Patents

Literature

36results about How to "Pitch stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

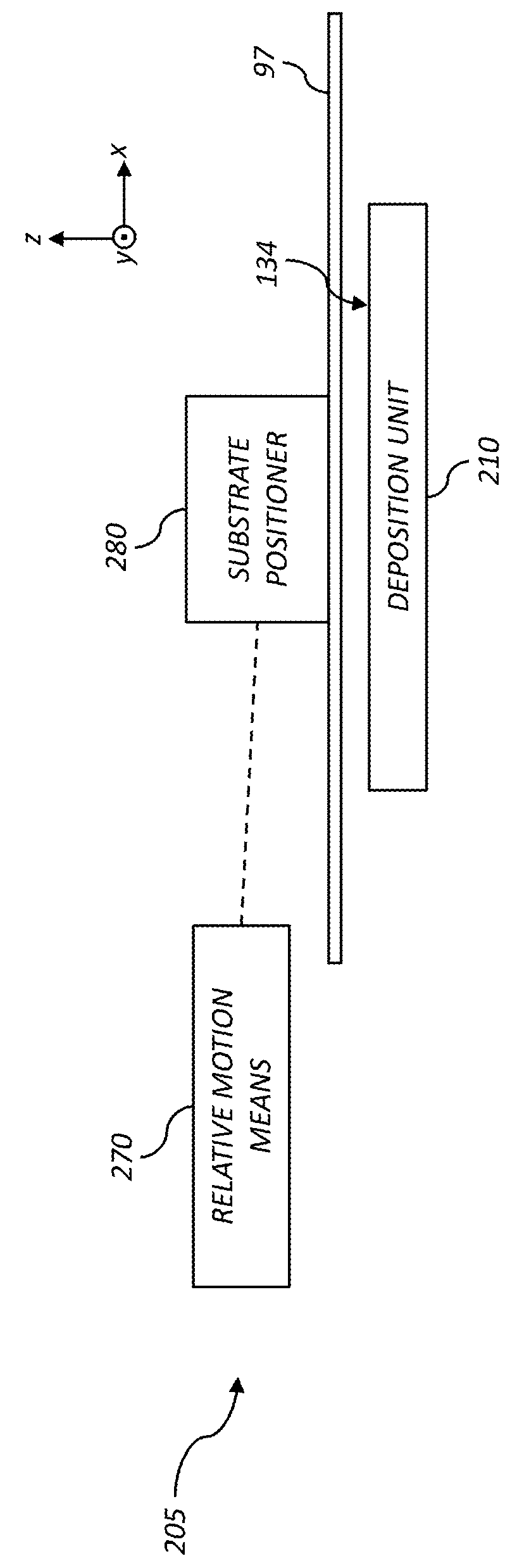

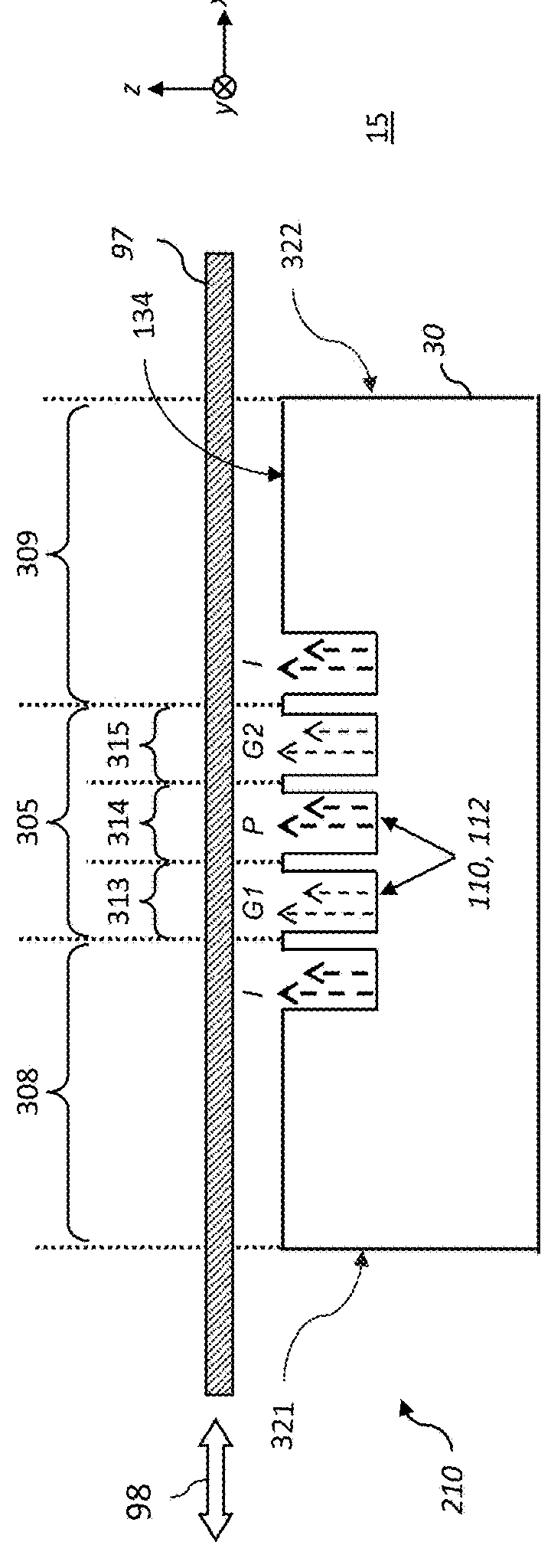

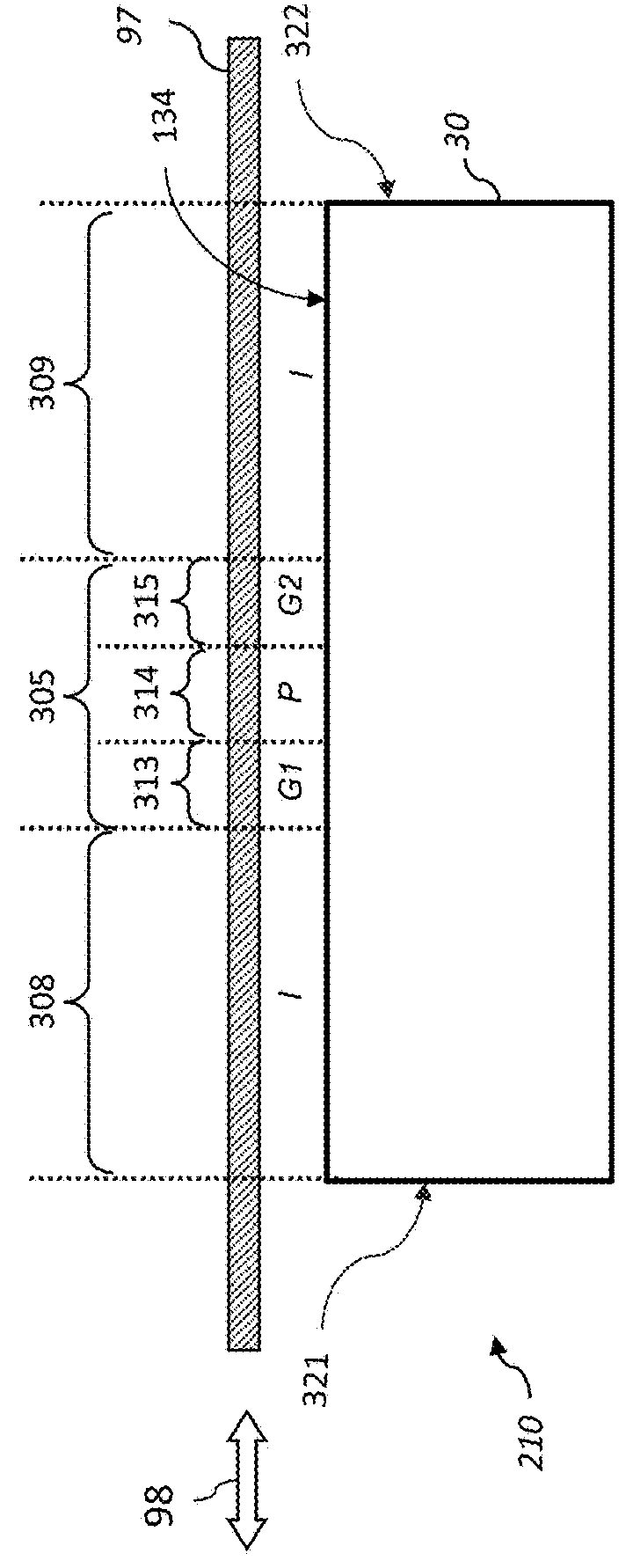

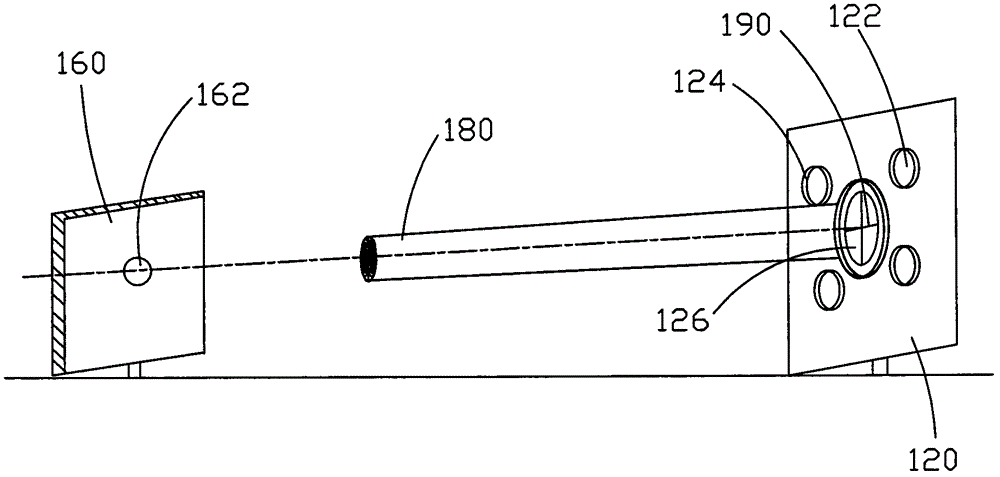

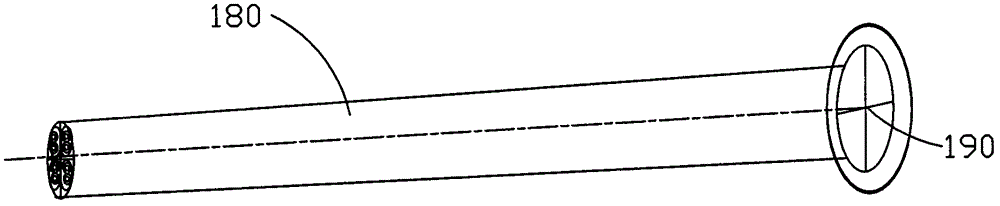

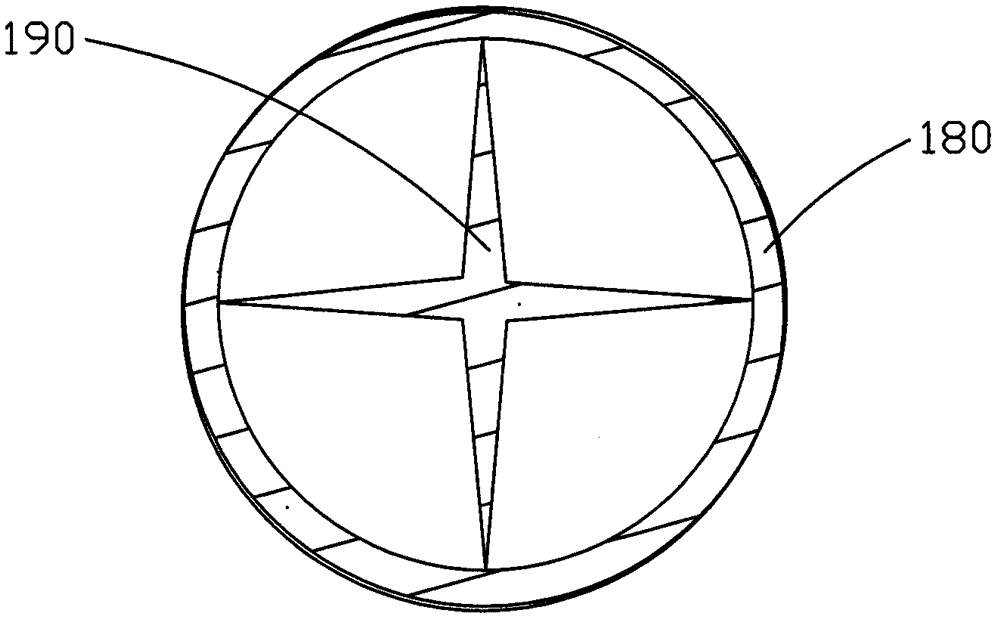

Dual gas bearing substrate positioning system

ActiveUS20180265969A1Improve coating qualityEasily accountedGas cushion bearingsSemiconductor/solid-state device manufacturingAirflowPositioning system

Owner:EASTMAN KODAK CO

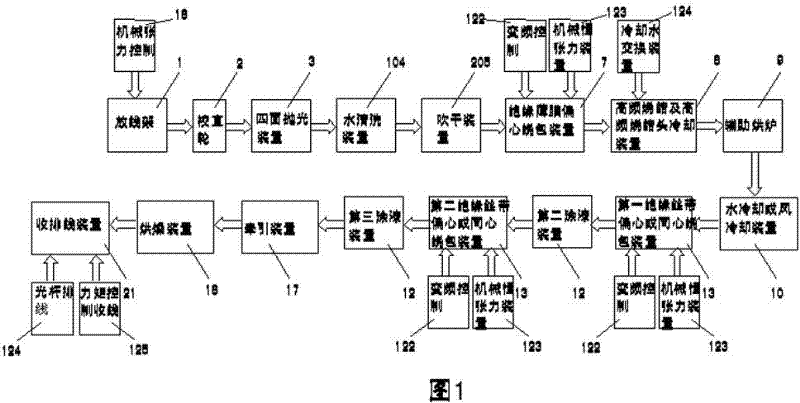

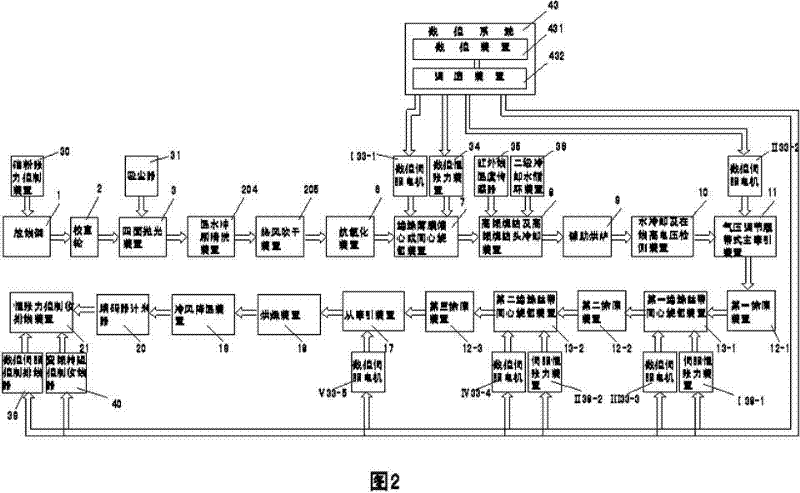

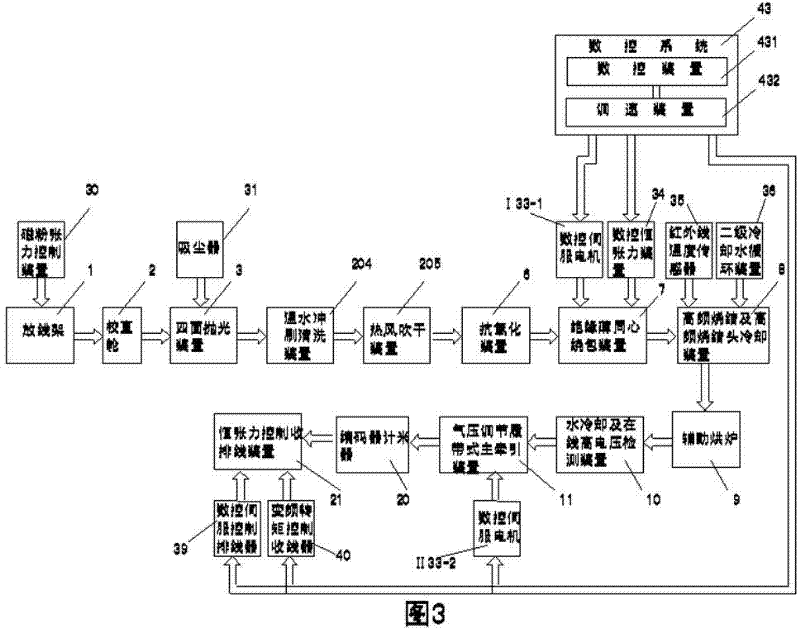

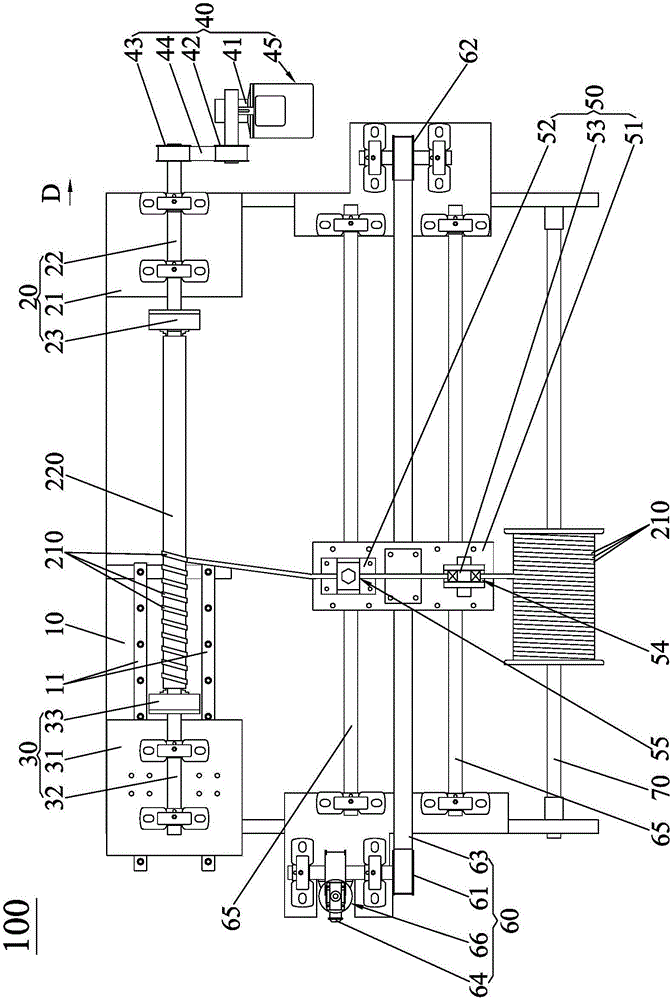

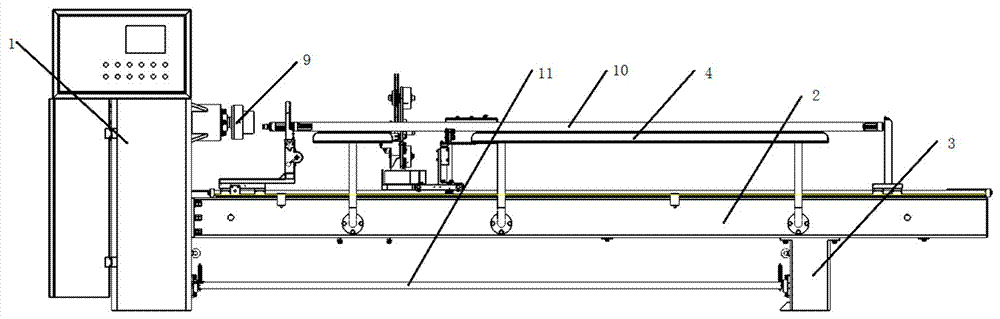

Numerical control multifunctional horizontal wrapping machine

ActiveCN102227091AImprove adhesionEasy to controlFilament handlingApplying solid insulationHigh frequencyBooster pump

The invention provides a numerical control multifunctional horizontal wrapping machine which comprises a constant tension line laying rack. The machine also comprises a straightening wheel, a four-side polishing device, a warm water washing cleaning device and a hot air blow-dry device which are installed on a first bench in order. The machine also comprises an insulation film eccentric or concentric wrapping device, a high frequency sintering and high frequency sintering head cooling device, an auxiliary oven and a water cooling and on-line high voltage detection device which are installed on a second bench in order. The machine also comprises a air pressure adjusting crawler type main draw gear, a first insulation ribbon eccentric wrapping device or concentric wrapping device, a second coating device, a second insulation ribbon eccentric wrapping device or concentric wrapping device, a third coating device, a draw gear, a drying device, and a wire arrangement collection device. The cleaning device is provided with a water heating device and a booster pump. An antioxidation device is provided between the hot air blow-dry device and the insulation film eccentric or concentric wrapping device. A constant tension device controlling film or filament disc material emptying on the wrapping head is a numerical control constant tension device. By using the numerical control multifunctional horizontal wrapping machine in the invention to wrap insulated wire, product quality and production efficiency of the insulated wire is raised.

