Filling master batch and preparation method and application thereof and polypropylene drawing material containing filling master batch

A technology of filling masterbatch and polypropylene, which is applied in the field of polypropylene wire drawing, can solve problems such as smoking, and achieve the effects of improving mechanical properties, good mechanical properties, and improving smoking problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

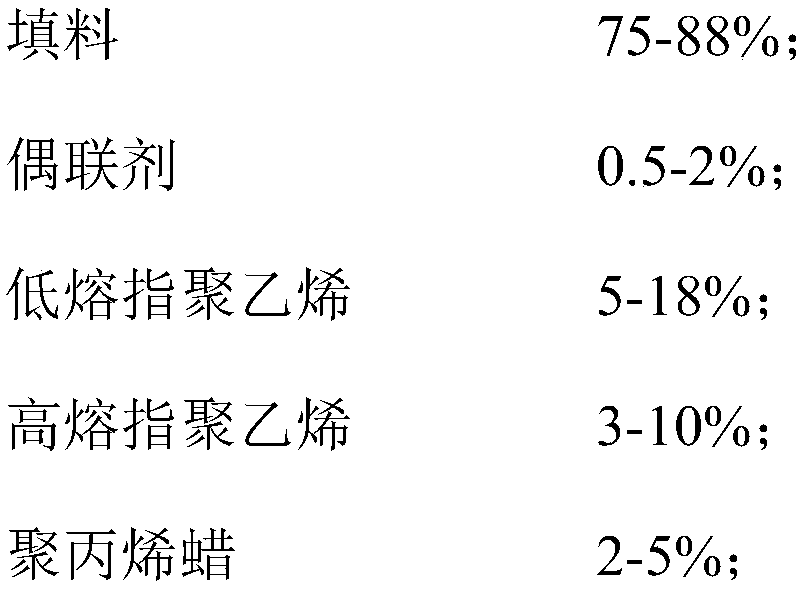

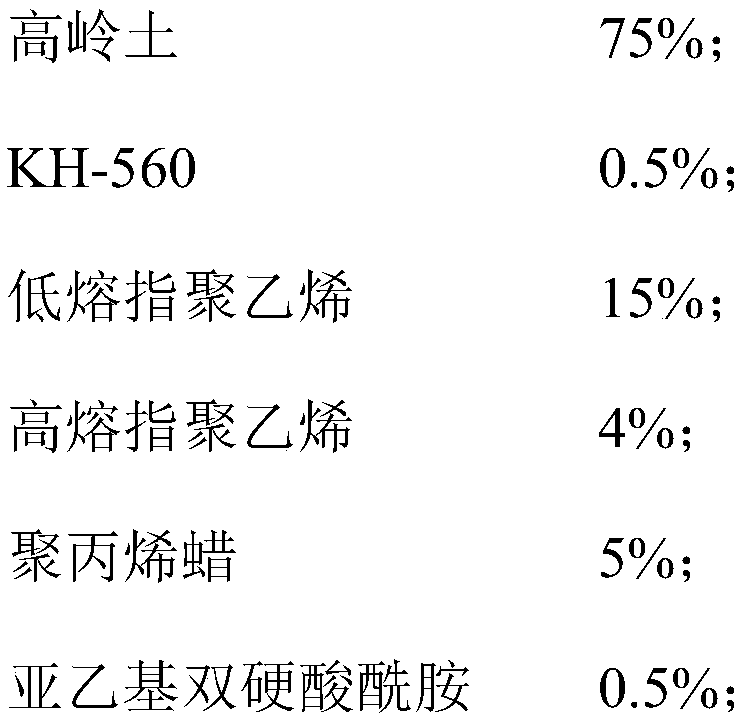

[0050] This embodiment provides a kind of filler masterbatch, comprises the component of following percentage by weight:

[0051]

[0052] Wherein, the particle size of the filler is 2-10 μm, the melt index of low-melt polyethylene is 0.01 g / 10min, and the melt index of high-melt polyethylene is 40 g / 10min.

