Patents

Literature

31results about How to "Equal weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

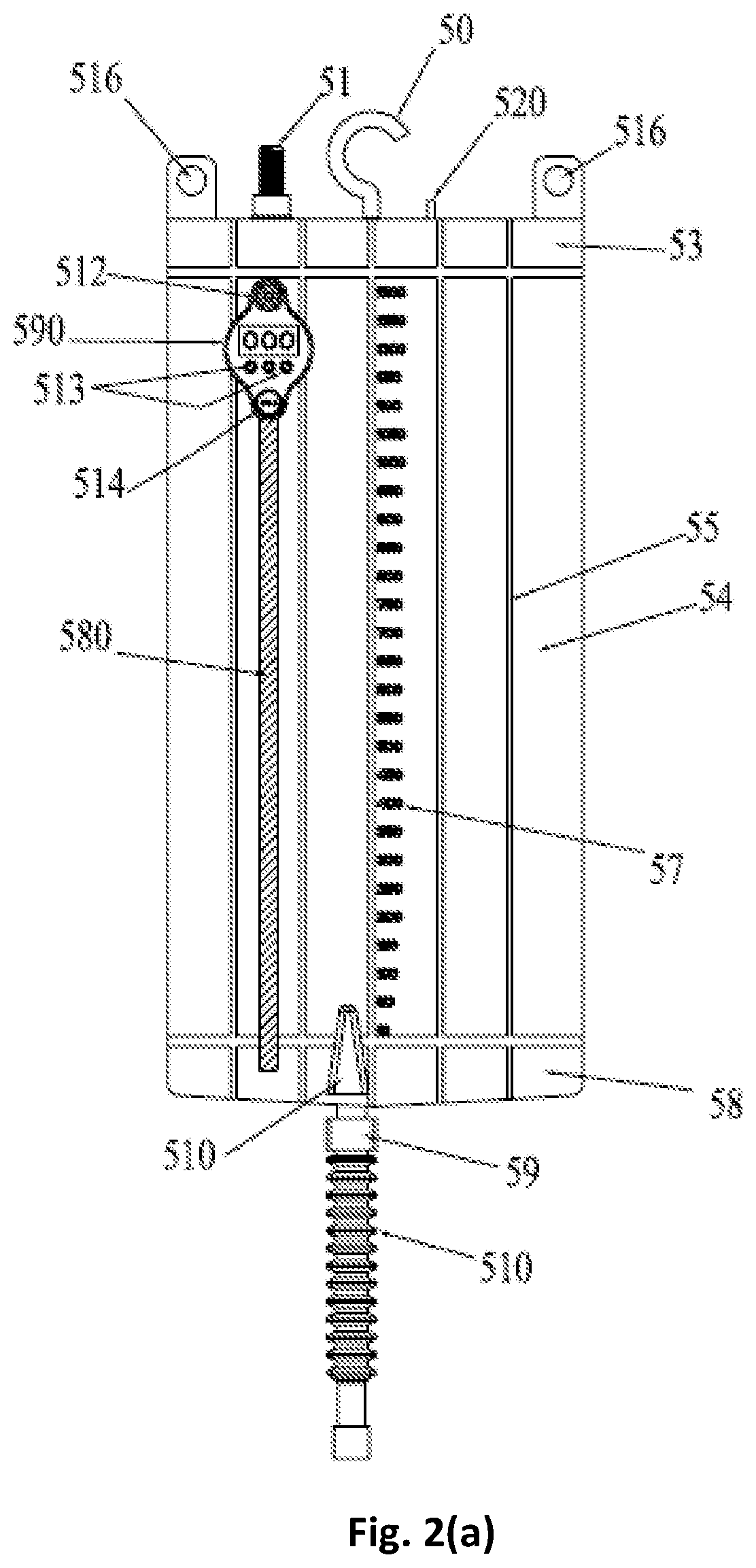

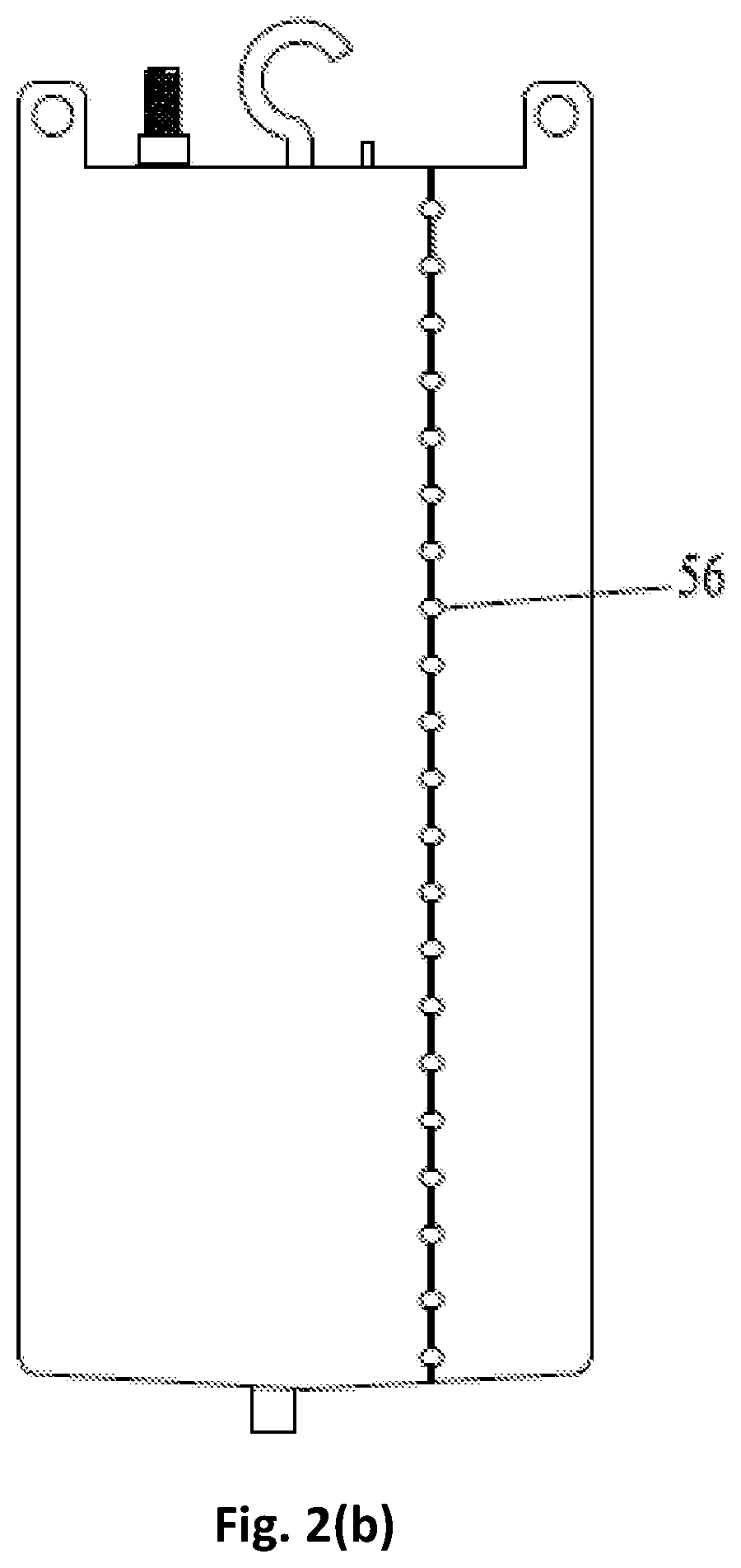

Attachment and liquid supplying

InactiveUS20050219281A1Uniform liquid jet qualityIncrease liquid pressureOther printing apparatusLiquid jetEngineering

