Thick X65 pipeline steel and production method thereof

A pipeline steel, X65 technology, applied in the field of thick X65 pipeline steel and its production, can solve the problems of reducing P and S content, high Nb content, high production cost, etc., and achieves strong operability, simple rolling process and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

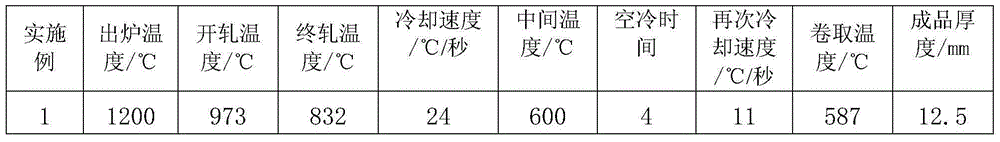

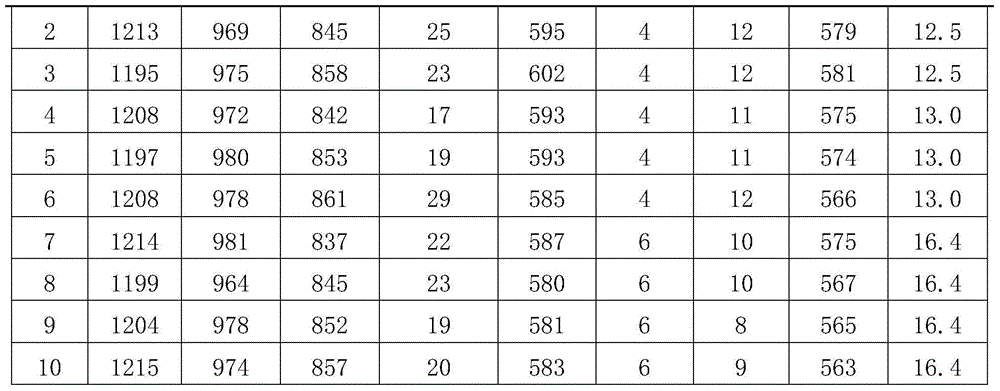

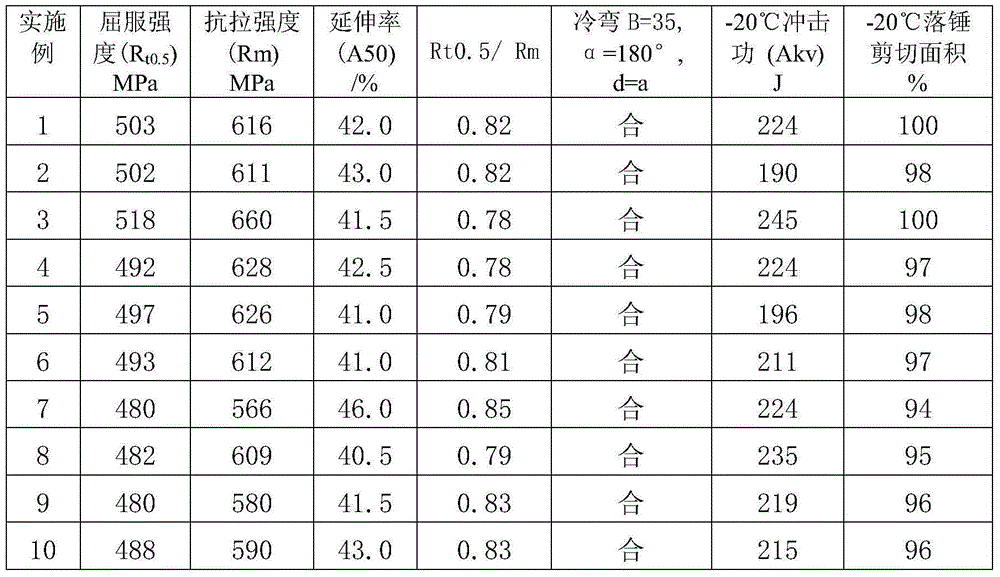

Examples

Embodiment Construction

[0024] The production process flow of the present invention is: desulfurization of molten iron→converter smelting compound blowing→deoxidation, alloying and desulfurization of high-alkalinity refining slag→replenishing Al wire and Ti microalloying on the small platform behind the furnace→feeding calcium wire→continuous casting→ Slab heating→high pressure water descaling→rough rolling→finish rolling→laminar cooling→coiling→packing and storage.

[0025] Thick gauge X65 pipeline steel, its chemical composition is composed by weight percentage: C: 0.07-0.10%, Si: 0.10-0.30%, Mn: 1.40-1.60%, P: ≤0.020%, S: ≤0.010%, Nb: 0.030-0.039%, V: 0.06-0.08%, Ti: 0.008-0.019%, Cr: 0.15-0.30%, and the rest are Fe and unavoidable impurities.

[0026] The preferred scheme is: C: 0.07-0.09%, Si: 0.15-0.25%, Mn: 1.45-1.55%, P: ≤0.018%, S: ≤0.005%, Nb: 0.035-0.039%, V: 0.06-0.08 %, Ti: 0.010-0.017%, Cr: 0.20-0.30%, and the rest are Fe and unavoidable impurities.

[0027] The production process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com