Formula granules containing fiber Mongolian medicine powder and preparation method thereof

A technology of formula granules and Mongolian medicine powder, applied in the field of Mongolian medicine, can solve the problems of poor processing performance of Mongolian medicines containing fibers, and achieve the effects of ensuring safety and effectiveness, improving compliance, and improving controllability and stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] The invention provides a preparation method of the fiber-containing Mongolian medicine powder formula granules, comprising the following steps: 1) pulverizing the fiber-containing Mongolian medicine powder to obtain fiber-containing Mongolian medicine powder, and 2) mixing the fiber-containing Mongolian medicine powder and powdered sugar After mixing and wetting with starch slurry, wet granulation is carried out to obtain fiber-containing Mongolian medicine powder formula granules.

[0042] In the present invention, fiber-containing Mongolian medicine is pulverized to obtain fiber-containing Mongolian medicine powder. In the present invention, the pulverization is preferably carried out by an impact pulverizer, which has a large capacity of vibrating sieve and has a better pulverization effect on fiber-containing Mongolian medicines with certain toughness and elasticity. In the present invention, the pulverization preferably further includes passing the pulverized mater...

Embodiment 1

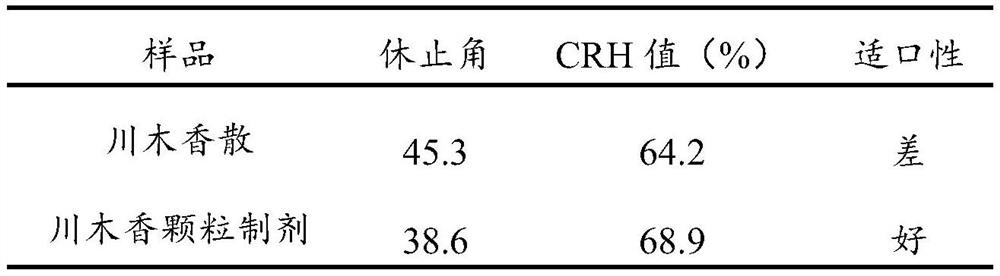

[0048] Preparation of Chuanmuxiang Granules

[0049] Weigh 35 kg of chuanbaxiang decoction pieces, pulverize with an impact mill, use an electromagnetic vibrating sieve to sieve chuanbaxiang powder, pass through a 100-mesh sieve, and collect the sieve to obtain 33.5 kg of chuanbaxiang powder.

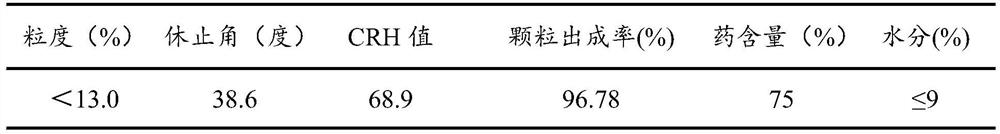

[0050] Mix 7.5 kg of Kawasaki powder and 2 kg of powdered sugar in a swing mixer for 30 minutes to obtain a mixed material. Wet the mixed material with 5kg of 10% starch slurry, place it in a granulator for wet granulation, granulate with 14-16 mesh, dry at 60°C until the moisture content is ≤9%, and granulate with 18-20 mesh.

[0051] The prepared Chuanmuxiang granule preparation is packaged and inspected for quality; the packaging material is a pharmaceutical transparent polyethylene bottle or a pharmaceutical PVC special bag designated by the state, and the specification is 250-300g / bottle or 250-300g / bag.

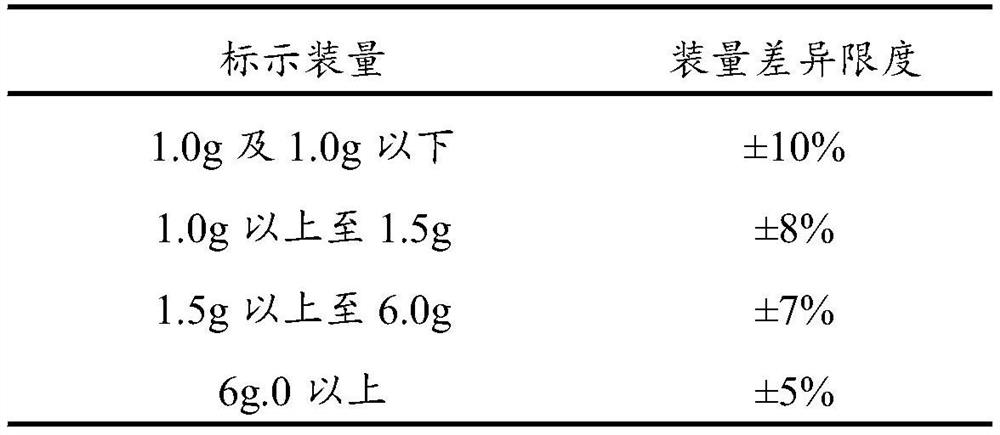

[0052] According to the "Chinese Pharmacopoeia" (2020 edition of the four g...

Embodiment 2

[0068] Preparation of rhubarb granules

[0069] The rhubarb decoction pieces were weighed 35kg, pulverized by an impact mill, and the rhubarb powder was sieved by an electromagnetic vibrating sieve, passed through a 100-mesh sieve, and 33.5 kg of the rhubarb powder was obtained by collecting the under-sieve.

[0070] Mix 7.5 kg of rhubarb powder and 2 kg of powdered sugar for 30 minutes to obtain a mixed material. Wet the mixed material with 5kg of 10% starch slurry, place it in a granulator for wet granulation, granulate with 14-16 mesh, dry at 60°C until the moisture content is ≤9%, and granulate with 18-20 mesh.

[0071] The prepared rhubarb granules are packaged and inspected; the packaging material is a nationally designated transparent polyethylene bottle for medicine or a special PVC bag for medicine, and the specification is 250-300g / bottle or 250-300g / bag.

[0072] According to the "Chinese Pharmacopoeia" (2020 edition of the four general rules 0104) for inspection. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle of repose | aaaaa | aaaaa |

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com