[0053] The preparation method of above-mentioned filling masterbatch is as follows:

[0054] (1) Put the filler into the high mixer, raise the temperature to 110°C, stir at a speed of 1480r / min for 5 minutes, then add a coupling agent, keep the speed, and mix for 4 minutes to obtain a modified filler;

[0055] (2) Add remaining components to the modified filler obtained in step (1), keep the rotating speed of 1480r / min, and continue mixing for 5min;

[0056] (3) Add the mixture obtained in step (2) into a twin-screw extruder, set the head temperature to 150°C, the temperature of the extrusion section to 150°C, and the screw speed to 190r / min, and extrude to obtain a f...

Embodiment 2

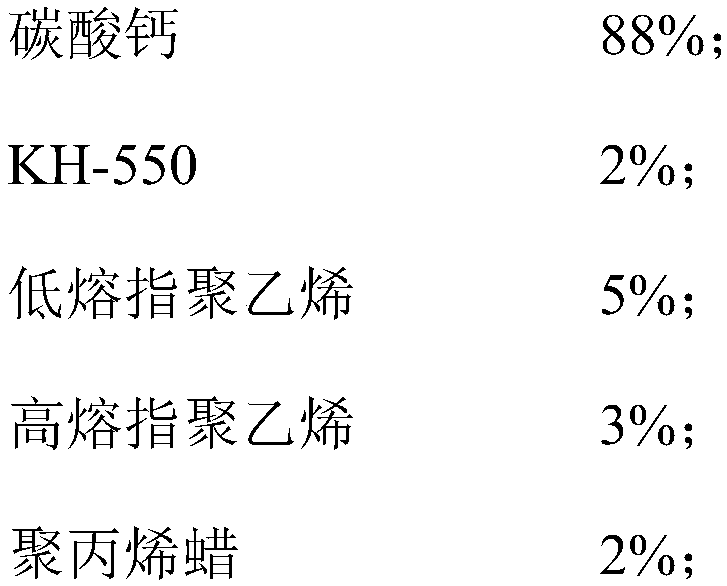

[0058] This embodiment provides a kind of filler masterbatch, comprises the component of following percentage by weight:

[0059]

[0060] Wherein, the particle size of the filler is 2-10 μm, the melt index of low-melt polyethylene is 2 g / 10 min, and the melt index of high-melt polyethylene is 30 g / 10 min.

[0061] The preparation method of above-mentioned filling masterbatch is as follows:

[0062] (1) Put the filler into the high mixer, heat up to 120°C, stir at a speed of 1200r / min for 10 minutes, then add a coupling agent, keep the speed, and mix for 6 minutes to obtain a modified filler;

[0063] (2) Add remaining components to the modified filler obtained in step (1), keep the rotating speed of 1200r / min, and continue mixing for 10min;

[0064] (3) Add the mixture obtained in step (2) into a twin-screw extruder, set the head temperature to 180°C, the temperature of the extrusion section to 180°C, and the screw speed to 800r / min, and extrude to obtain a filler materi...

Embodiment 3

[0066] This embodiment provides a kind of filler masterbatch, comprises the component of following percentage by weight:

[0067]

[0068] Wherein, the particle size of the filler is 2-10 μm, the melt index of low-melt polyethylene is 1.5 g / 10min, and the melt index of high-melt polyethylene is 20 g / 10min.

[0069] The preparation method of above-mentioned filling masterbatch is as follows:

[0070] (1) Put the filler into the high mixer, heat up to 115°C, stir at a speed of 1300r / min for 8 minutes, then add a coupling agent, keep the speed, and mix for 5 minutes to obtain a modified filler;

[0071] (2) Add remaining components to the modified filler obtained in step (1), keep the rotating speed of 1300r / min, and continue mixing for 8min;

[0072] (3) Add the mixture obtained in step (2) into a twin-screw extruder, set the head temperature to 170°C, the temperature of the extrusion section to 170°C, and the screw speed to 500r / min, and extrude to obtain a filler material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com