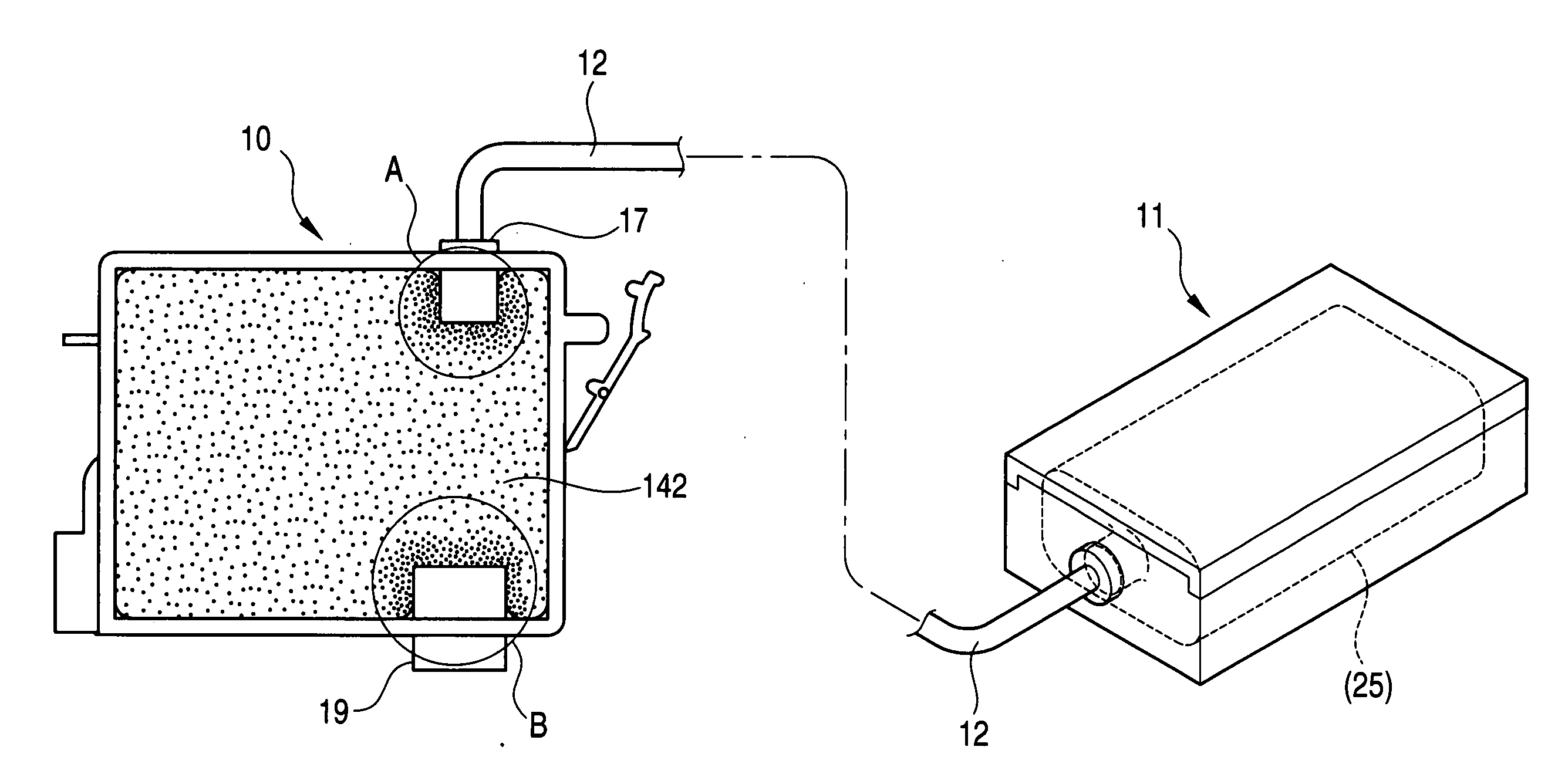

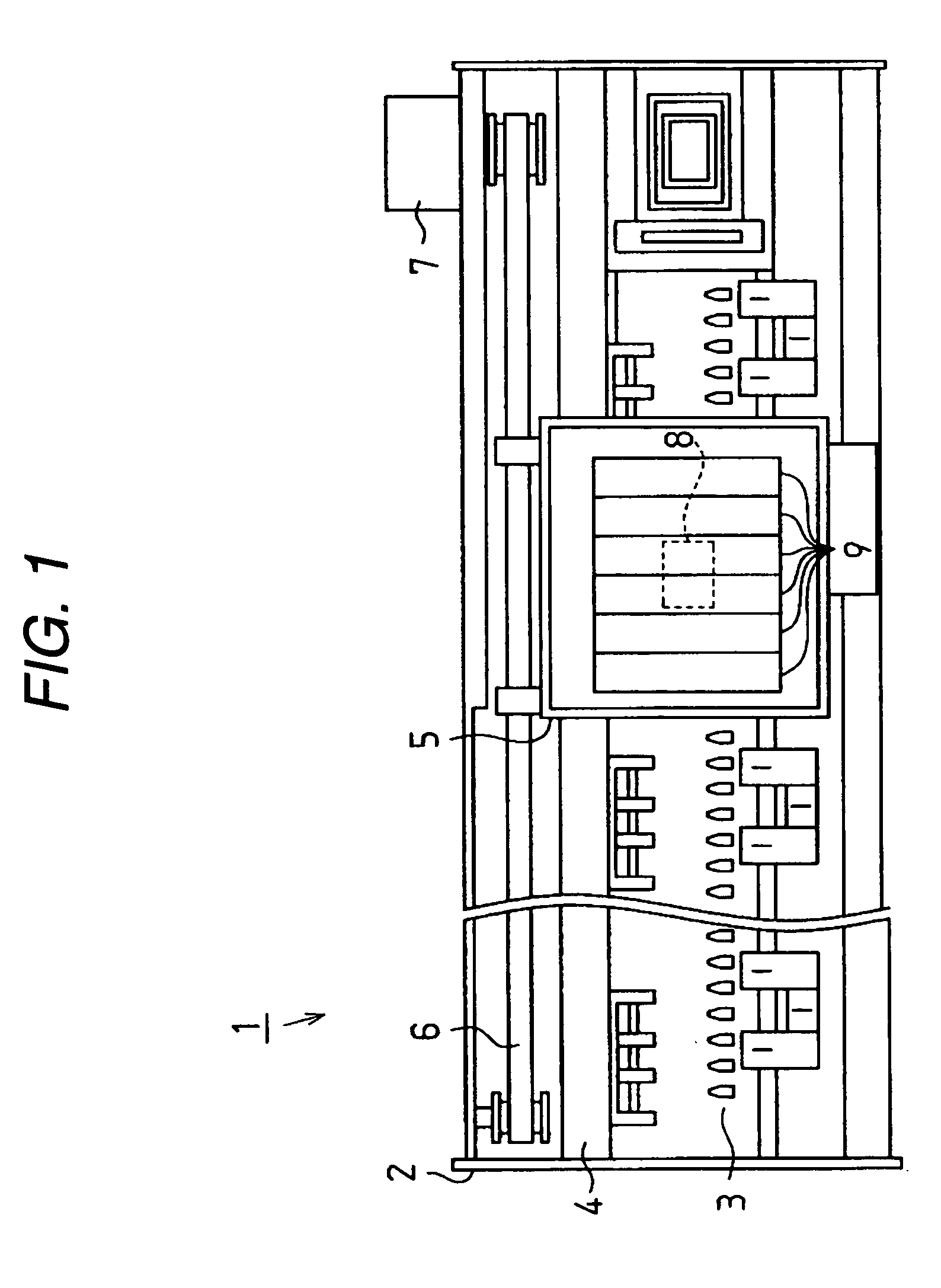

An attachment is mountable on a carriage in place of a liquid container that contains liquid and that is mounted on the carriage having a liquid jet head for jetting liquid, so that the attachment can supply liquid introduced from outside to the liquid jet head. The attachment has a pressure control means provided in a flow passage which is formed in an attachment body and through which the liquid introduced from the outside is supplied to the liquid jet head.

Owner:SEIKO EPSON CORP

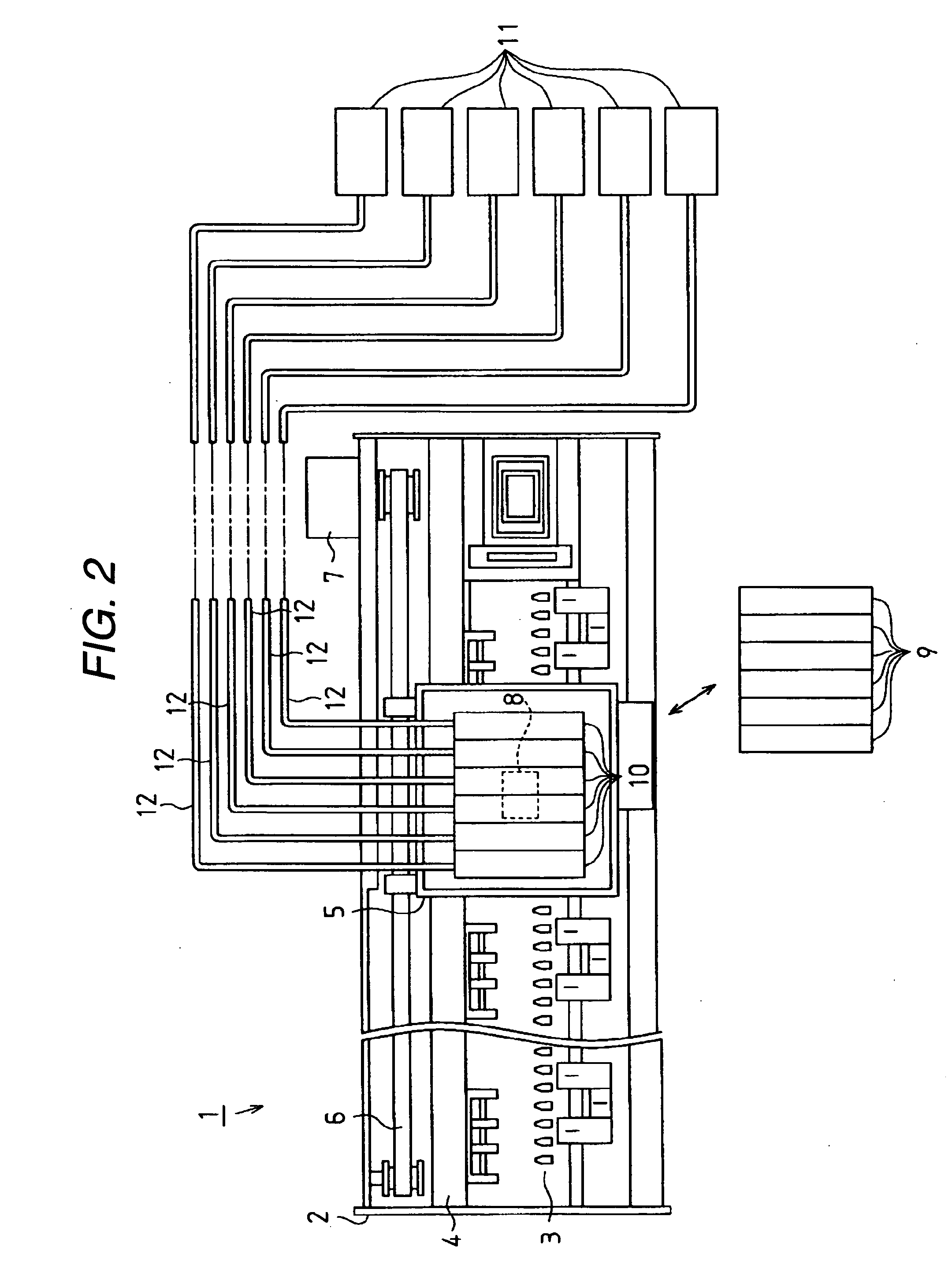

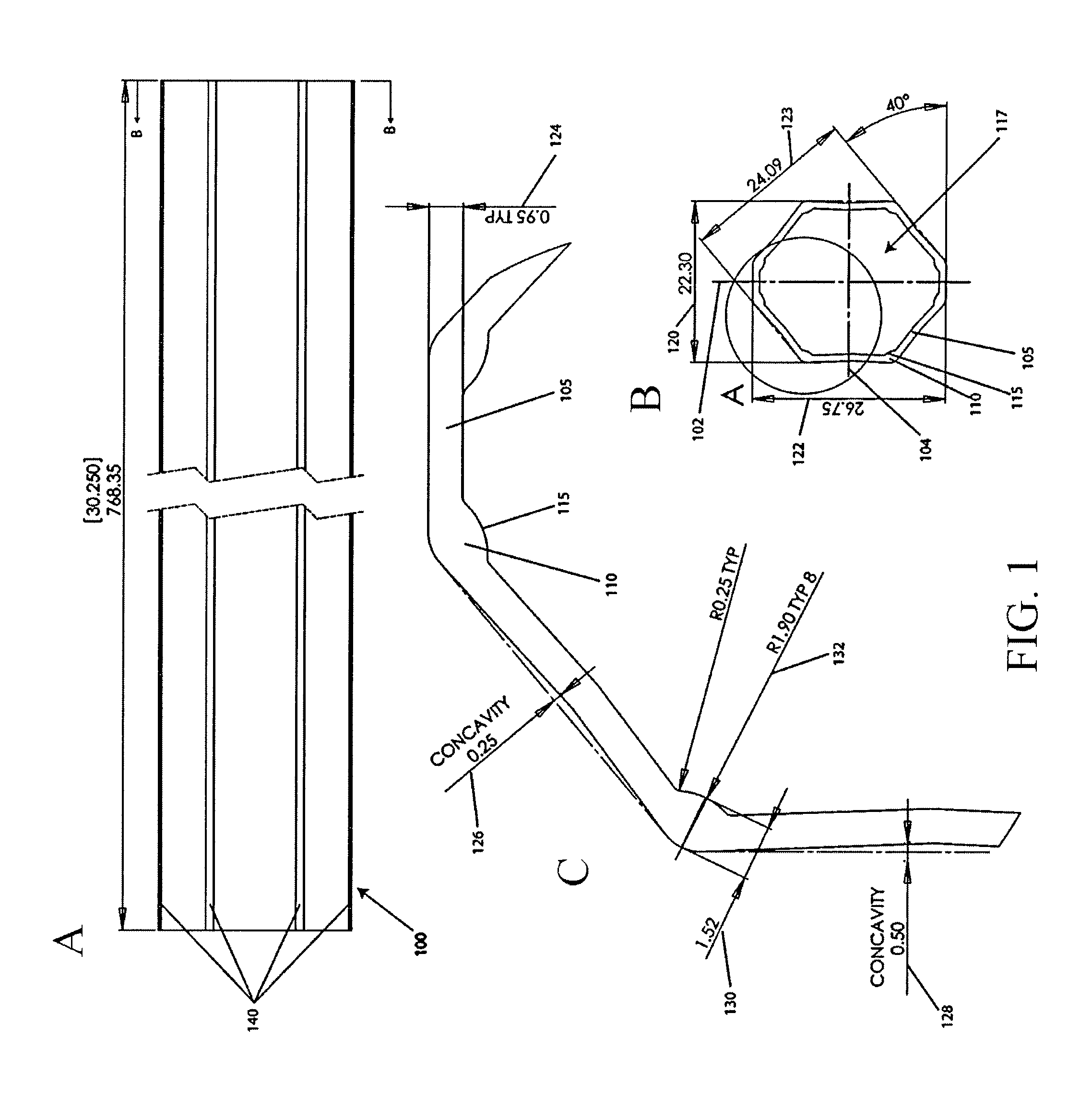

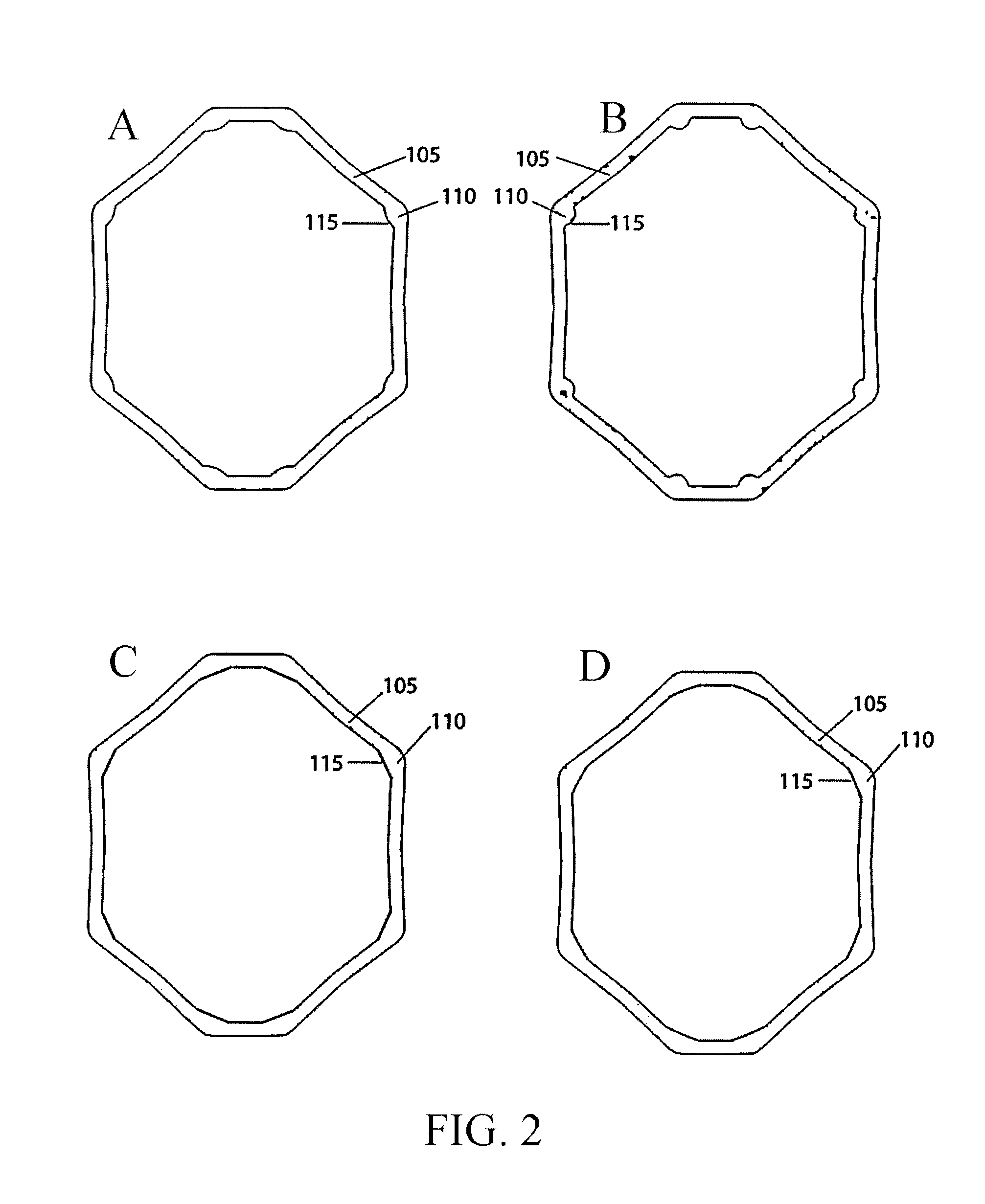

Sports equipment stick handle

A sports equipment stick handle comprising a hollow tubular member with a cross section comprising at least a first wall and a second wall that intersect at a corner having a reinforcement portion (fillet, bead or diagonal; easement, wherein the thickness of the corner is greater than the thickness of the first and second walls. The reinforcement portion increases dent resistance, strength, and stiffness.