Owner:GOLD CUP ELECTRIC APP CO LTD

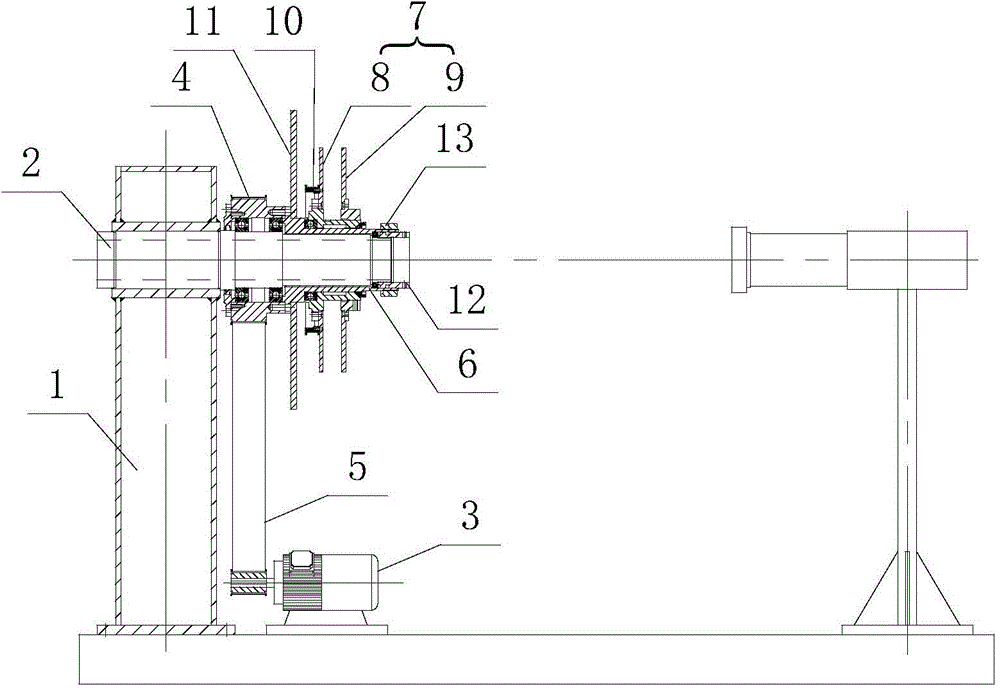

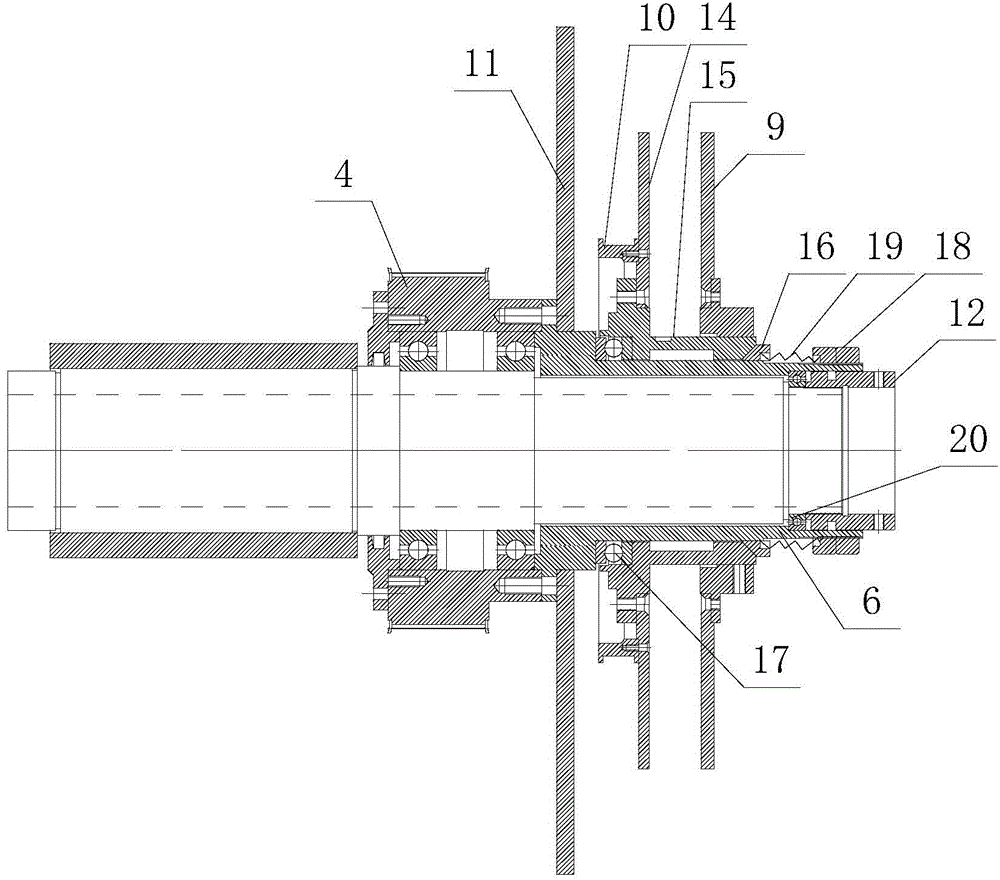

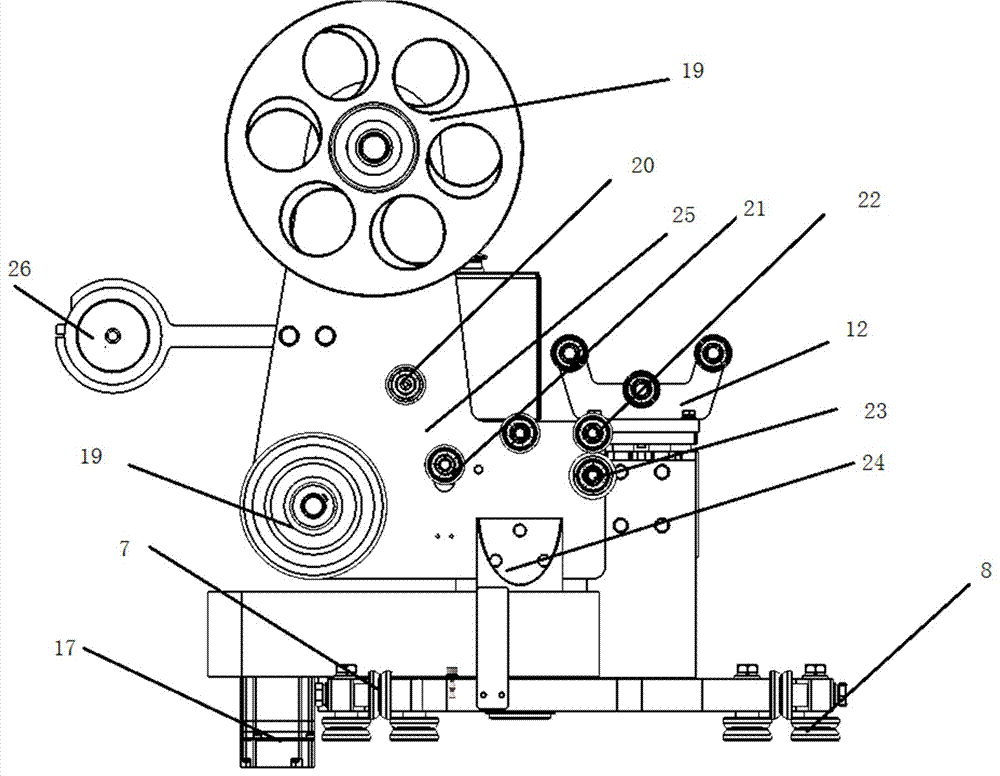

Device for wrapping shielding copper strip on cable

The invention discloses a device for wrapping a shielding copper strip on a cable. The device comprises a supporting seat, a hollow shaft fixed on the supporting seat, a motor with an encoder and a synchronous wheel rotatably arranged at the middle of the hollow shaft; the motor is in transmission with the synchronous wheel through a synchronous belt; the front part of the hollow shaft is sleeved with a hollow tube which rotates synchronously with the synchronous wheel; the hollow tube is sleeved with a copper strip disc which rotates relative to the hollow tube; the copper strip disc includes a copper strip bottom disc and a copper strip clamping disc; the hollow tube is sleeved with a brake wheel fixedly connected with the copper strip bottom disc; the front end of the hollow tube is provided with a copper strip disc locking device; the hollow tube is also sleeved with a shaft disc which rotates synchronously with the synchronous wheel; and a mould sleeve tightening ring is fixed at the front end of the hollow shaft. The device for wrapping the shielding copper strip on the cable of the invention has the advantages of stepless speed regulation, high rotation speed, stable pitches, low noise, fast speed rise, avoidance of oil leakage and high energy utilization rate. According to the device for wrapping the shielding copper strip on the cable, the separate brake wheel is arranged on the copper strip disc, and therefore, the rotation speed of the copper strip disc can be facilitated, and the copper strip can keep a certain tension force, and improvement on product quality can be benefitted.

Owner:PINGHU DIGONG MACHINERY MFG

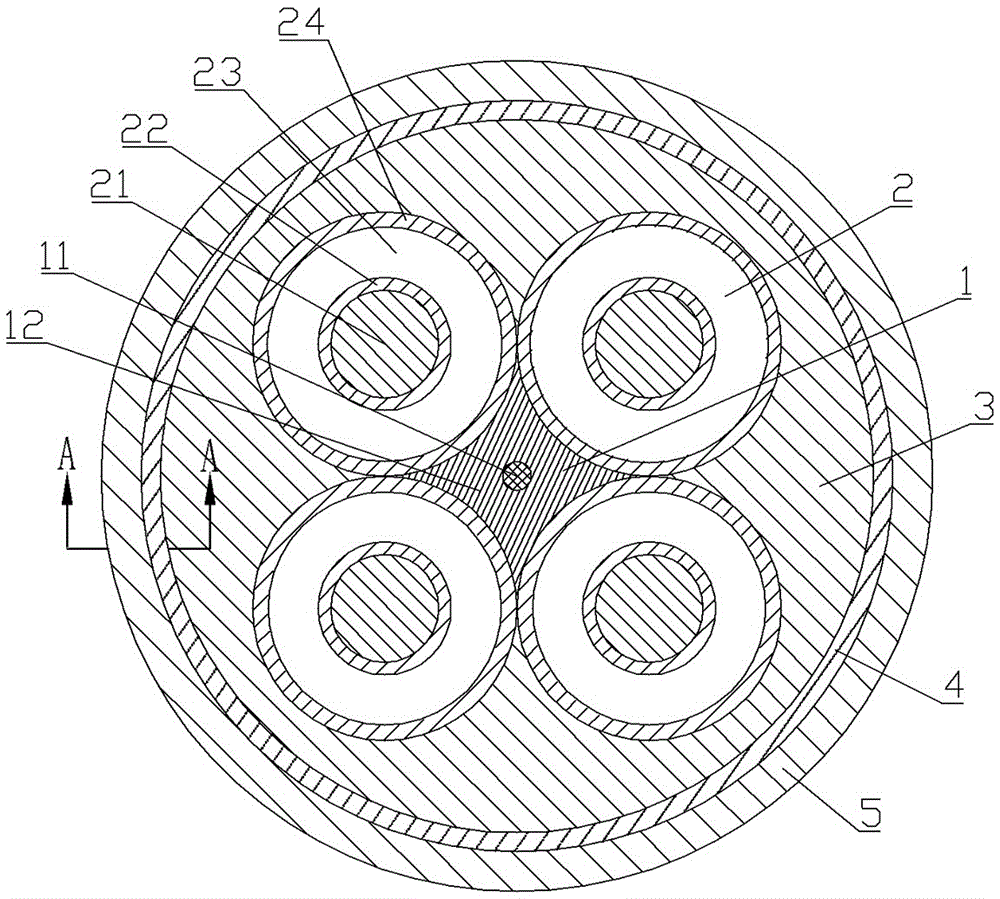

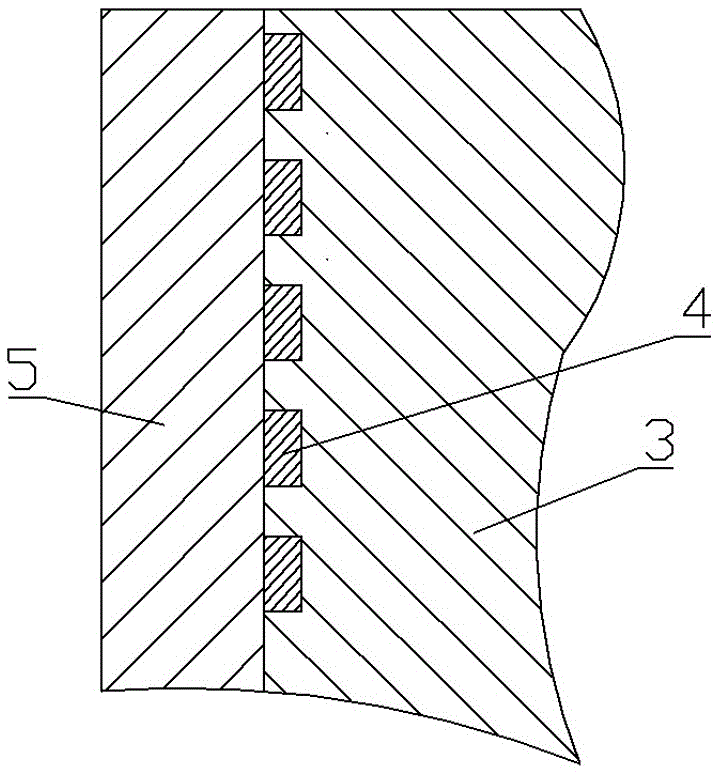

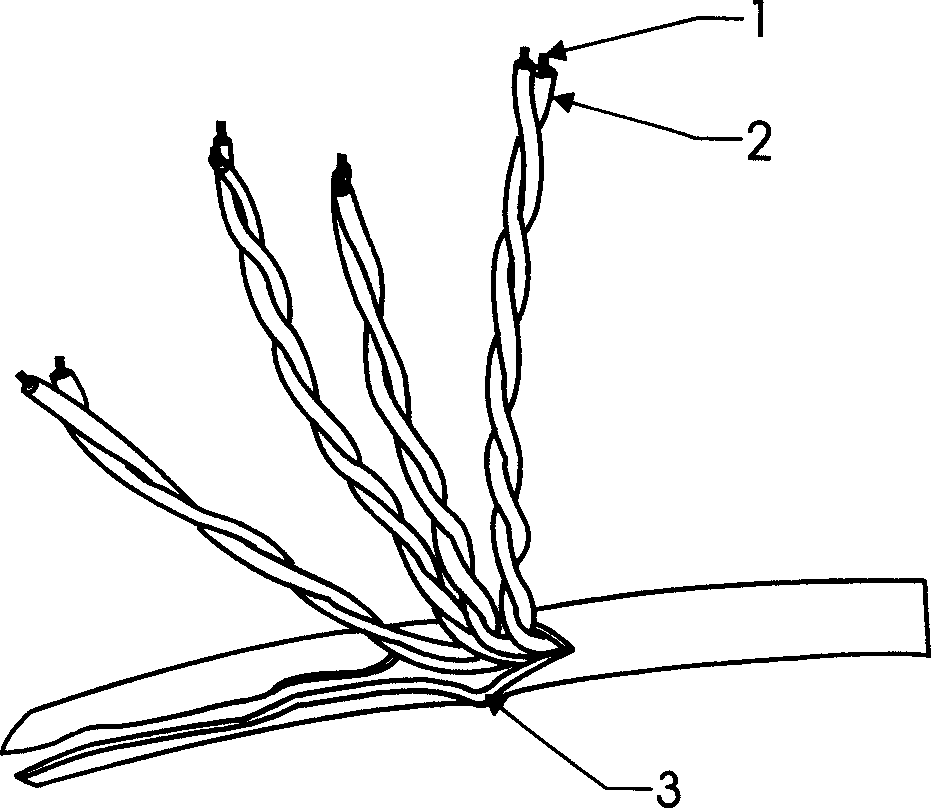

Deep submersion pressure-resistant waterproof cable and preparation method thereof

PendingCN105575511APitch stabilityGuaranteed against torsionSubmarine cablesCable/conductor manufactureSeawaterPull force

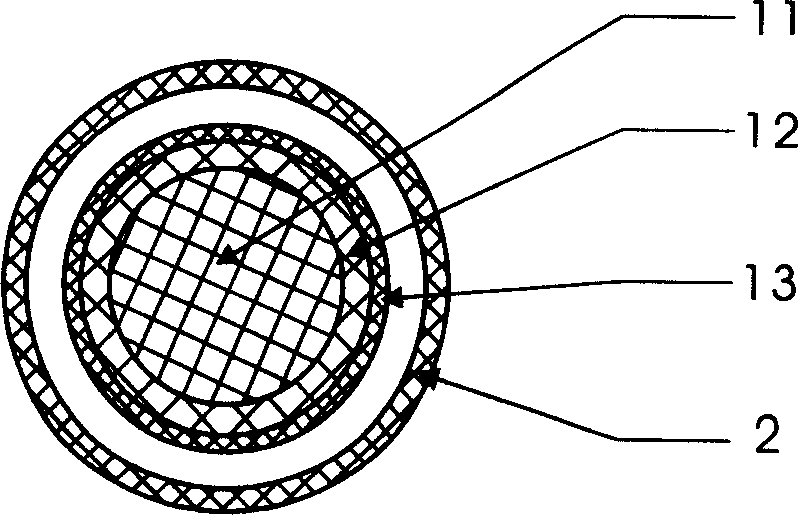

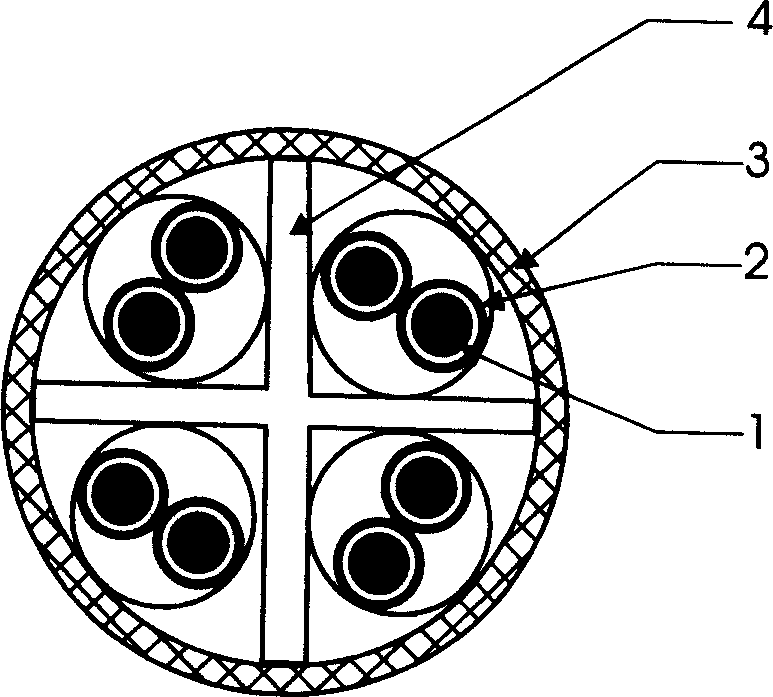

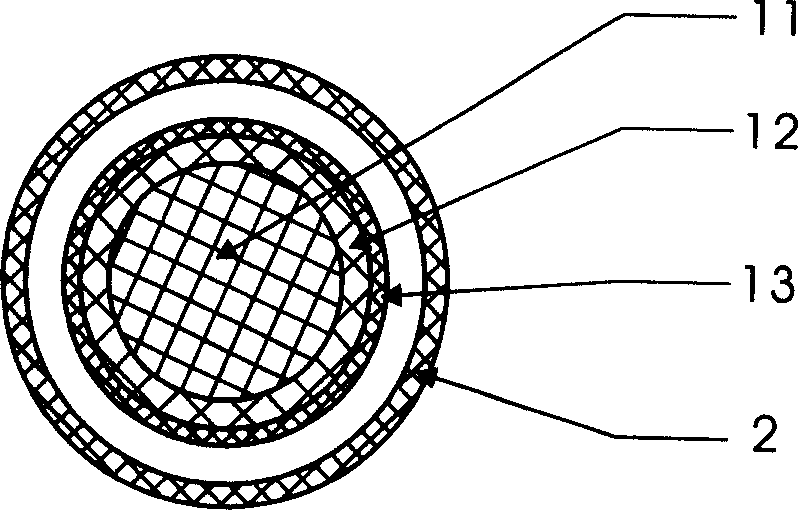

The invention provides a deep submersion pressure-resistant waterproof cable comprising a flexible cable core, insulting wire cores, an internal sheath layer, a braided reinforcing layer and an external sheath layer. There are at least four insulating wire cores which are evenly distributed around the flexible cable core so as to form a strand through twisting to enclose the flexible cable core. The internal sheath layer fills and adheres the external part of the insulating wire cores. The braided reinforcing layer open wraps the external part of the internal sheath layer. The external sheath layer wraps the external part of the braided reinforcing layer. The advantages of the deep submersion pressure-resistant waterproof cable are that the cable is compact in integral structure and stable in performance. The integral structure of the cable is formed, and force can be evenly dispersed when the cable bears deep seawater pressure, pull force of the cable and external pull force so that damage to the external sheath layer caused by force bearing can be effectively reduced, and the phenomenon of "snakeskin" of the sheath layer can be effectively prevented.

