12Cr2Mo1R steel plate for seal head and production method thereof

A production method and steel plate technology, applied in the field of metallurgy, can solve problems such as complex mechanical properties, complex heat treatment process, and large production difficulty of steel plate manufacturers, and achieve the effects of simple rolling process, simplified production process flow, and reduced risk of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

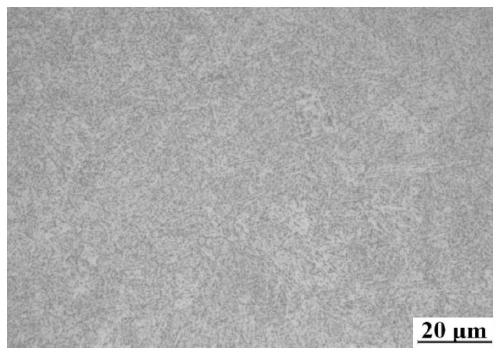

Embodiment 1

[0031] The thickness of the 12Cr2Mo1R steel plate used for the head of this embodiment is 8 mm, and its chemical composition and mass percentage are shown in Table 17.

[0032] The production method of the 12Cr2Mo1R steel plate for the head of this embodiment includes smelting, continuous casting, heating, rolling, heat treatment, sample processing and heat treatment procedures, and the specific process steps are as follows:

[0033](1) Smelting process: use electric arc furnace or converter for smelting, tap when the temperature of molten steel reaches 1600°C; tap molten steel into LF refining furnace for refining for 1 hour, use calcium carbide and carbon powder for weak deoxidation, and then feed Al Deoxidation is carried out in the way of deep deoxidation, and then the alloy is added and the content of Mn, Mo, Ni, Cr, and V is fine-tuned according to the desulfurization situation to meet the target composition requirements. After LF refining, the VD furnace is vacuumed for ...

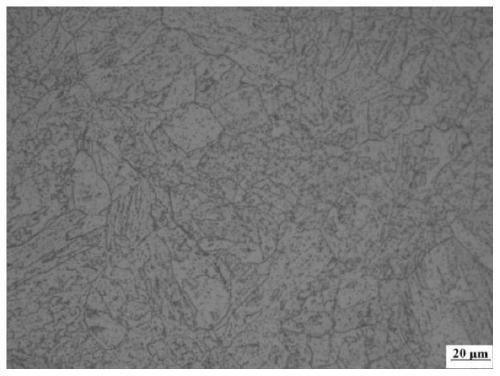

Embodiment 2

[0046] The thickness of the 12Cr2Mo1R steel plate used for the head in this example is 100 mm, and its chemical composition and mass percentage are shown in Table 17.

[0047] The production method of the 12Cr2Mo1R steel plate for the head of this embodiment includes smelting, continuous casting, heating, rolling, heat treatment, sample processing and heat treatment procedures, and the specific process steps are as follows:

[0048] (1) Smelting process: use electric arc furnace or converter for smelting, tap when the temperature of molten steel reaches 1602°C; tap molten steel is sent to LF refining furnace for refining for 1.1h, use calcium carbide and carbon powder for weak deoxidation, and then use feeding Deoxidation is carried out in the form of Al line deep deoxidation, and then the alloy is added and the content of Mn, Mo, Ni, Cr, and V is fine-tuned according to the desulfurization situation to meet the target composition requirements. After LF refining, the VD furnace...

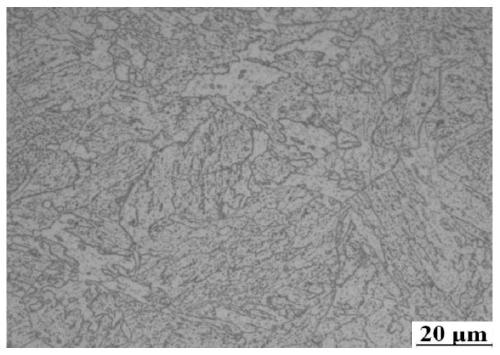

Embodiment 3

[0061] The thickness of the 12Cr2Mo1R steel plate used for the head of this example is 200 mm, and its chemical composition and mass percentage are shown in Table 17.

[0062] The production method of the 12Cr2Mo1R steel plate for the head of this embodiment includes smelting, continuous casting, heating, rolling, heat treatment, sample processing and heat treatment procedures, and the specific process steps are as follows:

[0063] (1) Smelting process: use electric arc furnace or converter for smelting, tap when the temperature of molten steel reaches 1601°C; tap molten steel into LF refining furnace for refining for 1.3h, use calcium carbide and carbon powder for weak deoxidation, and then use feeding Deoxidation is carried out in the form of Al line deep deoxidation, and then the alloy is added and the content of Mn, Mo, Ni, Cr, and V is fine-tuned according to the desulfurization situation to meet the target composition requirements. After LF refining, the VD furnace is va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com