Owner:WM T BURNETT IP

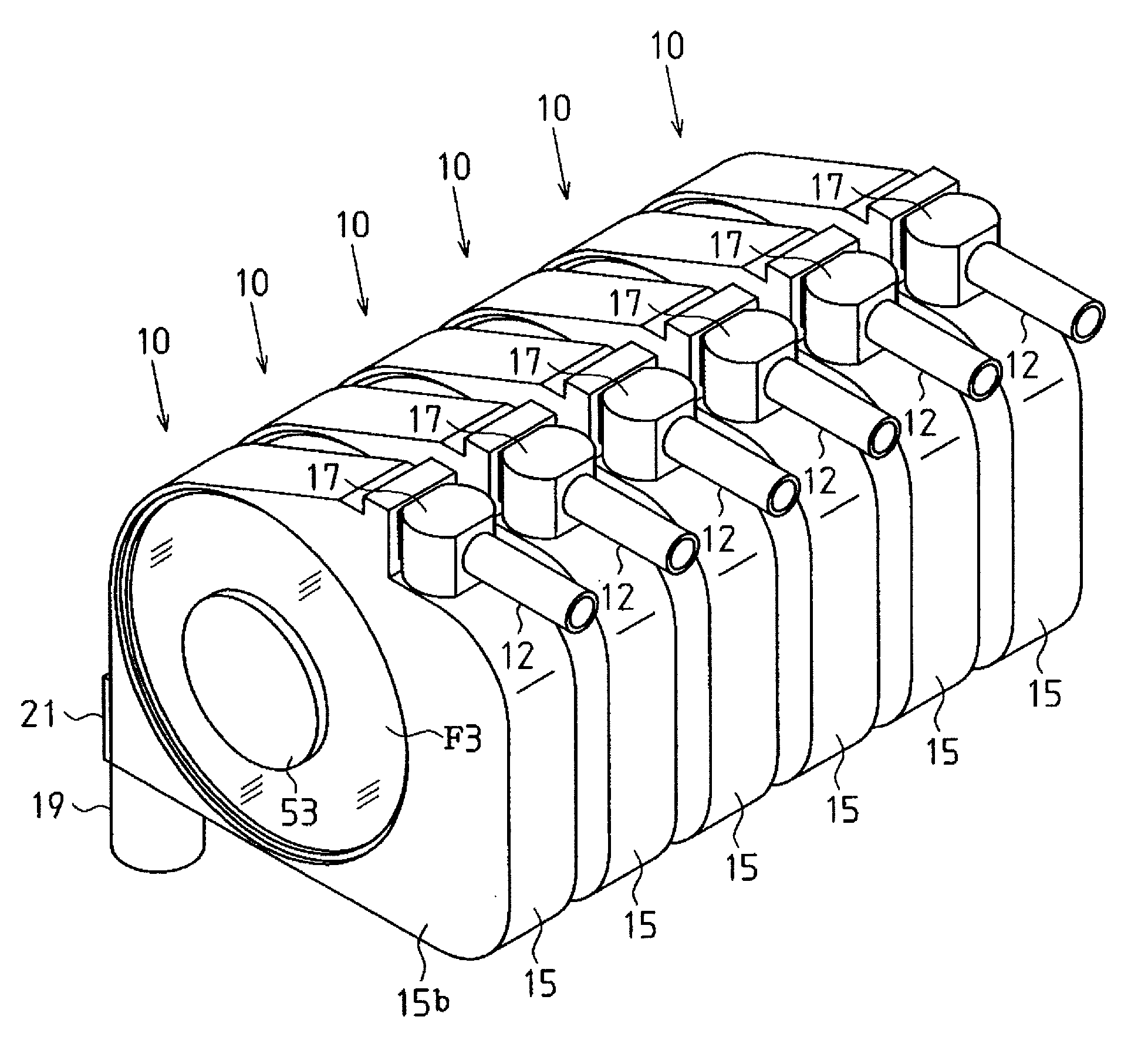

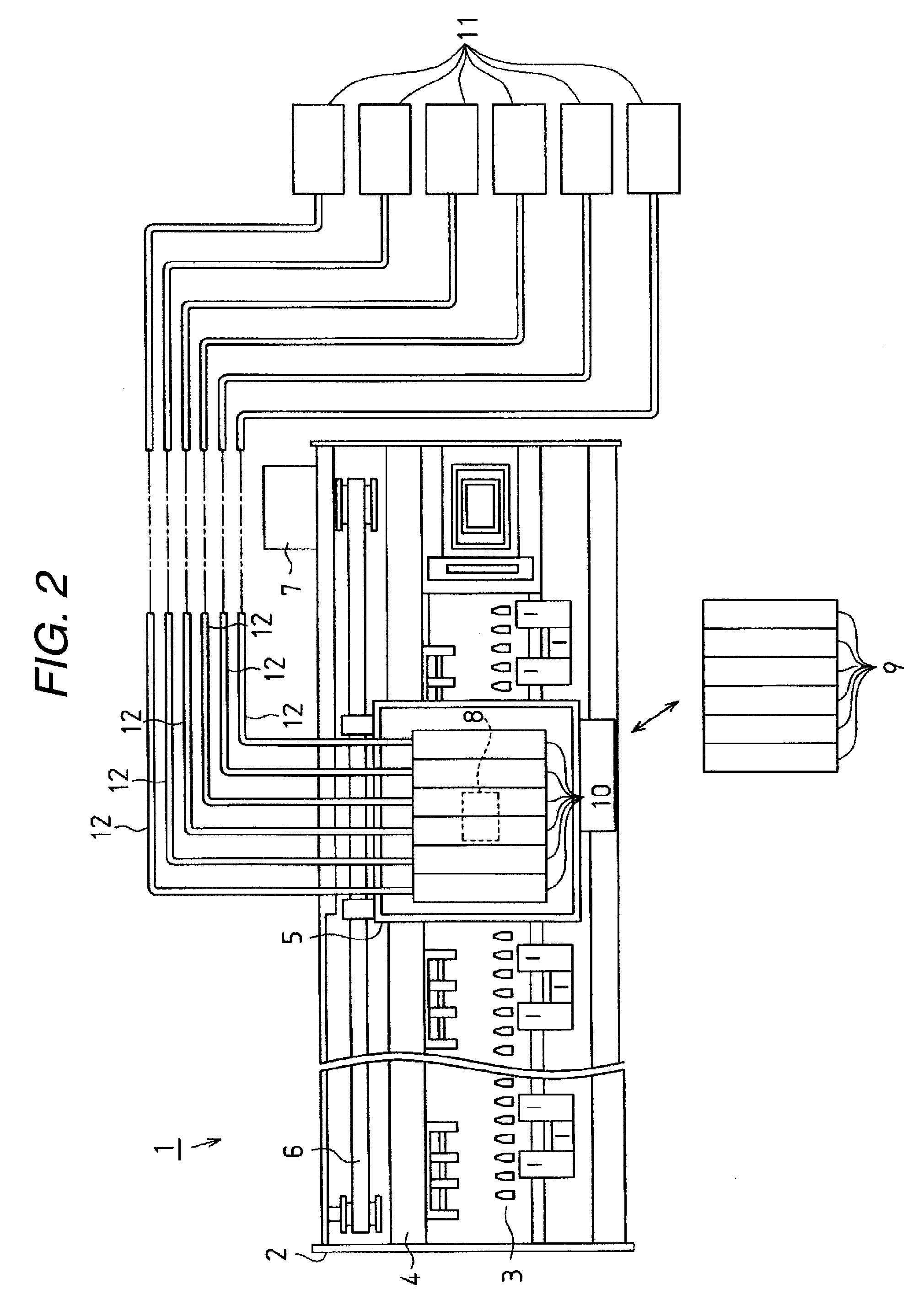

Attachment and attachment system

InactiveUS20100201762A1Uniform liquid jet qualityIncrease liquid pressureOther printing apparatusLiquid jetEngineering

Owner:SEIKO EPSON CORP

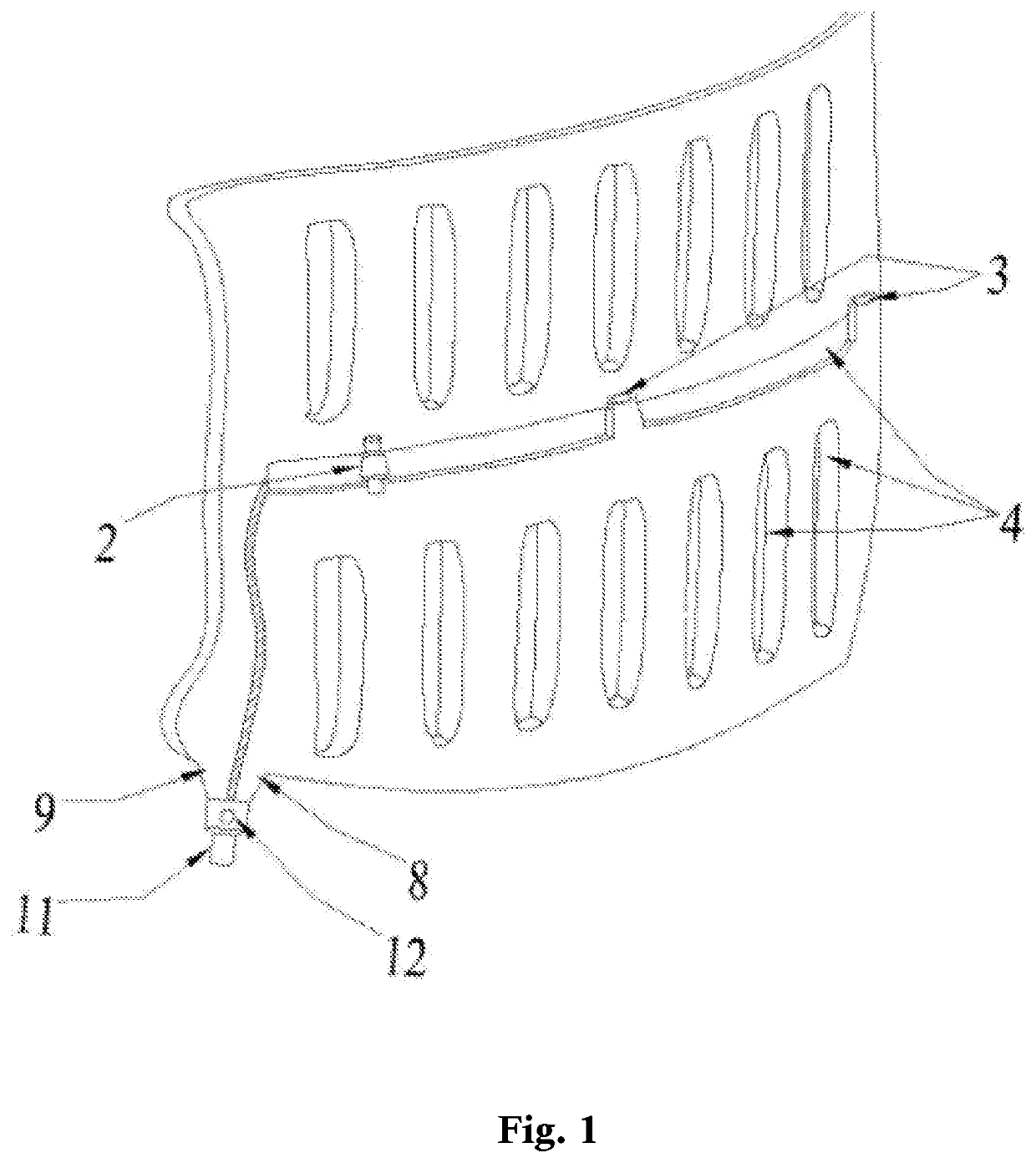

Multichambered urine collection device

ActiveUS20200276046A1InhibitionEqual weightNon-surgical orthopedic devicesSensorsUrine collectionUrine collection device

A user friendly multi-chambered flat urine collection device comprising an inlet port having a non-return valve, an upper chamber further divided into a plurality of vertical chambers, a lower chamber further divided into a plurality of vertical chambers, a plurality of breathing open areas intervening said upper, lower and vertical chambers, and a drainage tube. The inlet port is positioned at top of the upper chamber, said inlet port in turn is removably connected to a catheter. The breathing open areas between the vertical chambers of said upper and lower chambers allow the urine collection device to conform to shape of patient body. Moreover, the chambers distribute the weight of collected urine equally to avoid a bulging effect. Alternately, the urine collection device has absorbent layer insert to absorb the bodily discharge.

