Winding technique for waist drum type spring

A waist drum shape and process technology, applied in the field of coiled springs, can solve problems such as inapplicability of springs, and achieve the effects of improving quality, pitch and shape stability, and improving comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The implementation of the rolling process of the waist drum spring of the present invention will be described in detail below with reference to the drawings of the embodiments.

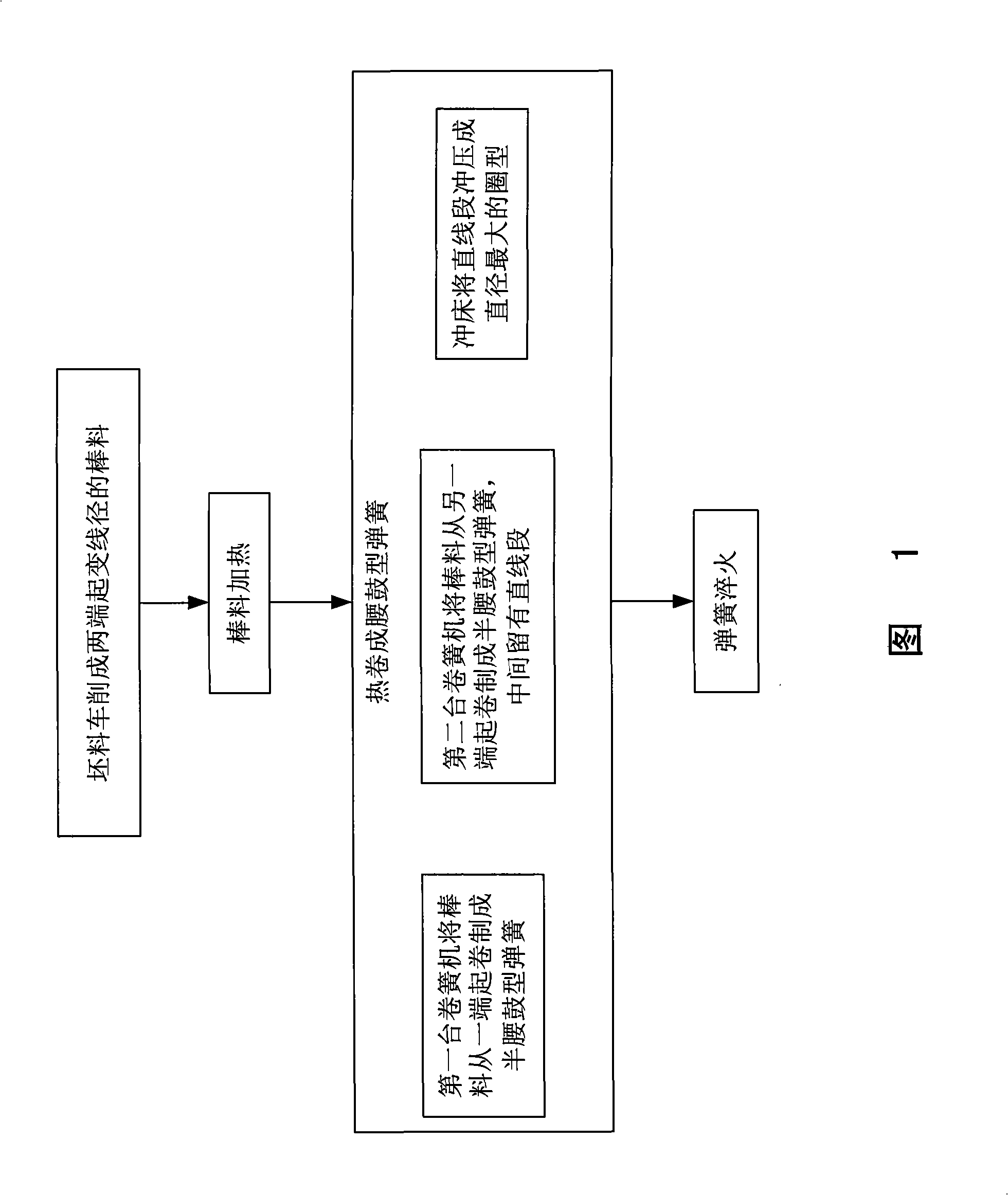

[0025] Fig. 1 is a schematic flow chart of the rolling process of the waist drum spring of the present invention.

[0026] The hot rolling forming process of the drum-shaped spring of the present invention is divided into the following processes.

[0027] First process: Bar turning

[0028] The bundled blanks are stripped into multiple bars whose wire diameters change from both ends by turning, that is, the wire diameters gradually increase from both ends, and the middle is the largest bar, and each bar is a waist drum Type spring blanks.

[0029] The second process: bar heating

[0030] Use a heating furnace to heat each bar with different wire diameters after turning. Since the wire diameter of each bar after turning is different, it must be used for each different wire diameter section of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com