Patents

Literature

73 results about "Annealing (metallurgy)" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In metallurgy and materials science, annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for a suitable amount of time, and then cooling.

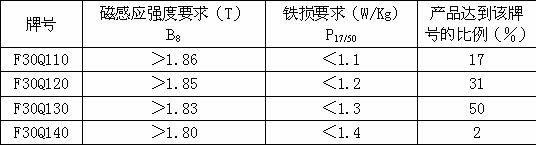

Full production process of low-temperature oriented silicon steel

The invention provides a full production process of a low-temperature oriented silicon steel, relates to the technical field of metallurgy, and aims at solving the technical problems of high slab heating temperature, short service life of a heating furnace, energy waste, low converter smelting designation hit rate of the oriented silicon steel due to narrow range of requirements on C and other chemical element contents, and the like of traditional cold-rolled oriented silicon steel. The full production process of the low-temperature oriented silicon steel comprises the following steps: molteniron pre-treatment, converter treatment, RH (Ruhrstahl-Heraeus) vacuum treatment, slab continuous casting, hot charging and hot delivery, slab heating, hot rolling, primary cold rolling, primary decarbonization and annealing, secondary cold rolling, low-temperature recovery annealing and magnesium oxide coating, high-temperature cover furnace annealing, stretching and insulating layer coating, aswell as slitting, packaging and storing to finally produce the low-temperature oriented silicon steel.

Owner:JIANGYOU FENGWEI NEW MATERIAL +2

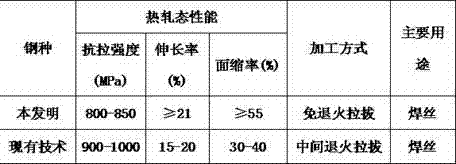

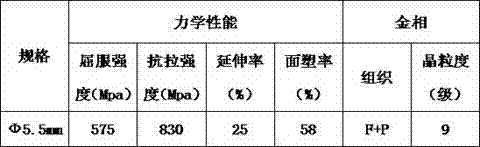

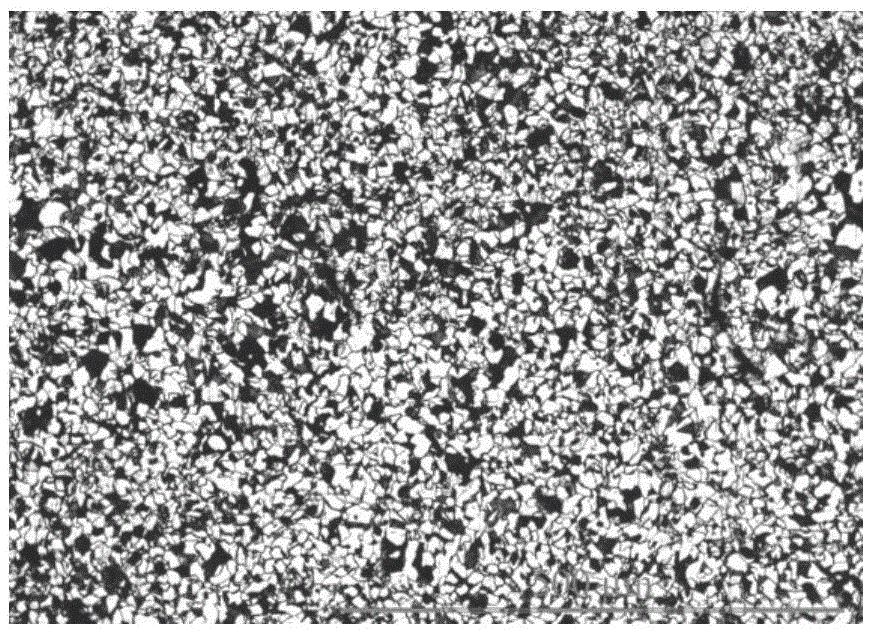

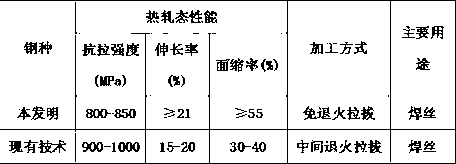

Steel wire rod for annealing-free solder wire and production process thereof

ActiveCN102513725AChemically stableImprove plastic indexWelding/cutting media/materialsSoldering mediaWire rodMechanical property

The invention belongs to the metallurgy field and relates to a production process of a steel wire rod, particularly the steel wire rod for an annealing-free solder wire and a production process of the steel wire rod, wherein the steel wire rod comprises elements in weight percentage as follows: 0.07-0.1% of C, 1.25-1.4% of Mn, 0.4-0.6% of Si, less than or equal to 0.02% of P, less than or equal to 0.02% of S, 0.2-0.55% of Mo, 0.5-1.0% of Ni, less than or equal to 0.2% of Cu, less than or equal to 0.2% of Ti and less than or equal to 0.1% of Al with the balance of Fe. The process comprises steps of detecting a blank, heating the steel blank, descaling by high-pressure water, roughly and intermediately rolling, pre-finishing rolling, cooling in a first section by water, finishing rolling bya unit, cooling in a second section by water, diameter reducing and sizing rolling, cooling in a third section by water, spinning, cooling by wind, finishing and delivering to a warehouse. The methodof the invention employs a rolling-controlled and cooling-controlled process to execute process control of the steel wire rod of the solder wire to obtain an F+P tissue appropriate to draw, and has advantages as follows: good comprehensive mechanical property is realized, a solder wire factory can avoid annealing and perform multi-pass drawing without wire breakage, the production efficiency is greatly increased and the production cost is reduced at the same time.

Owner:NANJING IRON & STEEL CO LTD

Low-alloy high-strength large-diameter thick-walled seamless steel pipe and manufacturing method thereof

ActiveCN105586532AGuaranteed mechanical performance indexEnough deformationSteelmakingRefining (metallurgy)

The invention relates to the technical field of metallurgy, and provides a low-alloy high-strength large-diameter thick-walled seamless steel pipe and a manufacturing method thereof. The method comprises the steps of steelmaking, wherein smelting and refining are performed to obtain target molten steel, and ingot casting is performed on the target molten steel to obtain static ingots; pipe billet forging, wherein forging and annealing are performed on the static ingots to obtain pipe billets; pipe rolling, wherein the pipe billets are heated inside an annular furnace at the temperature of 1230-1270 DEG C, holes are formed after heating is performed, and rolling forming is performed through a pipe mill; normalizing heat treatment, wherein normalizing heat treatment is performed on rolled and formed steel pipes, the normalizing furnace discharge pipe temperature is 920-940 DEG C in the normalizing heat treatment process, and the cooling mode is the air-cooling or air-cooling and mist spraying mode. The steel pipe produced through the manufacturing method is uniform in texture, good in performance and capable of achieving high-strength and excellent subzero 20 DEG C low-temperature toughness, in addition, by adopting the simplified production technology, the production efficiency can be improved, the production cost can be lowered, and meanwhile the steel pipe has the good using safety due to the low yield ratio.

