Method for preventing nodular cast iron roller core from loosening

A technology of nodular cast iron and rolls, applied in the field of metallurgy, can solve the problems affecting the rigidity and strength of the rolls, complex and changeable solidification sequence of molten iron, complex temperature fields and solidification characteristics, etc., to eliminate the abnormal phenomenon of broken rolls and eliminate flaw detection. The effect of back wave attenuation, significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

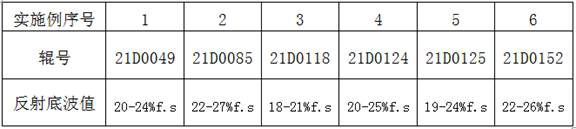

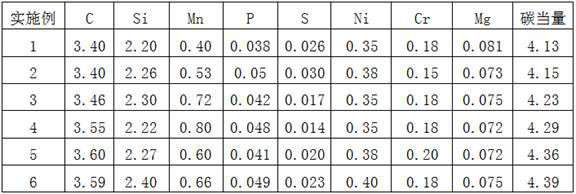

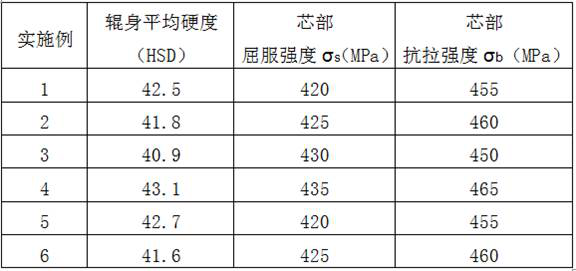

[0035] This embodiment is a centrifugal composite roll with a specification of Φ800mm*1880mm, and the chemical composition and mass percentage of the core ductile iron material are shown in Table 2.

[0036]The production process for preventing the loose core of the ductile iron roll in this embodiment includes smelting, molten iron deterioration treatment, pouring, heat preservation, and heat treatment processes. The specific process steps are as follows:

[0037] (1) Melting process: According to the material components required by the rolls, smelting is carried out in an intermediate frequency induction furnace. Sodium carbonate desulfurizer is used for desulfurization, the dosage is 6.3kg / t molten iron, the sulfur content of molten iron is controlled to 0.026%, and 23# rare earth ferrosilicon alloy (0.14% by weight of molten iron) is added to purify molten iron, reduce silicon content and residual Magnesium amount. The melting temperature is 1474℃, and it is sedated for 3...

Embodiment 2

[0045] This embodiment is a centrifugal composite roll with a specification of Φ820mm*2100mm, and the chemical composition and mass percentage of the core ductile iron material are shown in Table 2.

[0046] The production process for preventing the loose core of the ductile iron roll in this embodiment includes smelting, molten iron deterioration treatment, pouring, heat preservation, and heat treatment processes. The specific process steps are as follows:

[0047] (1) Melting process: According to the material components required by the rolls, smelting is carried out in an intermediate frequency induction furnace. Sodium carbonate desulfurizer is used for desulfurization, the dosage is 5.0kg / t molten iron, the sulfur content of molten iron is controlled to 0.030%, and 23# rare earth ferrosilicon alloy (0.18% by weight of molten iron) is added to purify molten iron, reduce silicon content and residual Magnesium amount. The melting temperature is 1479℃, and it is sedated for ...

Embodiment 3

[0055] This embodiment is a centrifugal composite roll with a specification of Φ1050mm*2500mm, and the chemical composition and mass percentage of the core ductile iron material are shown in Table 2.

[0056] The production process for preventing the loose core of the ductile iron roll in this embodiment includes smelting, molten iron deterioration treatment, pouring, heat preservation, and heat treatment processes. The specific process steps are as follows:

[0057] (1) Melting process: According to the material components required by the rolls, smelting is carried out in an intermediate frequency induction furnace. Sodium carbonate desulfurizer is used for desulfurization, the dosage is 9.1kg / t molten iron, the sulfur content of molten iron is controlled to 0.017%, and 23# rare earth ferrosilicon alloy (0.13% by weight of molten iron) is added to purify molten iron, reduce silicon content and residual Magnesium amount. The melting temperature is 1476℃, and it is sedated for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com