Device for wrapping shielding copper strip on cable

A copper tape and cable technology, applied in cable/conductor manufacturing, circuits, electrical components, etc., can solve the problems of low production efficiency, inability to achieve, high rotation speed, etc., and achieve the effect of improving production efficiency, speeding up, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

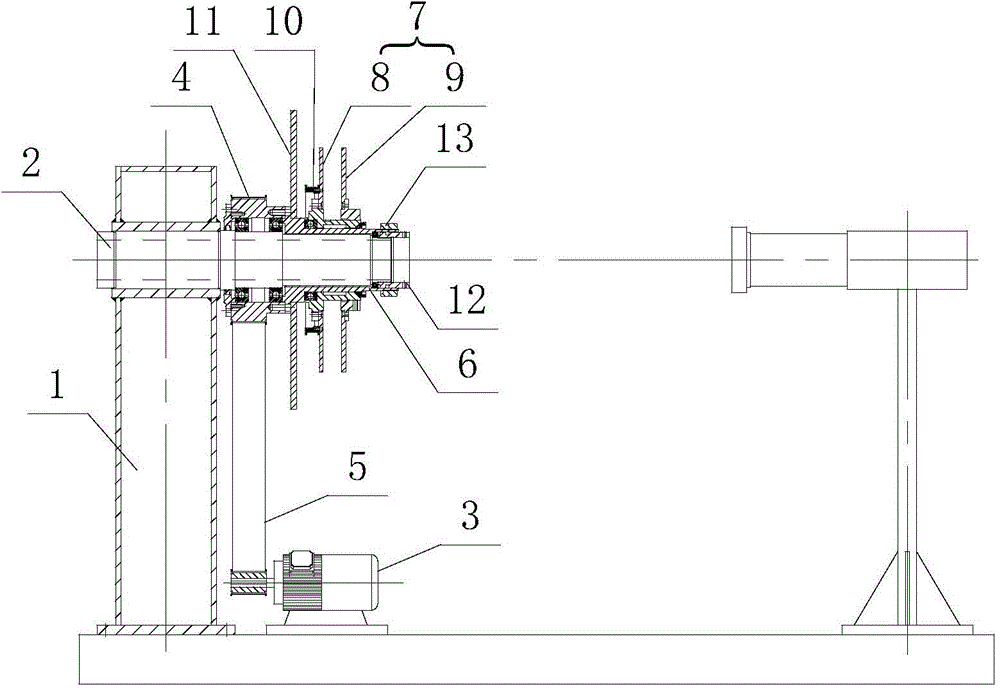

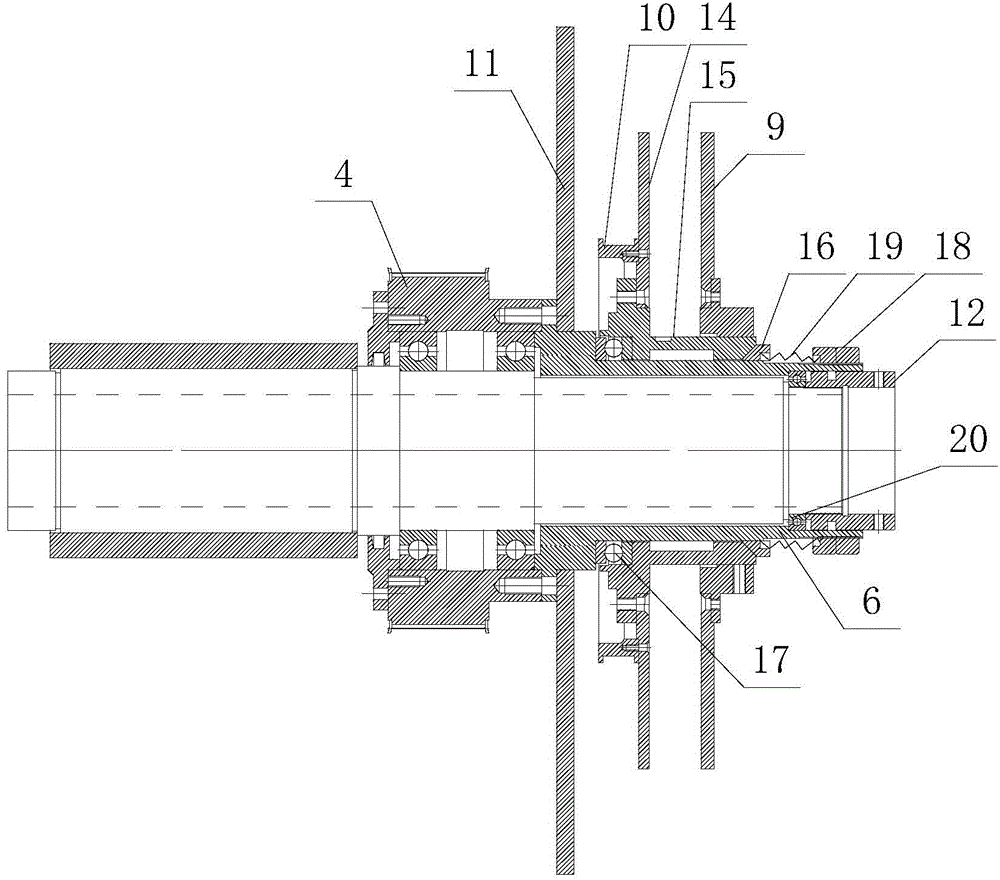

[0014] refer to figure 1 , figure 2 It is an embodiment of a cable winding shielded copper tape device of the present invention, a cable winding shielded copper tape device, including a support base 1, a hollow shaft 2 fixed on the support base 1, a motor 3 with an encoder, and a rotating device The synchronous wheel 4 in the middle of the hollow shaft 2, the motor 3 and the synchronous wheel 4 are driven by a synchronous belt 5;

[0015] The front part of the hollow shaft 2 is covered with a hollow tube 6 that rotates synchronously with the synchronous wheel 4. The hollow tube 6 is covered with a copper tape reel 7 that rotates relative to the hollow tube 6. The copper tape reel 7 includes a copper tape chassis 8 and a copper strip chuck 9, the hollow tube 6 is also covered with a brake wheel 10 fixedly connected with the copper strip chassis 8, the front end of the hollow tube 6 is provided with a copper strip disc 7 locking device 13, the hollow The tube 6 is also covere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com