Owner:PANGANG GROUP CHENGDU STEEL & VANADIUM

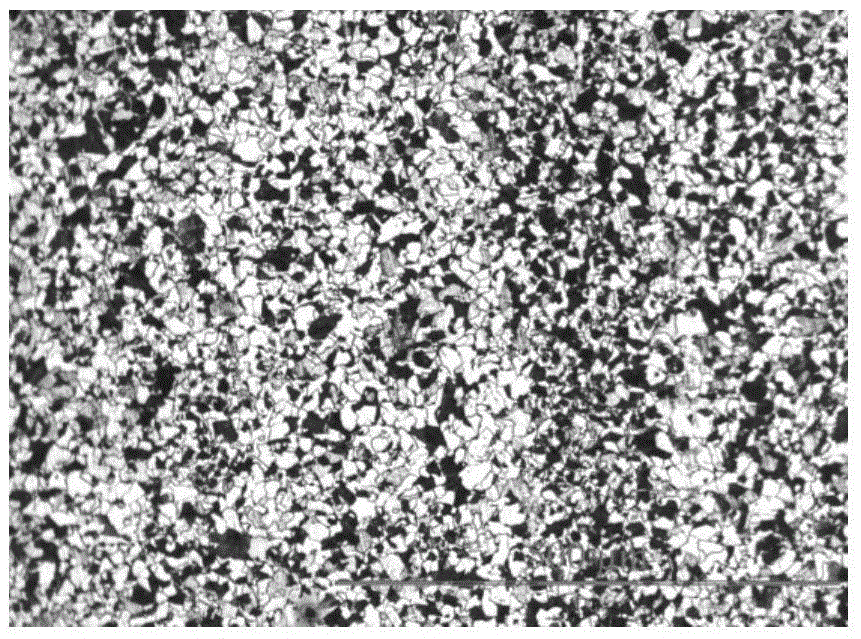

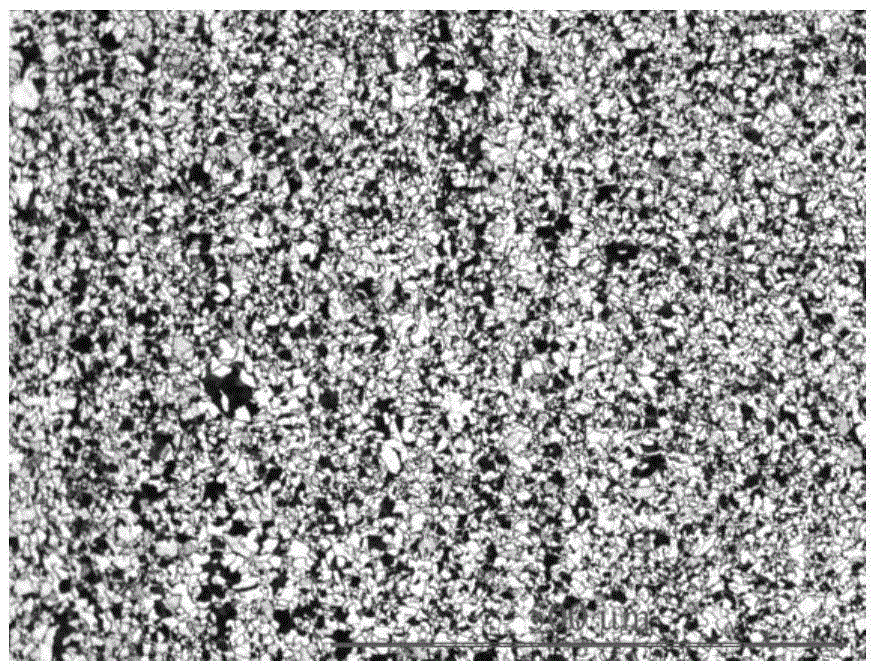

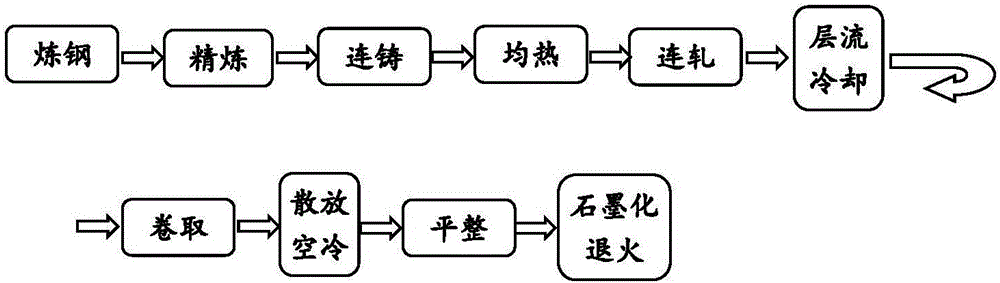

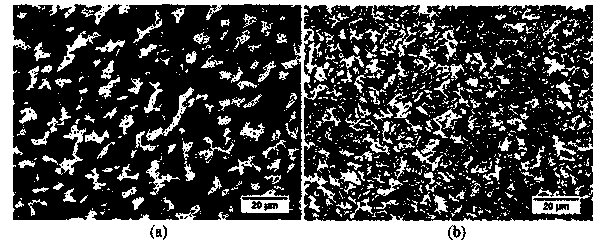

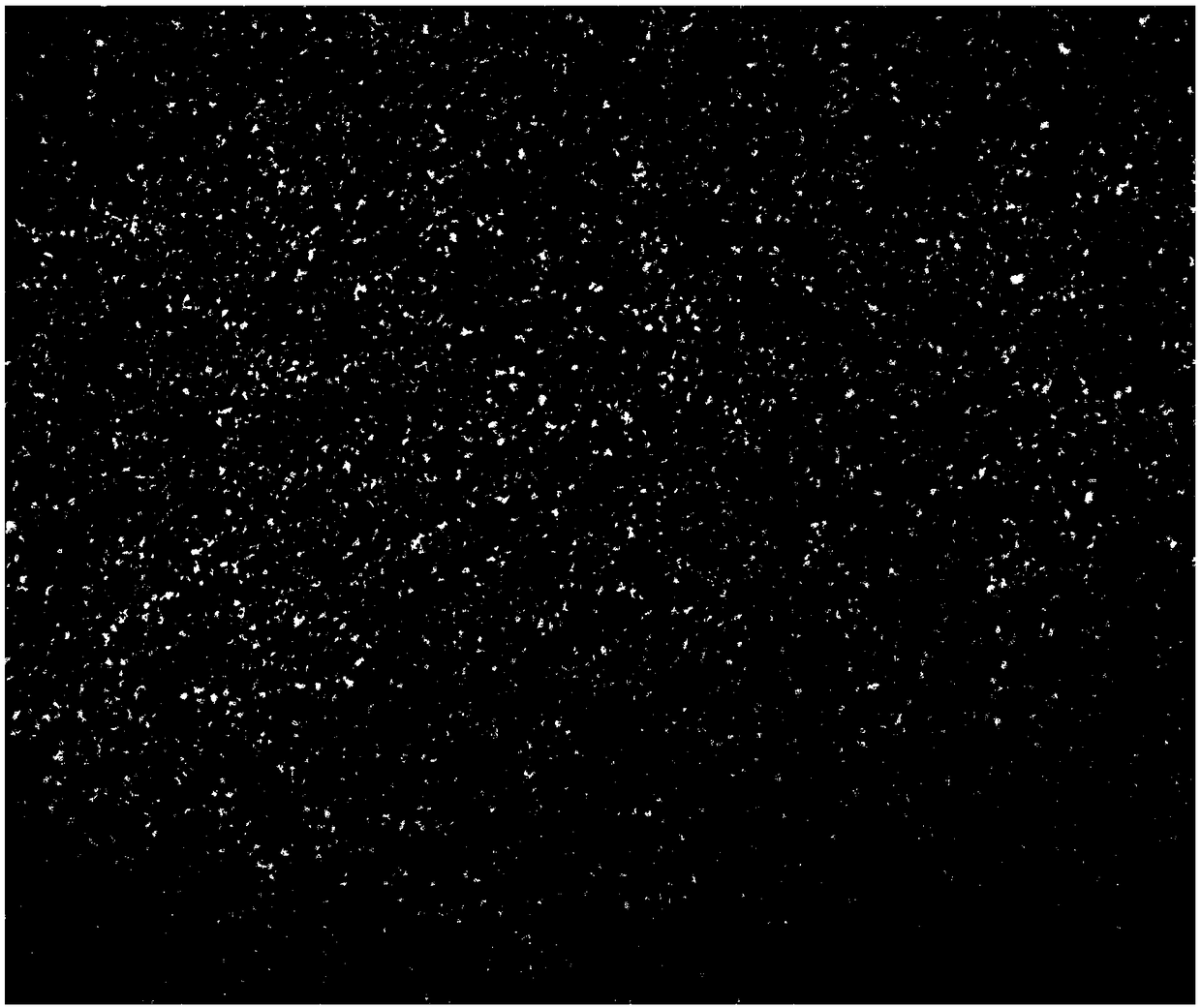

Preparation method of graphitizing hot rolled steel plate

The invention discloses a preparation method of a graphitizing hot rolled steel plate, which belongs to the technical field of metallurgy. The method mainly comprises the steps of steelmaking, refining, continuous casting, heating, hot continuous rolling, laminar cooling, coiling, steel coil spreading and air cooling, leveling and rolling, graphitizing annealing and the like. In order to increase the graphitizing rate and promote a graphitizing process, a pulsed magnet field is applied in a graphitizing annealing process, the magnetic field intensity is 10000 to 30000 A / m, and the magnetic field frequency is 20 to 100 Hz. Within the graphitizing time of 3 to 6 hours, the graphitizing rate can reach more than 90%, the diameter of graphite is 3 to 6 mum, the graphite is spherical or nearly spherical and is uniformly distributed, and the diameter range of ferrite grains is 20 to 30 mum. According to the structural features, the steel plate, especially the steel plate with high carbon content, has low hardness and high plasticity, therefore, the steel plate has good stamping and forming performance, and the preparation method is favorable for enlarging the application range of medium and high carbon steel plates in a stamping and forming process of components and parts in complex shapes.

Owner:UNIV OF SCI & TECH BEIJING

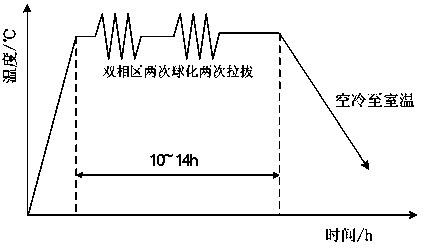

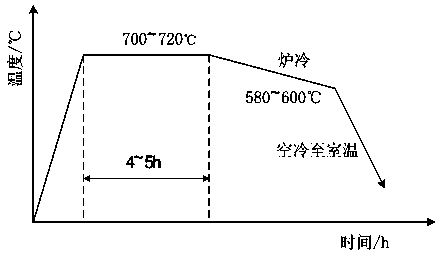

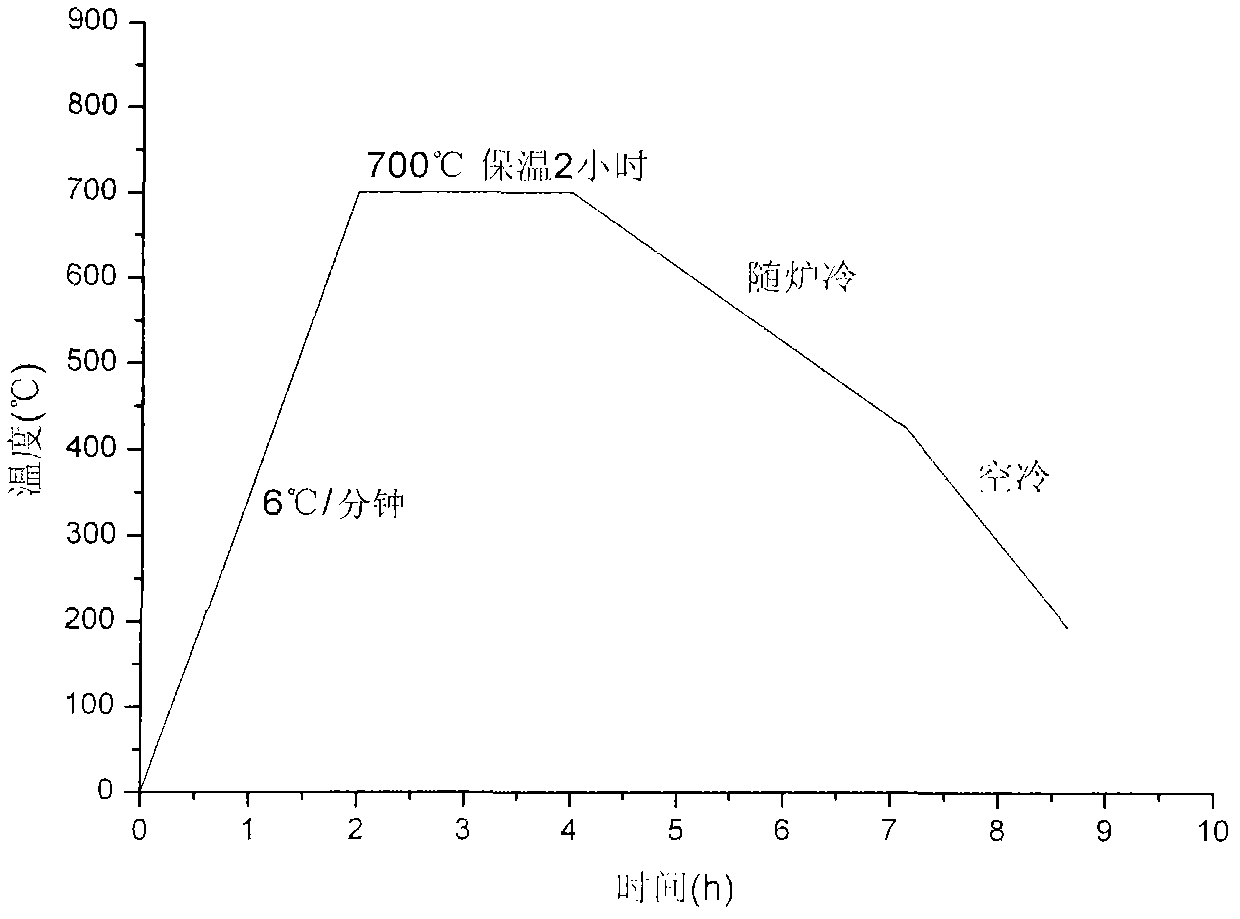

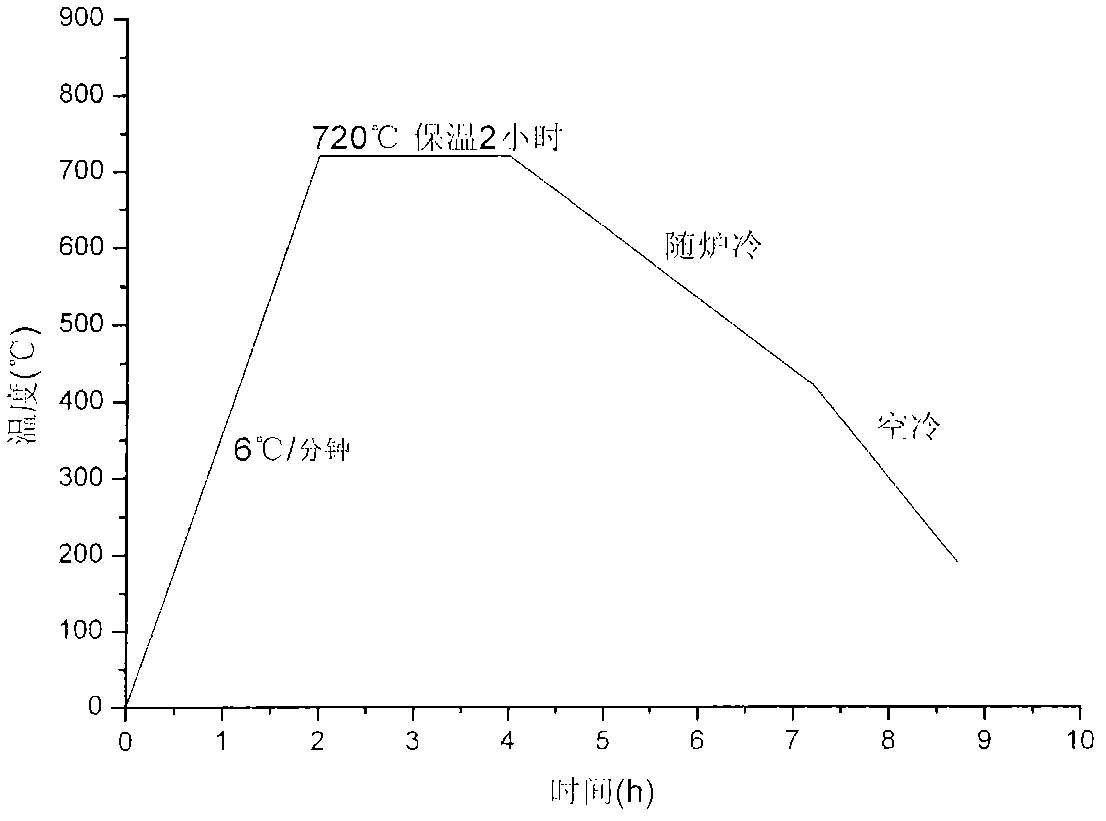

Spheroidizing annealing method for Cr and Mo steel with sheet type microstructure

The invention belongs to the technical field of metallurgy, and in particular relates to a spheroidizing annealing method for Cr and Mo steel with a sheet type microstructure. The spheroidizing annealing method comprises the steps of putting a Cr and Mo steel rolled product sample into a heating furnace, heating to 700-720 DEG C, preserving the temperature for 4-5 hours, then performing furnace cooling to 580-600 DEG C, taking out the Cr and Mo steel rolled product from the furnace, and cooling to room temperature, wherein the microhardness of the Cr and Mo steel rolled product subjected to spheroidizing annealing is 162.20-175.35HV, and the microstructure of the Cr and Mo steel rolled product consists of granular carbides dispersed on a ferritic matrix; the granular carbides have spheroidized structures in the level 5-6. According to the method, sub-medium temperature is preserved for certain time, and then the furnace cooling time is controlled, so that spheroidizing-annealed steel with high performance is obtained. The high preserved temperature is lower than the preserved temperature of the original technology, and the heat preservation time is shortened by almost three times, so that the energy consumption is obviously reduced, and the spheroidizing annealing efficiency is improved; the hardness of the steel subjected to the spheroidizing annealing technology is obviously reduced, the structure of a spheroidal pearlite is dispersive and fine, and the spheroidizing rate is high; the Cr and Mo steel subjected to spheroidizing annealing is high in cold heading performance and has a good application prospect.