Owner:STAALI AMINE +1

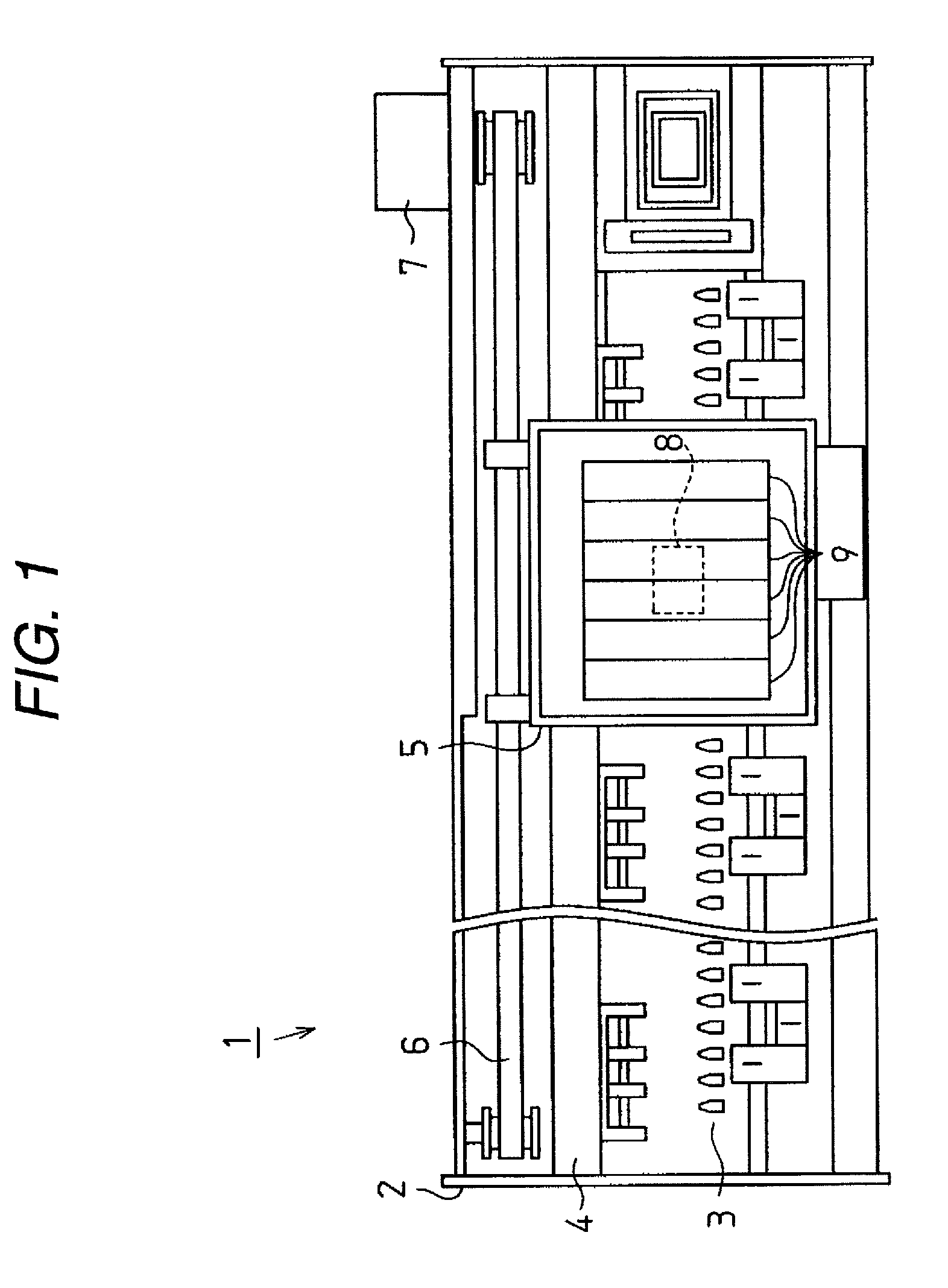

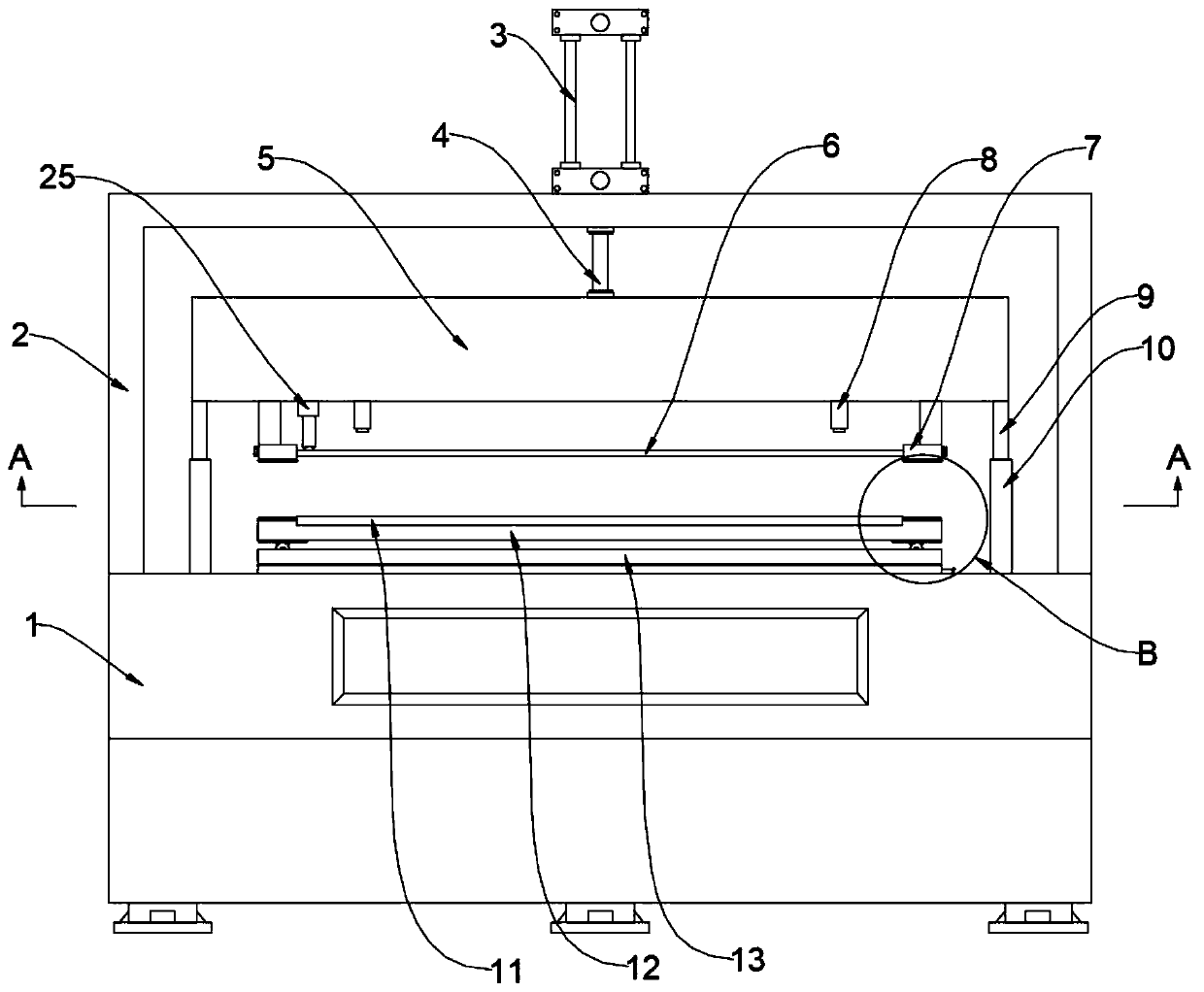

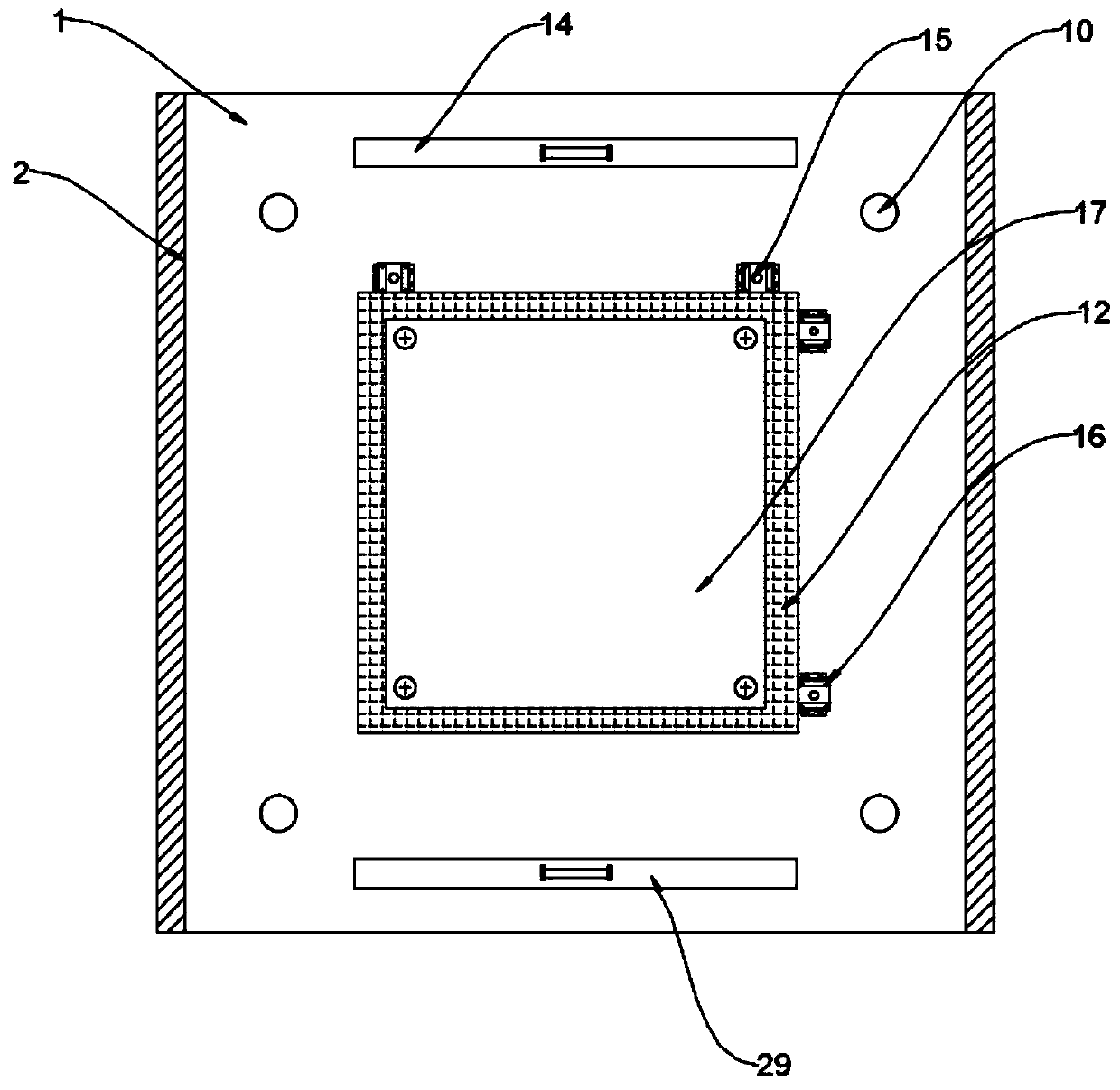

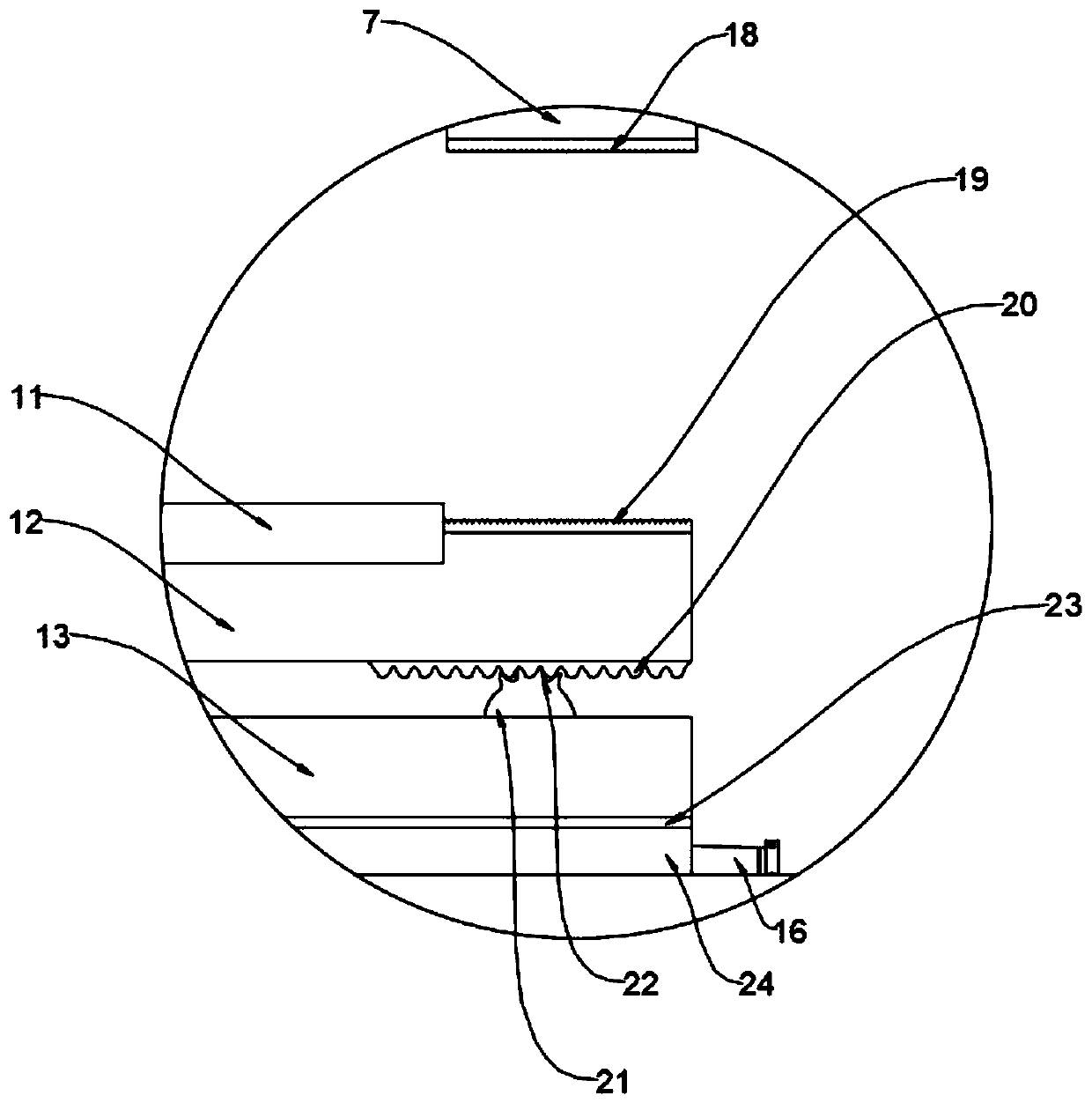

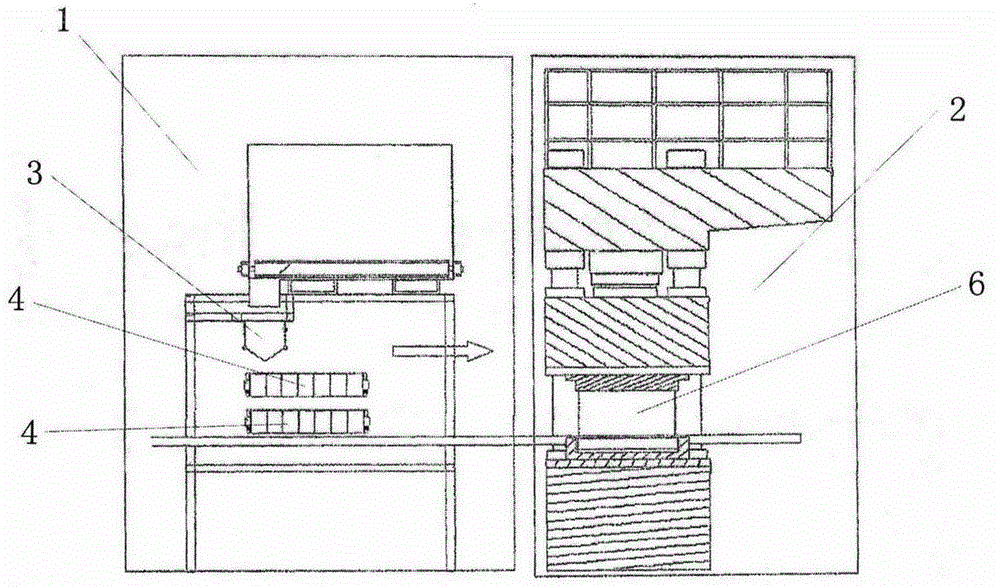

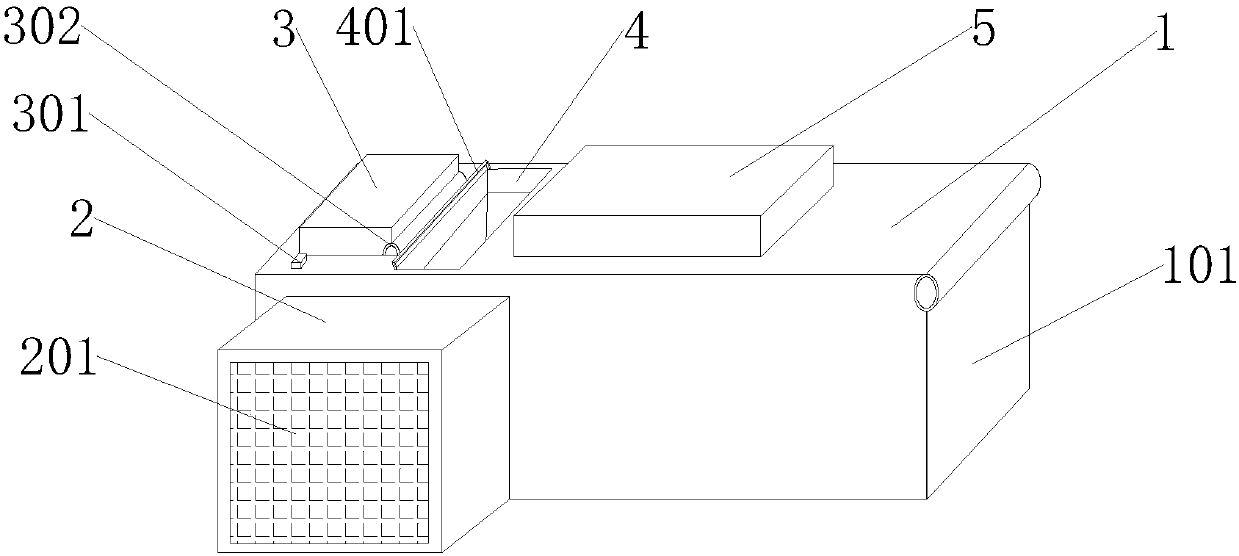

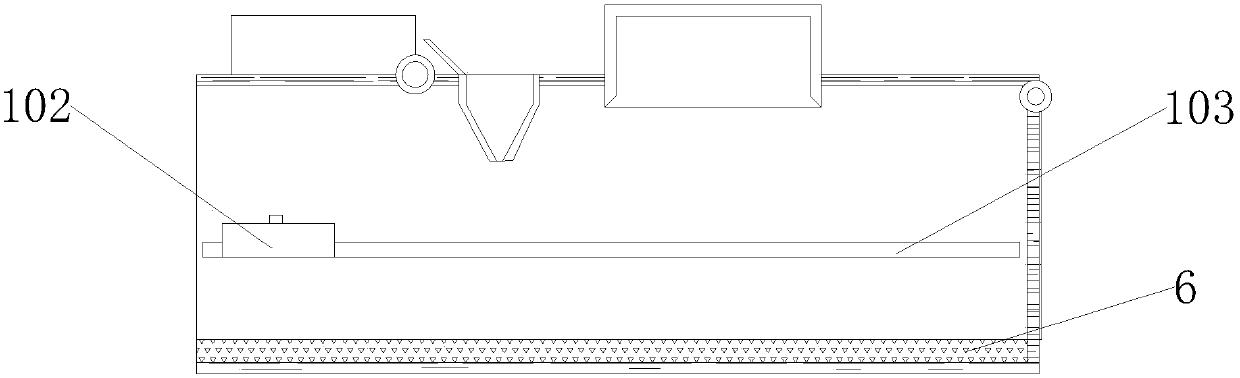

Circuit board printing device

PendingCN110789220AImprove drying efficiencyReduce the valueScreen printersConductive pattern formationEngineeringDrying time

The invention discloses a circuit board printing device, and relates to the related field of circuit board printing. The problem that in the prior art, in the drying process, heat is dissipated, heatis not concentrated on the printing portion, and consequently, drying time is long can be solved. The middle of the rear end of the upper end face of a worktable is provided with a first drying device, a second drying device is arranged in the middle of the front end of the upper end face of the worktable, the first drying device and the second drying device are connected with the worktable through sliding strips, the first drying device and the second drying device are embedded in the worktable, and the first drying device and the second drying