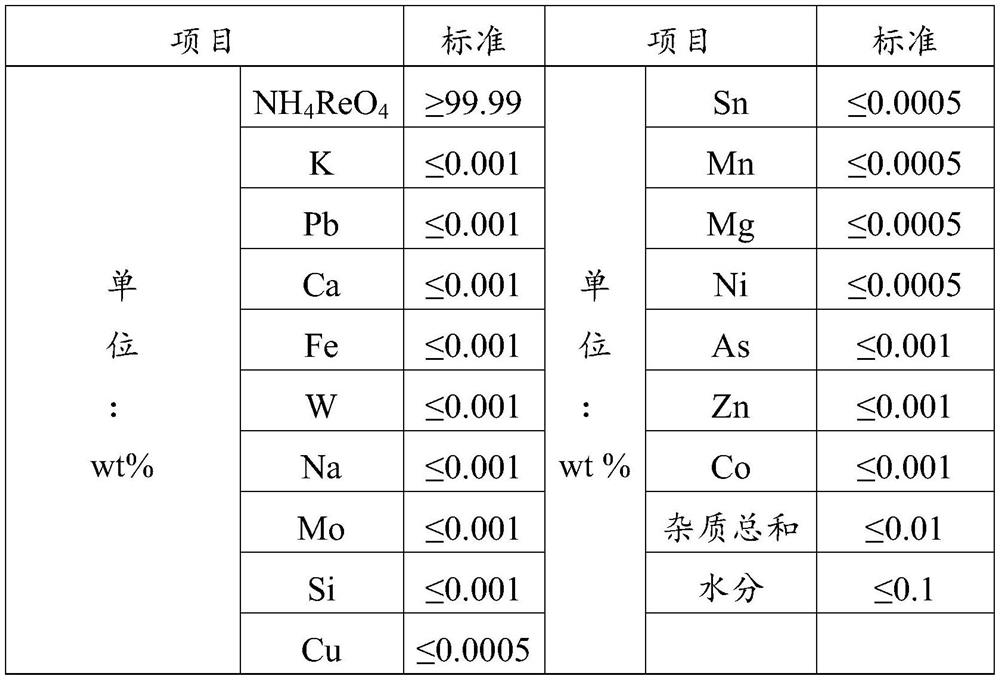

[0033] (1) Dissolving: the ammonium rhenate crude product (which meets the specified standard required in Table 1) with a purity of 99.99% (4N) is mixed with water, heated to 70° C. to dissolve it completely, and to obtain a mass concentration of 15%. Ammonium rhenate solution;

[0034] (2) Crystallization 1: under stirring conditions, the ammonium rhenate solution obtained by the treatment in step (1) was first cooled to 40° C. in 1 h, and then suction filtered after 3 h of crystallization to obtain crystal A and mother liquor A;

[0035] (3) Crystallization 2: under the condition of stirring, the temperature of the mother liquor A is lowered to 5° C. in 1 hour, and then suction filtration is carried out after 3 hours of crystallization to obtain the crystal B and the mother liquor B; ...

Embodiment 2

[0045] A kind of embodiment of the method for the ultra-high-purity ammonium rhenate crystal that the present invention prepares particle size controllable, it comprises the following steps:

[0046] (1) Dissolving: the ammonium rhenate crude product (which meets the specified standard required in Table 1) with a purity of 99.99% (4N) is mixed with water, heated to 80° C. to dissolve it completely, and to obtain a mass concentration of 20%. Ammonium rhenate solution;

[0047] (2) Crystallization 1: under stirring conditions, first cool the ammonium rhenate solution obtained through step (1) to 40° C. in 4 hours, and then carry out suction filtration after crystallization for 6 hours to obtain crystal A and mother liquor A;

[0048] (3) Crystallization 2: under the condition of stirring, the temperature of the mother liquor A was lowered to 5° C. in 4 hours, and then suction filtration was carried out after 6 hours of crystallization to obtain the crystal B and the mother liquo...

Embodiment 3

[0054] A kind of embodiment of the method for the ultra-high-purity ammonium rhenate crystal that the present invention prepares particle size controllable, it comprises the following steps:

[0055] (1) Dissolving: the ammonium rhenate crude product (which meets the specified standard required in Table 1) with a purity of 99.99% (4N) is mixed with water, heated to 60° C. to dissolve it completely, and to obtain a mass concentration of 15%. Ammonium rhenate solution;

[0056] (2) Crystallization 1: under stirring conditions, the ammonium rhenate solution obtained through the treatment of step (1) was first cooled to 40° C. in 2 hours, and then suction filtered after crystallization for 5 hours to obtain crystal A and mother liquor A;

[0057] (3) Crystallization 2: under the condition of stirring, the temperature of the mother liquor A was lowered to 5°C in 2 hours, and then suction filtration was performed after the crystallization was separated for 5 hours to obtain the crys...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com