Owner:NORTHEASTERN UNIV

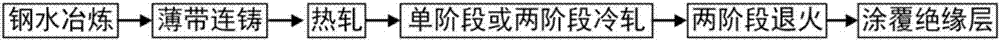

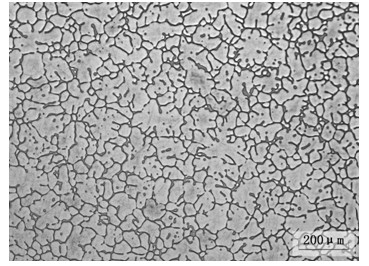

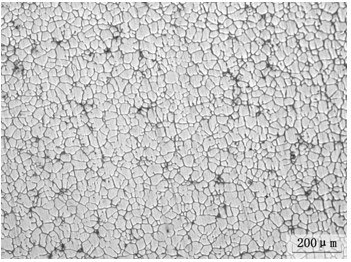

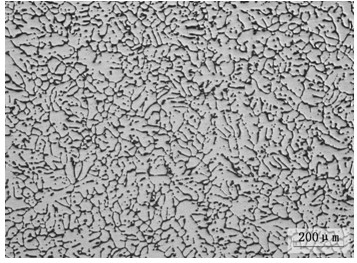

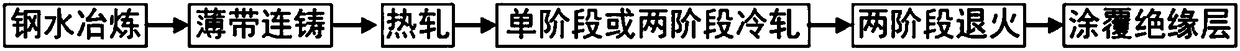

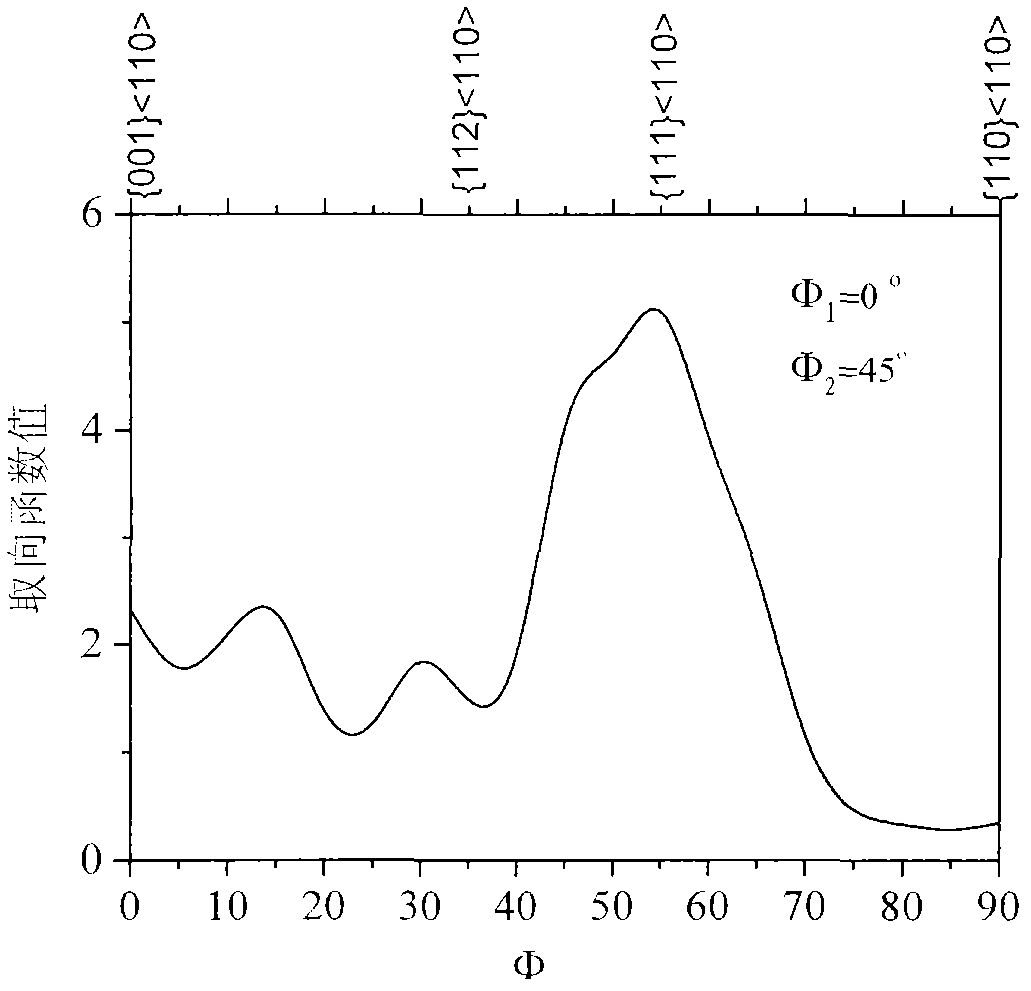

Method for preparing developed {100} texture non-oriented silicon steel thin belt based on thin belt continuous casting

The invention belongs to the technical field of metallurgy and particularly relates to a method for preparing a developed {100} texture non-oriented silicon steel thin belt based on thin belt continuous casting. The method is performed according to the following steps that firstly, molten steel is smelted according to the set components, and the components comprise, by weight percentage, 0.01-0.05% of C, 1.5-3.0% of Si, 0.2-0.3% of Mn, smaller than or equal to 0.005% of Al, 0.01-0.04% of V, 0.002-0.005% of S and the balance Fe and inevitable impurities; secondly, a cast belt is formed after the thin belt continuous casting process; thirdly, hot rolling is performed under the inert atmosphere condition; fourthly, scale is removed in a pickling manner, and then single-stage or two-stage cold rolling is performed; and sixthly, two-stage re-crystallization annealing is performed, an insulating coating is coated and dried, and high-performance non-oriented silicon steel is obtained. According to the method for preparing the developed {100} texture non-oriented silicon steel thin belt based on thin belt continuous casting, on the basis of partially utilizing the inherited effect of a {100} texture in an initial solidifying structure, the driving force is provided by means of a subsequent decarburization phase change, it is promoted that a developed {100} texture is formed in a finished product plate, and therefore the high-performance non-oriented silicon steel is obtained.

Owner:NORTHEASTERN UNIV

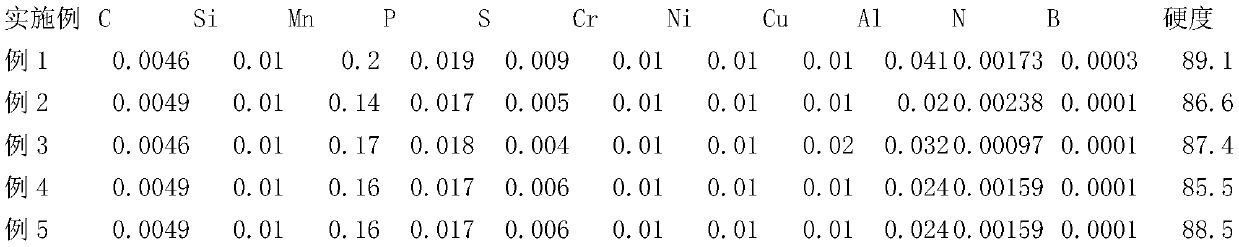

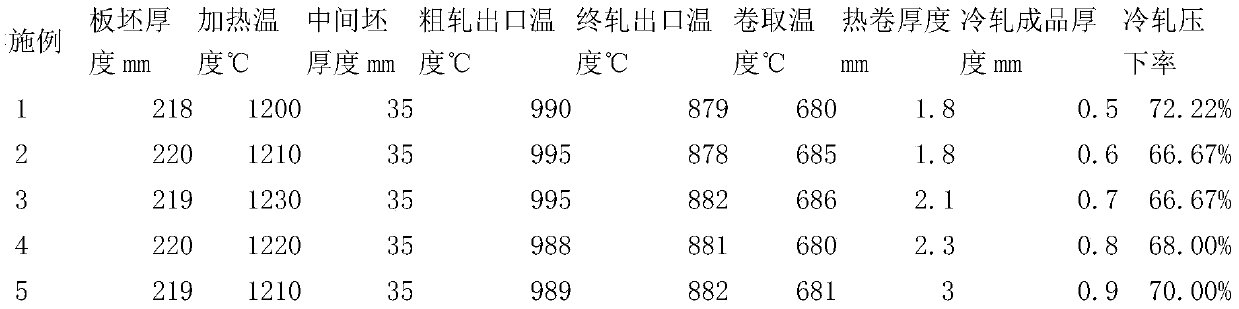

Manufacturing process of automobile low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation

The invention relates to a manufacturing process of an automobile low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation, and belongs to the technical field of metallurgy. The technical scheme of the invention is as follows: the manufacturing process comprises a smelting process, a hot rolling process and a cold rolling process, wherein in the cold rolling process, the annealing temperature control is as follows: the soaking temperature is 840-860 DEG C, the slow cooling temperature is 670-700 DEG C, the rapid cooling temperature is 410-430 DEG C, and the aging finish temperature is 350-370 DEG C; and according to strip steel of different thickness specifications, different annealing tape speed target values are planed: the tape speed of the strip steel of 0.8mm specification is 205m / min, the tape speed of the strip steel of 1.0mm specification is 165m / min, the tape speed of the strip steel of 1.2mm specification is 137m / min, the tape speed of the strip steel of 1.5mm specification is 110m / min, the tape speed of the strip steel of 1.8mm specification is 92m / min, the tape speed of the strip steel of 2.0mm specification is 82m / min, and the tape speed of the strip steel of 2.5mm specification is 66m / min. The manufacturing process of the automobile low-alloy high-strength steel cold-rolled sheet with the high product of strength and elongation disclosed by the invention has the beneficial effects that the low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation is produced by modifying the chemical elements and optimizing the hot rolling and cold rolling processes so that the product of strength and elongation of the low-alloy high-strength steel cold-rolled sheet reach 15GPa%, and simultaneously the quality is stably controlled.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Extra-deep drawing IF steel and annealing process thereof

InactiveCN102586679AIncrease productivityGood product performanceFurnace typesHeat treatment furnacesChemical compositionDeep drawing

Extra-deep drawing IF steel and an annealing process thereof belong to the technical field of metallurgy. The extra-deep drawing IF steel is characterized that the chemical components and the weight percentage content should conform to: C<=0.008%, Si<=0.015%, Mn<=0.15, P<=0.01%, S<=0.005%, Alt>=0.015%, Ti=0.01-0.07%, Nb=0.01-0.02%, and the balance Fe and trace impurities which cannot be detected. In the annealing process, continuous heating is adopted, the heating rate is 4-8 DEG C / min, the intermediate annealing temperature is 700 DEG C to 750 DEG C, the heat-preserving time is 1-50h, and cooling is performed along with a furnace. The second annealing temperature is 700 DEG C to 750 DEG, the heat-preserving time is 1-10h, and cooling is performed along with the furnace to 400 DEG C-450 DEG C, and discharging and air cooling are performed. The IF steel having excellent deep drawing performance can be obtained by the method, an IF steel sample processed by the process has excellent deep drawing performance, the tensile strength is 290-320MPa, the yield strength is 95-145MPa, the elongation is 45-65%, the plastic strain ratio n is not smaller than 0.27, and the plastic strain ratio r is not smaller than 2.0.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

Magnesium alloy with good millability and preparation method of magnesium alloy plate

The invention belongs to the technical fields of metal materials and metallurgy and particularly relates to a magnesium alloy with good millability and a preparation method of a magnesium alloy plate. The magnesium alloy with good millability is an Mg-Zn-Cu magnesium alloy and comprises the following components by weight percent: 1.0%-5.5% of Zn, 1.0%-4.0% of Cu, 0-1.0% of Mn or Zr, 0-1.0% of Y, Nd, Gd, Ce or MM, less than 0.005% of impurity Fe and the balance of Mg. The preparation method of the magnesium alloy plate comprises the following steps: preheating a magnesium alloy sample obtained through smelting and casting to 300-450 DEG C, and keeping the temperature for 2h; rolling at a roller temperature ranging from the room temperature to 200 DEG C, wherein the pass reduction rate is 10%-65% and the total reduction rate is 80%-90%; and thus obtaining the Mg-Zn-Cu magnesium alloy plate without edge cracks. The Mg-Zn-Cu magnesium alloy has no edge cracks in the hot rolling process; and if the rolling temperature is higher, the hot-rolled plate without edge cracks can be obtained under the condition that the roller is not heated and intermediate annealing is not performed to the plate.

Owner:NORTHEASTERN UNIV

A method for preparing non-oriented silicon steel thin strip with developed {100} plane texture based on thin strip continuous casting

The invention belongs to the field of metallurgical technology, and particularly relates to a method for preparing non-oriented silicon steel thin strips with developed {100} surface texture based on continuous casting of thin strips. Follow the following steps: (1) Smelt molten steel according to the set composition. Its composition by weight is: C 0.01~0.05%, Si 1.5~3.0%, Mn 0.2~0.3%, Al≤0.005%, V 0.01~0.04% , S 0.002~0.005%, the balance is Fe and inevitable impurities; (2) Cast strip is formed after thin strip continuous casting process; (3) Hot rolling under inert atmosphere conditions; (4) Pickling to remove oxide scale, Then perform single-stage or two-stage cold rolling; (6) two-stage recrystallization annealing, coating with insulating coating and drying to obtain high-performance non-oriented silicon steel. The present invention provides a method for preparing non-oriented silicon steel thin strips with developed {100} surface texture based on thin strip continuous casting. On the basis of partially utilizing the genetic effect of {100} texture in the initial solidification structure, it provides driving force through subsequent decarburization phase transformation. The force promotes the formation of a developed {100} plane texture in the finished plate, thereby obtaining high-performance non-oriented silicon steel.