device each comprise an outer frame, a placing groove, a connecting telescopic rod, a drying plate, a moving groove, a drying area, a drying device supporting plate and a pressure spring.

Owner:SUZHOU HUILIYUAN TECH CO LTD

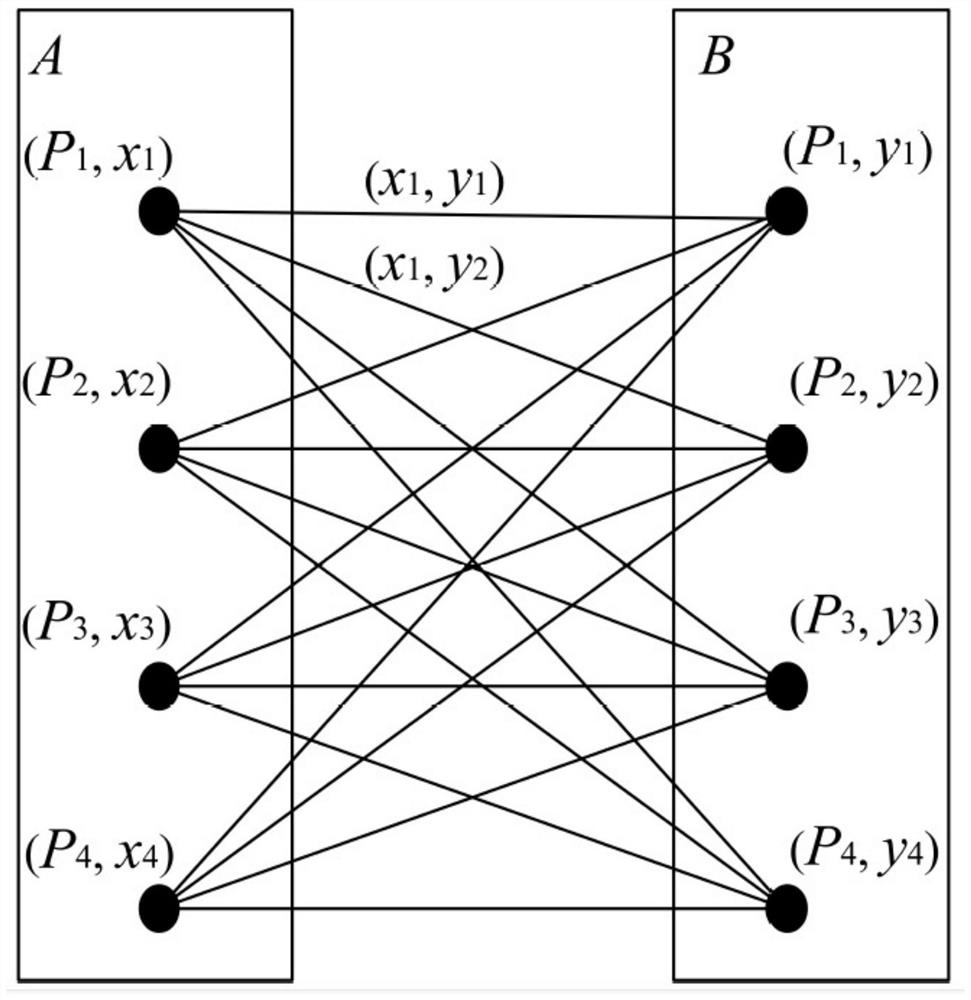

Secure multi-party multiplication method and system

ActiveCN112380495AEnsure safetyReduce overheadEnergy efficient computingComplex mathematical operationsDistributed computingCalculation technique

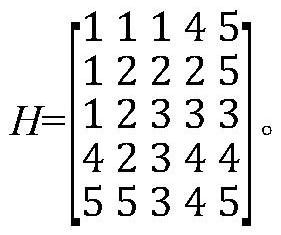

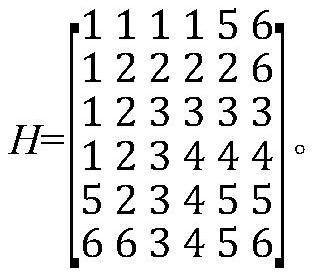

The invention relates to the technical field of distributed joint computing, and discloses a secure multi-party multiplication method and system, so as to realize repeated sharing through a round of optimal communication. The method comprises the following steps that: based on a multiplication shared component calculation protocol of data sharing bipartite graph division, bipartite graph modelingis carried out on data sharing for multiplication calculation, and division of multiplication result shared components is represented by an adjacent matrix, so that n participants can locally calculate multiplication shared components only by one round of communication.

