Multipurpose boat and multipurpose boat set for powder metallurgy sintering

A powder metallurgy, multi-purpose technology, applied in the field of multi-purpose boats, can solve the problems of dumping (domino effect, long strip products can not be placed flat, can not be placed upright, etc., to reduce material management costs, atmosphere density distribution Uniform, easy-to-manage results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

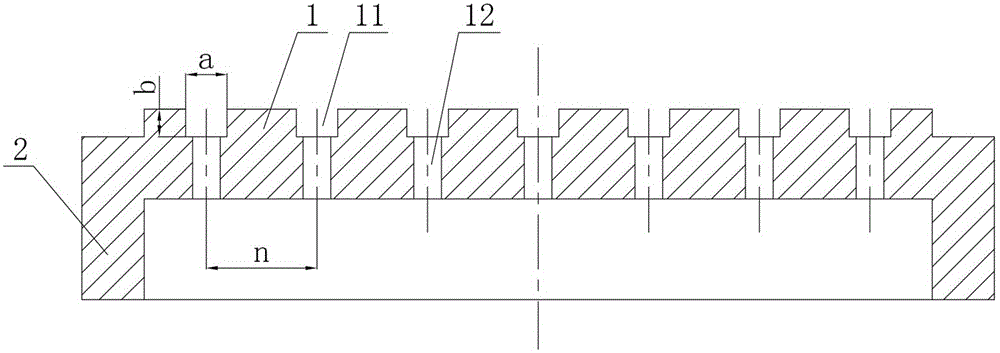

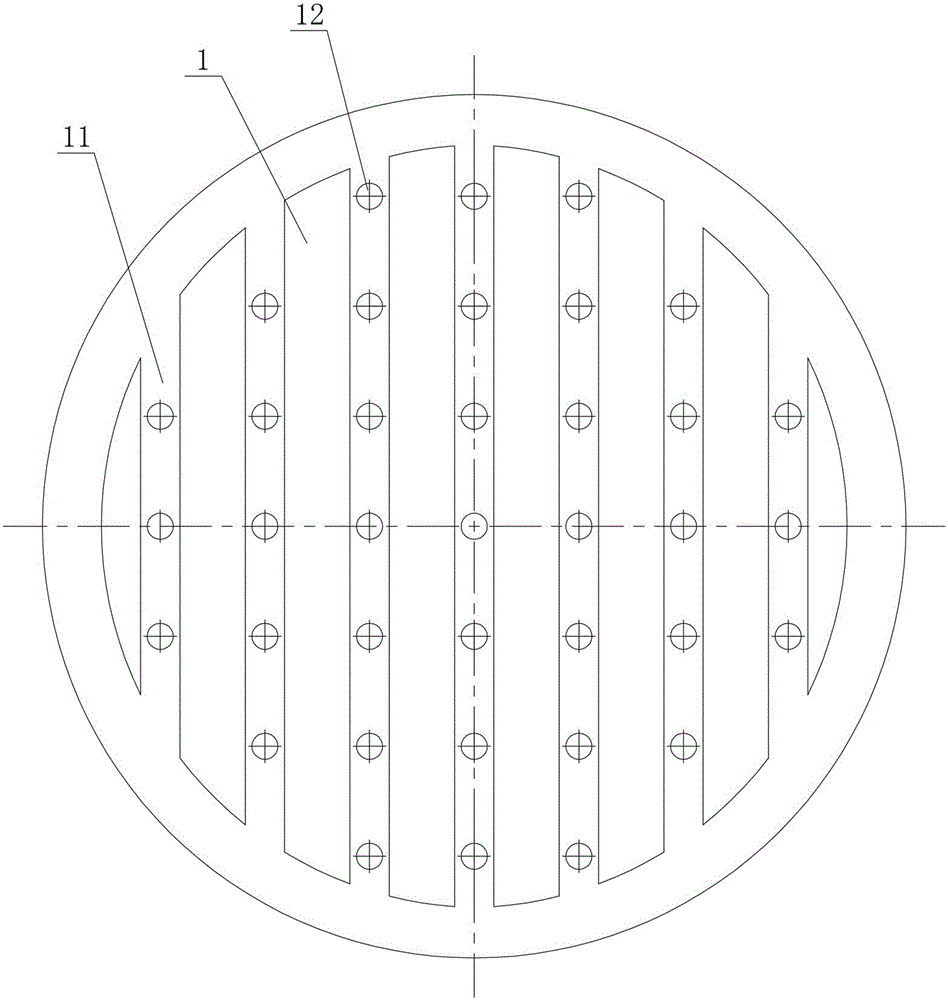

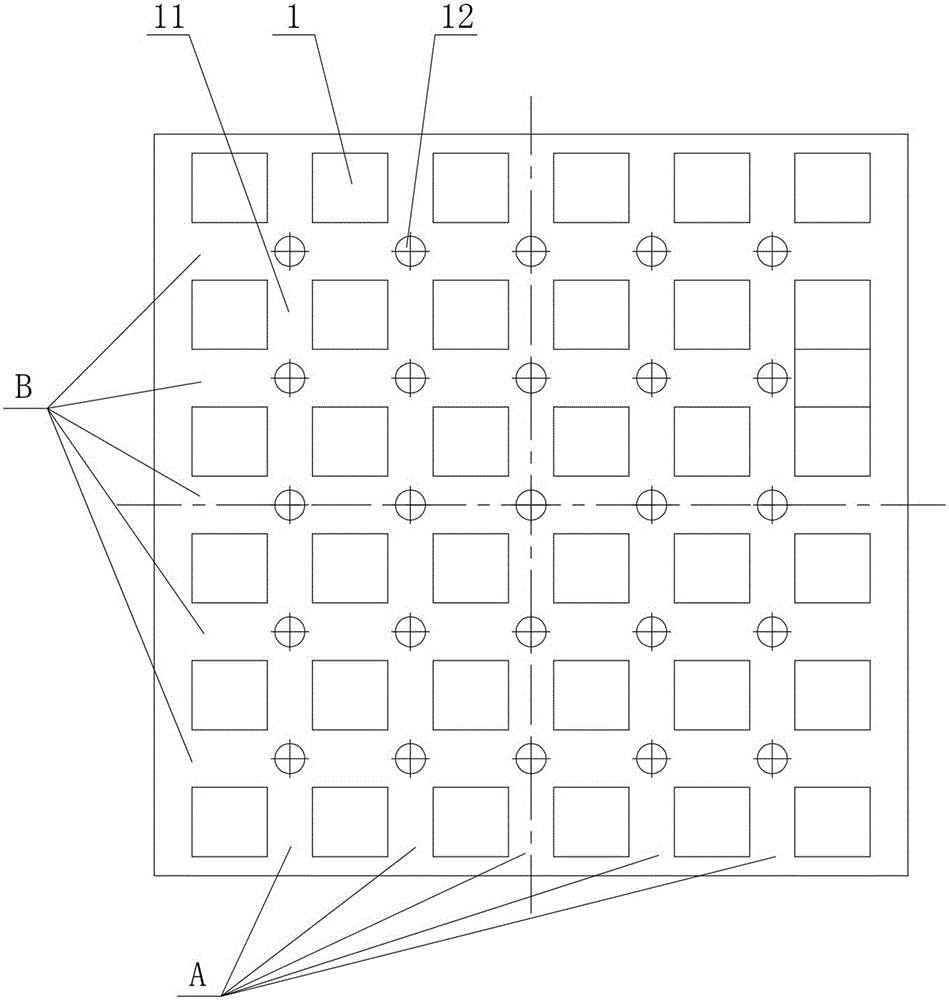

[0022] figure 1 with figure 2 It shows an embodiment of a multipurpose boat for powder metallurgy sintering of the present invention, the boat includes a disc-shaped graphite boat body surrounded by side walls 2 and bottom plate 1, and the graphite boat body is circular The graphite boat body is provided with several grooves 11 on the outside of the bottom plate 1. When the graphite boat body is turned upside down, these grooves 11 can be used to place the elongated powder metallurgy sintered body 3 that must be placed sideways. The groove 11 can be used to prevent the elongated powder metallurgy sintered body 3 placed sideways from toppling during the process of transfer and furnace loading, so as to avoid the products being damaged due to mutual collision. Therefore, the boat of the present invention can be used when the graphite boat body is normally placed It is used to sinter conventional powder metallurgy sintered bodies with general shapes, and can also be used to sin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com