Owner:NORTHEASTERN UNIV LIAONING

Hot-rolled high-carbon steel production method

InactiveCN111100977AImproved cold working propertiesImprove toughnessTemperature control deviceFurnace typesLaminar coolingHigh pressure water

The invention belongs to the field of a metallurgy technology, and particularly relates to a hot-rolled high-carbon steel production method. The hot-rolled high-carbon steel production method comprises the processes of extracting vanadium by a converter, smelting through the converter, refining through an LF (ladle furnace), carrying out slab continuous casting, heating a slab, descaling through high pressure water, controlled rolling, laminarly cooling, and coiling. The high-carbon steel is prepared from the chemical components in percentage by weight: 0.47 to 0.55 percent of C, less than orequal to 0.40 percent of Si, 0.80 to 1.0 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.015 percent of S, less than or equal to 0.006 percent of N, and the balance Feand inevitable impurity elements. According to the hot-rolled high-carbon steel production method provided by the invention, through the reasonable heating, rolling and coiling processes, in the obtained high-carbon steel, a pearlite structure is fine, the thickness of a decarburized layer is low, a favorable cold processing performance is realized, the annealing-free treatment can be realized, the processing cost is reduced, and a better economic benefit is achieved.

Owner:HEBEI IRON AND STEEL

IF steel containing niobium and titanium for advanced automobile and annealing process

InactiveCN102517498AIncrease productivityImprove performanceFurnace typesHeat treatment furnacesTest sampleNiobium

The invention relates to IF steel containing niobium and titanium for an advanced automobile and an annealing process, which belong to the technical field of metallurgy. The IF steel containing the niobium and the titanium for the advanced automobile and the annealing process are characterized in that continuous heating is adopted in the annealing procedure, the heating rate is 4 to 8 DEG C / minute, the annealing temperature is 700 to 750 DEG C, the heat-preservation time is 1 to 10 hours, and the material is cooled to 400 to 450 DEG C along with a furnace and is taken out of the furnace for air cooling. By the mode, IF steel with excellent deep drawability can be obtained; a test sample of the IF steel after being processed by the process has excellent deep drawability; in a longitudinal direction, the tensile strength reaches 290 to 330MPa, the yield strength is 125 to 155MPa, and the elongation rate is 40 to 55 percent; in a transverse direction, the tensile strength reaches 310 to 340MPa, the yield strength is 120 to 190MPa, and the elongation rate is 40 to 55 percent; and the plane anisotropy delta r of the strain hardening index is not greater than 0.25.

Owner:INNER MONGOLIA BAOTOU STEEL UNION

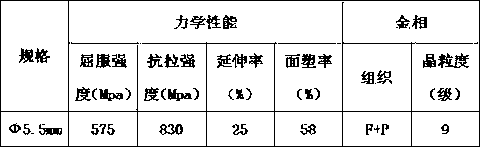

CRB600H prepared without low-temperature annealing treatment, and rolling process thereof

ActiveCN108286022AIncrease the area reduction rate of the rolled pieceIncrease the number of openingsWork cooling devicesMetal rolling arrangementsWire rodProduction line

The invention discloses CRB600H prepared without low-temperature annealing treatment, and a rolling process thereof, and relates to the technical field of metallurgy. The CRB600H comprises the following components in percentage by weight: 0.18%-0.25% of C, 0.35%-0.45% of Si, 0.5%-1.2% of Mn, 0.01%-0.04% of P, 0.01%-0.02% of S, 0.003%-0.007% of N, 0.1%-0.5% of Cr, 0.020%-0.040% of V, and the balance Fe and inevitable impurities. The rolling process for the CRB600H mainly comprises the following steps: base metal preparation, loading for round wire rods onto a production line, mechanical descaling, lubrication, pre-rolling ribbing and drawing, stress relief, and winding. The CRB600H prepared without the low-temperature annealing treatment does not need to be subjected to the low-temperatureannealing treatment, and the extensibility of the CRB600H is excellent while the yield strength and the tensile strength of the CRB600H reach the standards. The rolling process for the CRB600H prepared without the low-temperature annealing treatment is simple, saves the production cost, avoids the resource waste, achieves energy conservation and environment protection, and increases the economic benefits.

Owner:ANHUI BRC & MA STEEL WELDMESH

Production method of fused AZS hanging wall brick

The invention discloses a production method of a fused AZS (Al2O3-ZrO2-SiO2) hanging wall brick. By shifting a lost foam technology used for the metallurgy industry to the fusion-cast refractory industry, the invention realizes a production method of a fused AZS special-shaped product. The method comprises the steps of: (1) foam model making; (2) cartonning of the model and sand filling; (3) batching; (4) electric furnace casting; (5) insulation and annealing; and (6) cold working. The inside of the model is a ribbed hollow structure, which ensures the strength and dimension of the model and simultaneously reduces model volume, thus enhancing the casting effect. The fused AZS hanging wall brick produced in the invention is free of crack in the whole body, has regularity up to the standard requirement, and has a tolerance at the neck of -0.3-0.5mm, thus being in line with the profile requirement of mother brick equipment and acceptance criteria. Characterized by high internal densification degree, obviously reduced crack generation probability, good regularity, accurately controlled dimension, less unnecessary processing loss, reduced processing, cutting, polishing and production cost, and all physical and chemical indexes kept within a standard control scope, the fused AZS hanging wall brick produced in the invention can be applied in the glass industry.

Owner:郑州东方安彩耐火材料有限公司

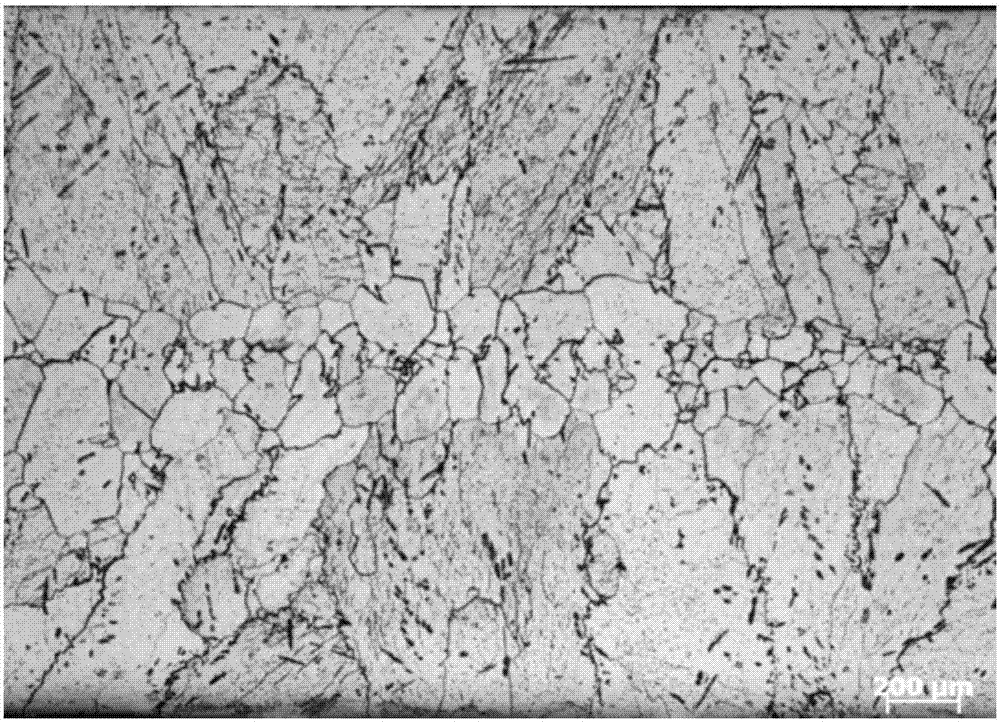

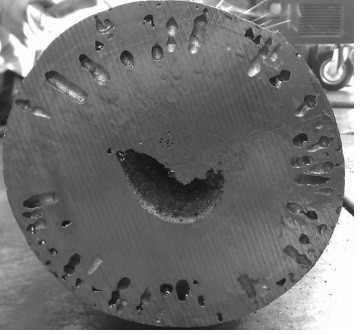

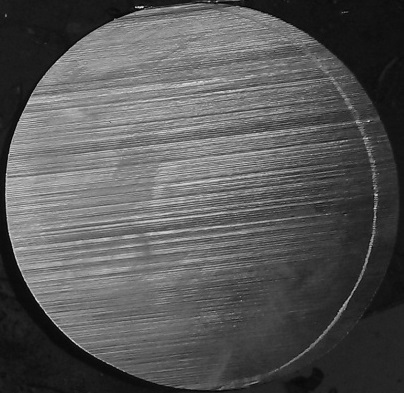

Production method of producing chromium-molybdenum steel plate made by steel ingot direct rolling molding

InactiveCN111793742AHeating evenlyAvoid internal cold and external heatFurnace typesWork cleaning devicesIngotUltimate tensile strength

The invention provides a production method of producing a chromium-molybdenum steel plate made by steel ingot direct rolling molding, and belongs to the technical field of metallurgy. The method comprises the processes of steel ingot pouring, annealing, heating, rolling and hot treatment; and the heating process comprises the steps of: (1) distressing step heating: a steel ingot is subjected to heat preservation at 680 to 730 DEG C for 6 to 7h, and then subjected to heat preservation at 890 to 930 DEG C for 2 to 3h; (2) low-temperature long-time heat preservation: the steel ingot is heated to1240 to 1280 DEG C and subjected to heat preservation for 15 to 18h, and the furnace pressure is controlled at 0 to 3MPa; and (3) before-tapping turn-over: the steel ingot is turned over and heated for 4-6h before being drawn out of a furnace. The steel plate produced is 15 to 35t in weight, the superficial quality of the steel plate is good, the grinding amount is low, and the flaw detection qualification rate is higher than or equal to 97%; and after high-temperature long-time die welding treatment, the high-temperature tensile yield strength of the steel plate at 454 DEG C is higher than orequal to 338MPa and the tensile strength is higher than or equal to 461MPa.