Owner:GUIZHOU EDUCATION UNIV

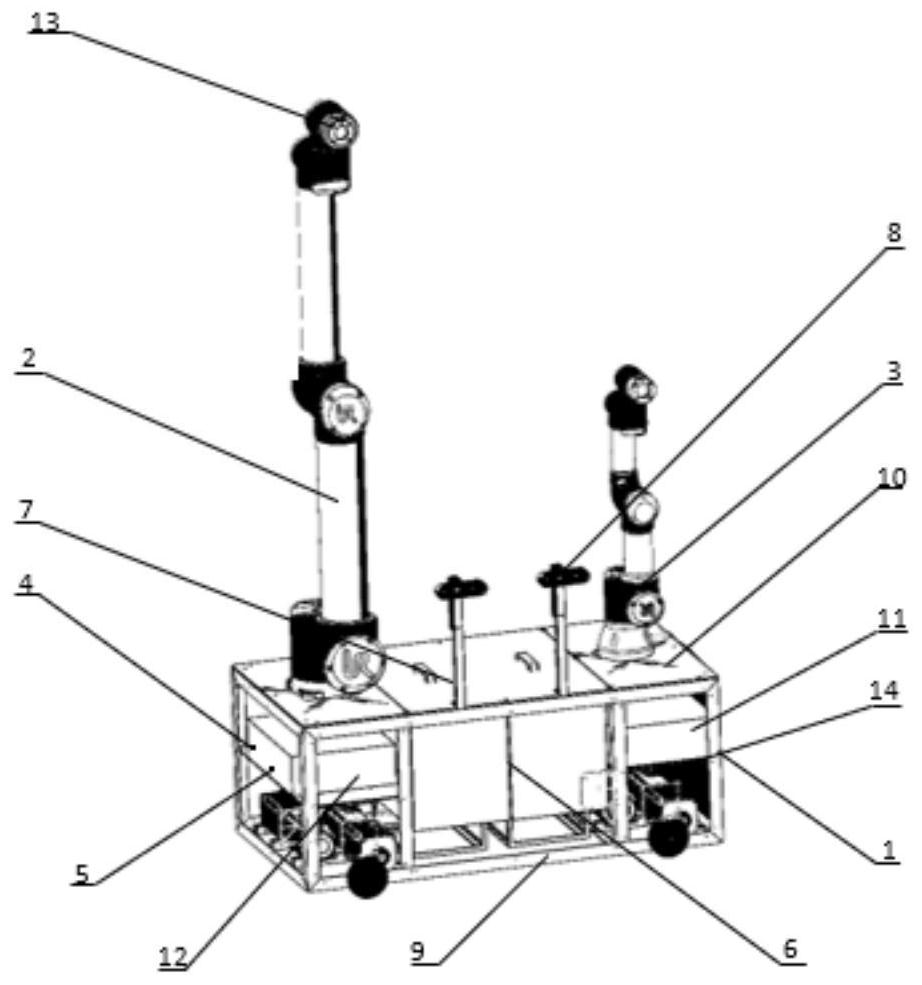

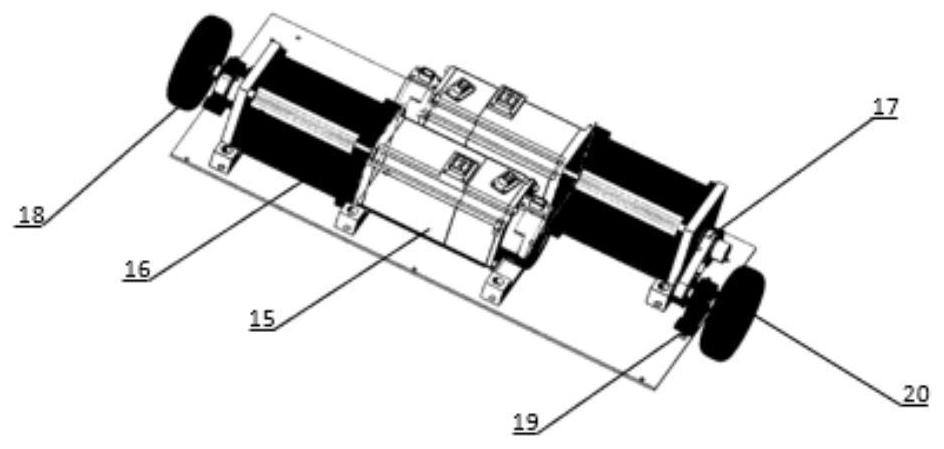

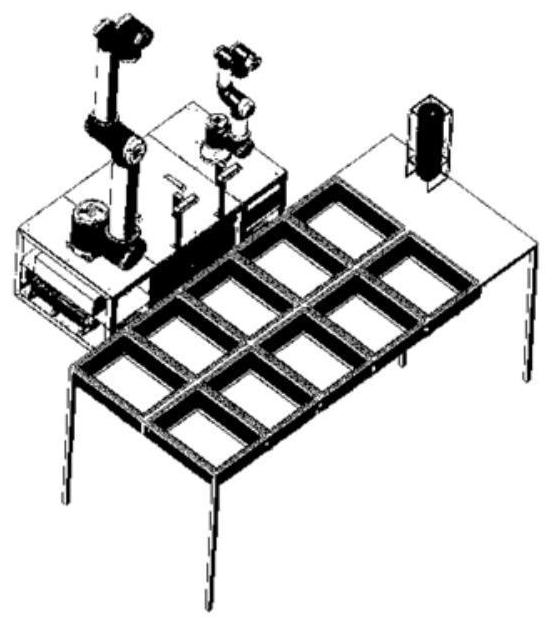

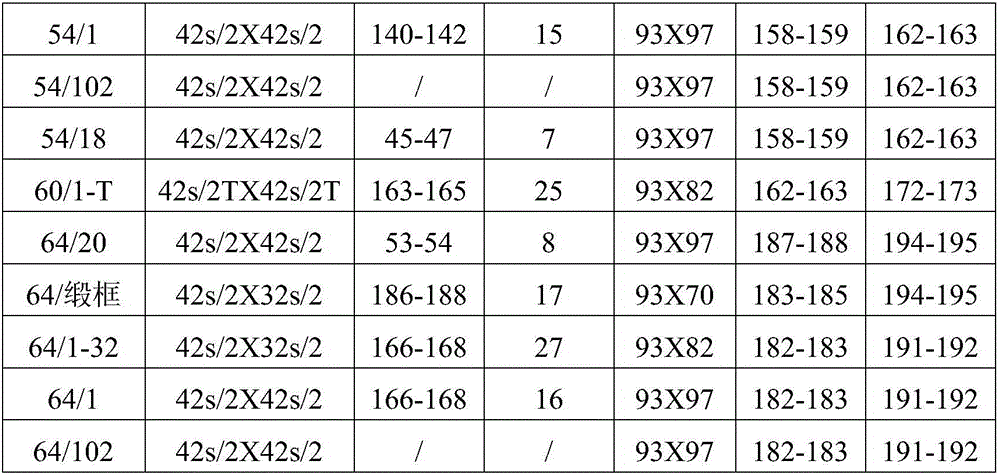

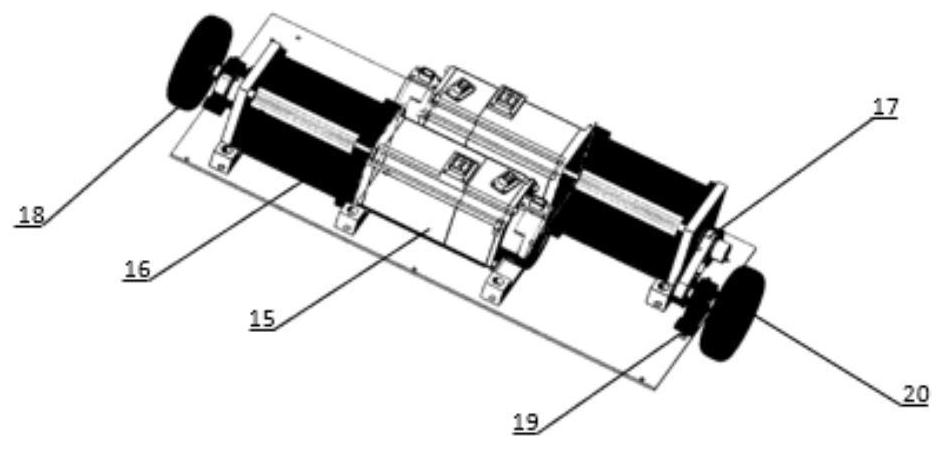

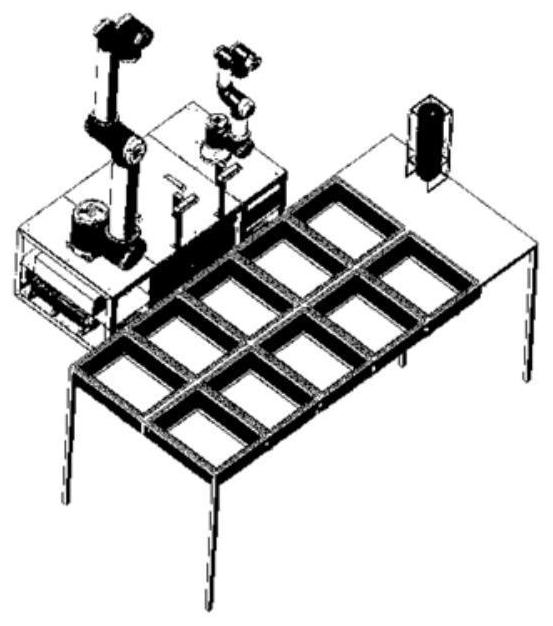

Robot moving platform for restaurant

ActiveCN112171689AMeet installation needsEasy loadingProgramme-controlled manipulatorLine sensorReduction drive

The invention discloses a robot moving platform for a restaurant. The robot moving platform comprises a moving platform body, a base plate, a vehicle cover, a first synchronous belt wheel, a second synchronous belt wheel, a third synchronous belt wheel, a fourth synchronous belt wheel, a first coupling, a second coupling, a third coupling, a fourth coupling, a first solid bearing rubber wheel, a second solid bearing rubber wheel, a third solid bearing rubber wheel, a fourth solid bearing rubber wheel, a first permanent magnet servo motor, a second permanent magnet servo motor, a third permanent magnet servo motor, a fourth permanent magnet servo motor, a first speed reducer, a second speed reducer, a third speed reducer, a fourth speed reducer, a first vertical mounted bearing, a second vertical mounted bearing, a third vertical mounted bearing, a fourth vertical mounted bearing, a balancing weight, a permanent magnet servo motor driver, a mechanical arm driver, an industrial personalcomputer, a first ultrasonic sensor, a second ultrasonic sensor, a first infrared sensor, a second infrared sensor, a long mechanical arm, a short mechanical arm, a supporting frame, a torque sensor,a first RGB-D depth camera and a second RGB-D depth camera, wherein the first permanent magnet servo motor, the second permanent magnet servo motor, the third permanent magnet servo motor, the fourthpermanent magnet servo motor, the first speed reducer, the second speed reducer, the third speed reducer, the fourth speed reducer, the first vertical mounted bearing, the second vertical mounted bearing, the third vertical mounted bearing, the fourth vertical mounted bearing and the balancing weight are fixed on the base plate, the permanent magnet servo motor driver, the mechanical arm driver and the industrial personal computer are fixed on the inner part, the first ultrasonic sensor, the second ultrasonic sensor, the first infrared sensor and the second infrared sensor are fixed to a platform, the long mechanical arm, the short mechanical arm and the supporting frame are fixed on the vehicle cover, the torque sensor is fixed on the mechanical arm, and the first RGB-D depth camera and the second RGB-D depth camera are fixed on the supporting frame. The robot moving platform is flexible to control and large in working range, has the functions of walking, grabbing and serving dishes,can quickly finish the work of ordering and serving dishes, and plays a role in reducing the burden of canteen workers.