Owner:长沙恒飞电缆有限公司

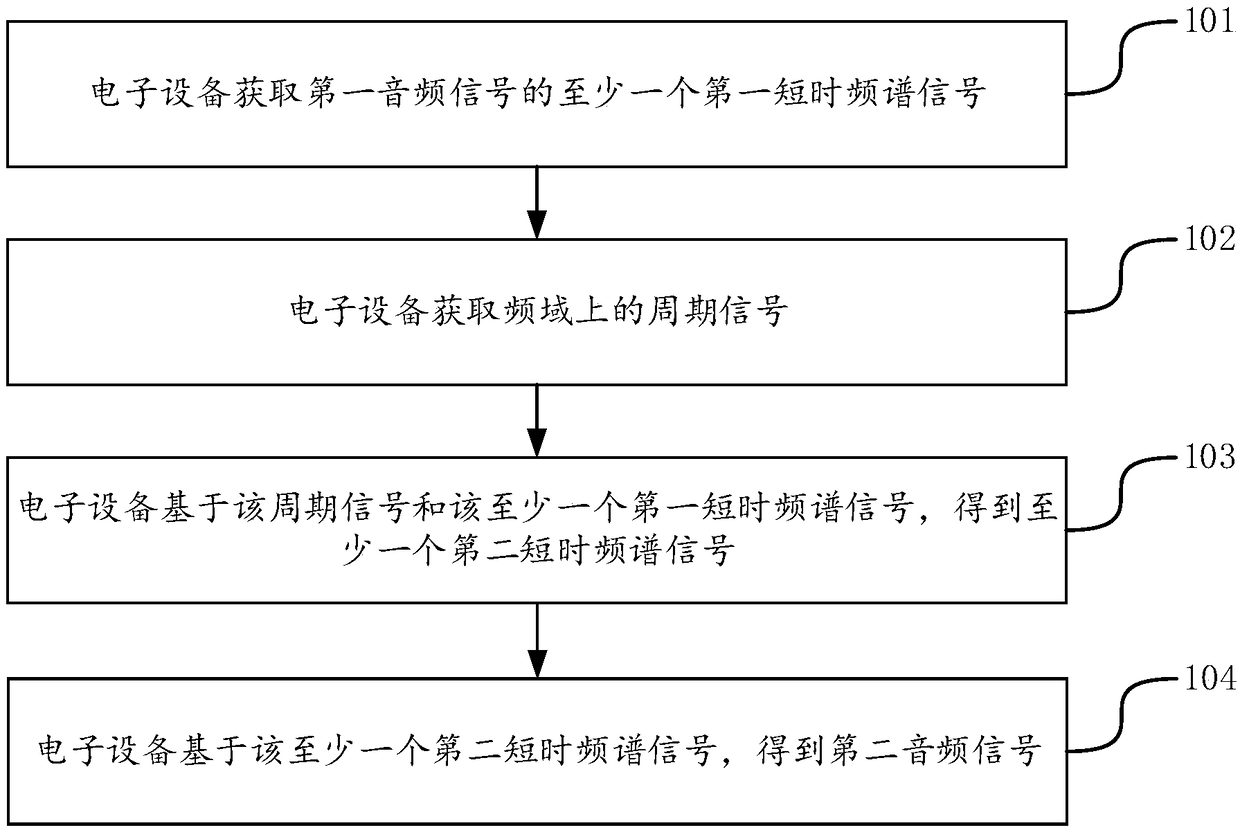

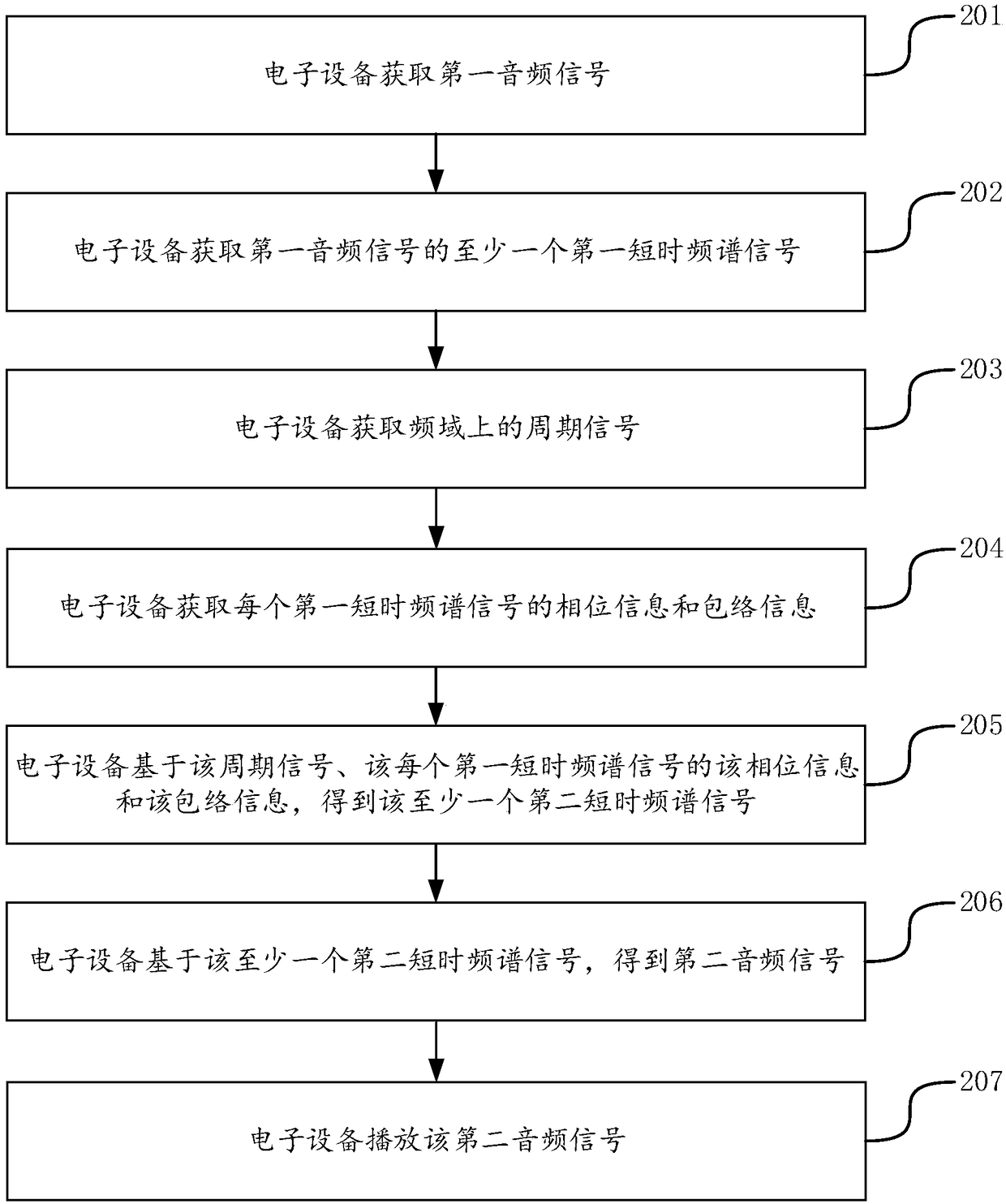

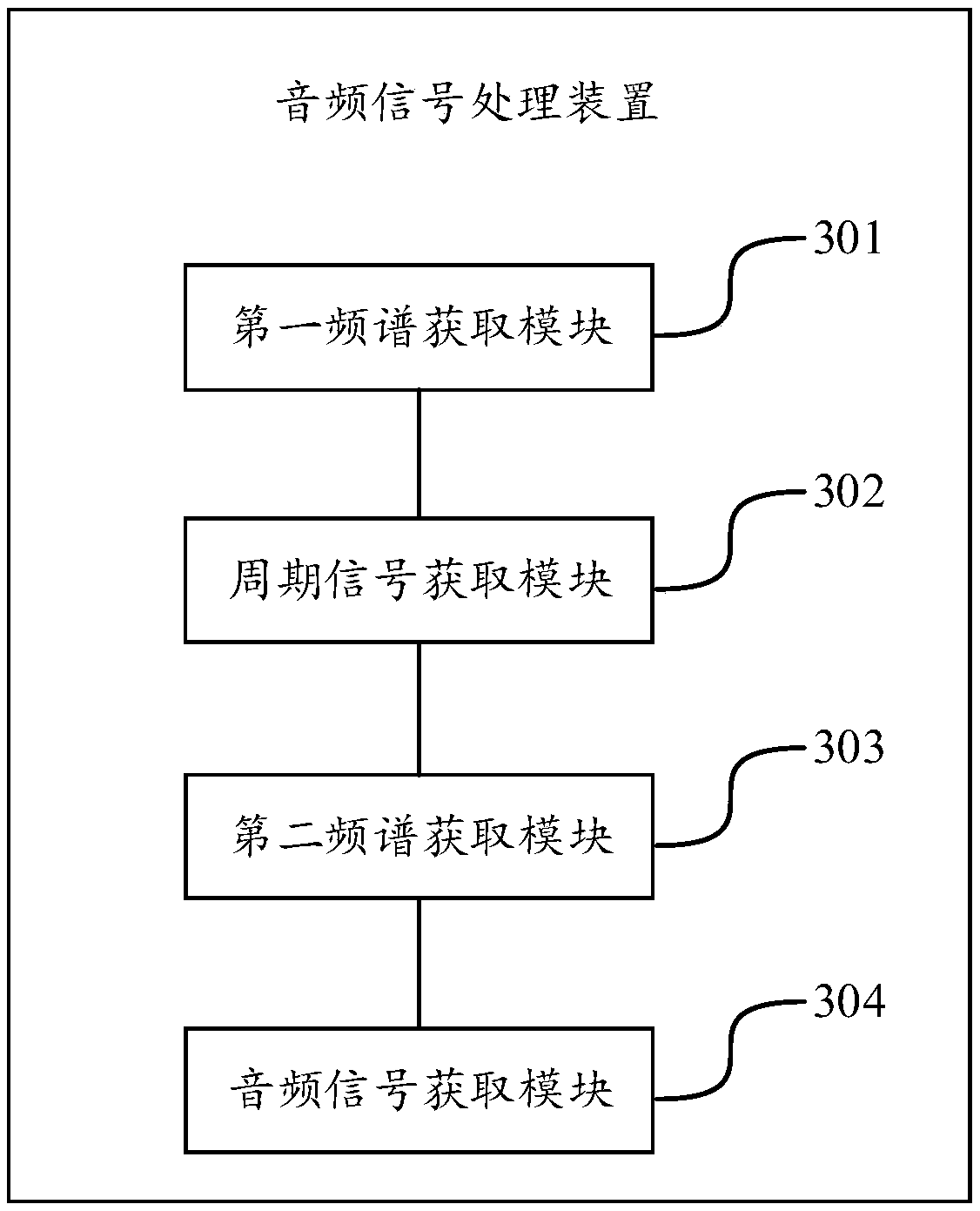

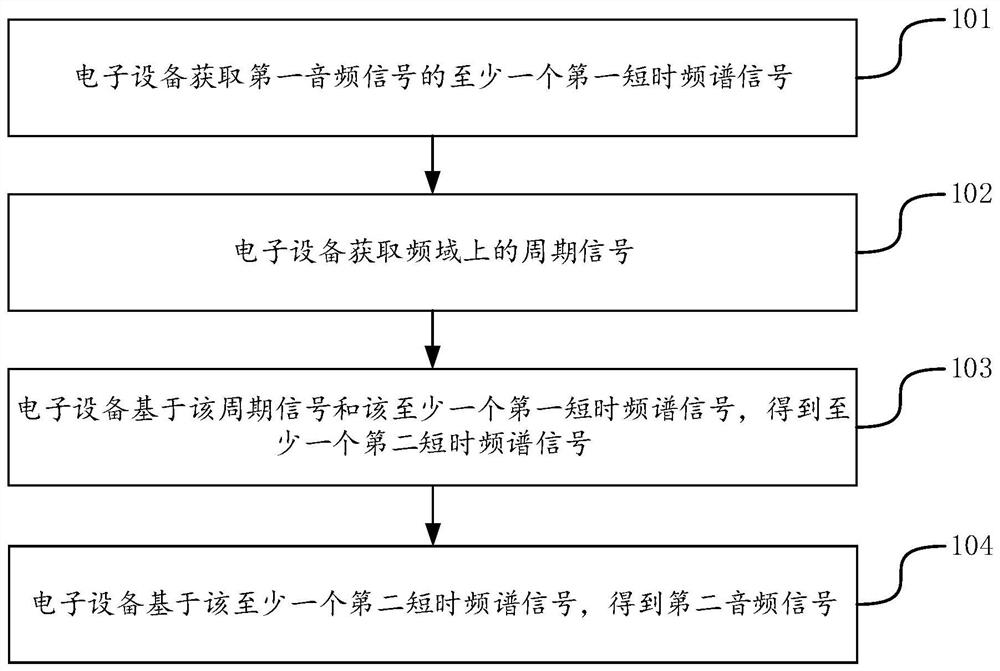

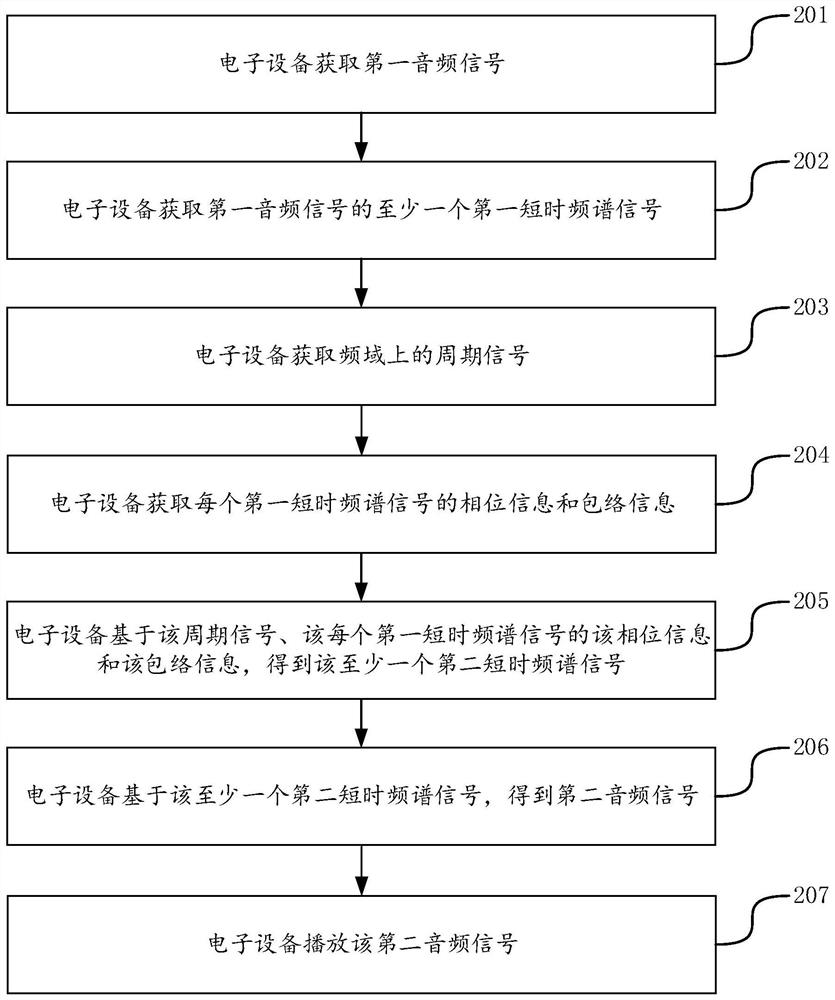

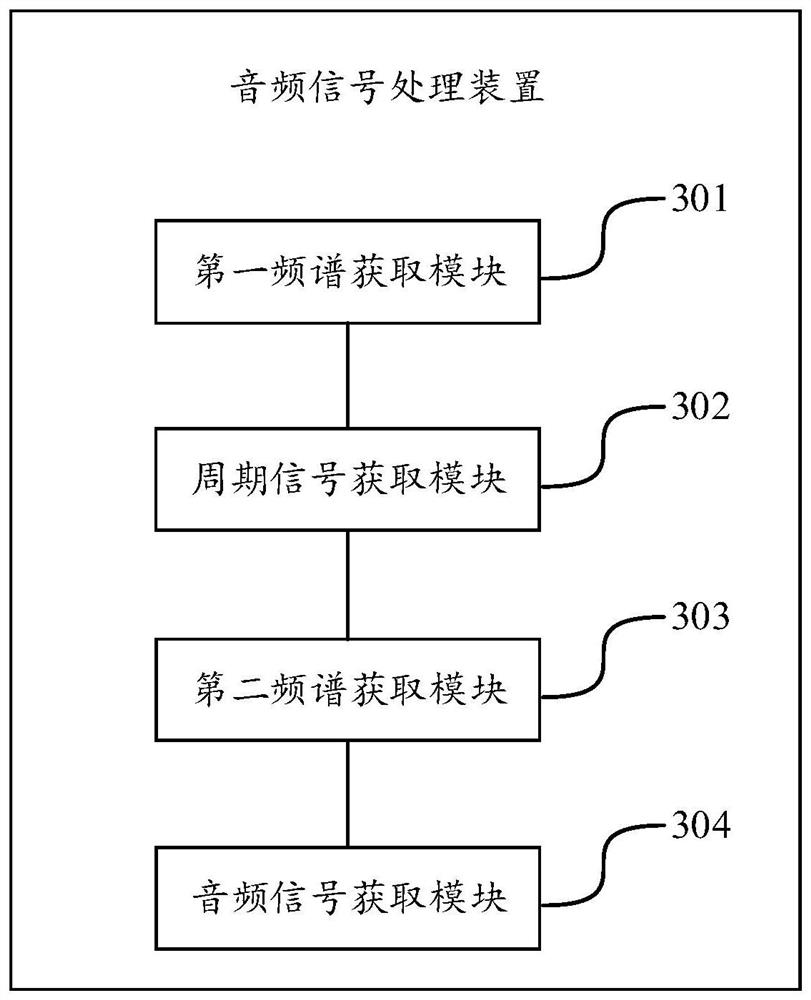

Method and device for audio signal processing, electronic device and storage medium

ActiveCN109243479APitch stabilityPreserve sound characteristicsSpeech analysisFrequency spectrumTime spectrum

The invention discloses a method and a device for audio signal processing, an electronic device and a storage medium, and belongs to the technical field of computers. The method includes: acquiring atleast one first short-time spectrum signal of the first audio signal; acquiring a periodic signal in the frequency domain, wherein a period of the periodic signal in the frequency domain is used to represent a pitch frequency of the periodic signal; and based on the periodic signal and at least one a short time spectrum signal, obtained at least one second short time spectrum signal, the fundamental frequency of each second short time spectrum signal being the same as the fundamental frequency of the periodic signal; and the second audio signal is obtained based on the at least one second short time spectrum signal The pitch frequency of the second audio signal is the same as the pitch frequency of the periodic signal. The pitch frequency of the second audio signal obtained by the invention is fixed, the pitch is always stable, the sound effect of "alien" is generated, and the sound characteristics in the first audio signal are retained, and the distortion rate is low, It is difficultto understand or understand when playing.

Owner:GUANGZHOU KUGOU COMP TECH CO LTD

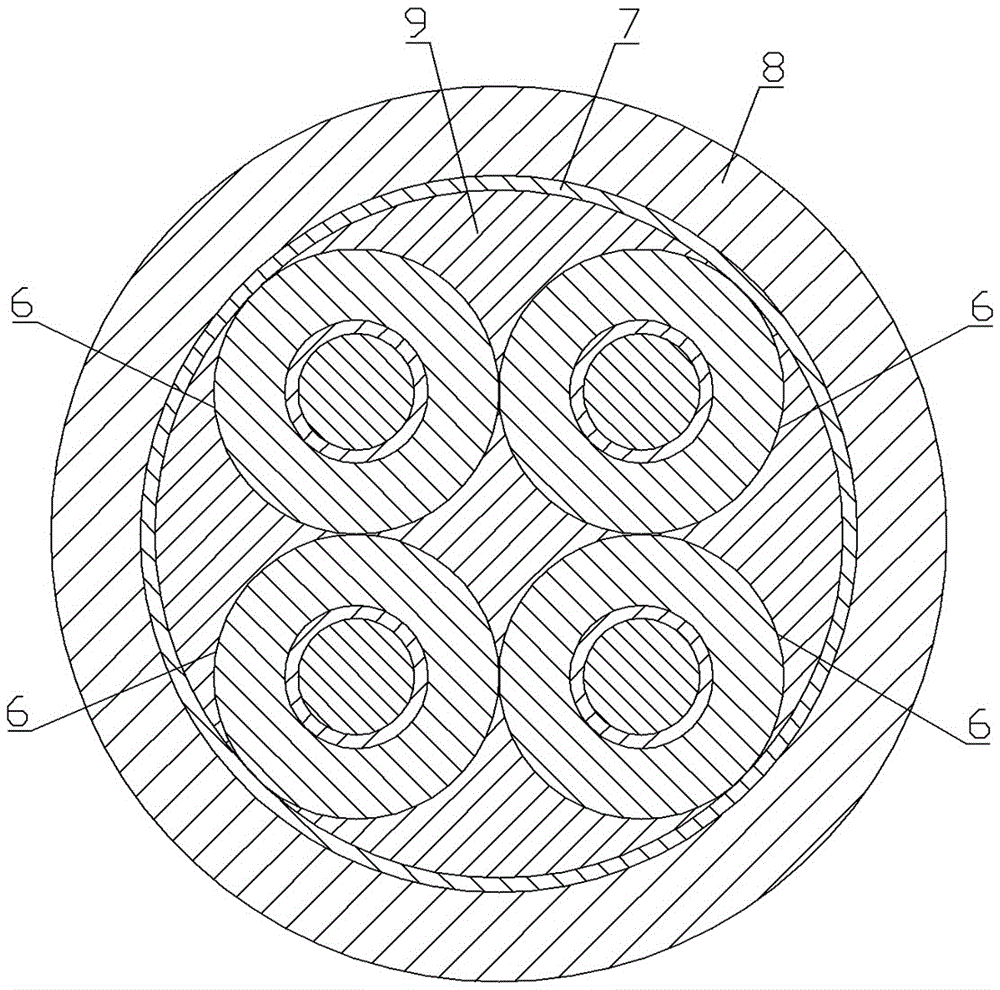

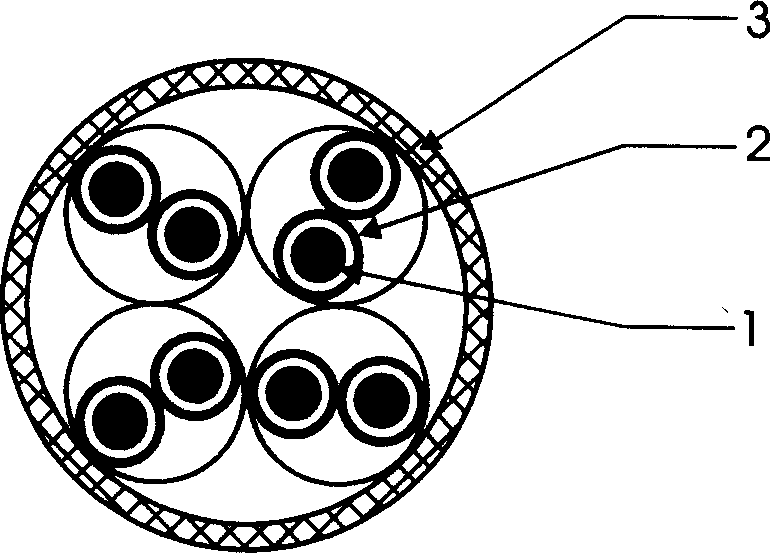

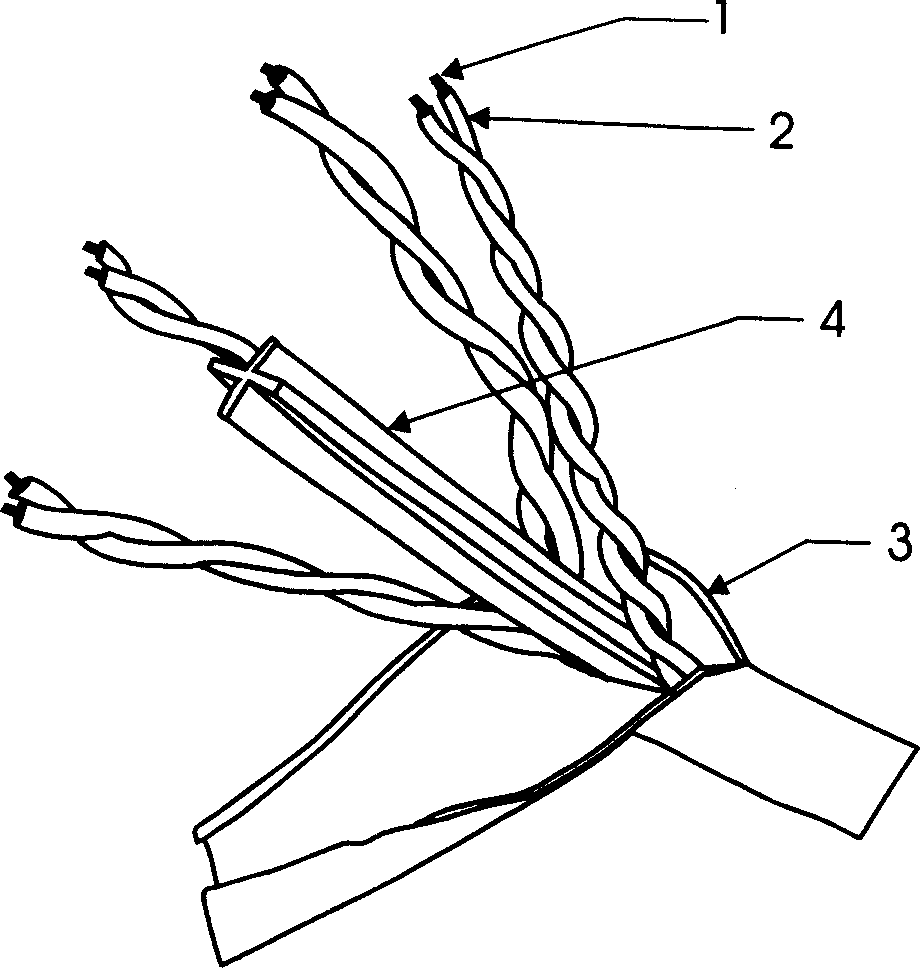

High-speed high-performance communication cable and its manufacturing process

InactiveCN1832056AReduce surface roughnessHigh concentricityInsulated cablesCable/conductor manufactureElectrical conductorHigh performance communication

A high speed data communication cable used on network is prepared as forming cable by four pairs of cable lines as each cable line pair being prepared by twisting two pieces of cable lines and being covered with insulation protective sheath then twisting four pairs together in certain sequence, forming each signal line by conductor cable core and insulation cover using copper covered steel as conductor cable core, applying CMP Teflon as material to prepare insulation protective sheath and insulation cover.