Owner:WUYANG IRON & STEEL

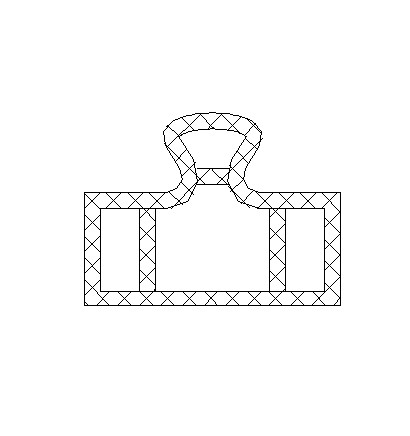

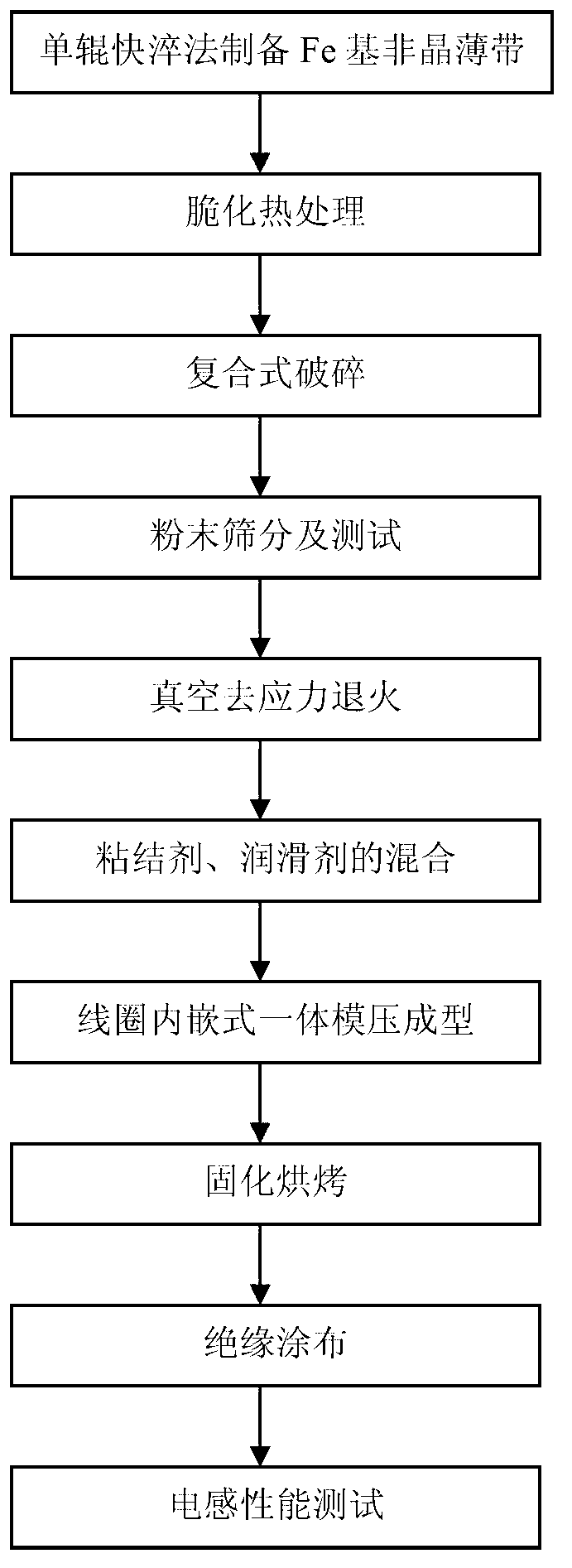

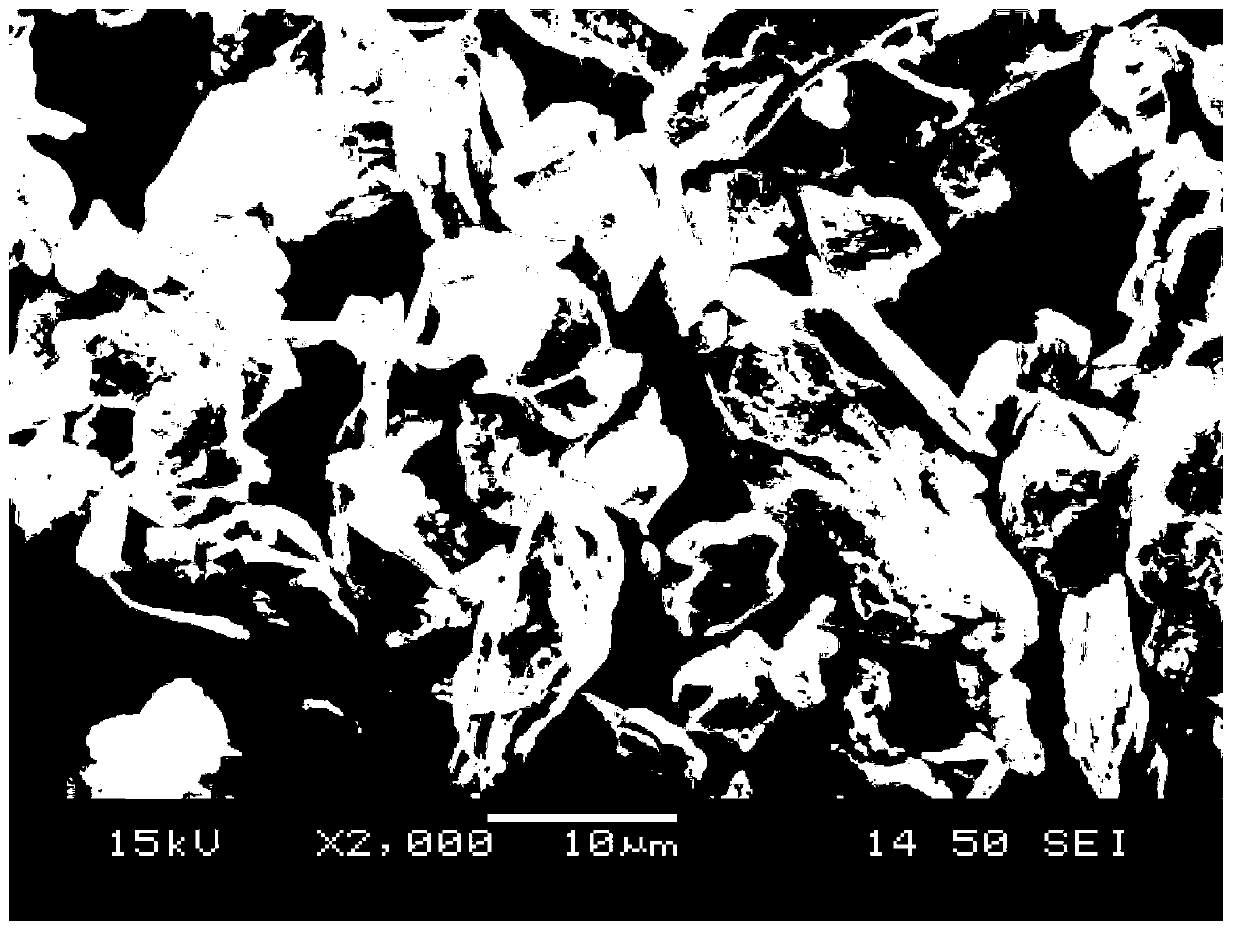

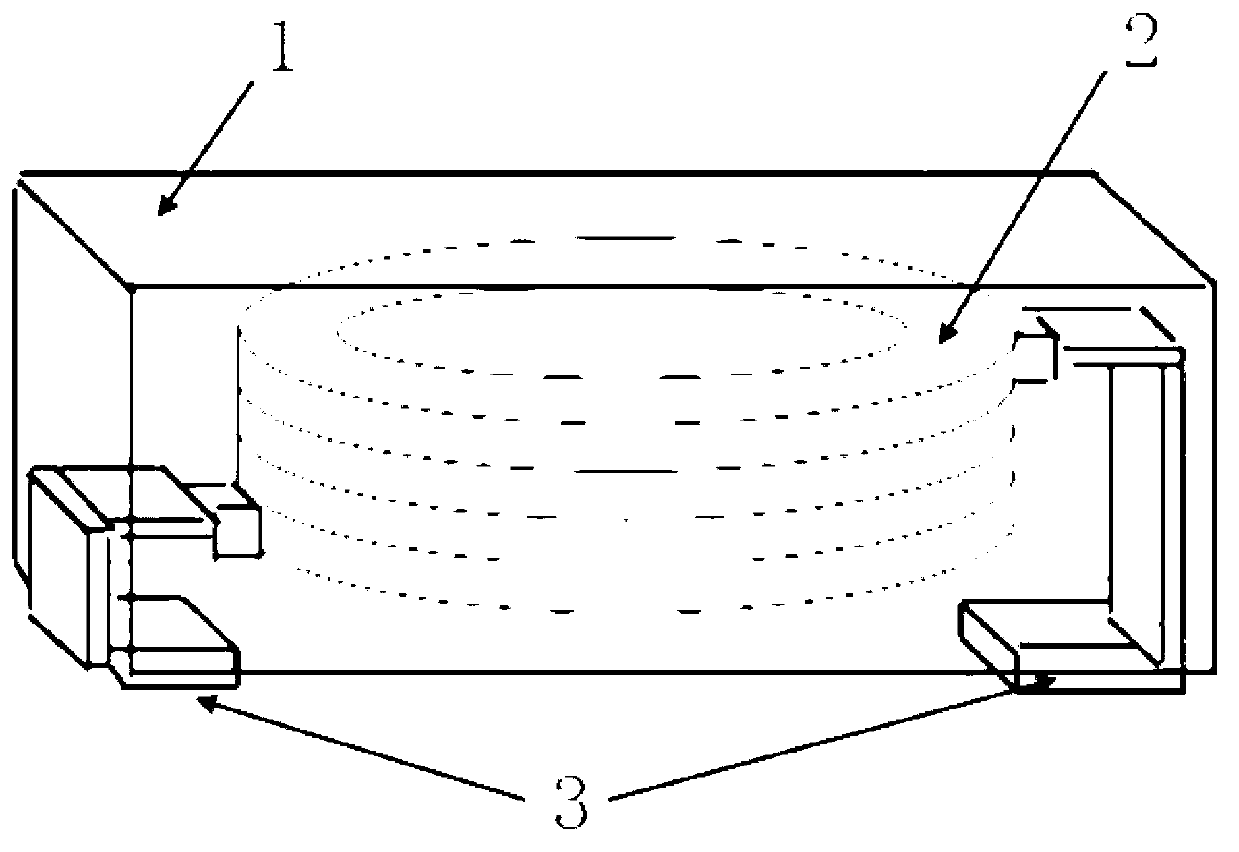

Iron-based amorphous powder and method for preparing coil-embedded integral-forming inductor

InactiveCN103273068AImprove efficiencyNot destroyedInductances/transformers/magnets manufactureCompression moldingInductor

The invention belongs to the field of powder metallurgy, and particularly relates to iron-based amorphous powder for preparing a coil-embedded integral-forming inductor. The inductor is prepared through the following steps that an iron-based amorphous thin belt obtained through a single-roller rapid quenching method is preheated, and is broken through a mechanical grinding and airflow grinding combined method, amorphous powder is screened in order to obtain the superfine iron-based amorphous powder, stress relieving annealing is conducted on the superfine amorphous powder in vacuum, then the superfine amorphous powder is mixed with a binding agent to conduct insulating coating granulating, coated powder after being granulated and a coil are formed in a compression molding mode to obtain the coil-embedded integral-forming inductor. The superfine iron-based amorphous powder and the coil-embedded integral-forming inductor with an excellent temperature rise character can be prepared through the method.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