Owner:HANGZHOU DIANZI UNIV

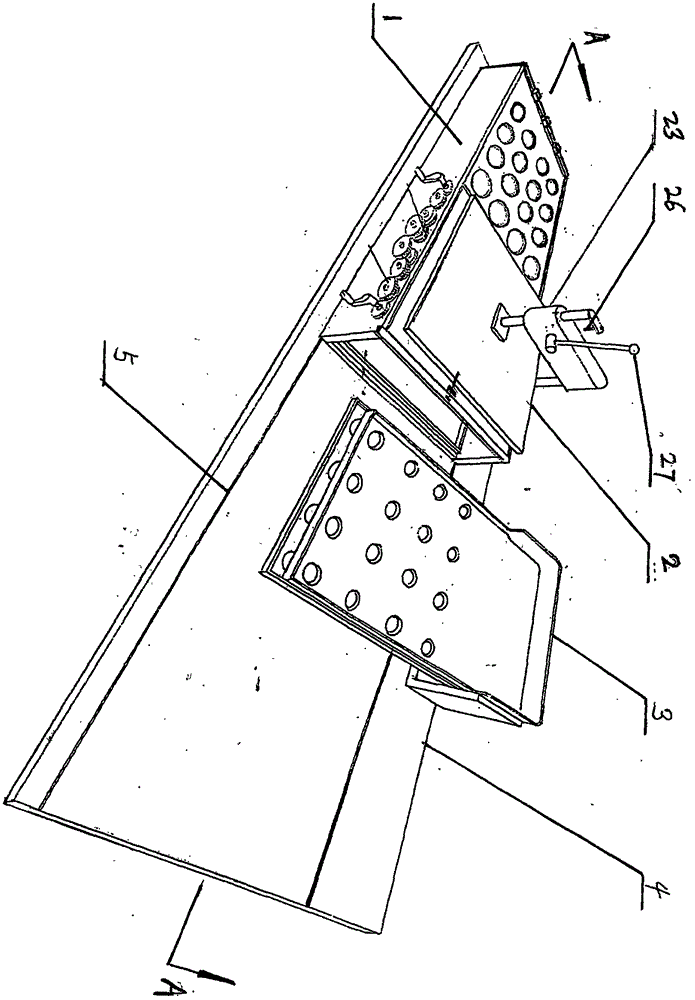

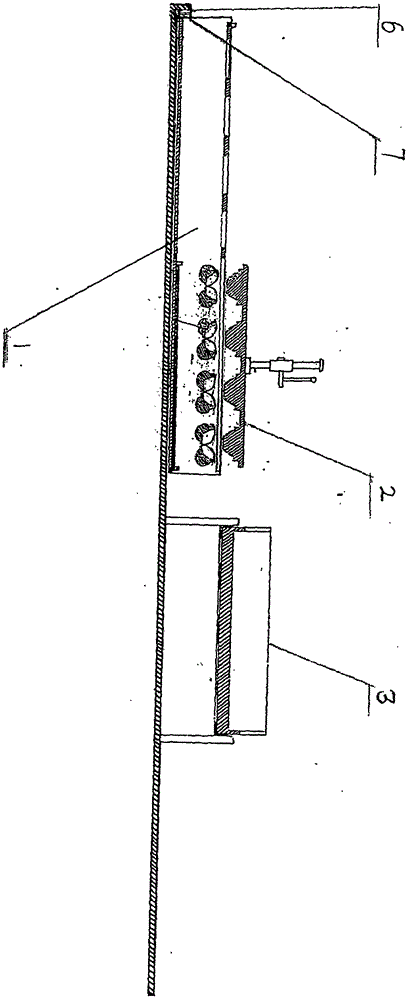

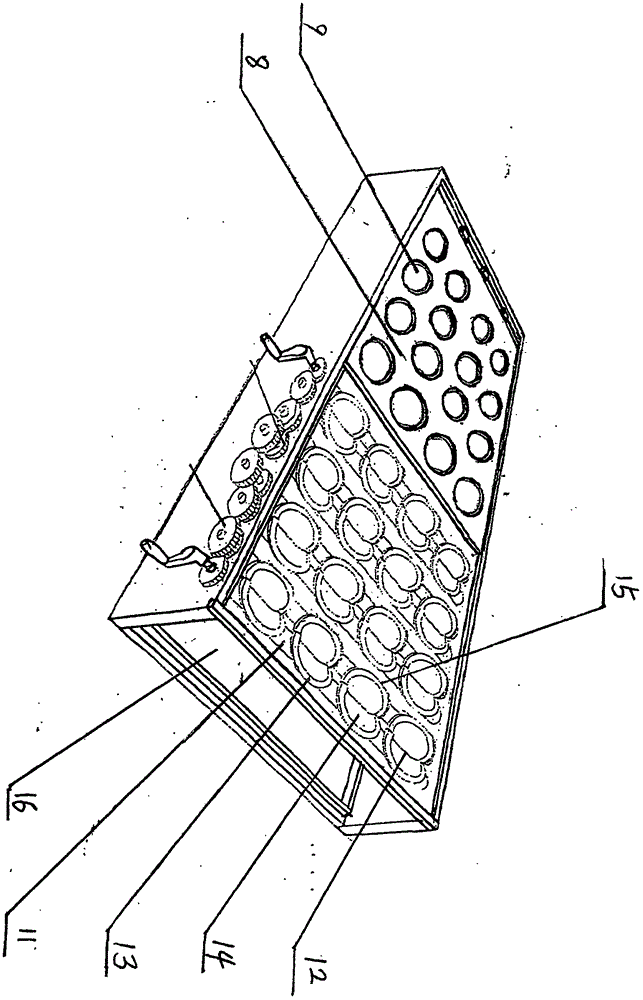

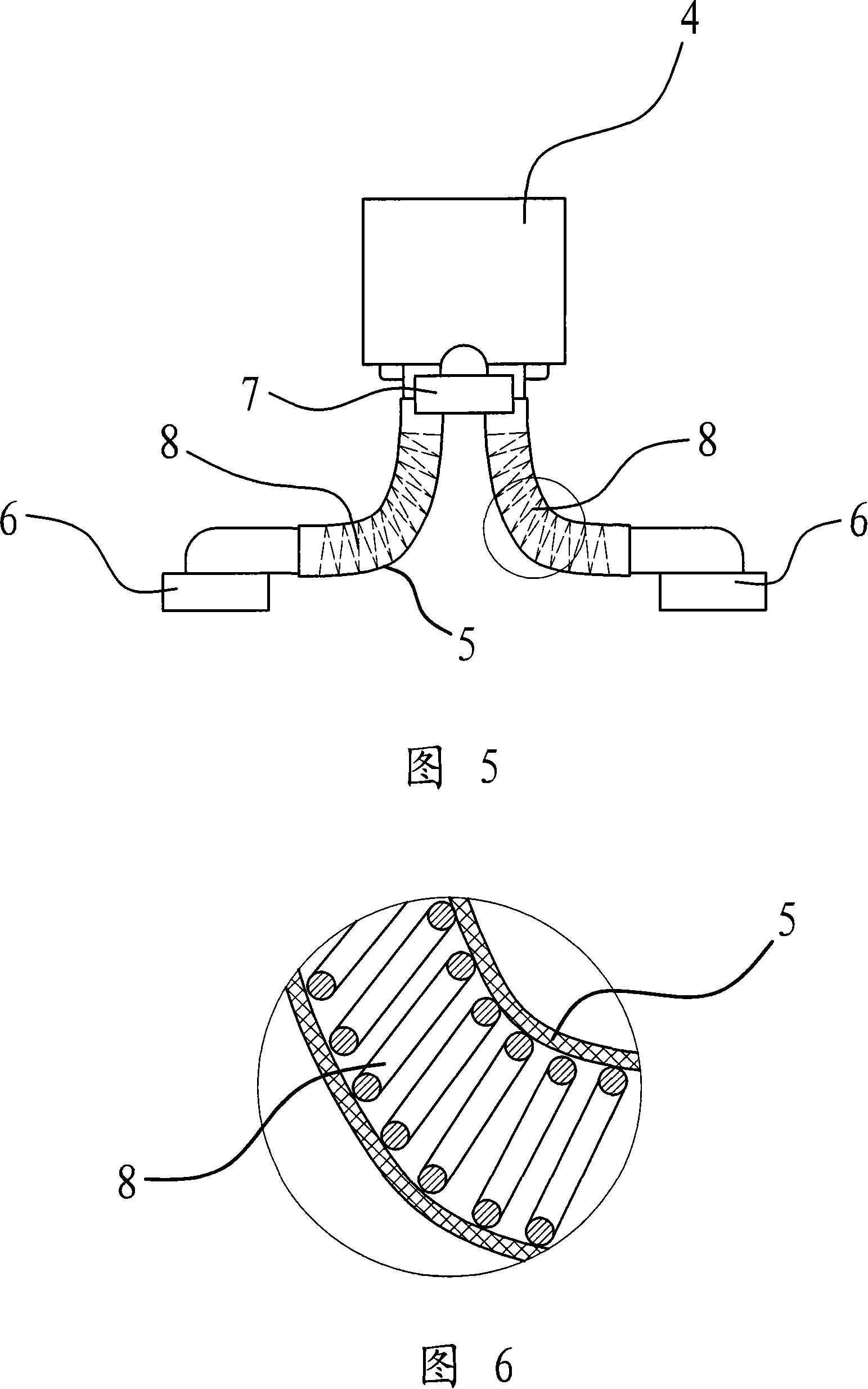

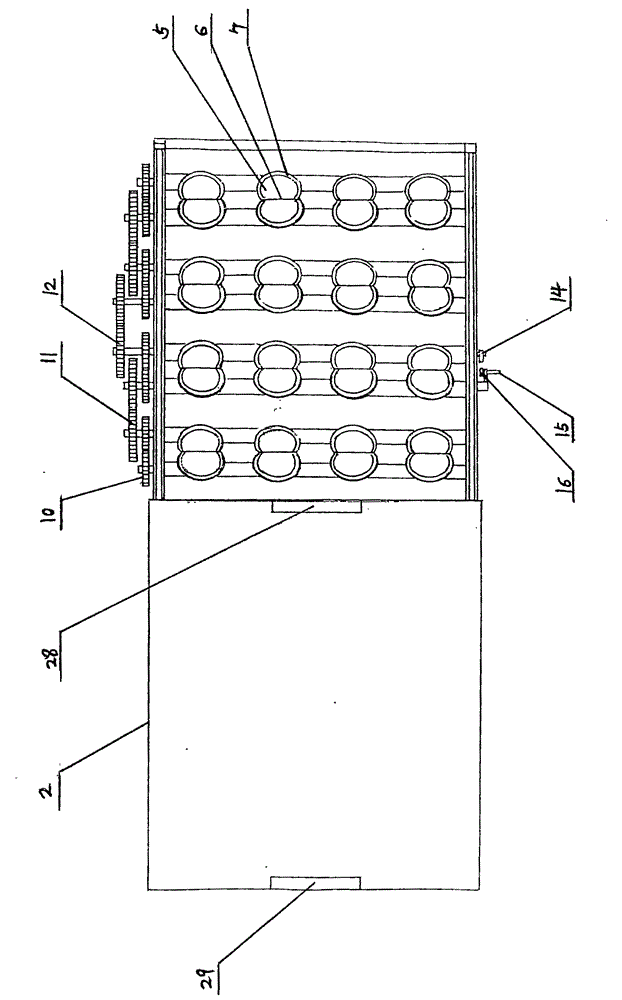

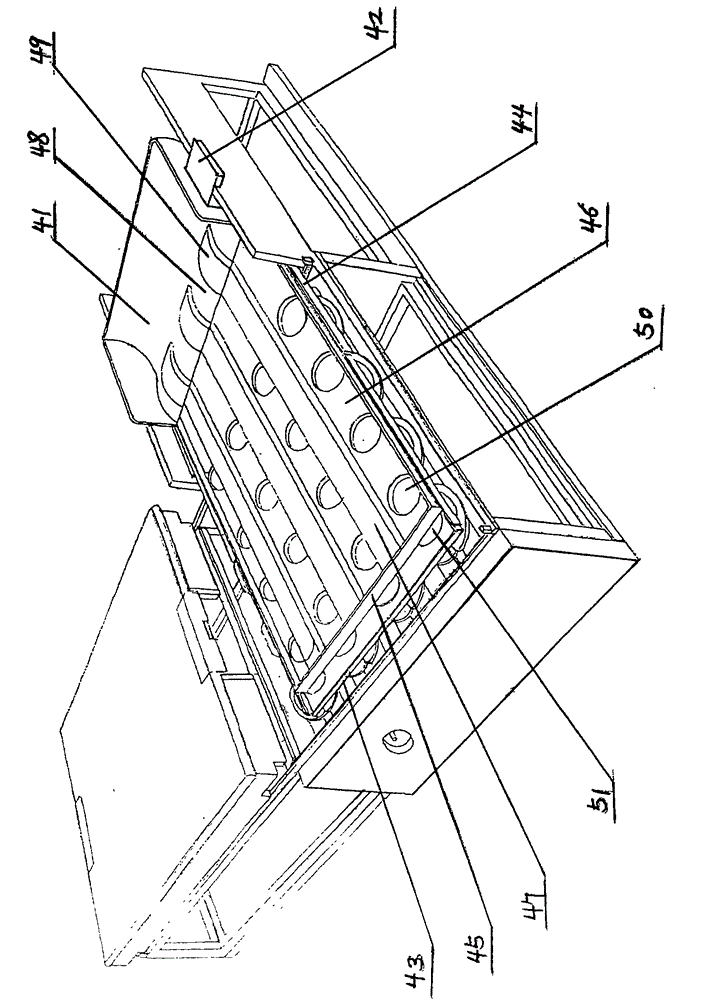

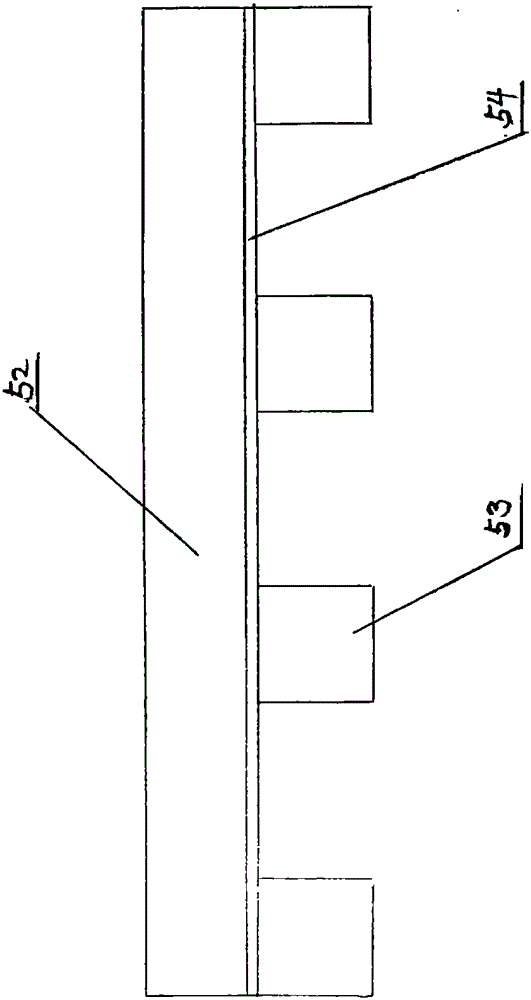

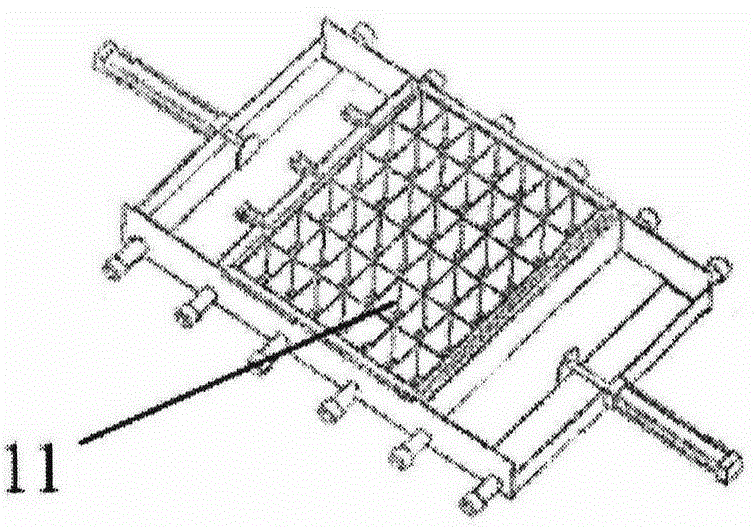

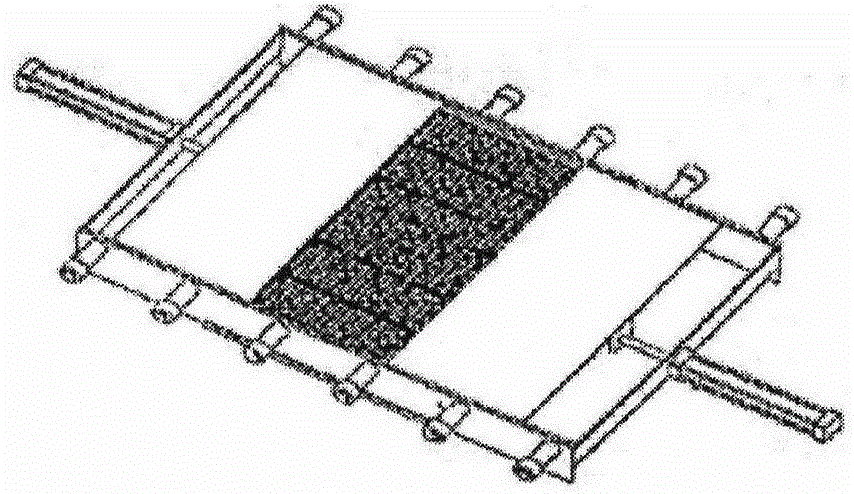

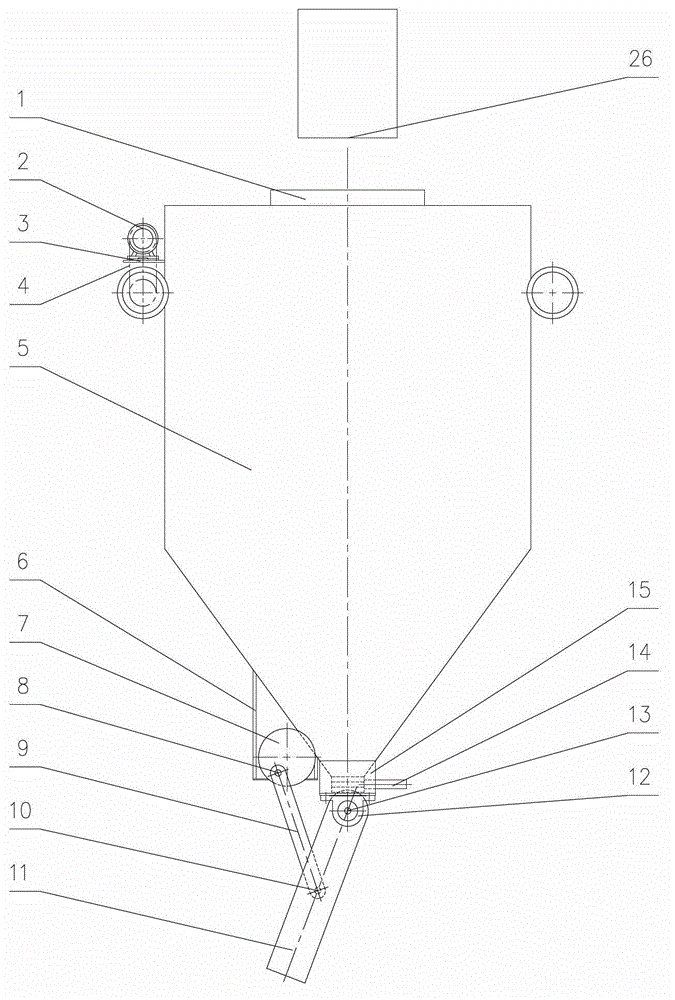

Handwork imitated dumpling making device

InactiveCN106605665AEqual weightDough-sheeters/rolling-machines/rolling-pinsDough processingBiomedical engineering

The present invention discloses a handwork imitated dumpling making device. A certain number of dumpling wrappers are sent into dumpling forming dies via a dumpling wrapper placing die orifice plate, then corresponding dumpling wrapper pressing dies press the dumpling wrappers into the dumpling forming dies, a dumpling forming die roller device slips into a corresponding position of a dumpling stuffing device, the dumpling wrappers in the dumpling forming dies molding are stuffed, the dumpling forming die roller is rolled for one circle, and the dumpling forming dies roll and wrap a certain number of the dumplings, so that the handwork imitated dumpling making device can wrap the certain amount of the dumplings once and is fast and convenient in the dumpling wrapping. The dumplings are thin in wrappers, much in stuffing, juicy, beautiful in shapes, and equal in each weight.

Owner:陈茂威

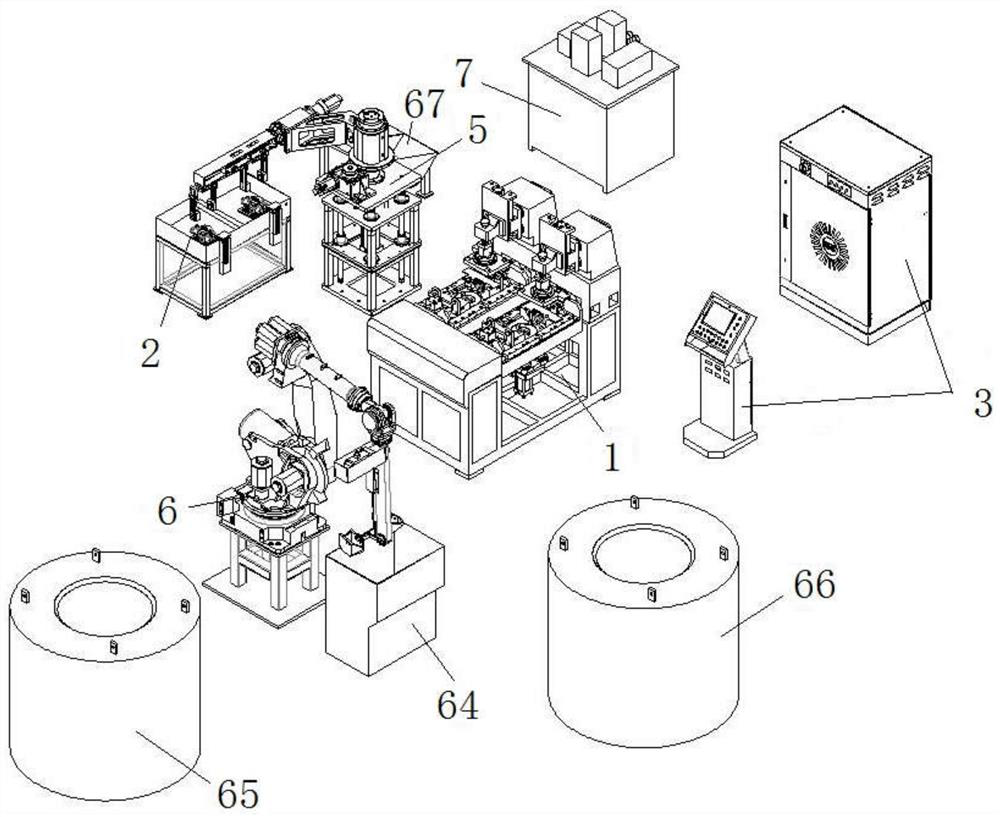

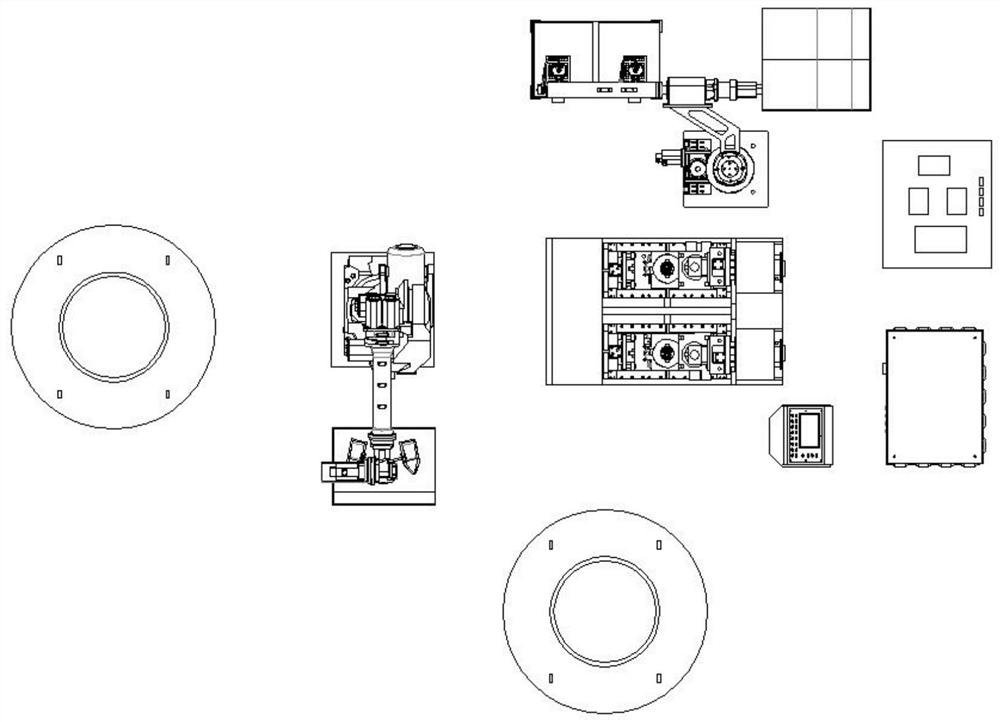

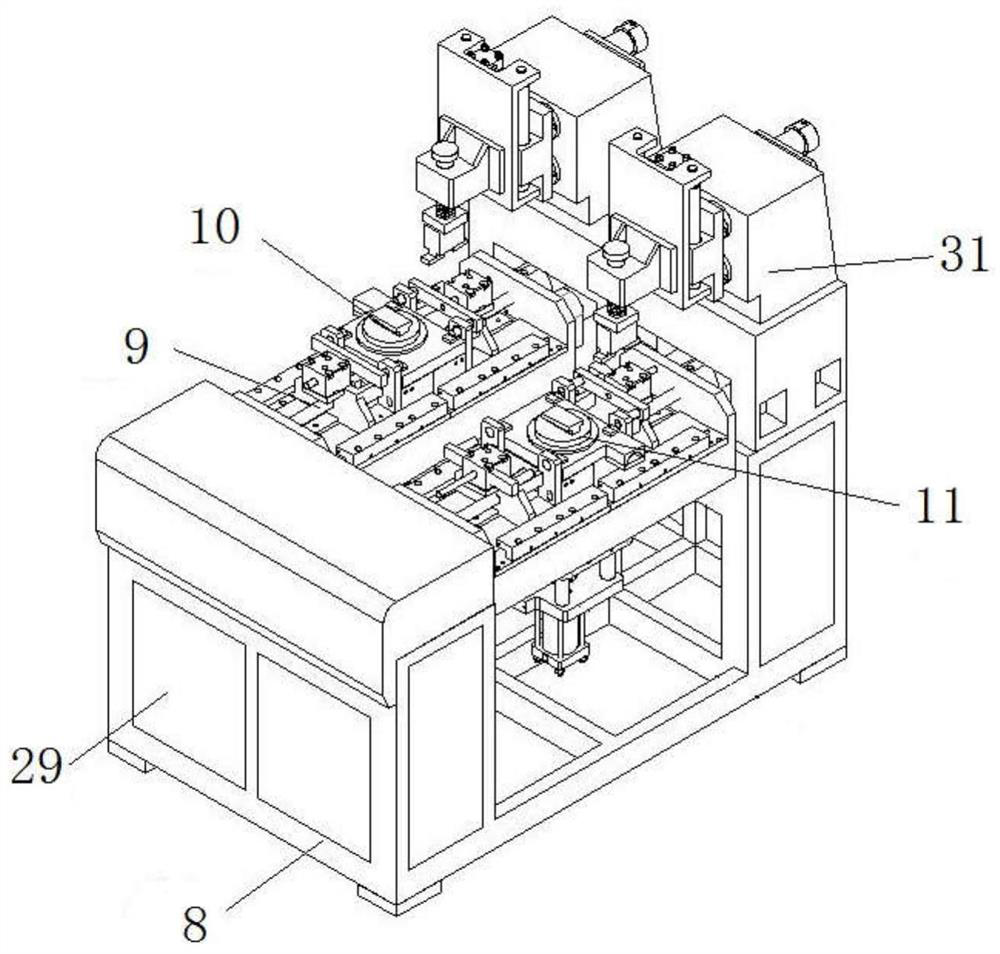