Owner:李明斌

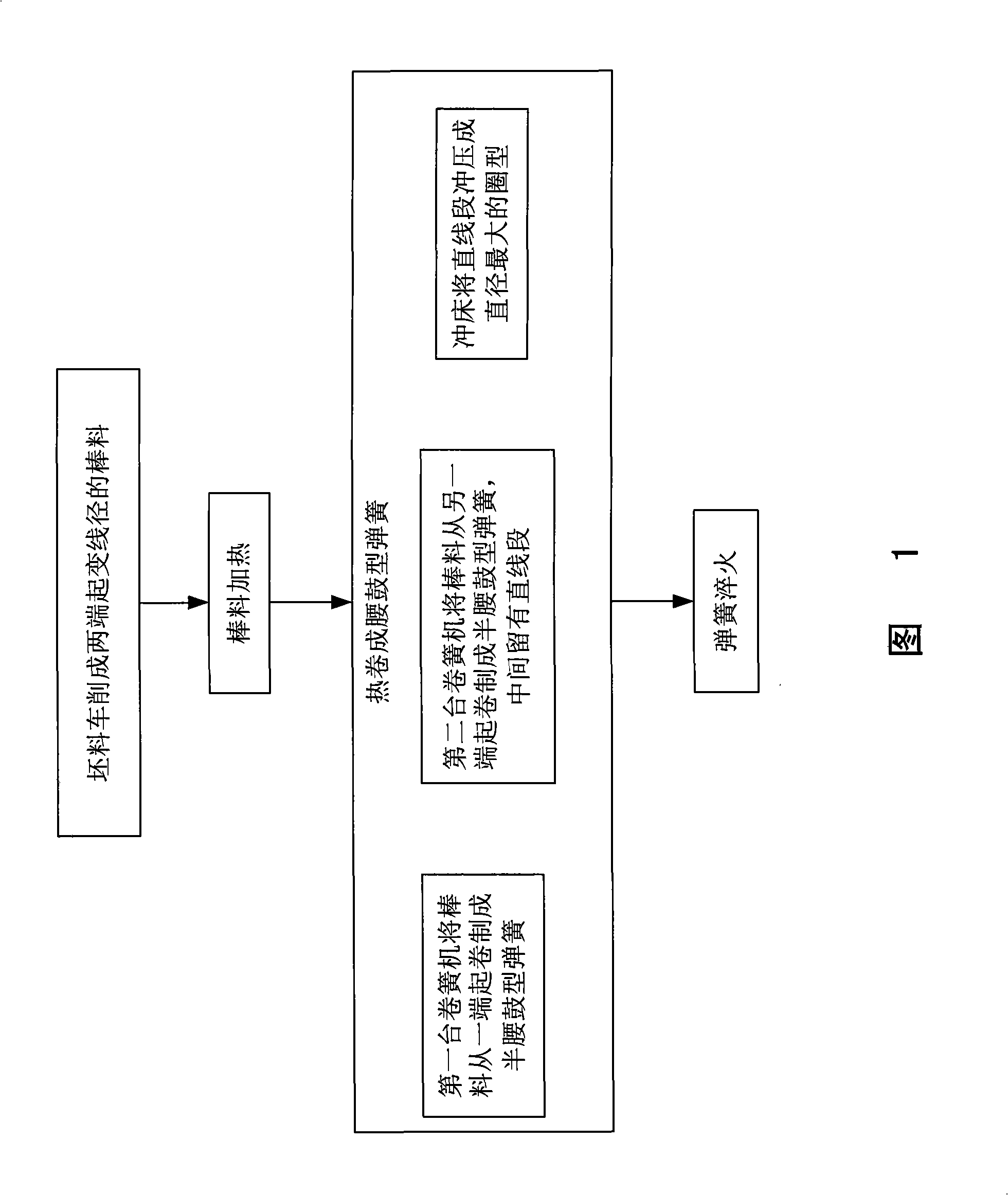

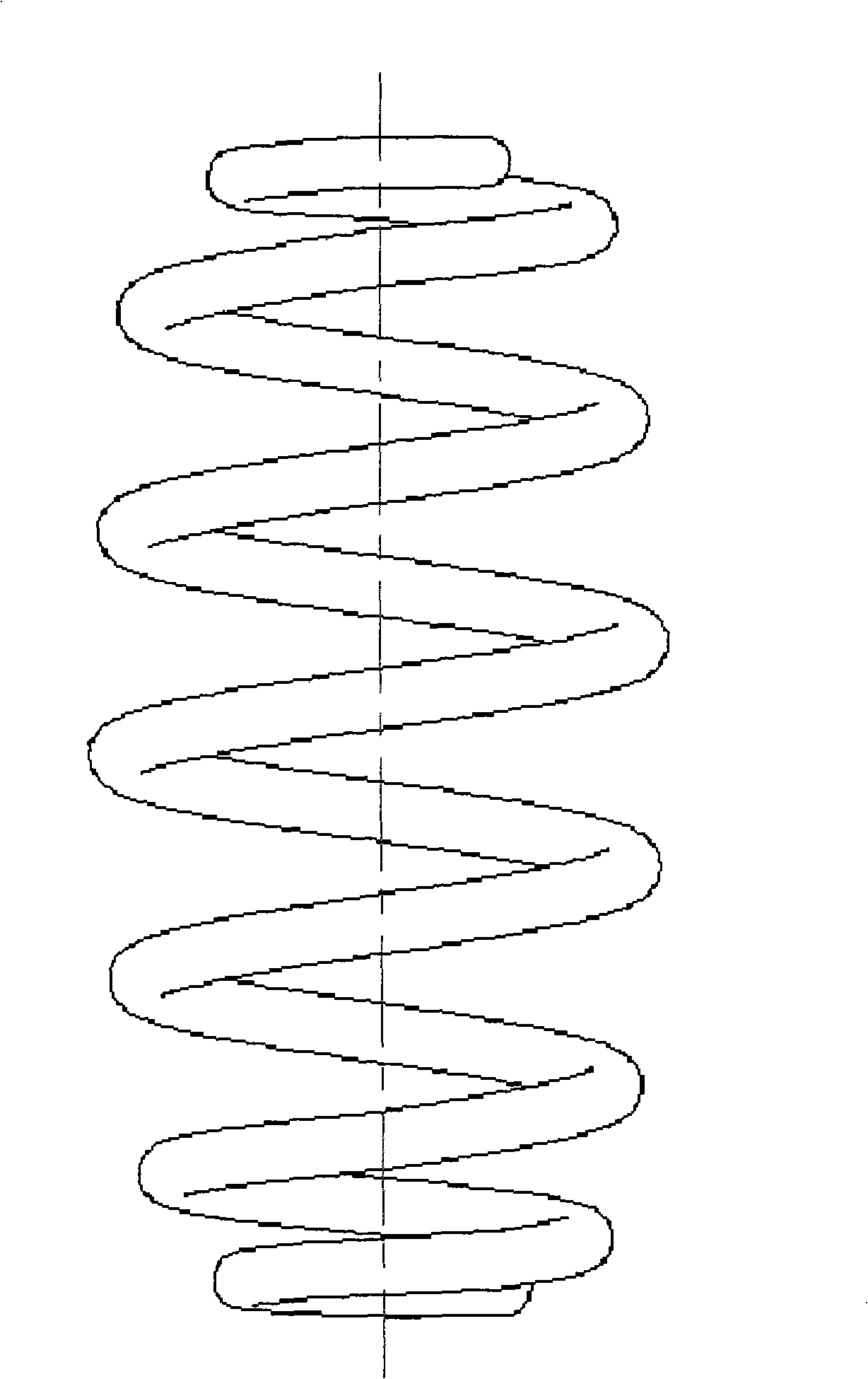

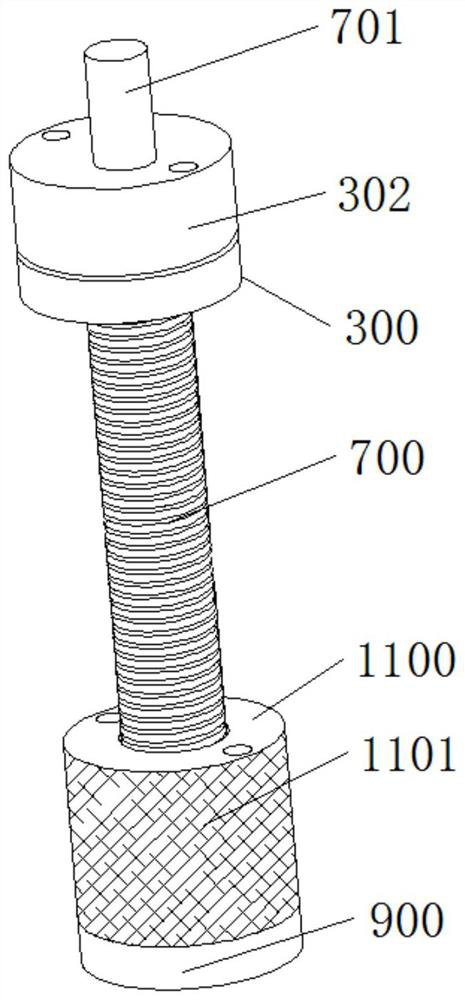

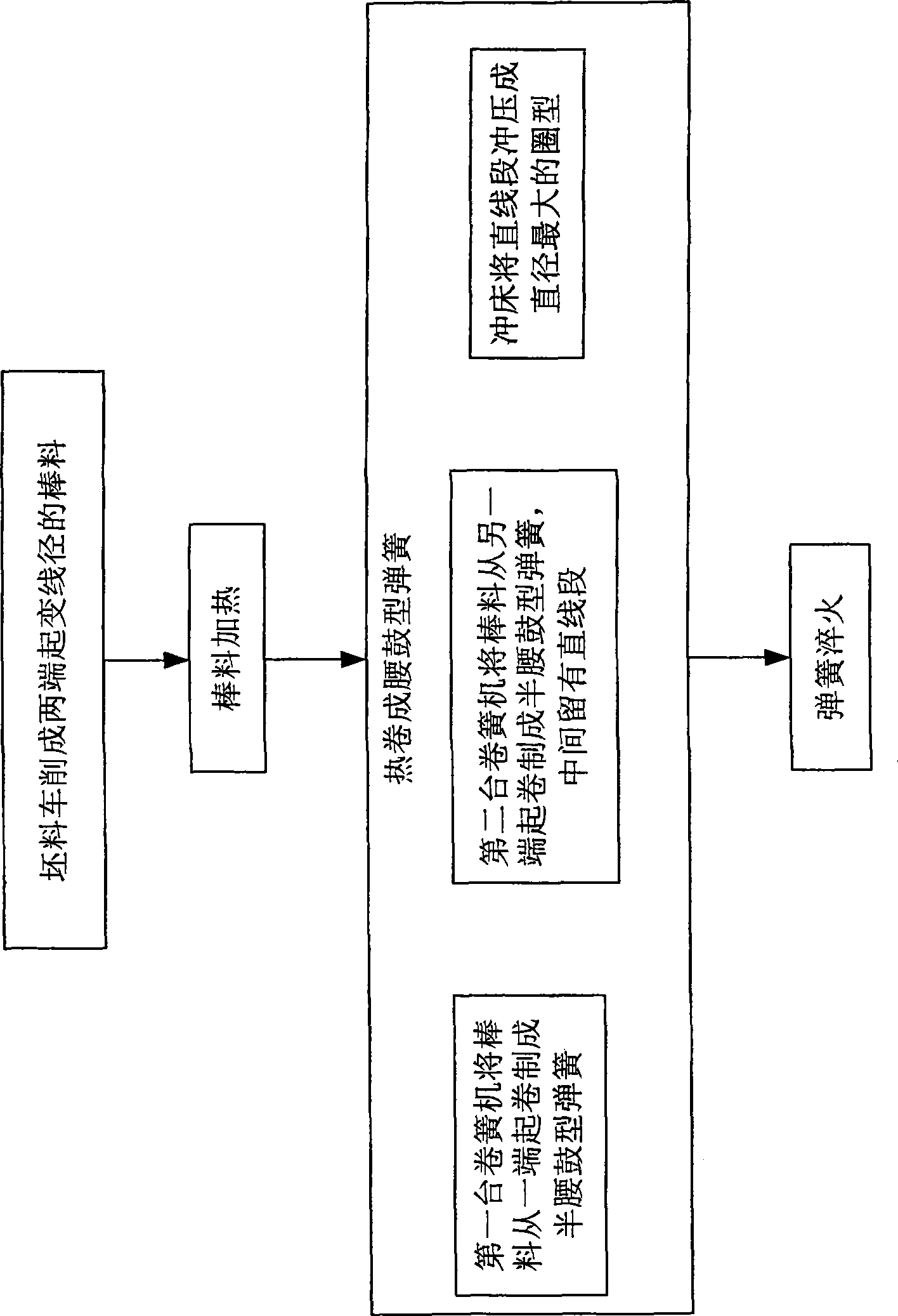

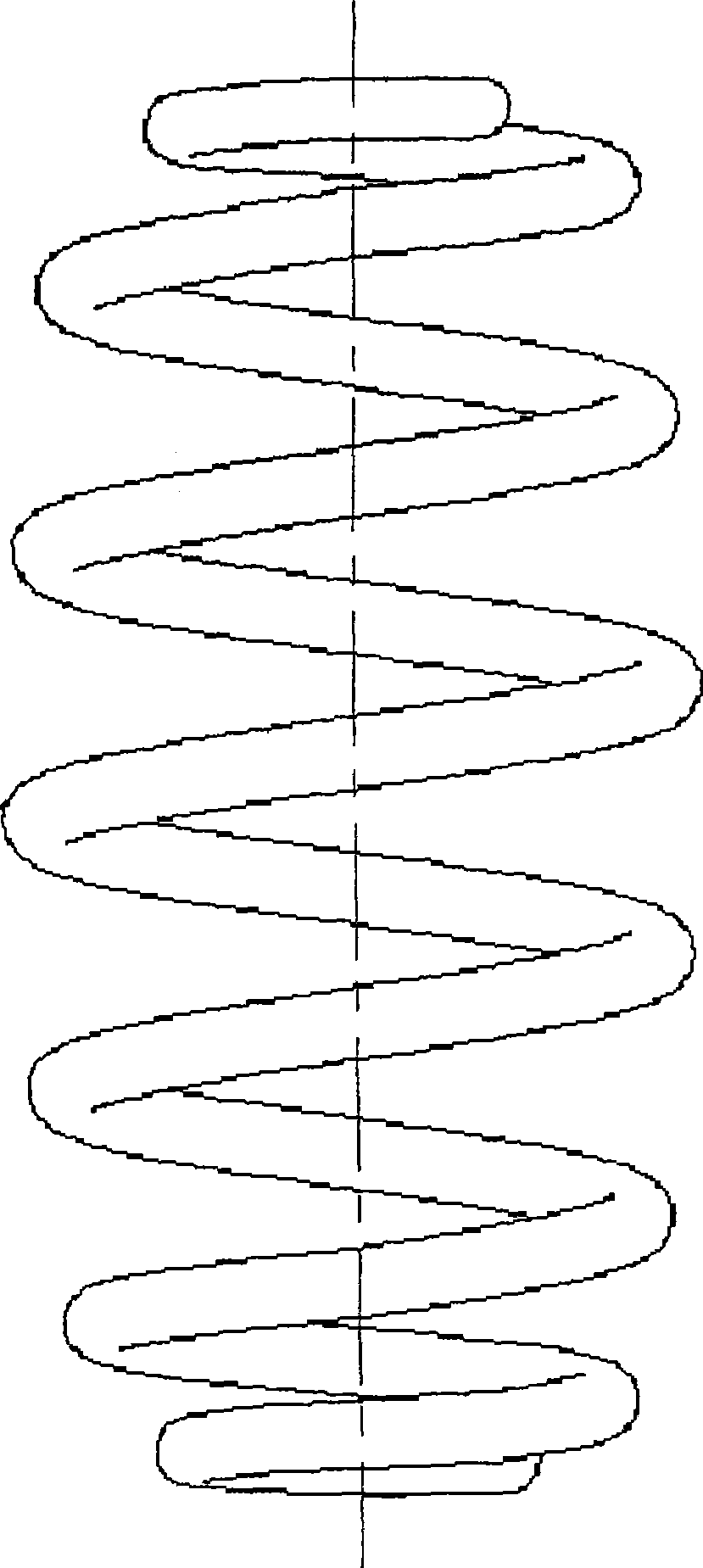

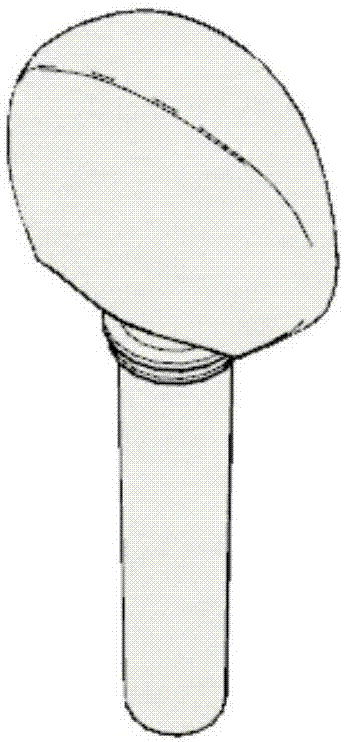

Winding technique for waist drum type spring

ActiveCN101269396ASimple rolling processImprove rolling qualityFurnace typesHeat treatment furnacesHot springEngineering

The invention relates to a rolling process of a drum-type spring, which is a hot-roll molding technology, including a first process: blank is turned into a plurality of bars which are changed from both ends into the diameters of the bars; a second process: After turning, the bars are heated; a third process: the bars heated after the three steps are heated and rolled into a drum-type hot spring: by a first spring coiling machine, the bars are rolled from the beginning of one end into the drum-type spring; by a second spring coiling machine, the bars are rolled from the other end into another drum-type spring which is symmetrical to the former one, with a straight line left in the middle part which is punched into a preset outer diameter; a fourth process: the drum-type spring made by heat rolling is carried out quenching and tempering, so as to make the drum-type spring. The rolling process is simple, the rolling quality is high and the speed is high; both transitional rings of the drum-type spring can be greater than 2.5, besides, all the line diameter, the outside diameter, the stiffness and the pitch can be changed.

Owner:SHANGHAI SPRING CORP

Preparation method of guitar string steel wires

InactiveCN108022571AEasy to stretchIncrease elasticityHot-dipping/immersion processesGuitarsWire rodThermoplastic

The present invention discloses a preparation method of the guitar string steel wires. The preparation method comprises the following concrete steps of (1) preparing a raw material, wherein the raw material is a wire rod; (2) peeling, immersing the wire rod in a pickling tank, removing an oxidation film on the surface of the wire rod by the chemical reaction, and then washing to clear the residualattachments at pickling; (3) using a drying case to dry the wire rod and removing the moisture; (4) carrying out the thermoplastic processing on the wire rod in a roller kiln to improve the plasticity of the wire rod; (5) cold-drawing the wire rod into the steel wires having the sizes needed by the strings; (6) coating a film, and immersing the steel wires in the tin to obtain a layer of protection film; (7) air drying the steel wires, and then packaging and storing. By the above mode, the preparation method of the present invention enables the extensibility and the elasticity of the steel wires to be improved effectively, after immersing in the tin, and coating a layer of protection film, the external corrosion is reduced, and the usage time is prolonged. Meanwhile, the steel wires havethe bright appearances and the smooth hand feeling, by a unique thermoplastic technology, the quality and the performances of the steel wires are improved, and when the steel wires are used as the strings, the tuning is fast, the pitch is stable and the tone quality is clear.

Owner:常熟市先锋乐器有限公司

String with stable pitch

InactiveCN104464693APitch stabilityImprove sound qualityStringed musical instrumentsInter layerZinc alloys

The invention discloses a string with the stable pitch. The string with the stable pitch comprises a protective film layer at the topmost layer, an alloy material layer at the middle layer and a filament plastic fiber layer at the bottommost layer in a combined mode. The alloy material layer is made of copper and zinc alloy, and the filament plastic fiber layer is made of polycarbonate fibers. The protective film layer is 5%-6% of the total weight of the string with the stable pitch, the alloy material layer is 44%-48% of the total weight of the string with the stable pitch, and the filament plastic fiber layer is 44%-50% of the total weight of the string with the stable pitch. The string with the stable pitch has the advantages of being good in tone quality, fast in tuning-up, stable in pitch and good in playing performance.

Owner:常熟市先锋乐器有限公司

High-speed high-performance data communication cable for network and manufacturing method thereof

InactiveCN1832055AHigh concentricityPitch stabilityCable/conductor manufactureCables with twisted pairs/quadsSignal linesEngineering

A high speed data communication cable used on network is prepared as forming cable by four pairs of cable lines as each pair being prepared by twisting two cable lines and being covered with insulation protective sheath, forming each signal line by conductor cable core and insulation cover, packing Teflon or PE material with cross form section in insulation protective sheath and applying copper covered steel conductor as conductor cable core and using flame proof CMP Teflon to prepare insulation protective sheath and insulation cover.

Owner:李明斌

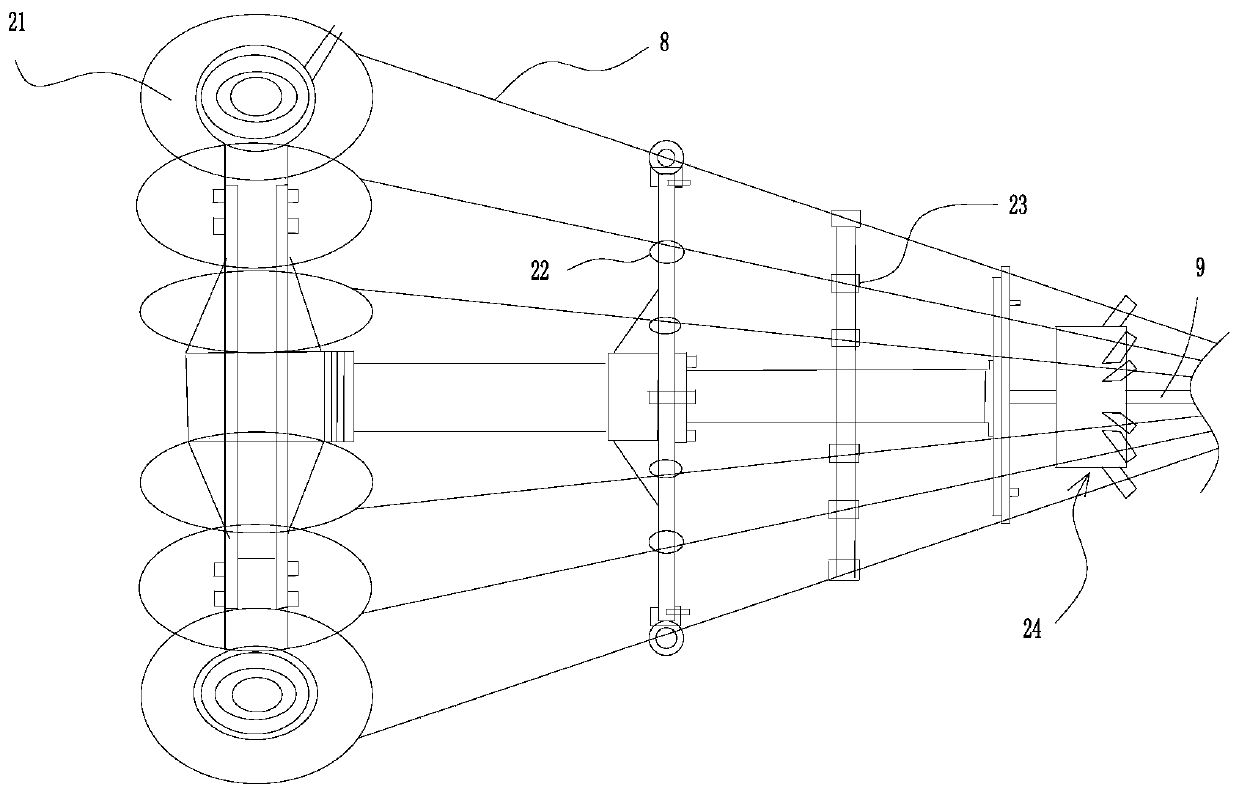

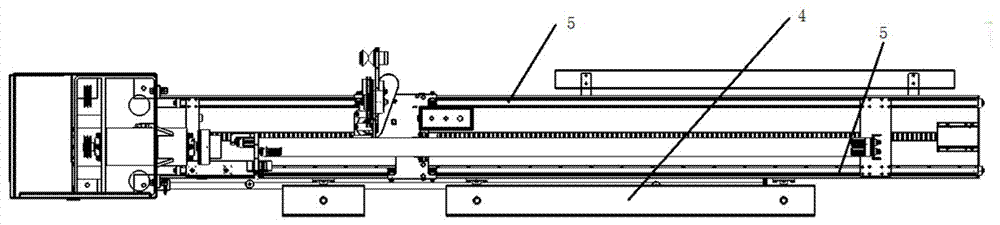

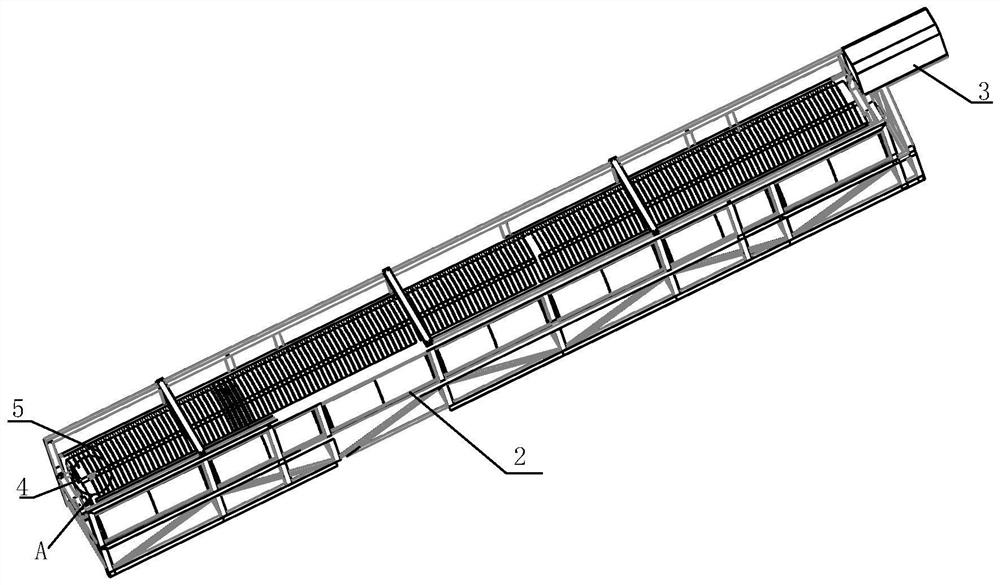

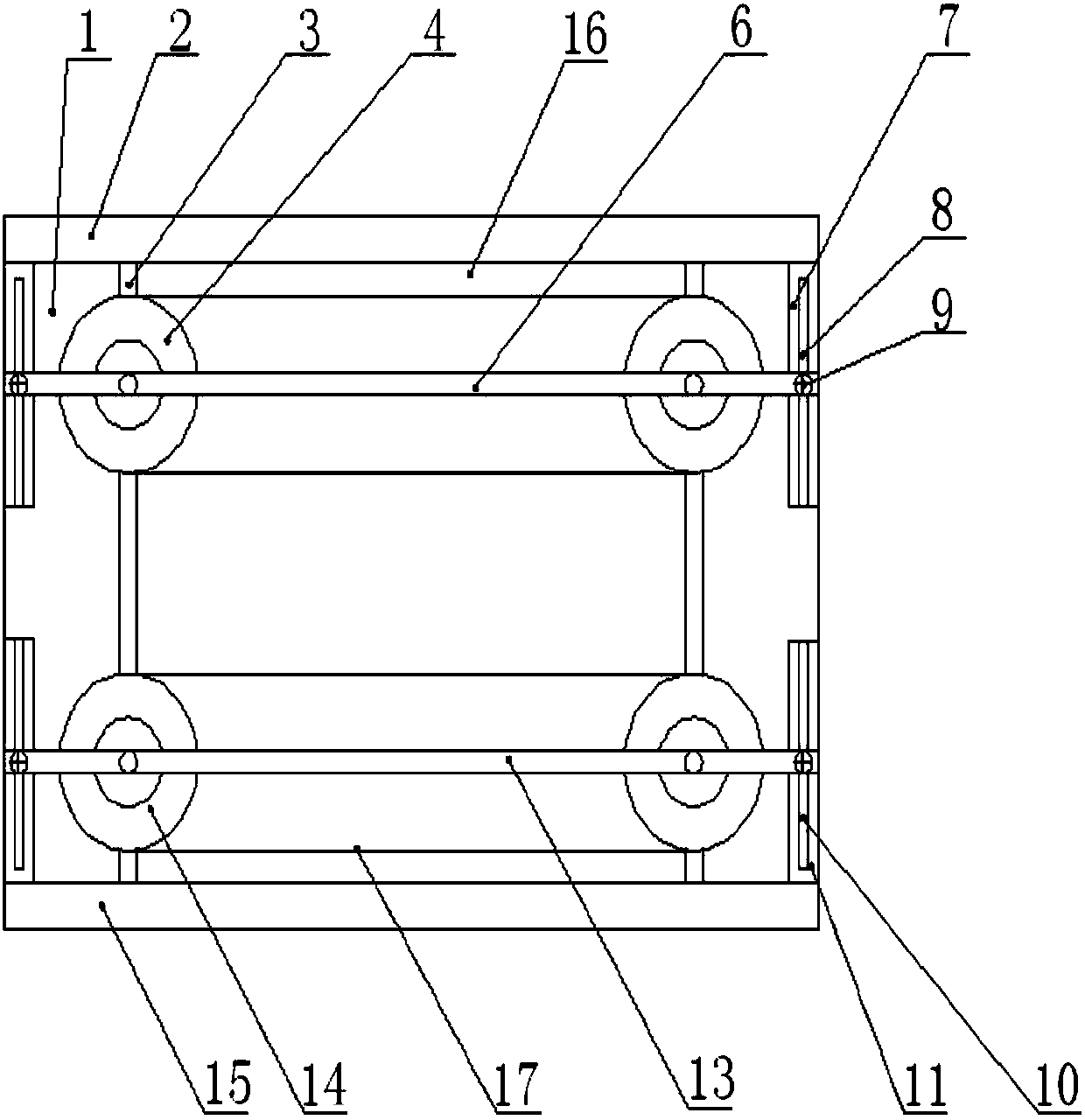

Winding device for tempered transmission rollers

InactiveCN106829625AReduce the burden onUniform pitchFilament handlingEngineeringMechanical engineering