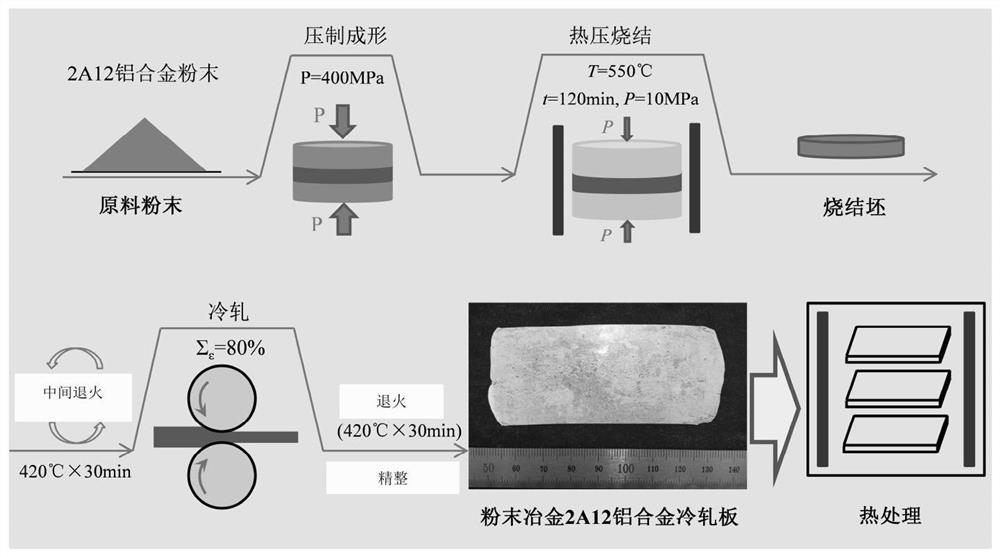

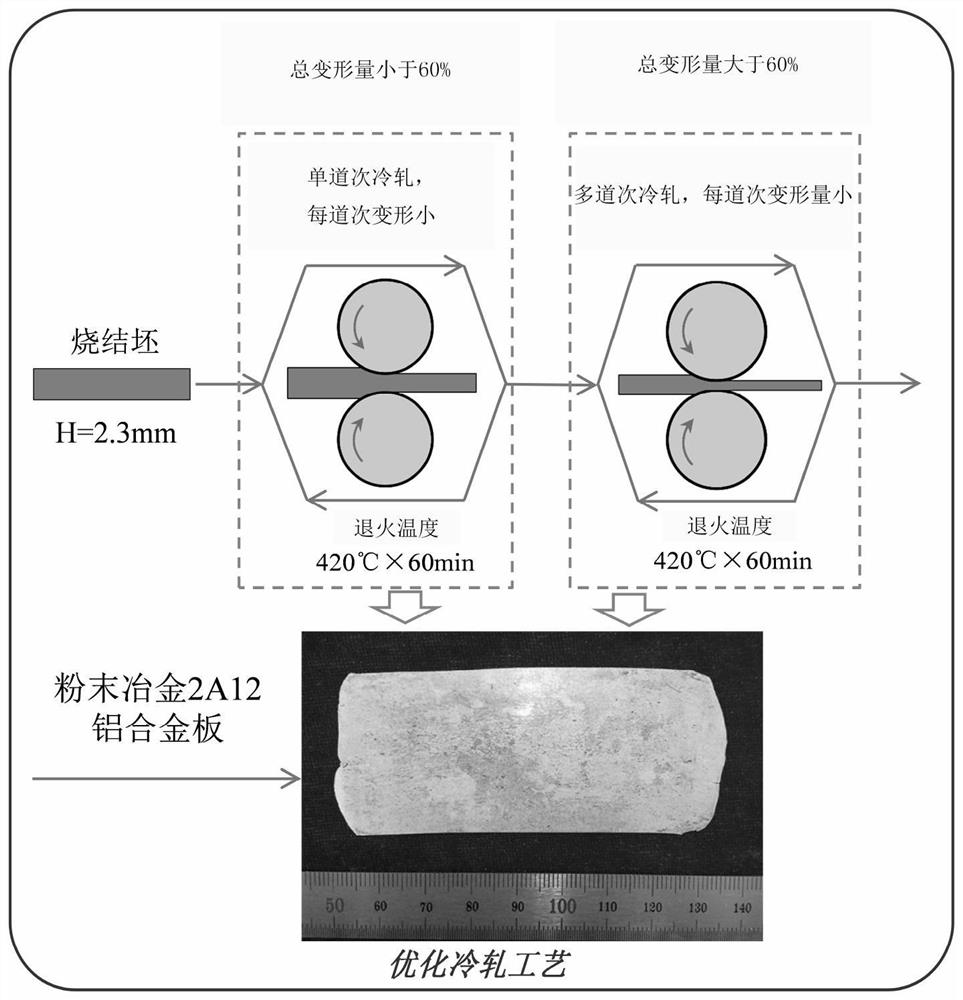

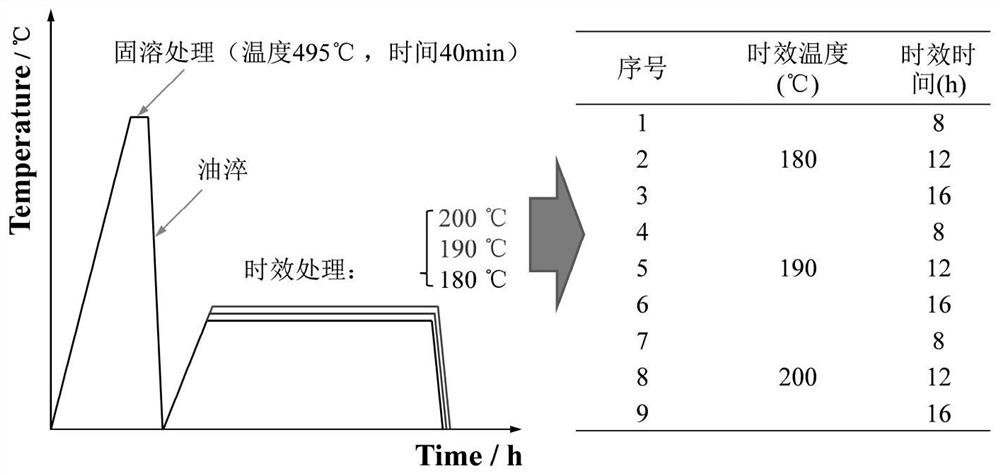

Heat treatment process of powder metallurgy aluminum alloy cold-rolled sheet

The invention provides a heat treatment process of a powder metallurgy aluminum alloy cold-rolled sheet. The heat treatment process comprises the steps of aluminum alloy powder pressing forming, sintering, annealing, cold rolling, intermediate annealing, finishing and heat treatment. Sintering is carried out in a vacuum hot pressing furnace; before cold rolling, blank annealing is conducted on a sintered blank; cold rolling is divided into two stages, in the first stage, when the cold rolling reduction rate is smaller than 60%, single-pass cold rolling with the rolling reduction amount smallerthan 3% and intermediate annealing are adopted in the stage, and cold rolling and intermediate annealing are alternately carried out till the total rolling reduction amount of the sheet reaches 60%;and when the total rolling reduction amount of cold rolling is larger than 60%, the second stage is executed, three passes of cold rolling (the rolling reduction of each pass is smaller than 3%) and intermediate annealing are adopted in the second stage, and the three passes of cold rolling and intermediate annealing are alternately conducted till the thickness of a sheet strip reaches the targetthickness. Heat treatment is that solid solution and aging treatment are carried out on the sheet with the required thickness so as to meet the final use requirement. The tensile strength of a powdermetallurgy 2A12 aluminum alloy obtained through the heat treatment process reaches about 540 MPa. The heat treatment process of the powder metallurgy 2A12 aluminum alloy cold-rolled sheet is high in practicability and wide in application range, and the mechanical property of the powder metallurgy aluminum alloy cold-rolled sheet can be remarkably improved.

Owner:CENT SOUTH UNIV

Steel wire rod for annealing-free solder wire and production process thereof

ActiveCN102513725BChemically stableImprove plastic indexWelding/cutting media/materialsSoldering mediaWire rodMechanical property

The invention belongs to the metallurgy field and relates to a production process of a steel wire rod, particularly the steel wire rod for an annealing-free solder wire and a production process of the steel wire rod, wherein the steel wire rod comprises elements in weight percentage as follows: 0.07-0.1% of C, 1.25-1.4% of Mn, 0.4-0.6% of Si, less than or equal to 0.02% of P, less than or equal to 0.02% of S, 0.2-0.55% of Mo, 0.5-1.0% of Ni, less than or equal to 0.2% of Cu, less than or equal to 0.2% of Ti and less than or equal to 0.1% of Al with the balance of Fe. The process comprises steps of detecting a blank, heating the steel blank, descaling by high-pressure water, roughly and intermediately rolling, pre-finishing rolling, cooling in a first section by water, finishing rolling bya unit, cooling in a second section by water, diameter reducing and sizing rolling, cooling in a third section by water, spinning, cooling by wind, finishing and delivering to a warehouse. The methodof the invention employs a rolling-controlled and cooling-controlled process to execute process control of the steel wire rod of the solder wire to obtain an F+P tissue appropriate to draw, and has advantages as follows: good comprehensive mechanical property is realized, a solder wire factory can avoid annealing and perform multi-pass drawing without wire breakage, the production efficiency is greatly increased and the production cost is reduced at the same time.

Owner:NANJING IRON & STEEL CO LTD

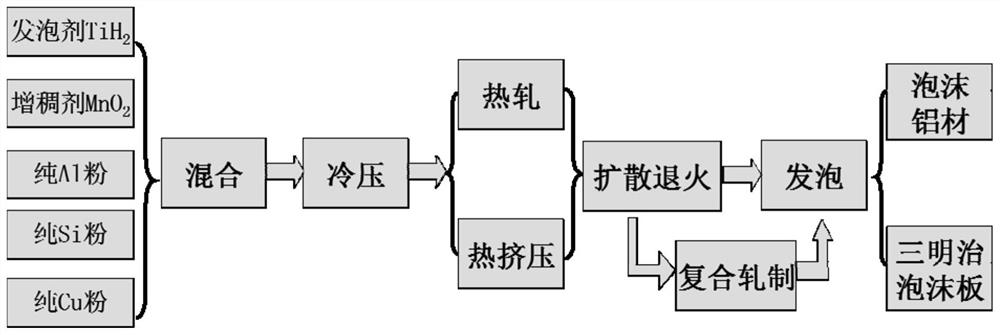

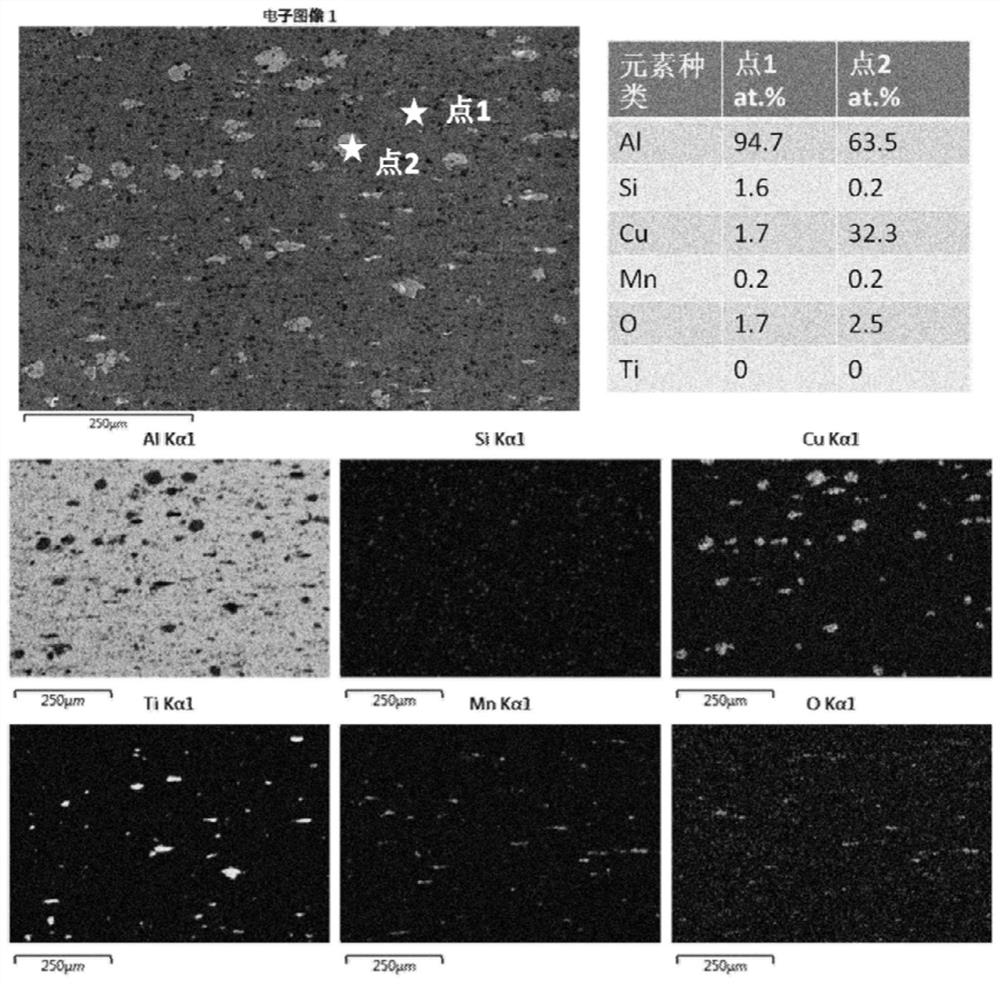

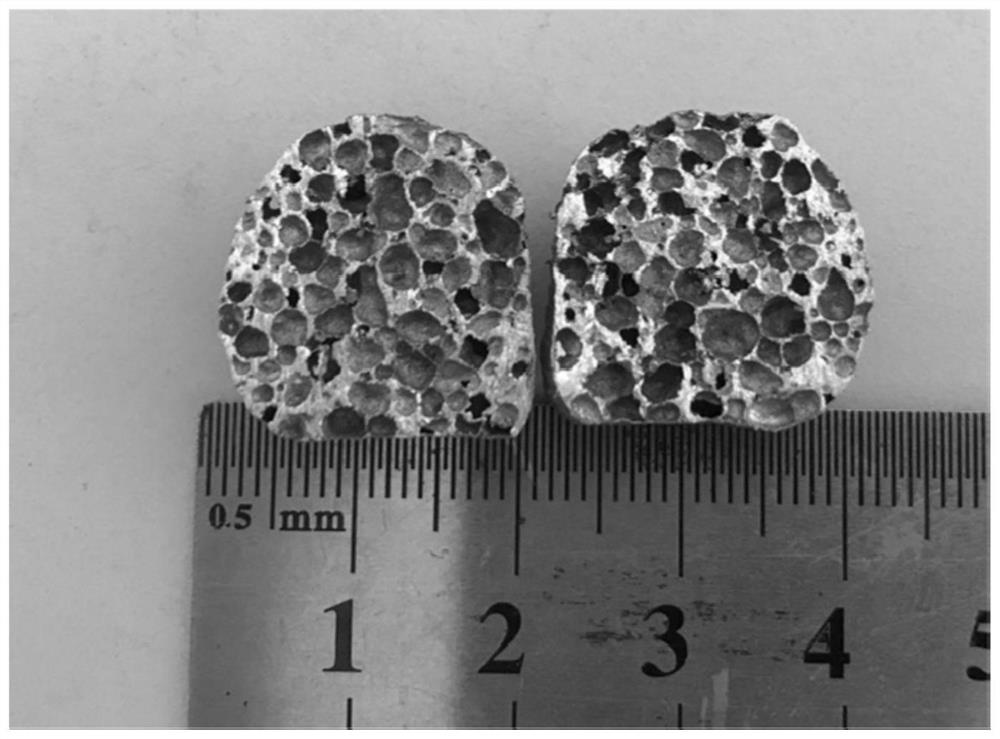

Powder metallurgy diffusion method for preparing foamed aluminum, foamed aluminum and sandwich foamed aluminum plate prepared by same

ActiveCN111842898AReduce defectsImprove qualityTurbinesOther manufacturing equipments/toolsAl powderFoaming agent

The invention relates to a powder metallurgy diffusion method for preparing foamed aluminum, the foamed aluminum and a sandwich foamed aluminum plate prepared by the method and belongs to the technical field of nonferrous metals. The method comprises the following specific steps of mixing aluminum powder, silicon powder and copper powder to replace traditional aluminum alloy powder, then mixing with a foaming agent and a thickening agent, performing cold pressing, hot rolling or hot extrusion, and then carrying out a diffusion annealing step, so that the defects of cracks, holes and the like are eliminated while aluminum, silicon and copper in the material are changed into an alloy phase; and then, performing heating and foaming to prepare the foamed aluminum, or carrying out composite hotrolling with a pure metal plate and then performing foaming to prepare the sandwich foamed aluminum plate. The method has the advantages that cold pressing and extrusion are completed by utilizing the excellent formability of the pure metal powder, then diffusion annealing is carried out, a foaming precursor with higher quality is obtained, and the components of the foam material are accurate, controllable and adjustable; and the foamed aluminum and the sandwich foamed aluminum plate have relatively uniform aperture and excellent mechanical property without large through holes and cracks.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

Manufacturing process of automobile low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation

The invention relates to a manufacturing process of an automobile low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation, and belongs to the technical field of metallurgy. The technical scheme of the invention is as follows: the manufacturing process comprises a smelting process, a hot rolling process and a cold rolling process, wherein in the cold rolling process, the annealing temperature control is as follows: the soaking temperature is 840-860 DEG C, the slow cooling temperature is 670-700 DEG C, the rapid cooling temperature is 410-430 DEG C, and the aging finish temperature is 350-370 DEG C; and according to strip steel of different thickness specifications, different annealing tape speed target values are planed: the tape speed of the strip steel of 0.8mm specification is 205m / min, the tape speed of the strip steel of 1.0mm specification is 165m / min, the tape speed of the strip steel of 1.2mm specification is 137m / min, the tape speed of the strip steel of 1.5mm specification is 110m / min, the tape speed of the strip steel of 1.8mm specification is 92m / min, the tape speed of the strip steel of 2.0mm specification is 82m / min, and the tape speed of the strip steel of 2.5mm specification is 66m / min. The manufacturing process of the automobile low-alloy high-strength steel cold-rolled sheet with the high product of strength and elongation disclosed by the invention has the beneficial effects that the low-alloy high-strength steel cold-rolled sheet with high product of strength and elongation is produced by modifying the chemical elements and optimizing the hot rolling and cold rolling processes so that the product of strength and elongation of the low-alloy high-strength steel cold-rolled sheet reach 15GPa%, and simultaneously the quality is stably controlled.

