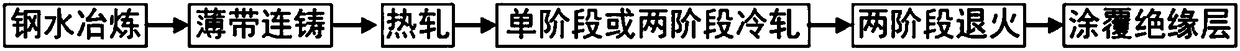

A method for preparing non-oriented silicon steel thin strip with developed {100} plane texture based on thin strip continuous casting

A technology of oriented silicon steel and thin strip, which is applied in the field of metallurgy, can solve the problems of the thickness limitation of finished products, the inability to produce thin-gauge and high-grade non-oriented silicon steel, etc., and achieve the effects of simplified rolling process, specific and feasible manufacturing method, and short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] In this embodiment, the method for preparing a non-oriented silicon steel strip with a developed {100} plane texture based on strip continuous casting is carried out according to the following steps:

[0038] The molten steel is smelted according to the set composition, and its composition is: C 0.01%, Si 1.5%, Mn 0.2%, Al0.0046%, S 0.002%, and the balance is Fe;

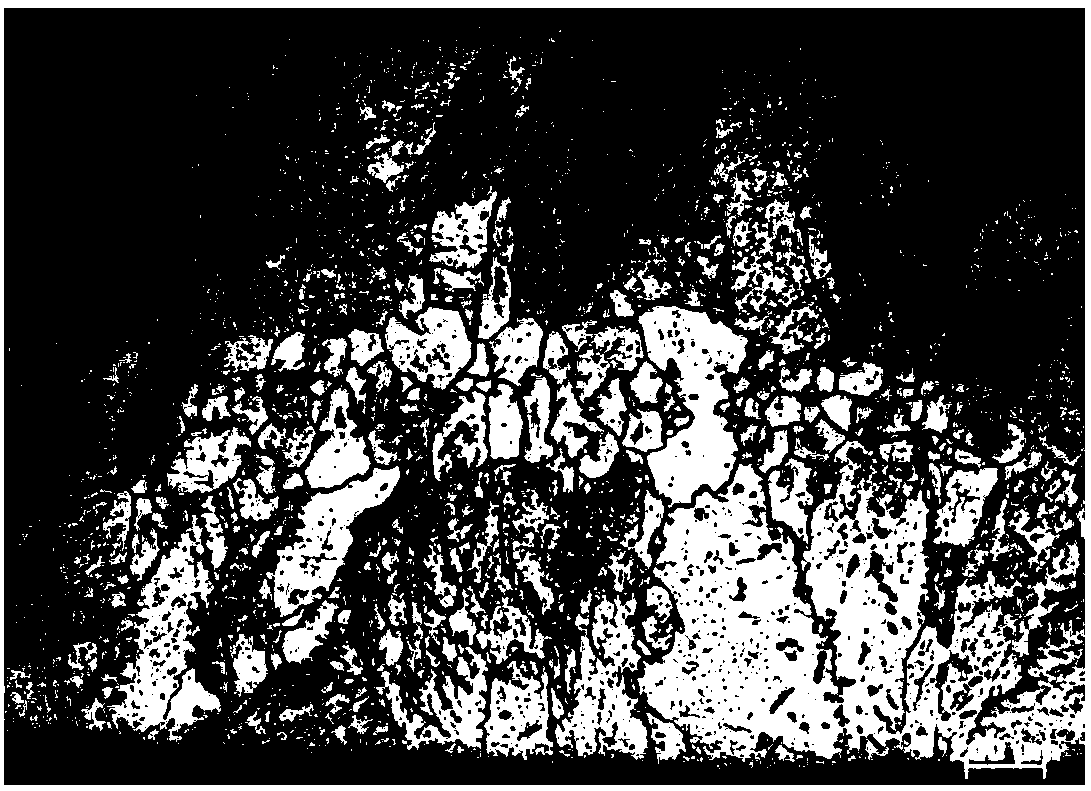

[0039] Strip continuous casting process: molten steel enters the tundish through the gate, the tundish preheating temperature is 1200°C, and the superheating degree is controlled at 45°C. The molten steel enters the thin strip continuous casting machine through the tundish to form a casting strip, and the casting speed is controlled at 45m / min, control the liquid level height of the molten pool to 130mm, and control the thickness of the casting strip to 1.8mm; the proportion of columnar crystals in the non-oriented silicon steel casting strip reaches 80%, and there is a small amount of uniformly distribu...

Embodiment 2

[0045] In this embodiment, the method for preparing a non-oriented silicon steel strip with a developed {100} plane texture based on strip continuous casting is carried out according to the following steps:

[0046] The molten steel is smelted according to the set composition, and its composition by weight percentage is: C 0.04%, Si 2.5%, Mn 0.3%, Al0.0038%, S 0.005%, and the balance is Fe;

[0047] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1230°C, and the superheating degree is controlled at 30°C. The molten steel enters the thin strip continuous casting machine through the tundish to form a casting strip, and the casting speed is controlled at 40m / min, control the liquid level height of the molten pool to 110mm, and control the thickness of the cast strip to 1.5mm; the proportion of columnar crystals in the non-oriented silicon steel cast strip is 55%, and there is a small amount of ...

Embodiment 3

[0052] In this embodiment, the method for preparing a non-oriented silicon steel strip with a developed {100} plane texture based on strip continuous casting is carried out according to the following steps:

[0053] The molten steel is smelted according to the set composition, and its composition by weight percentage is: C 0.02%, Si 2.0%, Mn 0.2%, Al0.0043%, S 0.002%, and the balance is Fe;

[0054] Strip continuous casting process: molten steel enters the tundish through the gate, the preheating temperature of the tundish is 1220°C, and the superheating degree is controlled at 40°C. The molten steel enters the thin strip continuous casting machine through the tundish to form a casting strip, and the casting speed is controlled at 60m / min, the liquid level height of the molten pool is controlled to 120mm, and the thickness of the cast strip is controlled to 2.1mm; the proportion of columnar crystals in the non-oriented silicon steel cast strip is 65%, and there is a smal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com