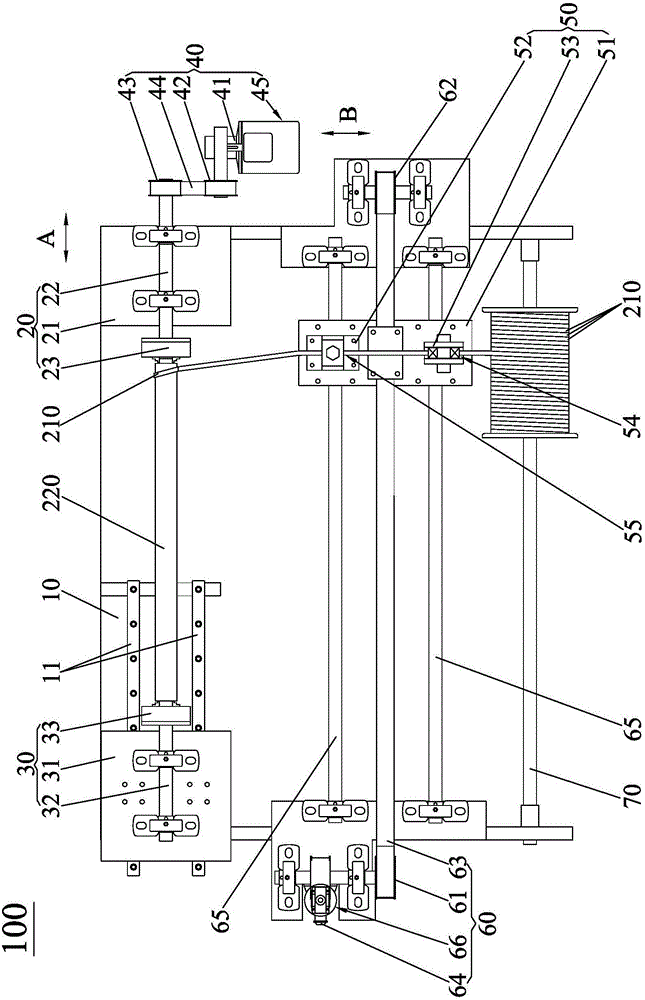

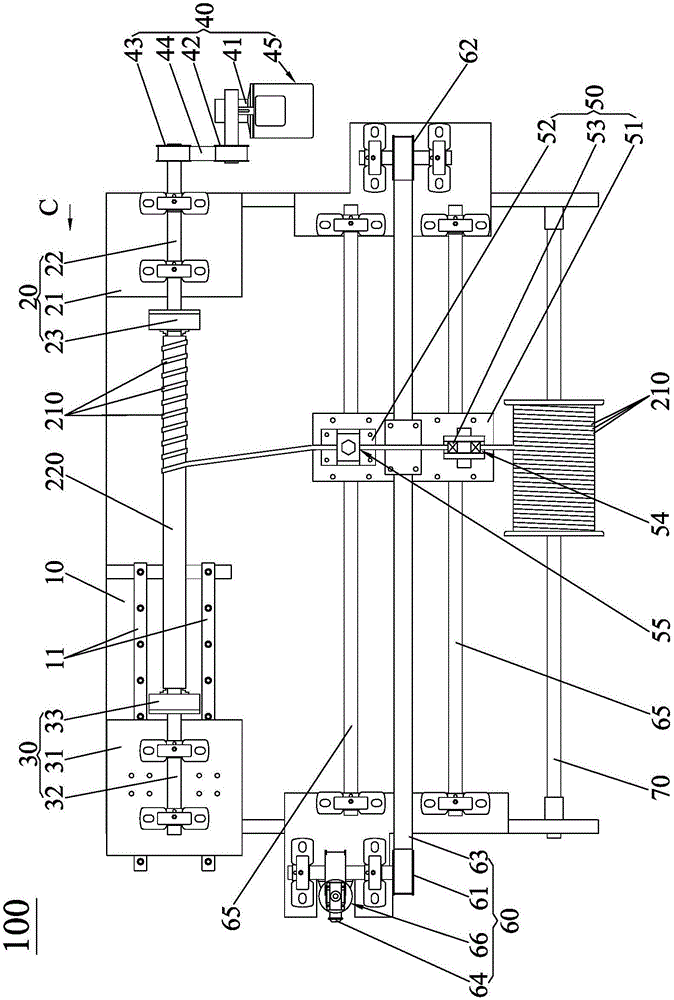

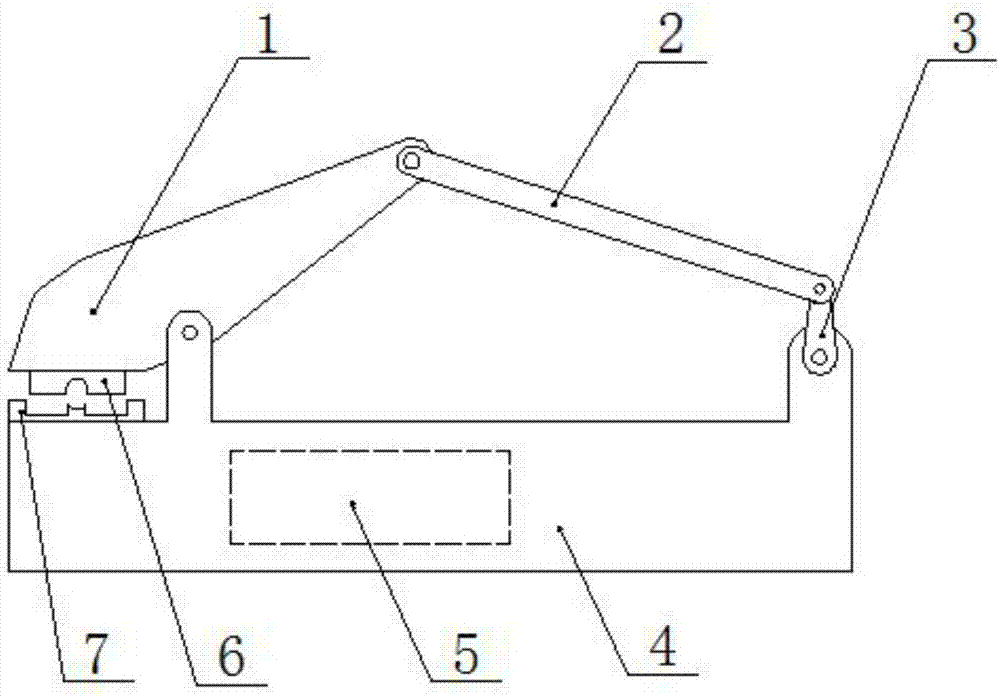

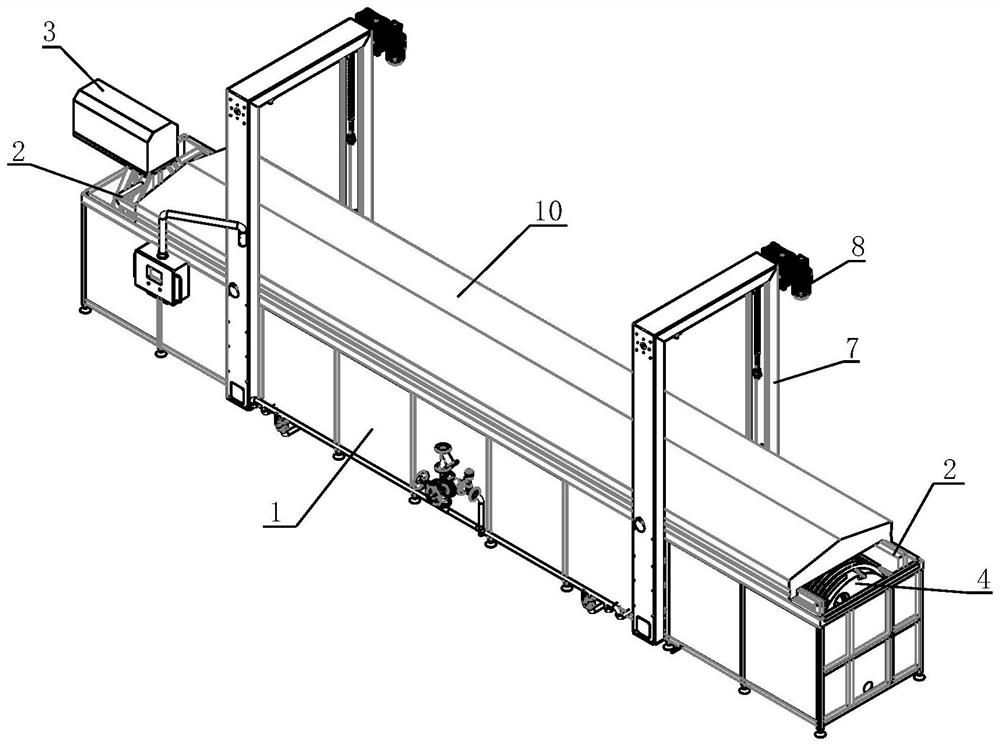

The invention discloses a winding device for tempered transmission rollers. The winding device comprises a framework, a rope guide, a first clamping mechanism, a second clamping mechanism, a first driving mechanism and a second driving mechanism. The first clamping mechanism is arranged at one longitudinal end of the framework, and one end of each tempered transmission roller is clamped by the first clamping mechanism; the second clamping mechanism is arranged at the other longitudinal end of the framework, the other end of each tempered transmission roller is clamped by the second clamping mechanism, and the tempered transmission rollers can rotate relative to the framework under the condition that the tempered transmission rollers are clamped by the first clamping mechanism and the second clamping mechanism; the tempered transmission rollers can be driven by the first driving mechanism to rotate; the rope guide is slidably arranged on the framework along the longitudinal direction of the framework, and starting ends of tempered auxiliary ropes penetrate the rope guide and then are fixed onto the tempered transmission rollers; the second driving mechanism is arranged on the framework, and the rope guide can be driven by the second driving mechanism to slide in a reciprocating manner. The winding device has the advantage that the tempered auxiliary ropes led out of the rope guide can be wound on the tempered transmission rollers along the axial arrangement of the tempered transmission rollers in a thread pitch manner under the matching effects of the first driving mechanism and the second driving mechanism and accordingly can be uniformly and reliably wound on the tempered transmission rollers.

Owner:东莞南玻工程玻璃有限公司 +1

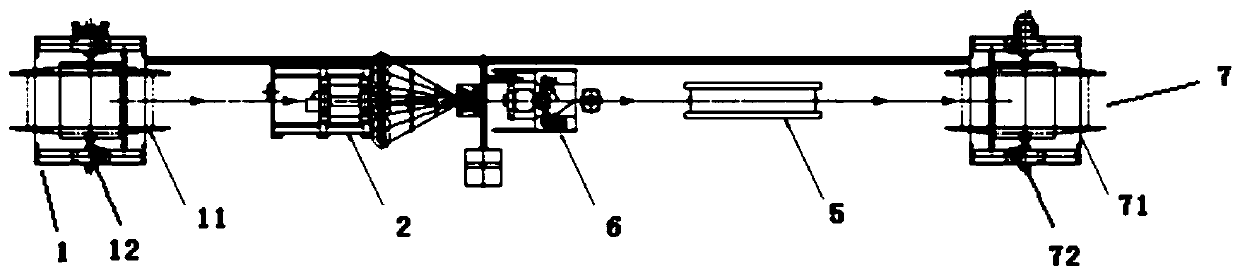

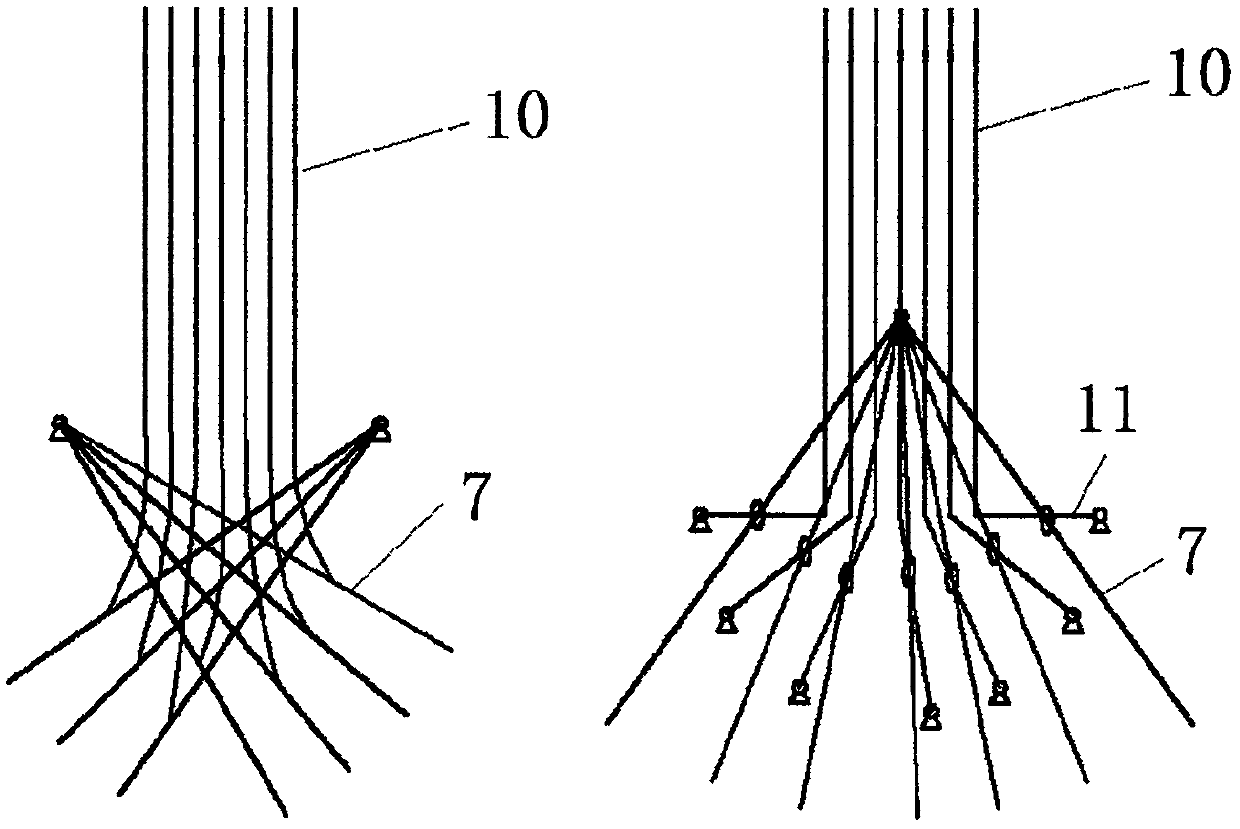

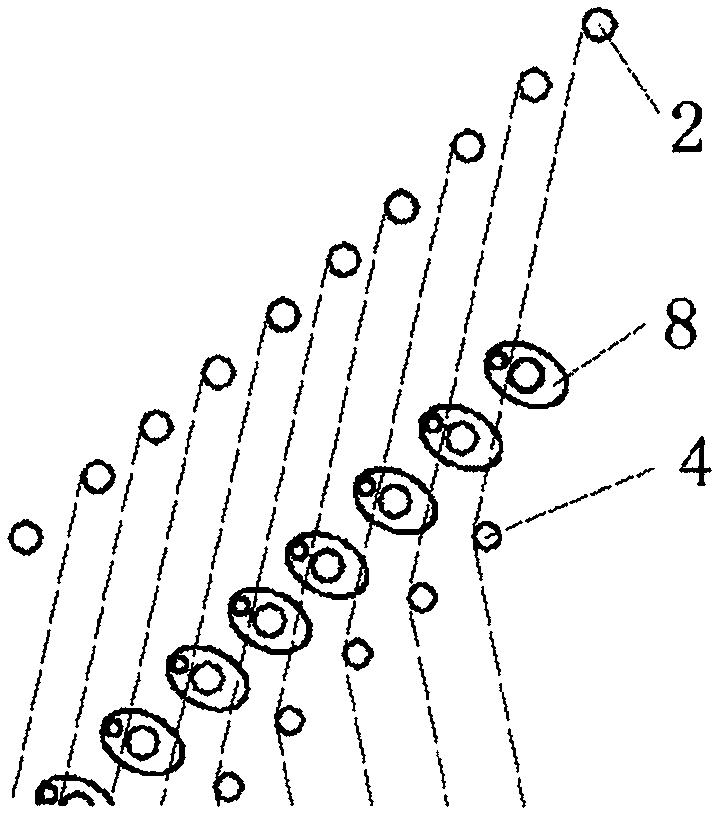

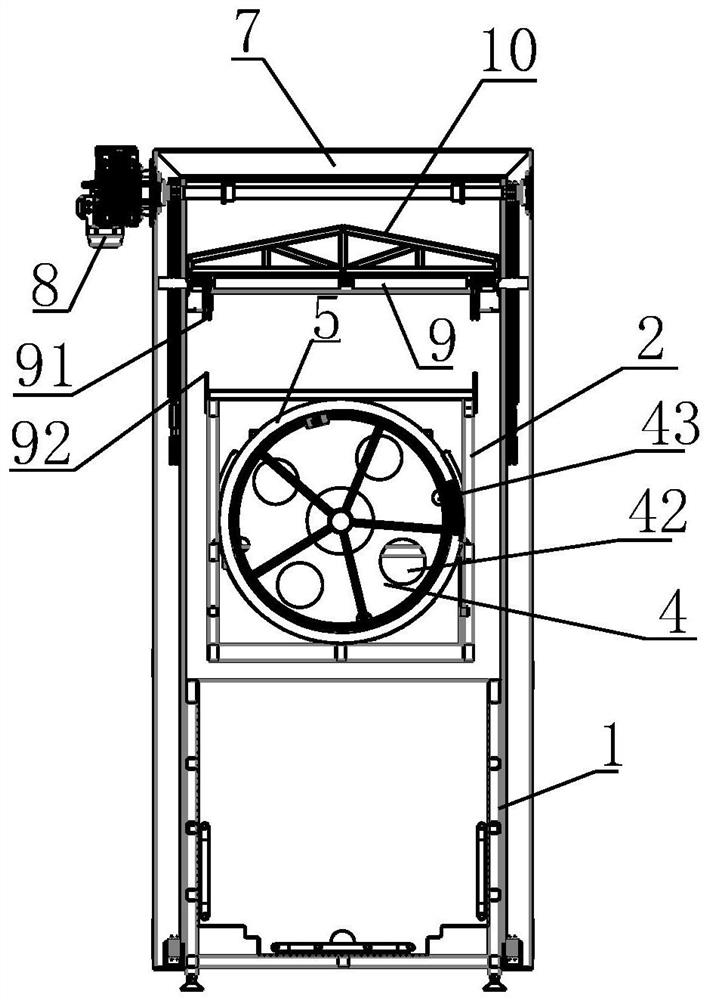

Cabling equipment for superconducting cable

PendingCN111128478AAchieve safe operationFully protectedSuperconductors/hyperconductorsSuperconductor devicesHigh temperature superconductingEngineering

The invention discloses cabling equipment for a superconducting cable. The equipment comprises a forming assembly and a traction device. The forming assembly comprises a wheel disc, a first guide wheel, a guide die and a first belt gathering frame which are successively arranged. The wheel disc is used for winding a belt body; the wheel disc, the first guide wheel and the guide die are correspondingly distributed and are collinearly arranged; the guide die comprises a base and an adjusting seat connected with the base, the adjusting seat can move along multiple degrees of freedom relative to the base, and the adjusting seat is used for guiding the belt body; the first belt gathering frame comprises a first frame body and a plurality of first extending ends located at an end of the first frame body, first through holes allowing the belt body to penetrate through are arranged in the first extending ends, and a base material penetrates through a center of the first frame body; when the first frame body rotates, the belt body can be wound around the surface of the base material to form the superconducting cable; and the traction device is used for driving the base material to move linearly. In the invention, a strip can be protected in a stranding process so as to ensure performance of the high-temperature superconducting cable.

Owner:EASTERN SUPERCONDUCTOR SCI & TECH SUZHOU CO LTD

Cable shielding copper strip device

InactiveCN106229093AIncrease productivityPitch stabilityInsulated cablesCable/conductor manufactureEngineeringCopper

The present invention provides a cable shielding copper strip device, relating to cable shielding copper strip devices. The cable shielding copper strip device comprises a base, a support base mounted at one side of the base, and a hollow shaft fixed on the support base. A copper strip disk rotating relative to a hollow tube sleeves on the hollow tube. The copper strip disk comprises a copper strip base disk and a copper strip chuck. A brake wheel fixedly connected with the copper strip base disk also sleeves on the hollow tube. The front end of the hollow tube is provided with a locking device of the copper strip disk. A shaft disk rotating along with a synchronous wheel synchronously also sleeves on the hollow tube. A positioning device is also disposed at the right side of the base. The cable shielding copper strip device further comprises a lead device at the right side of the positioning device. The lead device comprises a support. The front and back of the support is provided with a pair of parallel transverse pressure roller. An axis of the transverse pressure rollers is perpendicular to the support. A pair of vertical pressure roller is disposed above and below the transverse pressure rollers. One vertical pressure roller is connected with a second motor. The cable shielding copper strip device has a reasonable structure design, is convenient and efficient in use.

Owner:CHAOHU JINYE ELECTRIC MACHINERY

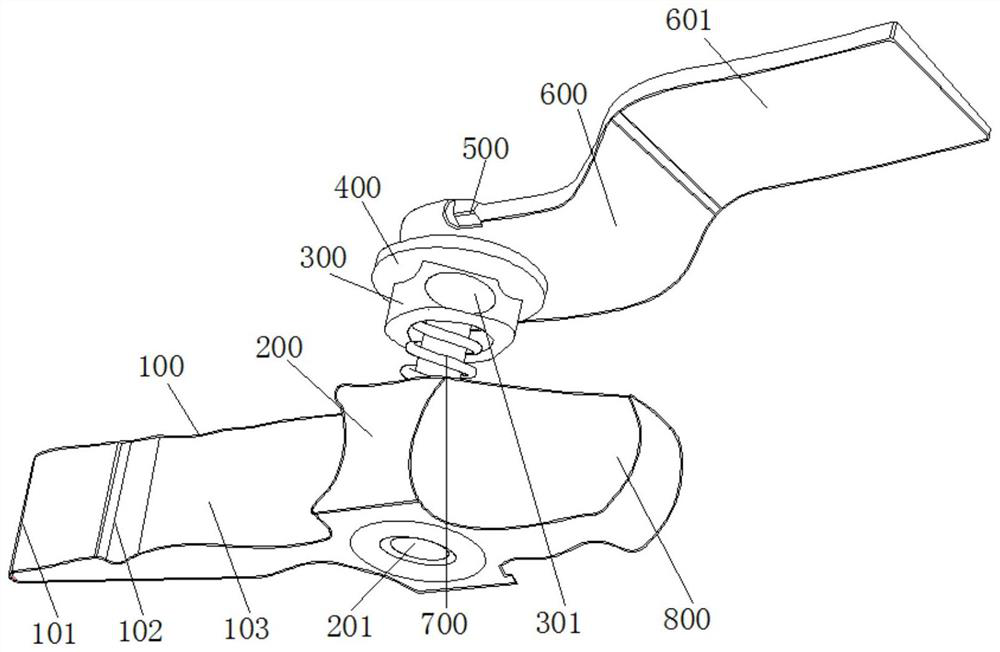

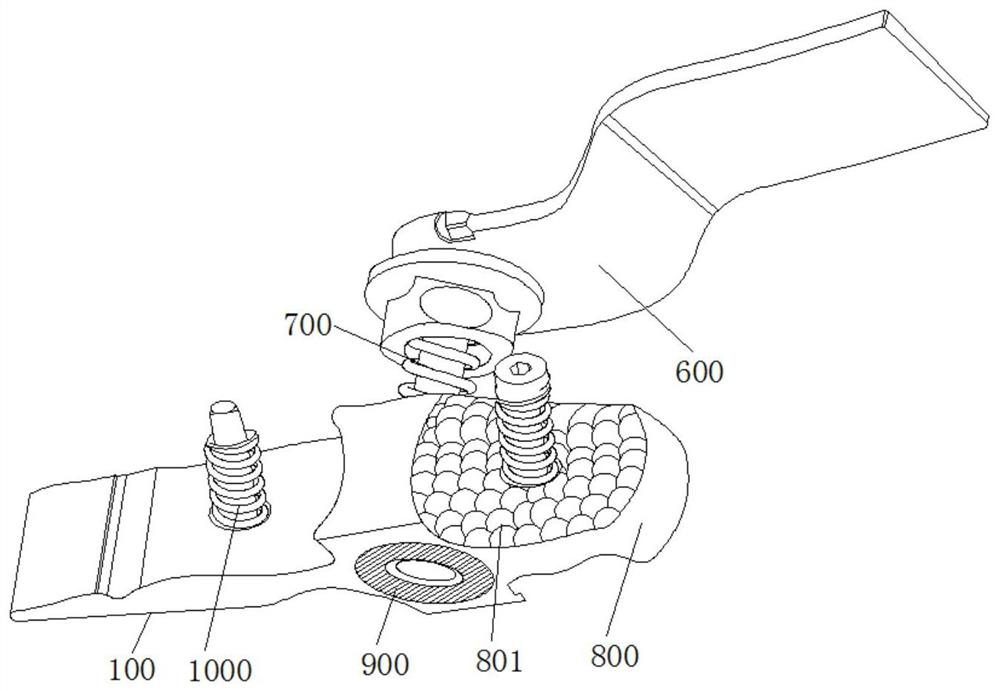

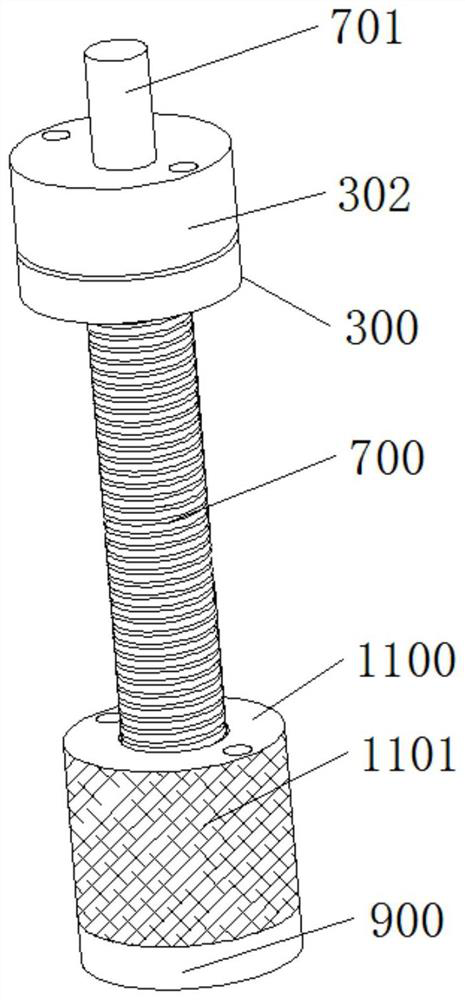

Variable tension tone changing system of Konghou and harp

InactiveCN109817185AGood tuning effectImprove sound qualityStringed musical instrumentsControl systemEngineering

The invention discloses a variable tension tone changing system of a Konghou and a harp, relates to an improvement on a musical instrument control system and in particular relates to an improvement ona variable tension tone changing system of a Konghou and a harp. A chord pressing position is on a tone changing disc between musical instrument nails and a chord rest; a tone changing shifting blockis used for exerting action force onto a chord between the musical instrument nails and the chord rest, then the tension of the chord can be changed, and the pitch of the chord can be changed; the system further comprises a dispersion rod, wherein the dispersion rod is connected with a through rod; the dispersion rod has a dispersion function; a pedal is connected with the dispersion rod. The chord pressing direction of the tone changing shifting block is in a direction parallel to a musical instrument body and approaches to directions of chords. As tones are changed by changing the chord tension, good tone quality is achieved after tone changing, and stable intonation is achieved; the level of tone changing and sound variation of the Konghou or the harp can be further increased.