Owner:HBIS COMPANY LIMITED HANDAN BRANCH COMPANY

Machining method suitable for transverse and longitudinal 90-degree bent and rolled hard steel coil

The invention relates to a machining method suitable for a transverse and longitudinal 90-degree bent and rolled hard steel coil, and belongs to the field of ferrous metallurgy. The machining processof the bent and rolled hard steel coil comprises the steps of slab continuous casting, slab reheating, rough rolling, finish rolling, cooling, coiling and cold rolling. The machining method is characterized in that in the slab continuous casting stage, a steel billet comprises the chemical components of, by mass, not greater than 0.01% of C, 0.1-0.2% of Mn, not greater than 0.02% of P, not greaterthan 0.012% of S, not greater than 0.03% of Si, 0.01-0.05% of Al, not greater than 60ppm of N and the balance iron and impurities. According to the machining method suitable for the transverse and longitudinal 90-degree bent and rolled hard steel coil, the low-carbon and low-manganese component design, the high-finish-rolling and high-coiling-temperature hot rolling control process and the low-cold-rolling compression ratio control measure are adopted, the hardness of the rolled hard coil is reduced so as to meet the requirement that the transverse and longitudinal 90-degree bent and rolled hard steel coil does not crack, the machining method is used for replacing an annealed coil, and the annealing process is reduced.

Owner:ZHANGJIAGANG YANGTZE RIVER COLD ROLLED PLATE CO LTD +1

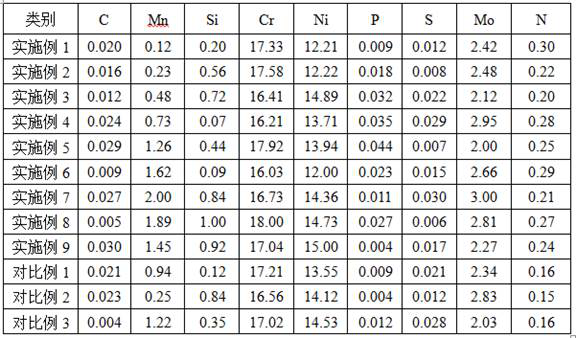

High-nitrogen 316LN stainless steel welding wire and production method thereof

InactiveCN112442633AShorten the production cycleHigh tensile strengthWelding/cutting media/materialsSoldering mediaWire rodElectro-slag remelting

The invention belongs to the technical field of metallurgy, and relates to a high-nitrogen 316LN stainless steel welding wire and a production method thereof. The welding wire comprises the followingchemical components in percentage by mass: less than or equal to 0.03% of C, less than or equal to 1.00% of Si, less than or equal to 2.00% of Mn, less than or equal to 0.035% of P, less than or equalto 0.03% of S, 12.0-15.0% of Ni, 16.0-18.0% of Cr, 2.0-3.0% of Mo, 0.2-0.3% of N and the balance of Fe and inevitable impurities. The production method comprises the procedures of smelting, electro slag remelting, homogenizing treatment, forging, wire rod rolling, acid pickling and annealing drawing, and nitrogen increasing treatment is carried out in the annealing drawing process. Compared witha smelting nitrogen increasing process, the production period of the welding wire is shortened, the production cost is reduced, the nitrogen element in the obtained welding wire is far higher than that in a conventional welding wire, and the tensile strength and the yield strength of the welding wire are obviously improved.

Owner:HEBEI IRON AND STEEL

Preparation method of nickel-based superalloy ultra-thin strip

ActiveCN114086092AAvoid breakingEasy to shapeFurnace typesHeat treatment furnacesSolution treatmentSuperalloy

The invention discloses a preparation method of a nickel-based superalloy ultra-thin strip, relates to the field of metallurgy, and aims to provide a novel method for preparing the nickel-based superalloy ultra-thin strip. According to the technical scheme, the preparation method of the nickel-based superalloy ultra-thin strip comprises the steps that a solid-solution-state nickel-based superalloy plate serves as a blank for rolling, then the blank is subjected to three-rolling and two-annealing rolling through a four-roller cold rolling mill, a semi-finished ultra-thin strip is obtained, finally, solid-solution treatment and aging treatment are conducted, and the finished ultra-thin strip is obtained. The blank is subjected to three-rolling and two-annealing rolling by adopting a four-roll cold rolling mill, and the deformation of each cold rolling pass is reasonably distributed so that the influence of work hardening on the rolling process is effectively reduced, and the rolling passes are reduced as much as possible; and meanwhile, the rolling speed and tension are reasonably controlled, effective deformation of the blank in the rolling process is controlled, and the blank is prevented from being snapped. The method is used for preparing the nickel-based superalloy ultra-thin strip with the thickness of 0.10-0.16 mm.