Owner:鲁璐

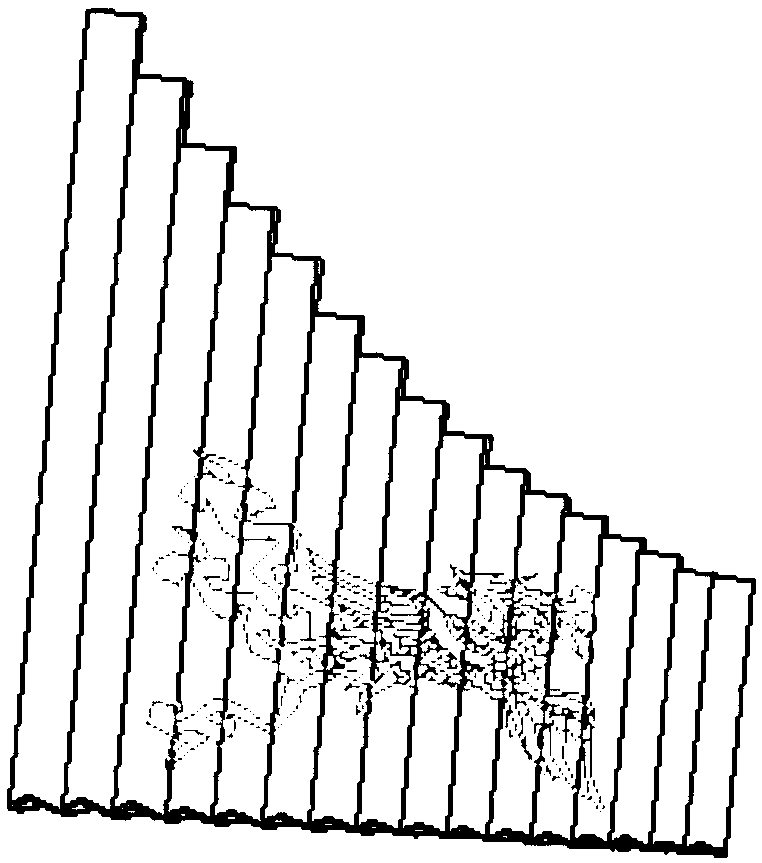

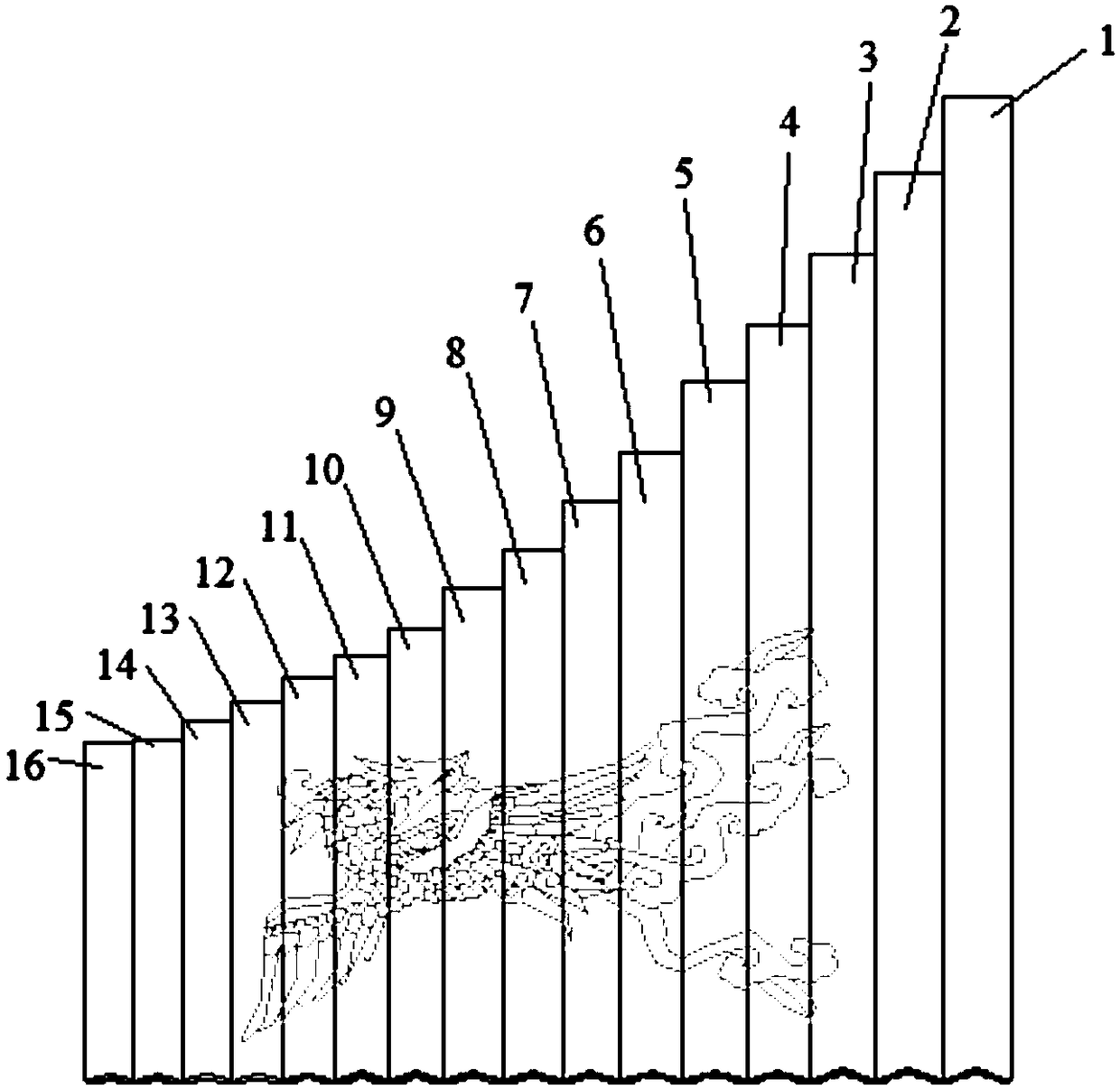

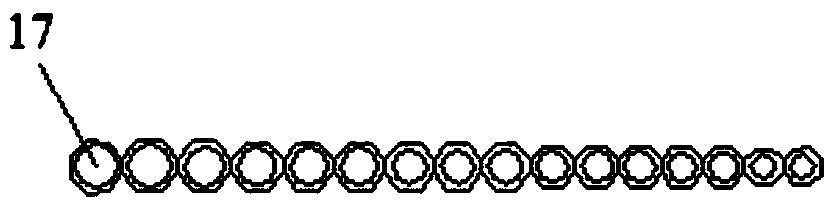

Improved panpipe and making method thereof

PendingCN109493835AClear and bright soundPitch stabilityWind musical instrumentsCooking & bakingEngineering

The invention discloses a making method of an improved panpipe. The method comprises the steps of material selection, baking, measuring, length fixing, surface planing, pipe sticking, polishing, paintspraying, decorating and tone tuning. According to the improved panpipe, the defects of early panpipes and existing panpipes are overcome, the materials of the panpipe, the glue materials, colors, decoration, patterns and the like are changed, and a wind instrument which is bright in tone, stable in intonation and attractive in shape is made.

Owner:PINGDINGSHAN UNIVERSITY

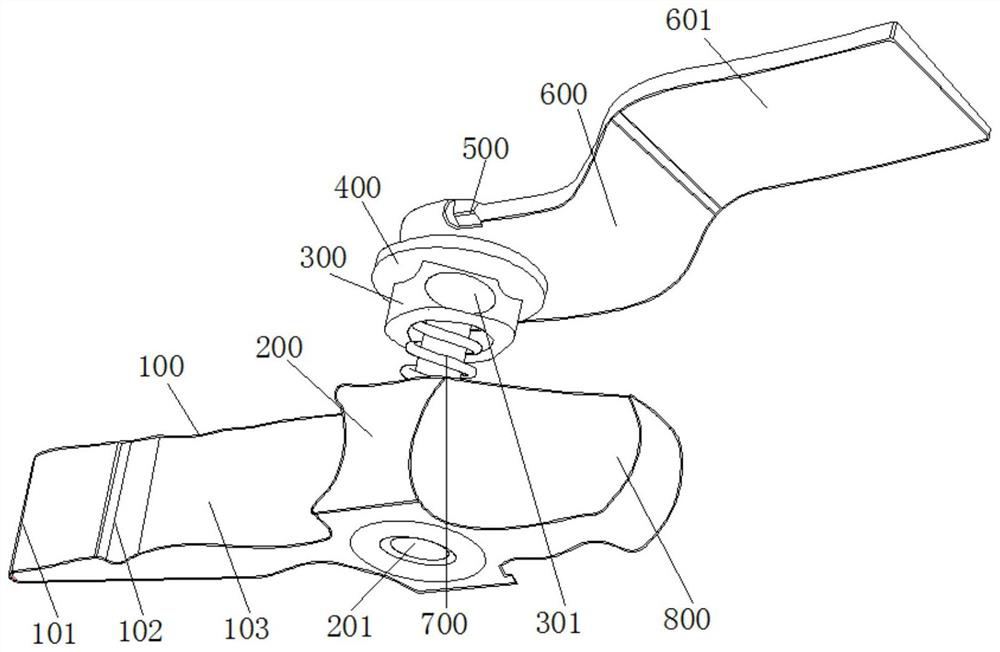

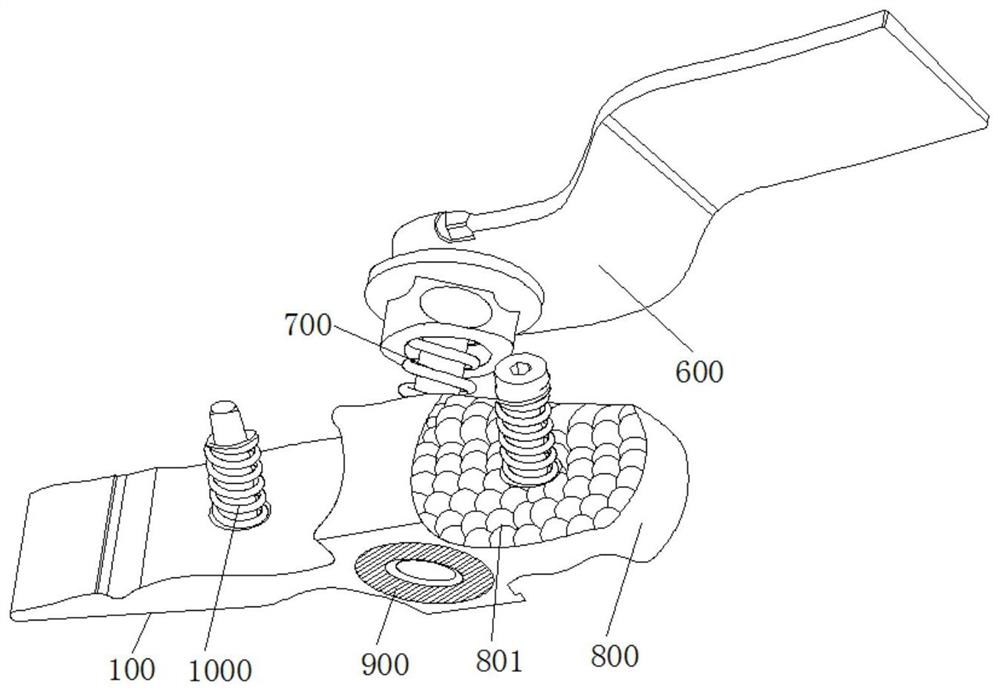

Dust-proof conductive touch body for precise conductive contact mechanism

ActiveCN108447464BEqual weightGood playing feelElectrophonic musical instrumentsMusicPianoDust control

The dust-proof conductive touch body for the precise conductive contact mechanism includes a dust-proof handle, through which the dust infiltrated under the hammer is covered and blocked in a large area, which solves the weight error caused by the difference in the construction of the keys, resulting in The learner’s playing tactility is wrong, and the dust falls to the bottom and gradually accumulates during long-term use, resulting in fluctuations in the touch reflection time. The problem of scrapping the piano is that after the dust enters the bottom of the keys, the dust-proof handle at the bottom of the keys blocks and closes the dust. Through the vibration of the keys, the scale-like dust-removing sheet on the dust-removing table is lifted. The dust is vibrated out, so that the dust does not accumulate inside, and the rebound speed is fast. The conductive screw can enhance the spring speed of the guide core, greatly speeding up the sounding time of the piano and improving the playing efficiency.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

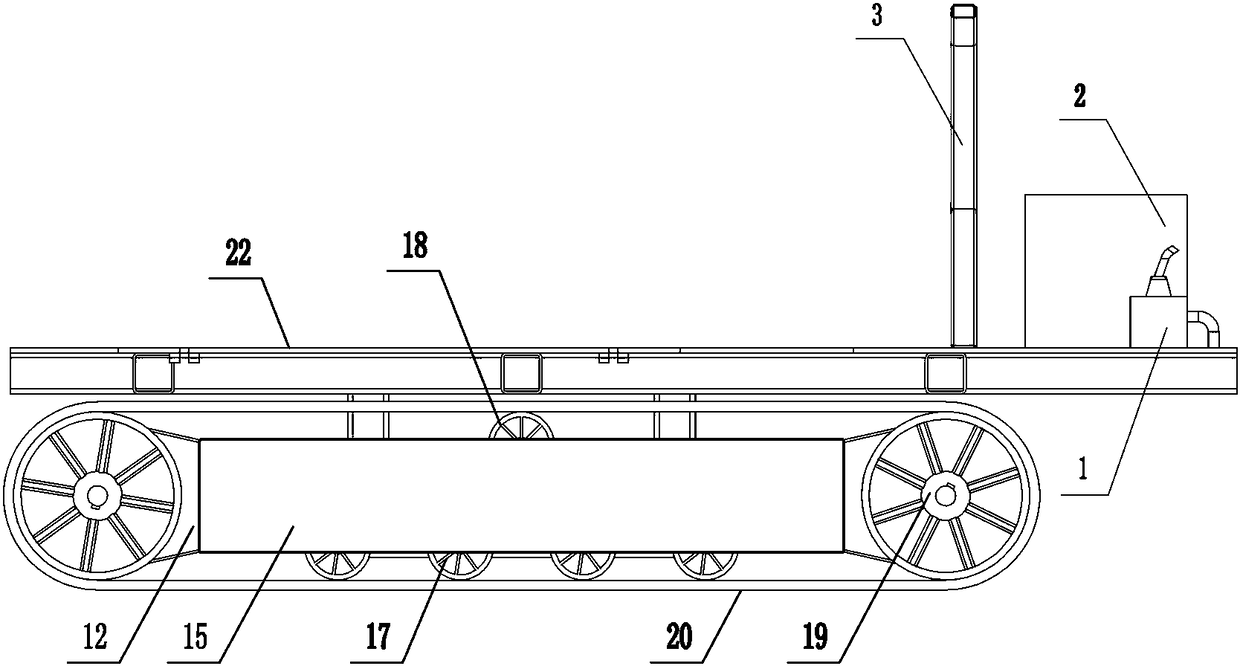

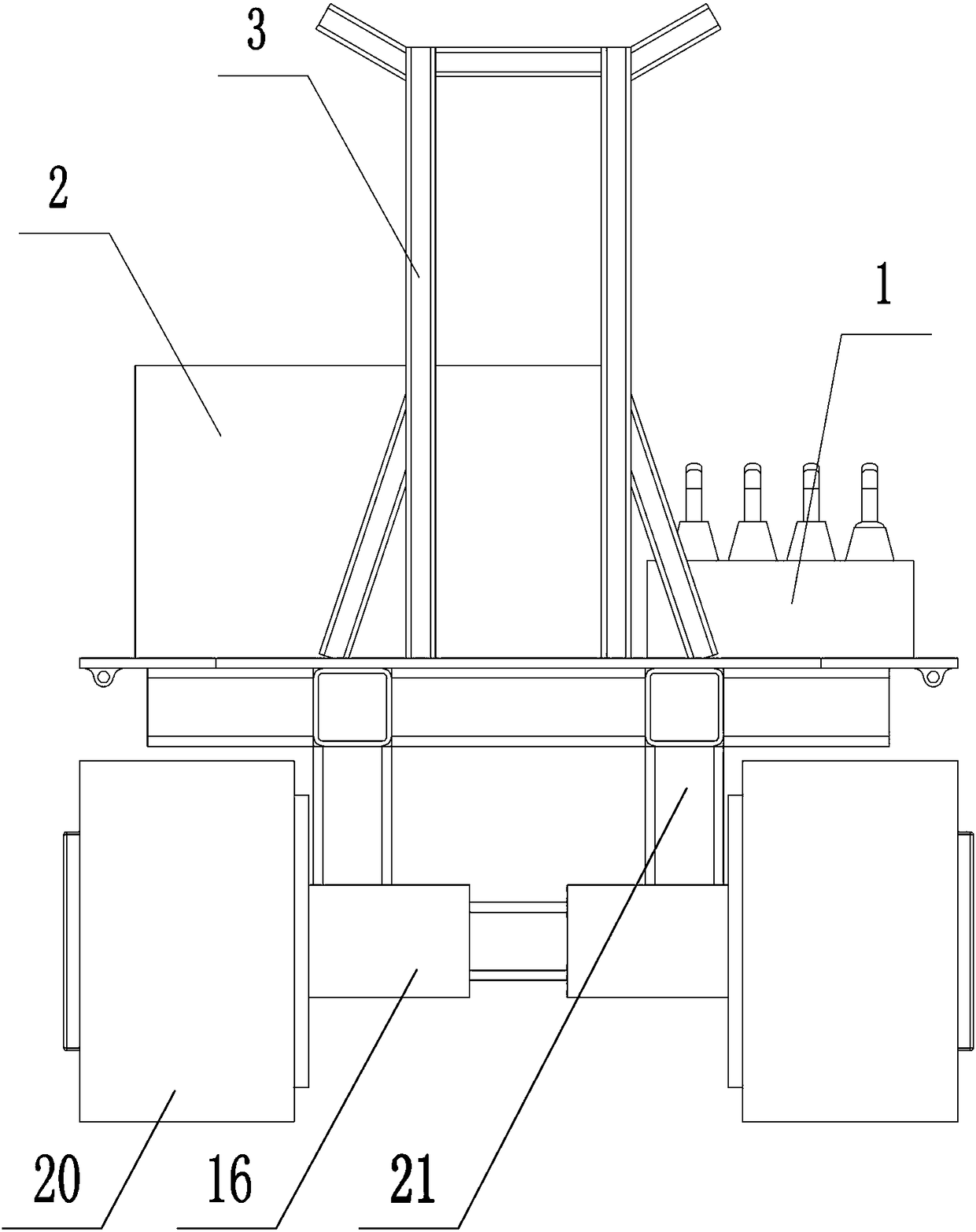

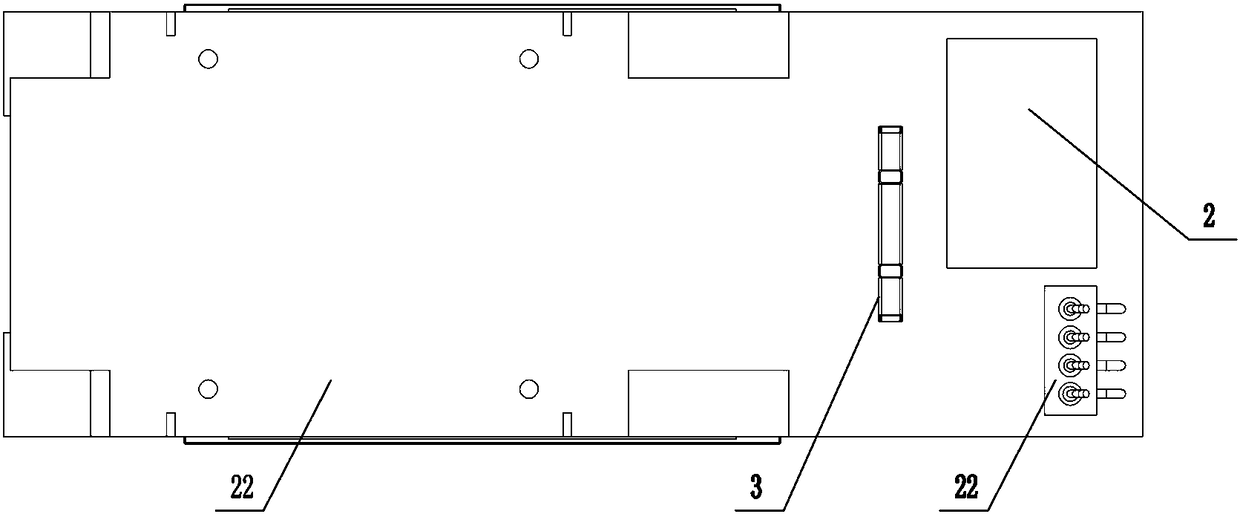

Crawler type transport vehicle

PendingCN108189921ASimple structureEasy maintenanceEndless track vehiclesHydraulic motorRubber material

The invention relates to the field of transport vehicles, and particularly relates to a crawler type transport vehicle. The crawler type transport vehicle comprises a chassis, a running system, a control assembly, an engine and a cargo boom supporting bracket, the control assembly, the engine and the cargo boom supporting bracket are fixed on the upper end face of the chassis, the running system comprises a supporting wheel baffle, traveling motors, supporting wheels, a carrier roller, a guiding wheel and a tension wheel, the supporting wheel baffle is fixed on the lower end face of the chassis, the traveling motors comprise cycloid hydraulic motors and planetary reducers, output shafts of the cycloidal hydraulic motors are in transmission connection with the planetary reducers, output shafts of the planetary reducers are in transmission connection with driving wheels, two driving wheels are arranged on each side, and crawler belts are arranged between the two driving wheels on each side and made of a rubber material. The transport vehicle has high structural strength and good power output environment, and is applied to power system operation and other construction sites where space is small but joint operation is required and large equipment cannot enter, safe and civilized production is achieved, and labor productivity is improved.

Owner:STATE GRID CORP OF CHINA +2

Dust-proof conductive touch body

The dust-proof conductive touch body includes a dust-proof handle, through which the dust infiltrated under the hammer is covered and blocked in a large area, which solves the weight error caused by the difference in the construction of the keys, which causes the learner's playing touch to appear Mistakes, as well as dust falling to the bottom and gradually accumulating during long-term use, resulting in fluctuations in the touch reflection time. The piano has always been poorly protected against dust on the touch body, and the internal dust cannot be dealt with, leading to the scrapping of the piano. After the dust enters the bottom of the keys, the dust-proof handle at the bottom of the keys blocks and closes the dust. Through the vibration of the keys, the scale-like dust removal sheet on the dust removal table is lifted, and the dust is vibrated out through multiple rapid vibrations to prevent dust from accumulating. Internally, the rebound speed is fast, and the conduction screw can enhance the bounce speed of the guide core, greatly speeding up the sounding time of the piano and improving the playing efficiency.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Cable gathering and positioning die

InactiveCN102543284BRound appearanceEvenly distributedInsulated cablesInsulated conductorsTransmission performanceSupport plane

Owner:深圳市领亚电子有限公司

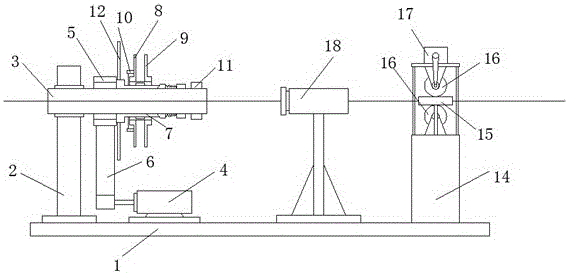

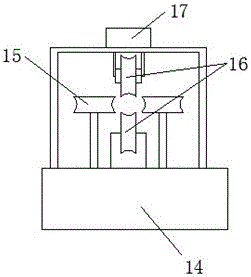

Cross thermal transfer ribbon patterning machine for fishing rod

The invention relates to the technical field of fishing rod production, in particular to a cross thermal transfer ribbon patterning machine for a fishing rod. The cross thermal transfer ribbon patterning machine comprises a machine body, a chuck unit and a slide carriage assembly. The slide carriage assembly is driven by a slide carriage drive motor via a synchronous belt and a gear set. The cross thermal transfer ribbon patterning machine is characterized in that a tilt angle mechanism and a film recovering unit are arranged; the tilt angle mechanism is composed of a rotating shaft drive motor, the synchronous belt, the gear set and a rotating shaft, the rotating shaft drive motor drives the rotating shaft to rotate through the synchronous belt and the gear set, the lower end portion of the rotating shaft is connected with a bottom plate through a rotating shaft sleeve, a deep groove ball bearing and a shaft elastic check ring all of which are matched, and the upper end portion of the rotating shaft is provided with a ribbon guide supporting plate which is fixedly connected with the rotating shaft; and the ribbon guide supporting plate is provided with a ribbon releasing unit and the film recovering unit, the film recovering unit comprises a film recovering disk and a film recovering motor, and the film recovering disk is driven by the film recovering motor. The cross thermal transfer ribbon patterning machine has the beneficial effects that operation is convenient, the production efficiency is high, and the thermal transfer ribbon thread pitches are stable.

Owner:SHANDONG HUANQIU FISHING TACKLE

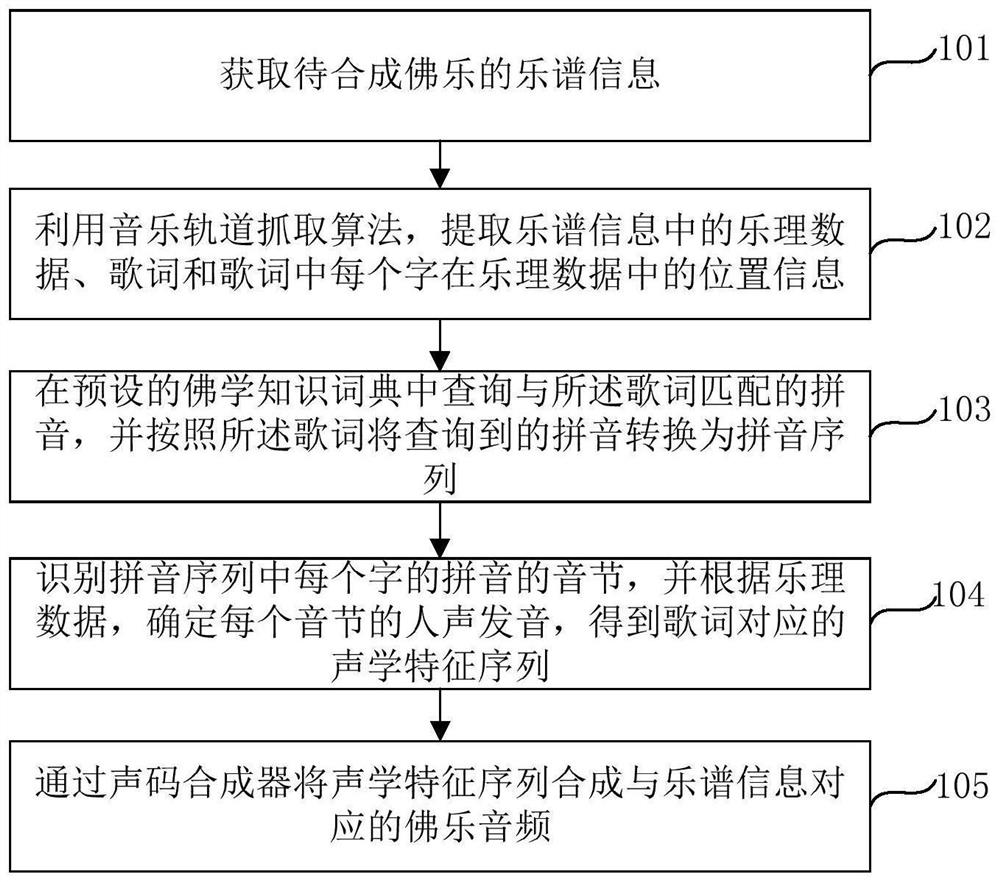

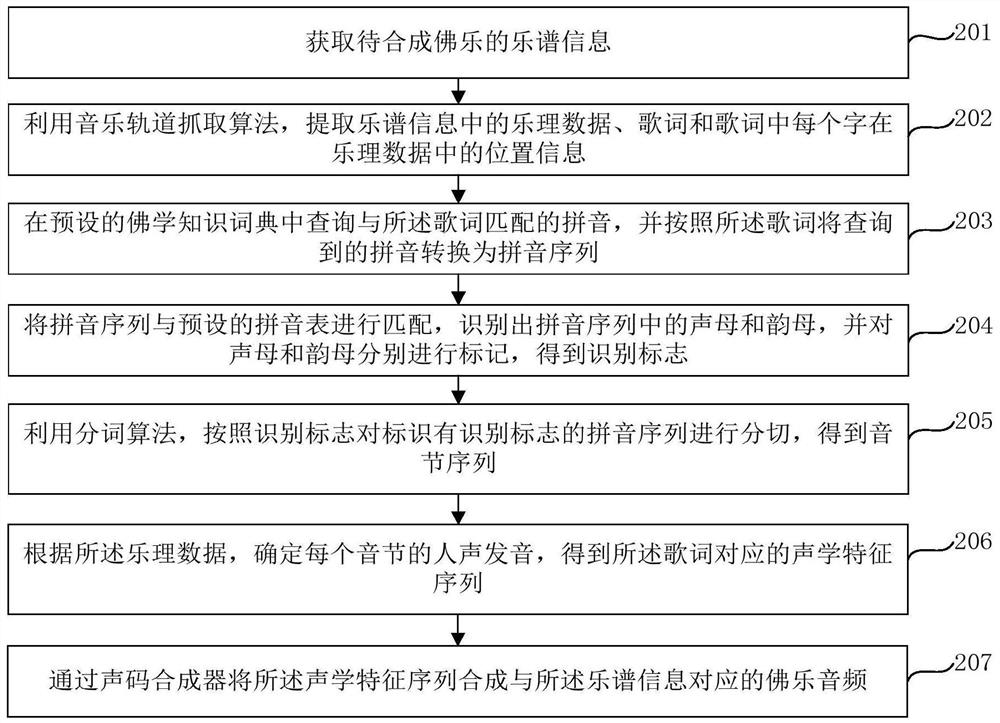

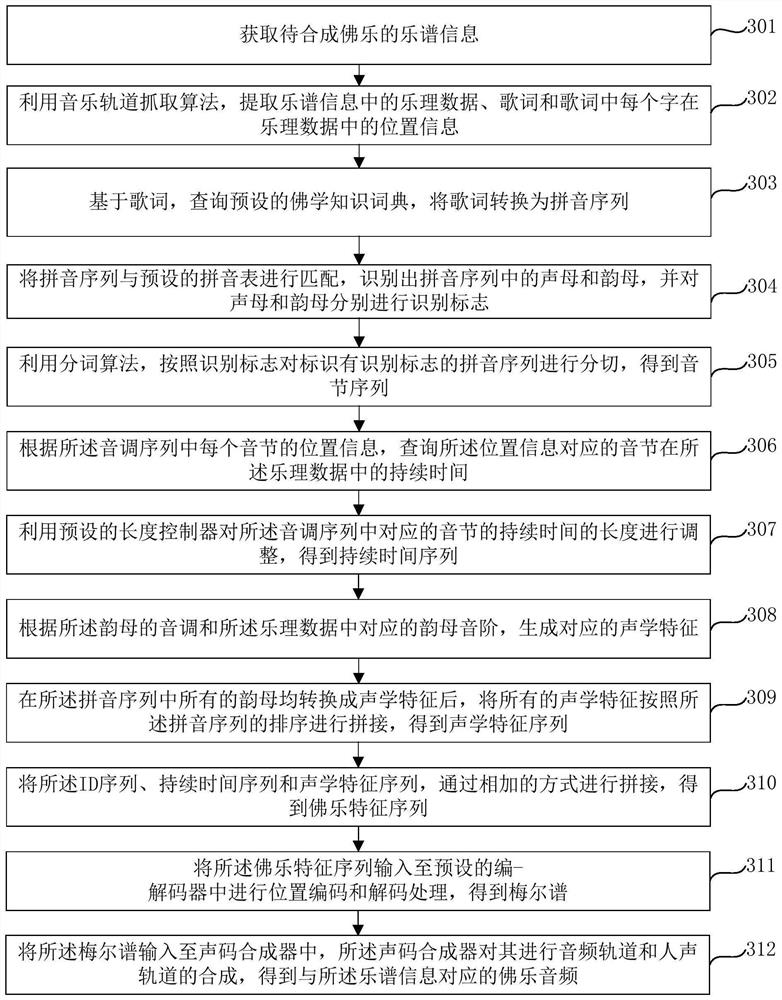

Human voice synthesis method, device and equipment for Buddhist music and storage medium

The invention relates to the technical field of artificial intelligence, and discloses a human voice synthesis method, device and equipment for Buddhist music and a storage medium. According to the method, music theory data, lyrics and position information of each character in the lyrics in the music theory data are extracted from music score information by utilizing a music track capturing algorithm, a preset Buddha knowledge dictionary is queried based on the lyrics, the lyrics are converted into a pinyin sequence, syllables of pinyin of each character in the pinyin sequence are recognized, the voice pronunciation of each syllable is determined according to the music theory data to obtain an acoustic feature sequence corresponding to the lyrics, the acoustic feature sequence is synthesized into a Buddha music audio corresponding to the music score information through a sound code synthesizer, the music score information of Buddha music is converted into human voice based on the syllables of Pinyin, and synthesis is carried out. The generated Buddhist music audio is stable in pitch and breath, the auditory experience of a user is improved, and the human voice synthesis efficiency is improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

Bamboo flute

PendingCN111128095APrevent performance interruptionLower the volumeWind musical instrumentsFluteEngineering

The invention discloses a bamboo flute which comprises a bamboo flute body. An adjusting part is rotationally connected to a diaphragm hole of the bamboo flute body, two through holes are formed in the adjusting part, connection and communication between the through holes and the diaphragm hole are achieved by rotating the adjusting part, and flute diaphragms are bonded to the through holes. The flute diaphragms are adhered to the two through holes in the adjusting part, and when one of the flute diaphragms is damaged, the adjusting part is rotated to rotate the other through hole bonded withthe flute diaphragm to the diaphragm hole, so that rapid replacement of the flute diaphragm is realized, and the problem that two flutes need to be carried during playing is solved. When the diaphragmhole is blocked, the flute can be adjusted to a diaphragm-hole-free mode for playing through rotation of the adjusting part. Therefore, the problem that playing is interrupted when the flute diaphragm is suddenly stressed and broken can be solved, and the flute can be rapidly switched between the diaphragm-hole mode and the diaphragm-hole-free mode.

Owner:三台县新鲁镇山水乐器厂

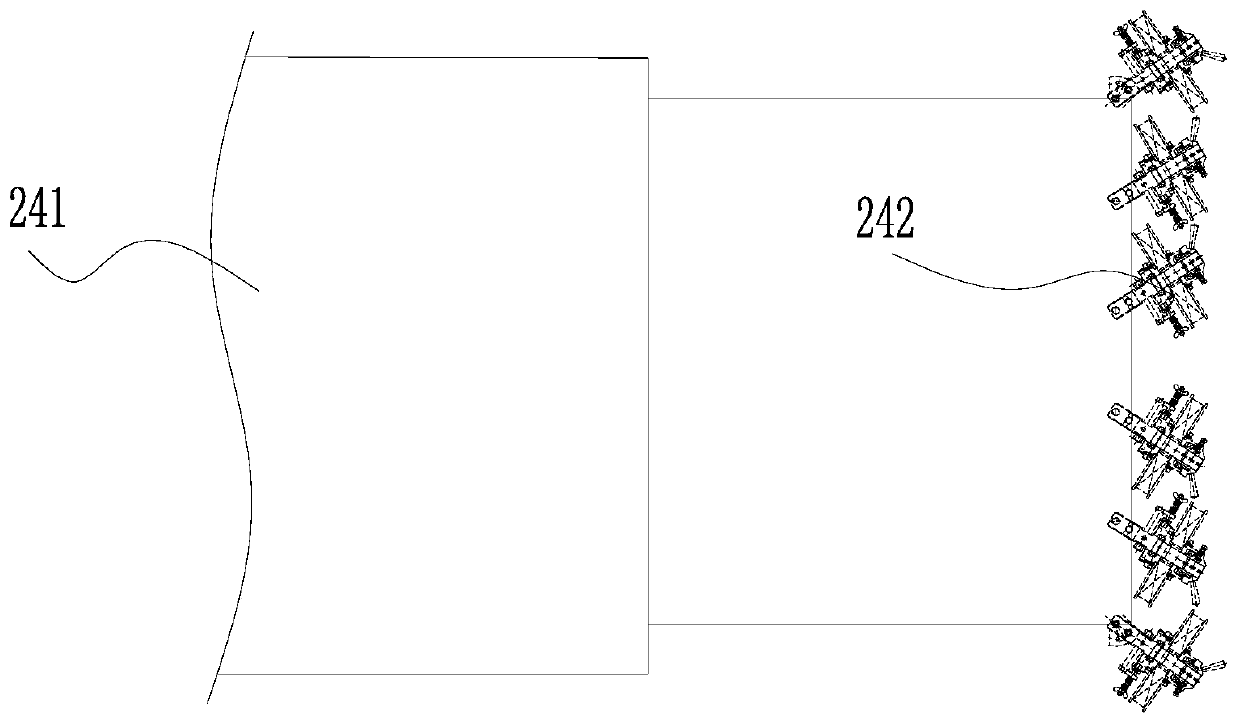

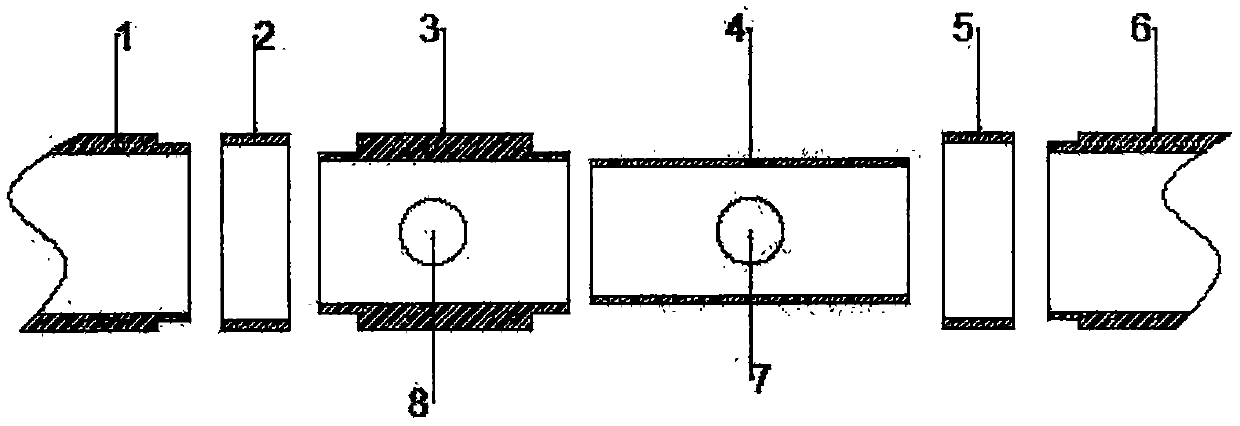

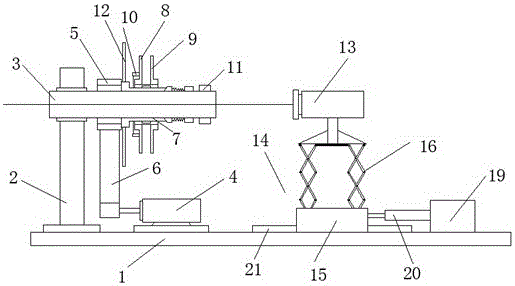

Cabling pitch stabilizing device for layer-stranding cable

PendingCN107991744APrecise and controllable operationIncrease pressureFibre mechanical structuresPunch pressEngineering

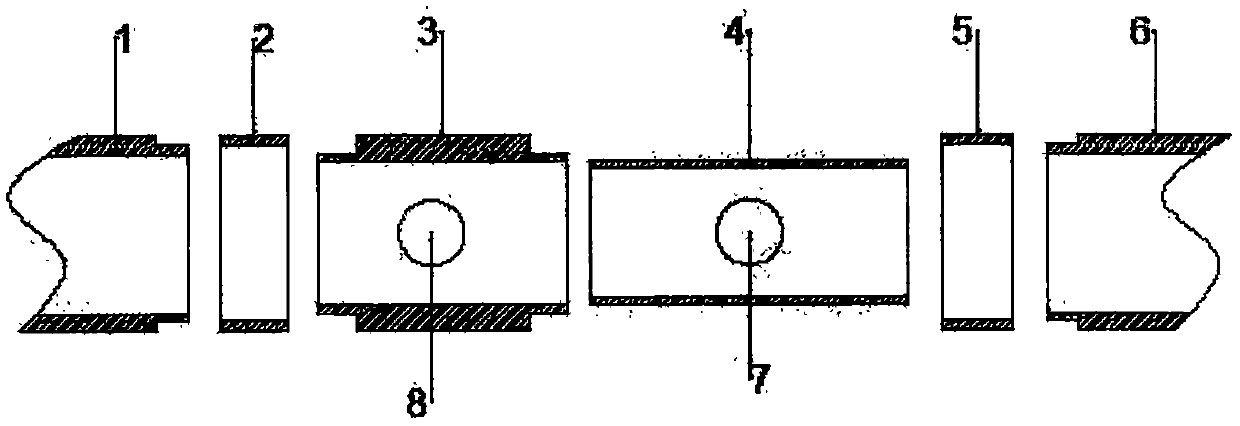

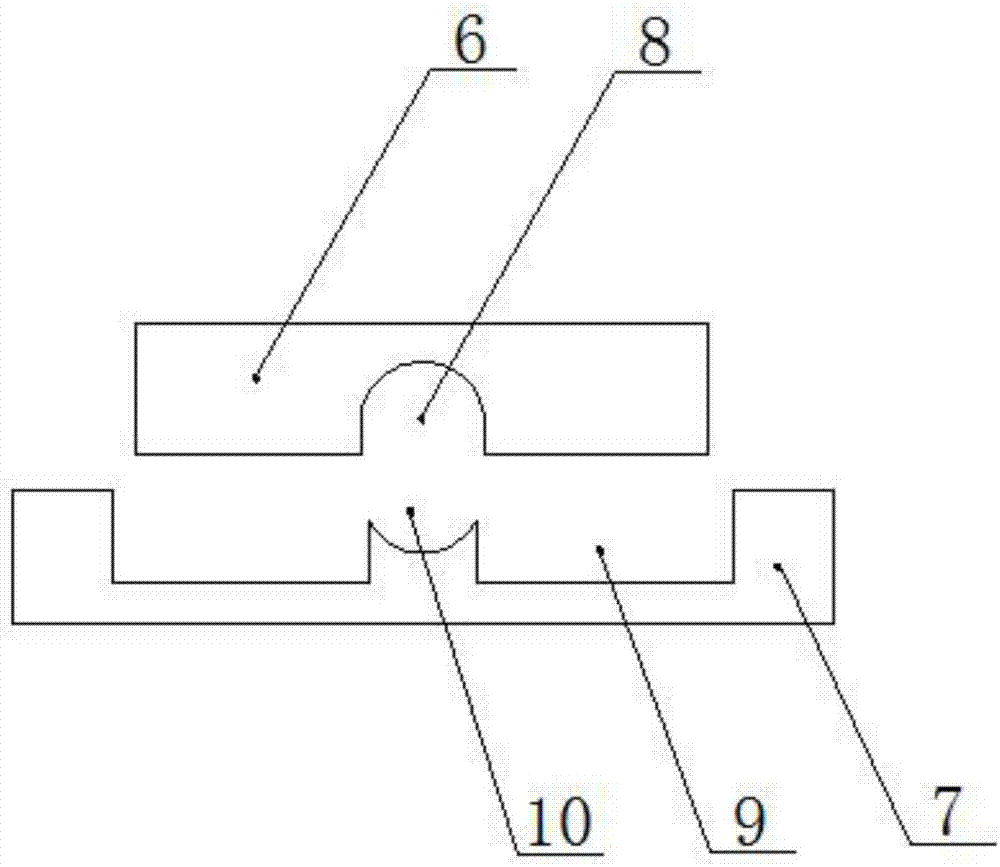

The invention relates to a cabling pitch stabilizing device for a layer-stranding cable. The cabling pitch stabilizing device comprises a bracket, a driving rod, a connecting rod, a punch, an upper die and a lower die. The bracket is of a hollow structure, a driving motor is arranged internally and drives the driving rod to rotate, the driving rod drives the connecting rod to make the punch pressed down, and a die is mounted on the punch. The cabling pitch stabilization of the layer-stranding cable is maintained through relative squeezing of the upper die and the lower die. The cabling pitch stabilizing device is simple in structure, convenient to manufacture, simple to operate and low in cost, and the phenomenon that the resistance of the periphery of a cable core becomes small due to thefilling of oil paste, which makes the cable core slide easily and make the loose tube pitch vary easily is effectively avoided. The cabling pitch is stabilized, the cabling pitch stabilization of thelayer-stranding cable is maintained efficiently, the product quality is improved, and the cabling pitch stabilizing device is economical, efficient and suitable for being massively promoted and used.

Owner:天津立孚光电科技股份有限公司

Spiral water boiling machine

PendingCN114128822ANo manual traction requiredImprove labor safetyFood shapingWater boilMechanical engineering

The invention belongs to the technical field of food processing equipment, and particularly relates to a spiral poaching machine which comprises an outer box body, a roller mounting frame is arranged in the outer box body, a roller driven by a power mechanism is rotatably mounted on the roller mounting frame, a spiral guide blade is arranged outside the roller, and the spiral guide blade is rotatably mounted on the roller mounting frame. The inner edge of the spiral guide blade is close to the outer peripheral surface of the roller; a track extending parallel to the axial direction of the roller is arranged on the peripheral face of the roller, a traction guide wheel is arranged in the track, and the top of the traction guide wheel is located in a gap between adjacent blades of the spiral guide blades. According to the spiral boiling machine provided by the invention, the traction guide wheel drags sausage to be wound on the roller along the spiral guide blade, manual traction is not needed, the production safety is greatly improved, and the roller can be lifted, so that the roller can be conveniently cleaned and kept clean and sanitary.

Owner:山东省春华机械科技有限公司

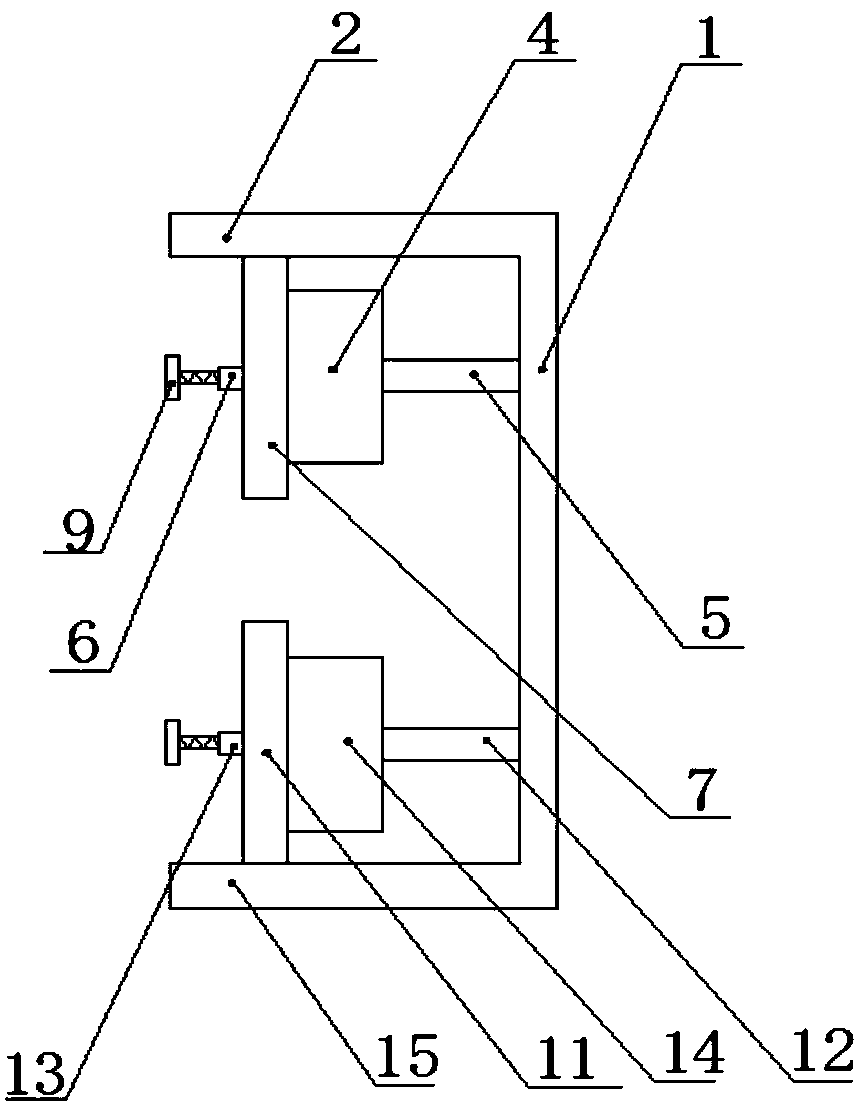

Device for keeping cabling pitch of layer-stranded cable stable

InactiveCN105954852AImprove pass ratePrecise and stable operationFibre mechanical structuresEngineeringMechanical engineering

The invention relates to a device for keeping cabling pitch of a layer-stranded cable stable. The device is formed by a support, a support rods and plastic wheel sets. The plastic wheel sets comprise an upper plastic wheel set and a lower plastic wheel set, which are oppositely arranged. The upper plastic wheel set is slidbly arranged on an upper vertical plate of the support through the upper support rod; the lower plastic wheel set is slidbly arranged on a lower vertical plate of the support through the lower support rod; and a channel for allowing optical cables to pass is arranged between the upper plastic wheel set and the lower plastic wheel set. The device is simple in structure, convenient to produce, simple to operate and low in cost, and effectively prevents the case that the use effect of the finished product is influenced due to damage of the structure of the optical cable since the cabling pitch is easy to change, so that the cabling pitch is allowed to be stable; and the device keeps the cabling pitch of the layer-stranded cable stable efficiently, improves product quality, is economic and efficient and is suitable for wide application and use.