Owner:CHENGDU ADVANCED METAL MATERIALS IND TECH RES INST CO LTD

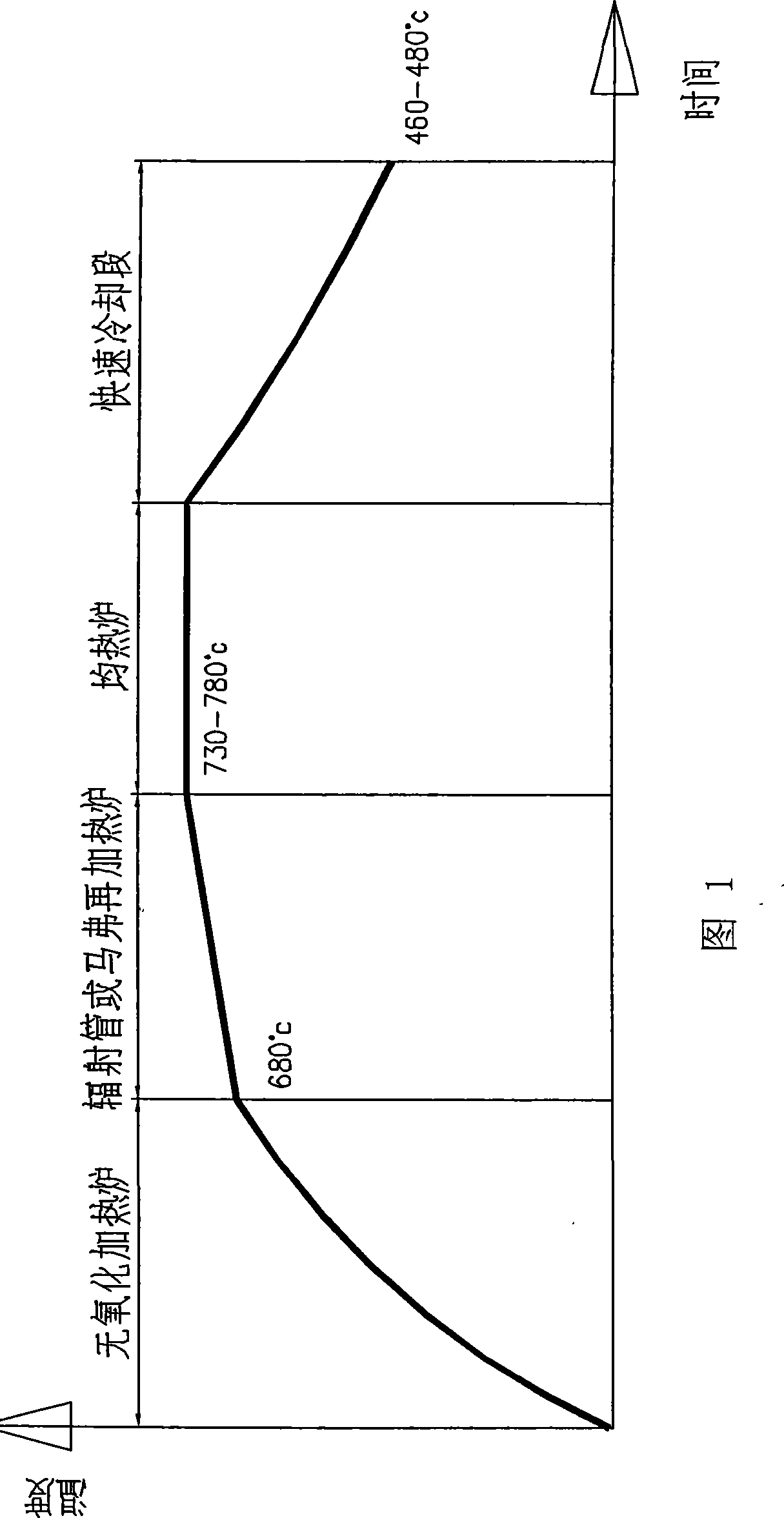

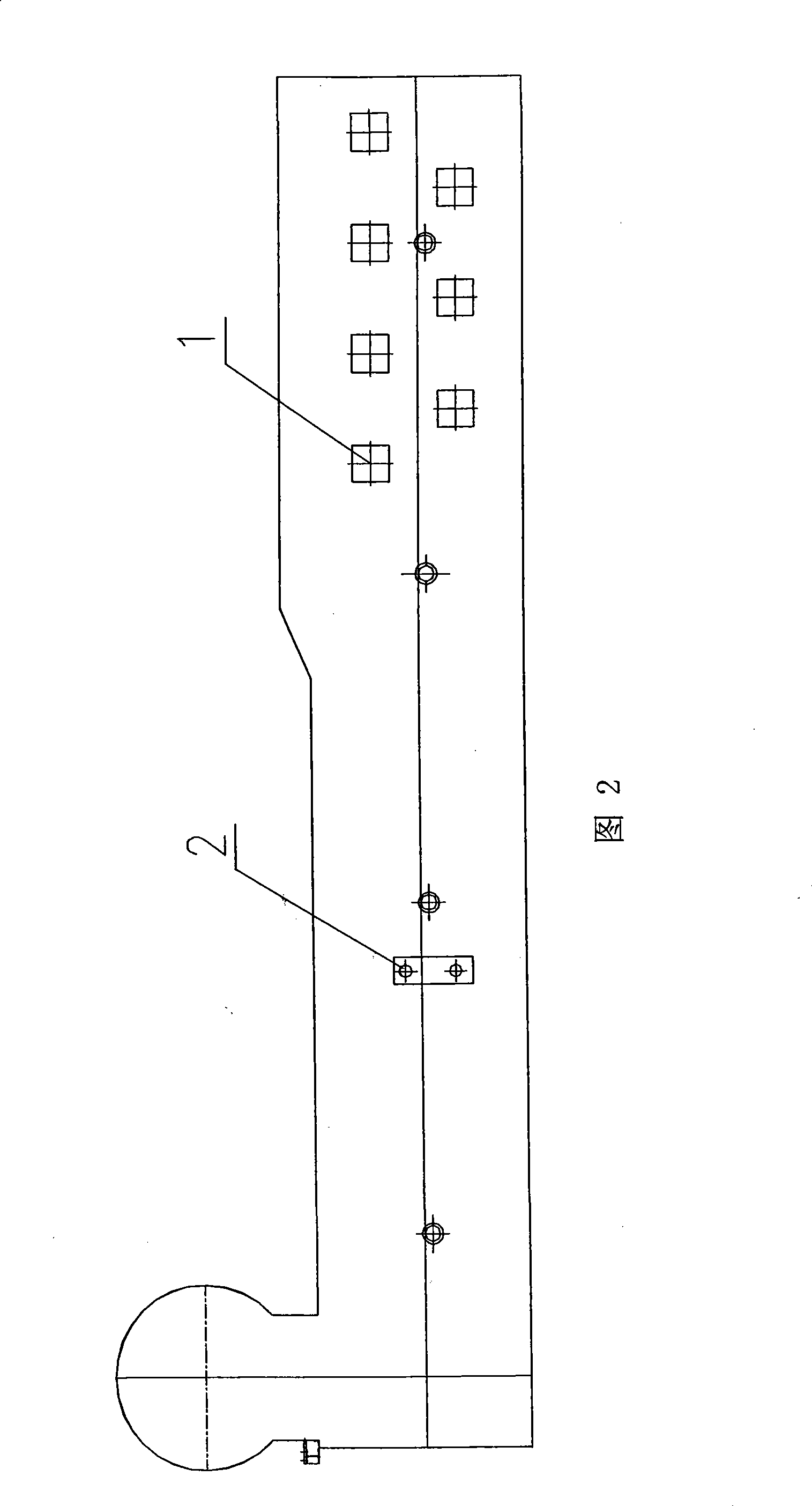

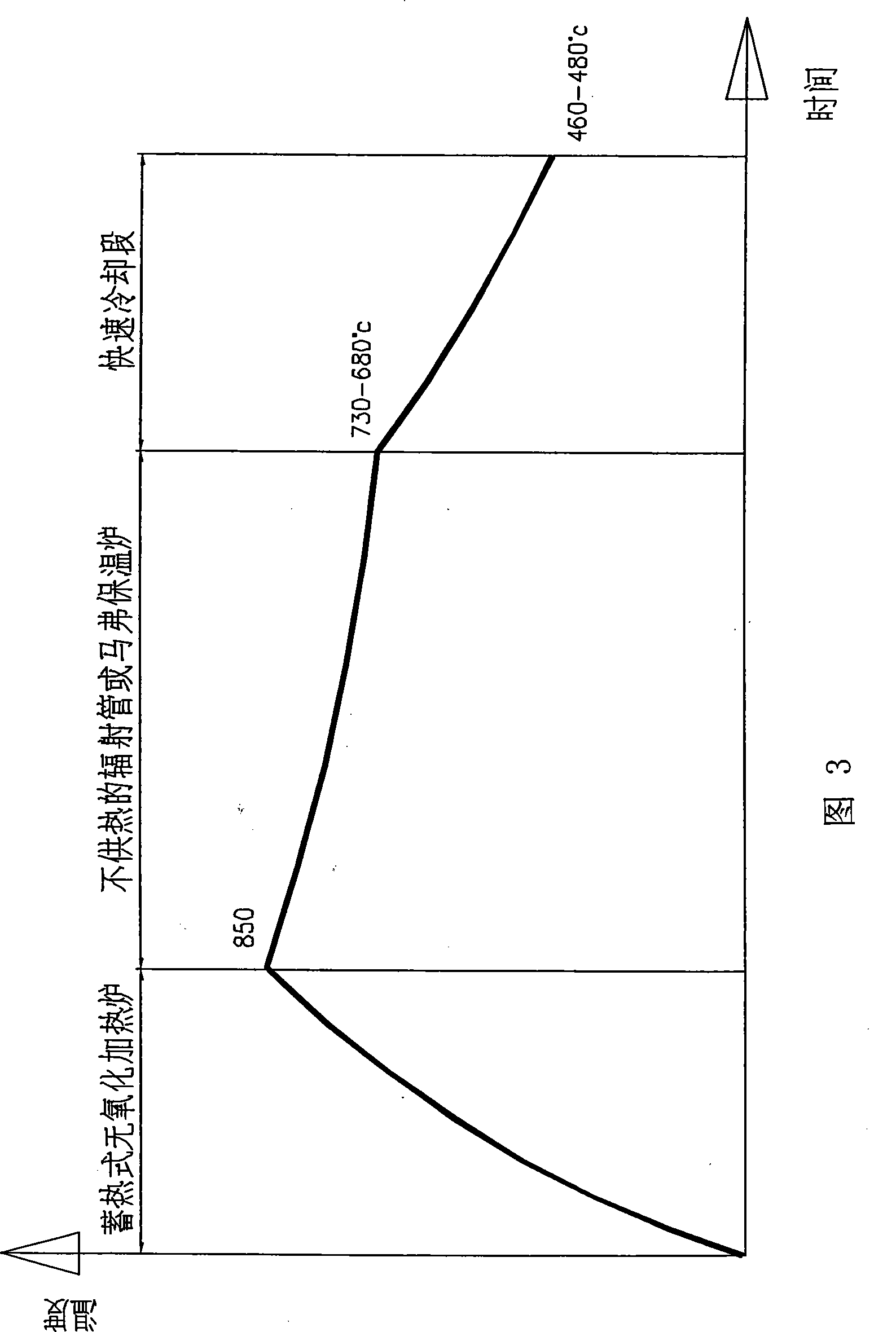

Hot dip galvanizing annealing process and high temperature annealing furnace

InactiveCN101435018AInvestment in energy-saving equipmentLess investment in equipmentHot-dipping/immersion processesFurnace typesZincHeating furnace

The invention belongs to the technical field of metallurgy, and discloses a method for heat treatment, in particular a hot galvanizing annealing technique and a high temperature annealing furnace, which are adopted by galvanized wires. The method comprises the following steps: strip steel is heated in a non-oxidation regenerative heating furnace; the heated strip steel enters a heat holding furnace without supplying heat so as to lead the strip steel to complete reduction and recrystallization annealing; after the recrystallization annealing is completed, the strip steel enters a fast cooling section and then enters a zinc pot by a steering roll chamber after being cooled. The high temperature annealing furnace used by the annealing technique comprises the non-oxidation regenerative heating furnace, the heat holding furnace without supplying heat and the fast cooling section. The invention can reduce the cost of one-time investment by more than 30 percent, simultaneously save the energy by more than 30 percent and can be widely applied to the hot galvanizing annealing technique of the galvanized wires.

Owner:CHONGQING CISDI THERMAL & ENVIRONMENTAL ENG CO LTD

A deformable low-expansion magnesium alloy

Owner:厦门火炬特种金属材料有限公司 +1

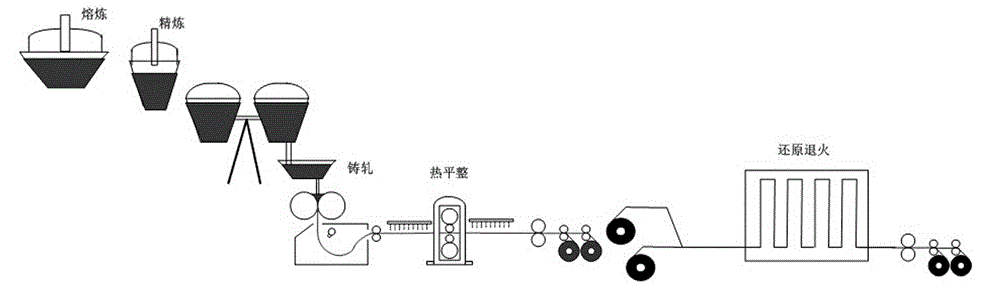

A method for producing hot-rolled pickling-free plates by strip continuous casting combined with reduction annealing

The invention belongs to the technical field of material metallurgy, and specifically relates to a method of thin strip continuous casting combined with reduction annealing to produce hot-rolled pickling-free plates. The specific steps are to first obtain refined molten steel, prepare cast-rolled strip, perform hot leveling, and then uncoil the cast-rolled strip for reduction annealing. In the reduction section, first remove the iron oxide scale on the surface of the cast-rolled strip, and use H2 atmosphere conditions to protect the reduction. The reduction temperature is 800-1100°C, and the reduction time is 10-30 minutes; H2 and N2 atmosphere protection is used in the high-temperature annealing section, the reduction temperature is 500-1000°C, and the reduction time is 1-5 minutes to achieve control of the structure and performance of the thin strip and obtain a thin strip. Strip steel products. The technical solution of the present invention directly reduces the annealing of the cast-rolled thin strip without pickling, eliminating the cold-rolling pickling process. At the same time, the pre-oxidation process before continuous retreat can be completely eliminated, which will greatly improve the continuity of the thin strip production process. While improving production efficiency, it also reduces production costs and reduces waste acid and other pollutant emissions, producing huge economic and social benefits.

Owner:NORTHEASTERN UNIV

Preparation method of powder metallurgy tool and mould steel

ActiveCN111014704AReduce gas contentReduce gas content especially oxygen contentTransportation and packagingMetal-working apparatusRefining (metallurgy)Carbide

The invention relates to a preparation method of powder metallurgy tool and mould steel. The structure density and carbide dispersity of the powder metallurgy tool and mould steel can be improved. Thepreparation method comprises the following main process steps that after the tool and mould steel is molten, sufficient deoxidation and refining are carried out, and the gas content of molten steel is controlled; high-purity nitrogen is adopted for sufficiently atomizing the molten steel in a high-vacuum-degree atomization chamber; the tool and mould steel is screened, and powder of different particle sizes is mixed according to a certain proportion and then is loaded in a sheath; vacuumizing and nitrogen filling gas removal treatment is carried out on the sheath cyclically, and the number oftimes of circulation is not smaller than 3; after rapid temperature increase treatment is carried out on the welded sheath, hot isostatic pressing is carried out; and after forging, rolling and otherhot machining are carried out on the powder metallurgy tool and mould steel, carbide desolvation pretreatment is carried out, and then finished product annealing is carried out. The tool and mould steel produced by the method is high in density, carbide is fine, dispersed and uniform, and products have high toughness and plasticity, high hardness and wear resistance.

Owner:SOUTHEAST UNIV +1

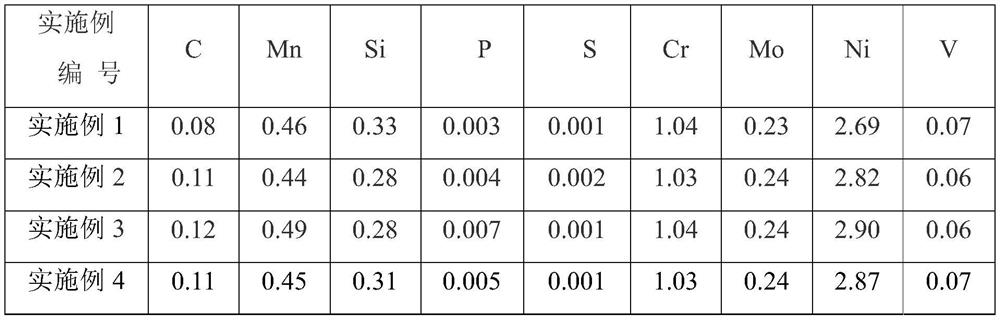

10CrNi3MoV round tube blank and preparation method and application thereof

InactiveCN111647723AImprove purityImprove toughnessFurnace typesHeat treatment furnacesElectric arc furnaceRefining (metallurgy)

The invention relates to the field of ferrous metallurgy processing, and discloses a 10CrNi3MoV round tube blank and a preparation method and application thereof. The method comprises the following steps that 1, burdening is carried out according to the formula amount, and after electric arc furnace smelting, ladle furnace refining and vacuum degassing refining are carried out in sequence, an electroslag consumable electrode is obtained; (2) electroslag remelting is performed on the electroslag consumable electrode obtained in the step (1) to obtain a steel ingot; and (3) when the taper of thesteel ingot is smaller than or equal to 1.5%, stress relief annealing is conducted, and a round tube blank is obtained; and when the taper of the steel ingot is larger than 1.5%, stress relief annealing, forging and annealing treatment are sequentially carried out, and the round tube blank is obtained. The 10CrNi3MoV round tube blank prepared by the method has high purity, good toughness and excellent formability and corrosion resistance, and can be used for preparing high-pressure seamless steel tubes and high-pressure seamless steel cylinders with excellent comprehensive performance.

Owner:PANGANG GROUP JIANGYOU CHANGCHENG SPECIAL STEEL

Cold-rolled bifocal plate as well as manufacturing method and application thereof

ActiveCN111334709AImprove surface qualityQuality improvementMetal rolling arrangementsContinuous rollingFerrous metallurgy

The invention belongs to the technical field of ferrous metallurgy and particularly relates to a manufacturing method of a cold-rolled bifocal plate. The manufacturing method is characterized by comprising the following steps: sequentially carrying out hot continuous rolling, acid pickling cold continuous rolling, batch annealing, levelling and finishing on a plate slab to obtain the cold-rolled bifocal plate; wherein the relative reduction rate of the acid pickling cold continuous rolling procedure is controlled to be 50% or above; the roughness of a last rack working roll in the acid pickling cold continuous rolling procedure is 1.5-2.0 microns to realize that the roughness of a chill roll obtained when the plate slab is sequentially subjected to the hot continuous rolling and acid pickling cold continuous rolling is 0.3-0.6 micron; and the roughness of a temper mill working roll is controlled to be 0.2-0.6 micron during the levelling procedure to realize that the roughness of the cold-rolled bifocal plate is 0.15-0.30 micron. Through copying and transferring of the roughness of the working roll, the purpose of producing the high-quality cold-rolled bifocal plate with the roughness being 0.15-0.30 micron is realized.

Owner:湖南华菱涟源钢铁有限公司 +1

Method for preparing phosphorus-containing silicon steel sheet with high magnetic performance through powder sintering

InactiveCN112846180AResolve hard-to-form defectsSolve forming problemsTurbinesOther manufacturing equipments/toolsCrucibleAlloy

The invention discloses a method for preparing a phosphorus-containing silicon steel sheet with high magnetic performance through powder sintering, and belongs to the technical field of powder metallurgy. Alloy powder with the component range of Fe-(3-6.5) wt.% Si-(0.05-1) wt.% P is prepared through vacuum melting and gas atomization, the alloy powder is placed in a ceramic crucible to be evenly compacted, a heavy object is placed for pressing, then high-temperature sintering is conducted to enable the alloy powder to be metallurgically bonded, and after hot rolling, cold rolling, annealing and other treatment are conducted, the phosphorus-containing silicon steel sheet with the excellent performance is obtained. A P element is added into a silicon steel material system, iron loss can be effectively reduced, the magnetic performance is optimized, and activated sintering is promoted; the gas atomization powder is adopted, so that few inclusions and the purity of the product can be well ensured; and under the synergistic effect of the low-melting-point P element and powder pressure sintering, the defect that spherical gas atomization powder is difficult to form is overcome, the problems of process complexity and subsequent degumming and carbon residues caused by the fact that a forming agent needs to be added are avoided, the preparation process flow is effectively shortened, and the method has the beneficial effects of being easy to operate, high in production efficiency, short in process flow, excellent in performance and the like.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com