Owner:天津立孚光电科技股份有限公司

Audio signal processing method, device, electronic device and storage medium

ActiveCN109243479BPitch stabilityPreserve sound characteristicsSpeech analysisFrequency spectrumEngineering

The invention discloses an audio signal processing method, device, electronic equipment and storage medium, belonging to the technical field of computers. The method includes: acquiring at least one first short-time spectrum signal of the first audio signal; acquiring a periodic signal in the frequency domain, and the period of the periodic signal in the frequency domain is used to represent the pitch frequency of the periodic signal; based on the periodic signal and at least one first A short-time spectrum signal, at least one second short-time spectrum signal is obtained, and the pitch frequency of each second short-time spectrum signal is the same as the pitch frequency of the periodic signal; based on at least one second short-time spectrum signal, a second audio signal is obtained , the pitch frequency of the second audio signal is the same as that of the periodic signal. The base tone frequency of the second audio signal obtained by the present invention is constant, and the pitch is very stable all the time, which produces the sound effect of "alien", and retains the sound characteristics in the first audio signal, with low distortion rate and no It is difficult or incomprehensible to understand during playback.

Owner:GUANGZHOU KUGOU COMP TECH CO LTD

Winding technique for waist drum type spring

The invention relates to a rolling process of a drum-type spring, which is a hot-roll molding technology, including a first process: blank is turned into a plurality of bars which are changed from both ends into the diameters of the bars; a second process: After turning, the bars are heated; a third process: the bars heated after the three steps are heated and rolled into a drum-type hot spring: by a first spring coiling machine, the bars are rolled from the beginning of one end into the drum-type spring; by a second spring coiling machine, the bars are rolled from the other end into another drum-type spring which is symmetrical to the former one, with a straight line left in the middle part which is punched into a preset outer diameter; a fourth process: the drum-type spring made by heat rolling is carried out quenching and tempering, so as to make the drum-type spring. The rolling process is simple, the rolling quality is high and the speed is high; both transitional rings of the drum-type spring can be greater than 2.5, besides, all the line diameter, the outside diameter, the stiffness and the pitch can be changed.

Owner:SHANGHAI SPRING CORP

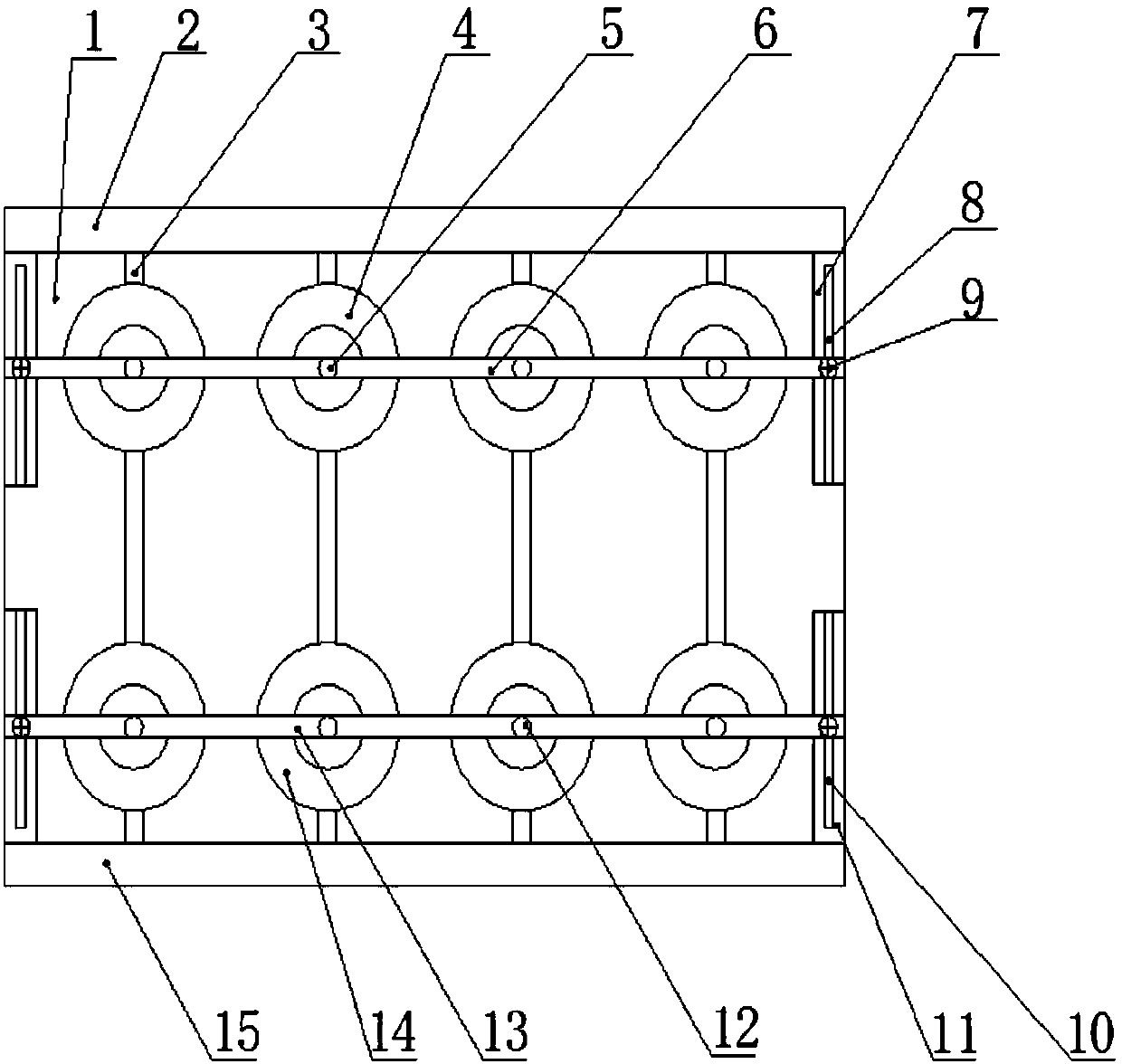

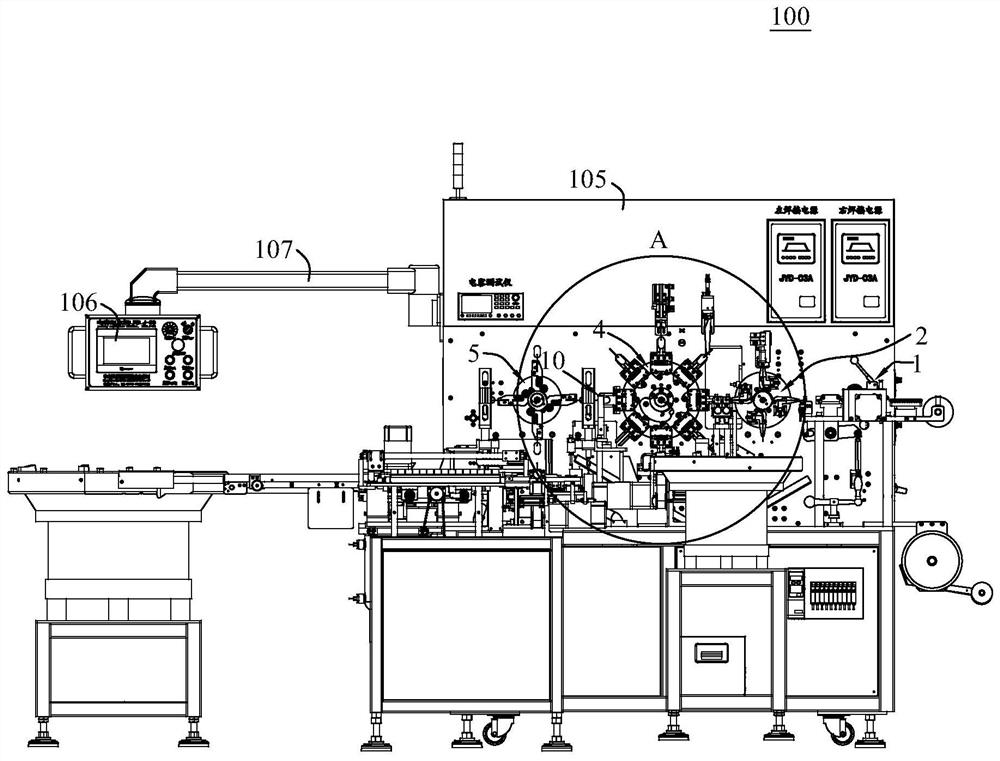

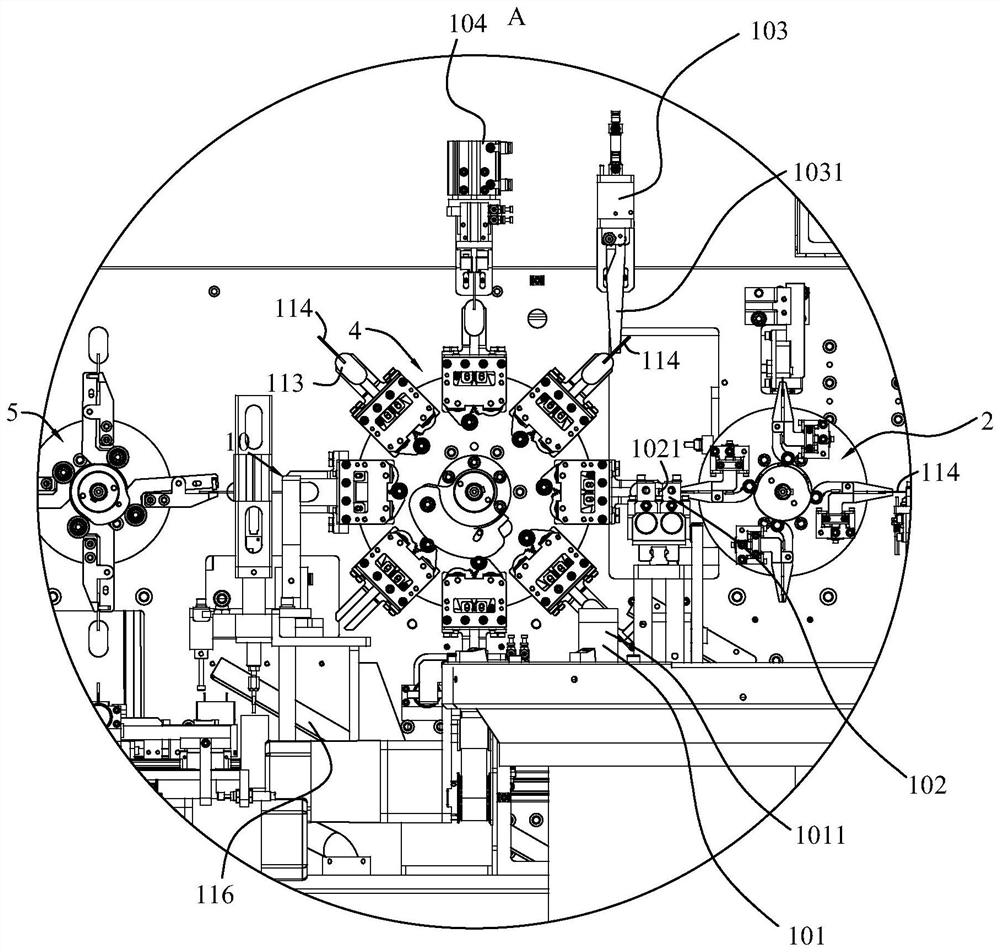

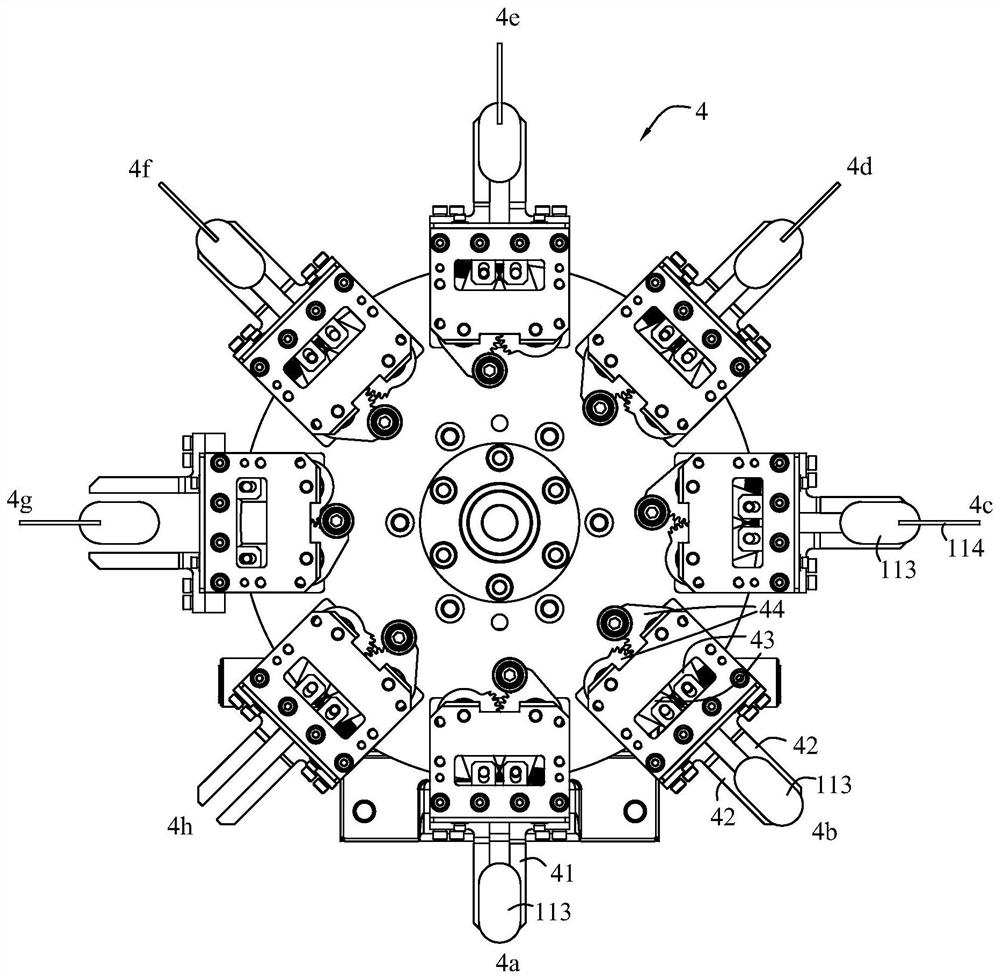

Capacitor set machine

ActiveCN109637847BPitch stabilityGuaranteed SpecificationsThin/thick film capacitorStacked capacitorsCapacitanceElectric properties

The invention discloses a capacitor assembly machine comprising a wire feeding mechanism, a wire clamping separator, an element feeding mechanism, an element clamping separator, a reversing separator,a box feeding mechanism, a box inserting mechanism, a box outputting mechanism, a soldering strength detecting mechanism and a soldering s electrical property detecting mechanism. The soldering strength detecting mechanism detects the soldering strength of an element and a lead at a station of the element clamping separator. The soldering electrical property detecting mechanism detects the soldering electrical property of the element and the lead at a station of the element clamping separator. According to the capacitor assembly machine, the mechanical detection station and the electrical detection station are simultaneously disposed on the element clamping separator, and the soldering strength detecting mechanism and the soldering electric property detecting mechanism are provided so asto complete the mechanical detection and the electrical detection when the element clamping separator rotates, thereby not only improving production efficiency, but also making the whole device compact in structure.

Owner:中山隆科机械制造有限公司

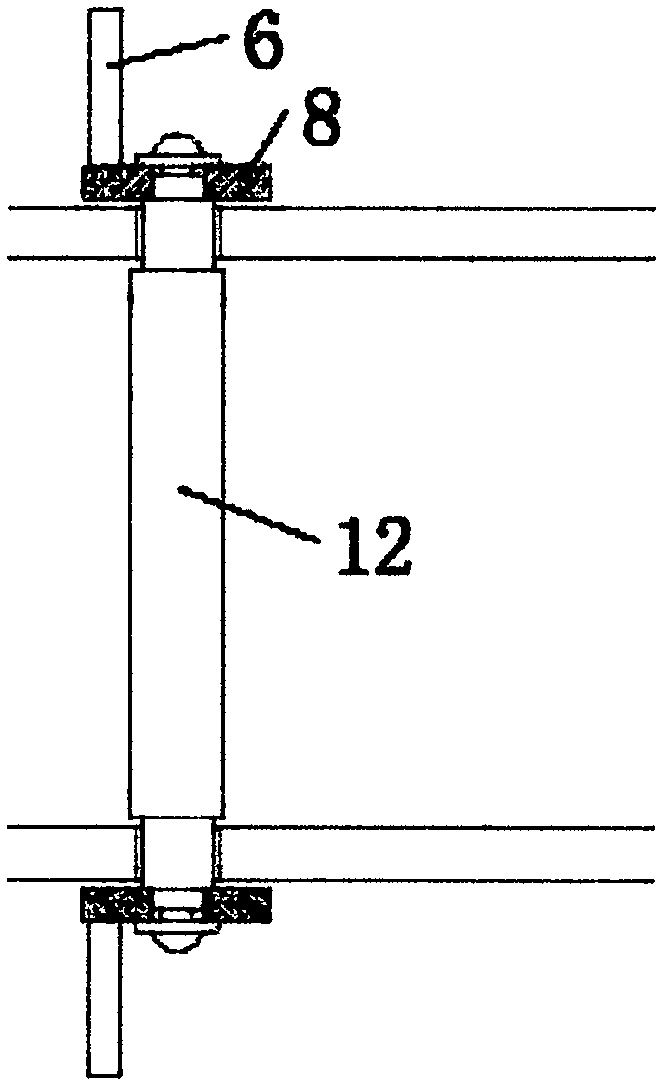

Lifting and positioning mechanism for cable shielding machine

The invention provides a lifting and positioning mechanism for a cable shielding machine, and relates to the field of cable processing machinery. The lifting and positioning mechanism comprises a base, a support seat arranged at one side of the base, and a hollow shaft fixedly arranged on the support seat, and also comprises a motor, a synchronizing wheel rotationally arranged in the middle of the hollow shaft, wherein a synchronous belt drives between the motor and the synchronizing wheel, and a hollow tube synchronously rotates with the synchronizing wheel sleeves the front of the hollow tube; a copper strip disc rotating relative to the hollow tube sleeves the hollow tube, and comprises a copper strip chassis and a copper strip chuck, and a baking wheel fixedly connected with the copper strip chassis also sleeves the hollow tube; a locking device of the copper strip is arranged at the front end of the hollow tube, and a shaft disc rotating synchronously with the synchronizing wheel also sleeves the hollow tube; a positioning device is also arranged at the right side of the base, and a lifting device is also arranged; the lifting device is fixedly arranged on the base, and the top of the lifting device is connected with the bottom of the positioning device. The lifting and positioning mechanism provided by the invention has the advantages of reasonable structural design, convenience in use and high efficiency.

Owner:CHAOHU JINYE ELECTRIC MACHINERY

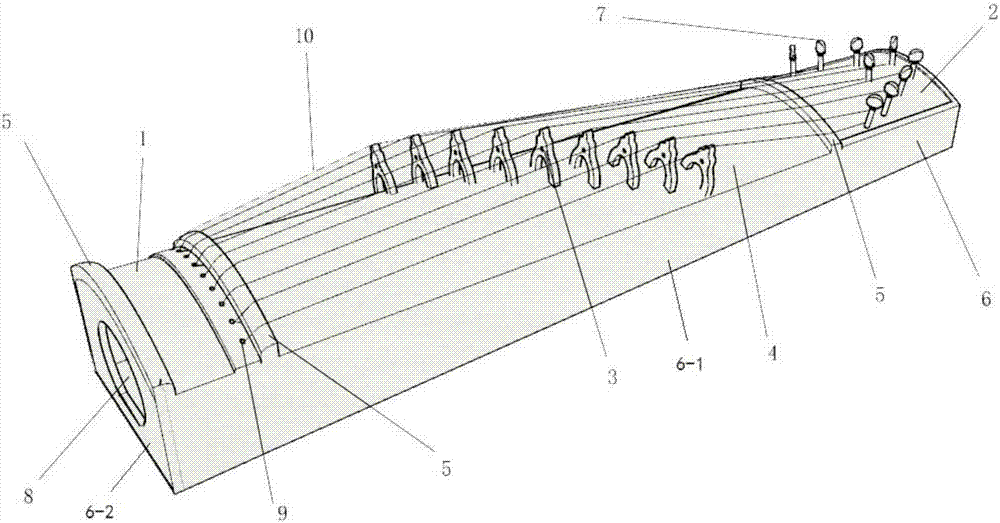

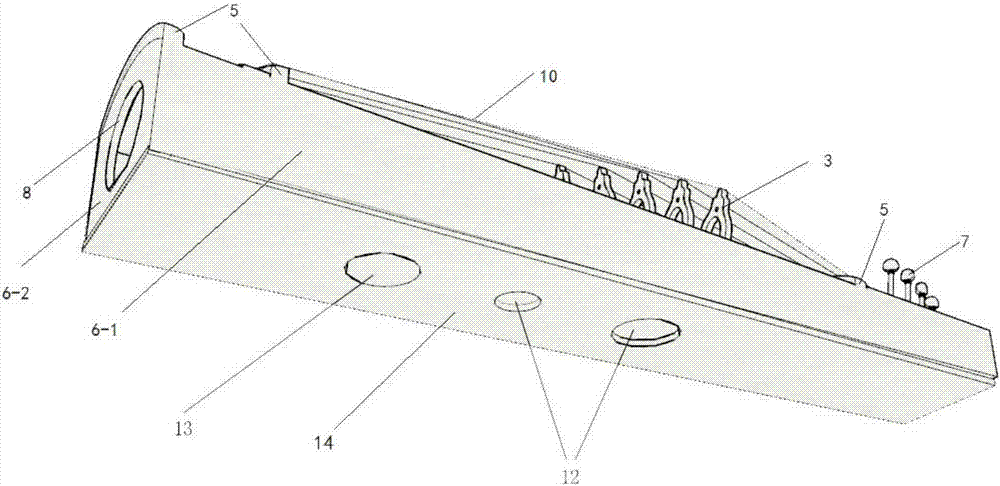

Improved-type Bowed zither

The invention discloses an improved-type Bowed zither, and belongs to the technical field of musical instruments. The Bowed zither comprises a zither box, the zither box comprises a zither top, a zither bottom and a zither clapper, the zither top arcs upwards to present an arc shape, a zither head is arranged at the left end of the zither box, a zither tail is arranged at the right end of the zither box, two rows of yue mountains are arranged at the top surface of the zither head, one row of yue mountain is arranged at the zither tail, an abatjour is arranged at the left side surface of the zither head, nine chord holes are formed between the two rows of yue mountains on the zither head, nine chord shafts are arranged at the right side of the yue mountain on the zither tail, zither chords are arranged between the chord holes and chord shafts, and the zither clapper comprises long zither clappers at the front side and the rear side, and short zither clappers at the left side and the right side. In the improved-type Bowed zither, the shortcomings of early Bowed zithers are overcome, and a string instrument which is beautiful in tone, large in sound volume, convenient to tune and stable in intonation, and can be combined with instruments like zhuihu(a kind of bowed instrument), guzheng, Chinese lute, big string, bangzi and the like. The single playing method of string drawing is expanded to playing, and stirring, the improved-type Bowed zither can be held in hand and placed in front of the chest, and can be embraced in the arms or placed on the tabletop to be played.

Owner:PINGDINGSHAN UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com