Double-mold automatic casting machine capable of rotating by 90 degrees to pour aluminum piston blank and using method of double-mold automatic casting machine

PendingCN112828277AImprove mechanical propertiesImprove heat resistanceCasting plantsMolten metal supplying equipmentsMachinePiston

The invention relates to a double-mold automatic casting machine capable of rotating by 90 degrees to pour an aluminum piston blank anda using method of the double-mold automatic casting machine, and belongs to the technical field of piston casting. The device comprises a pouring system, a part taking mechanical hand, a joint pouring robot, a hydraulic system, an electrical operating system and a quenching cooling box, the pouring system is arranged on the ground, the part taking mechanical hand is arranged on the ground on one side of the pouring system, the joint pouring robot is arranged on the opposite side of the pouring system, and the joint pouring robot extracts molten aluminum to pour the molten aluminum into the pouring system. The quenching cooling box is arranged on one side of the part taking mechanical hand, the part taking mechanical hand clamps the piston blank poured by the pouring system to the quenching cooling box, the pouring system is connected to the hydraulic system, and the hydraulic system, the part taking mechanical hand and the joint pouring robot are all connected to the electrical operation system. The overall automatic operation is achieved, the production efficiency is improved, and the mechanical performance and the thermal fatigue resistance of the piston blank are improved.

Owner:山东进化者新材料有限公司

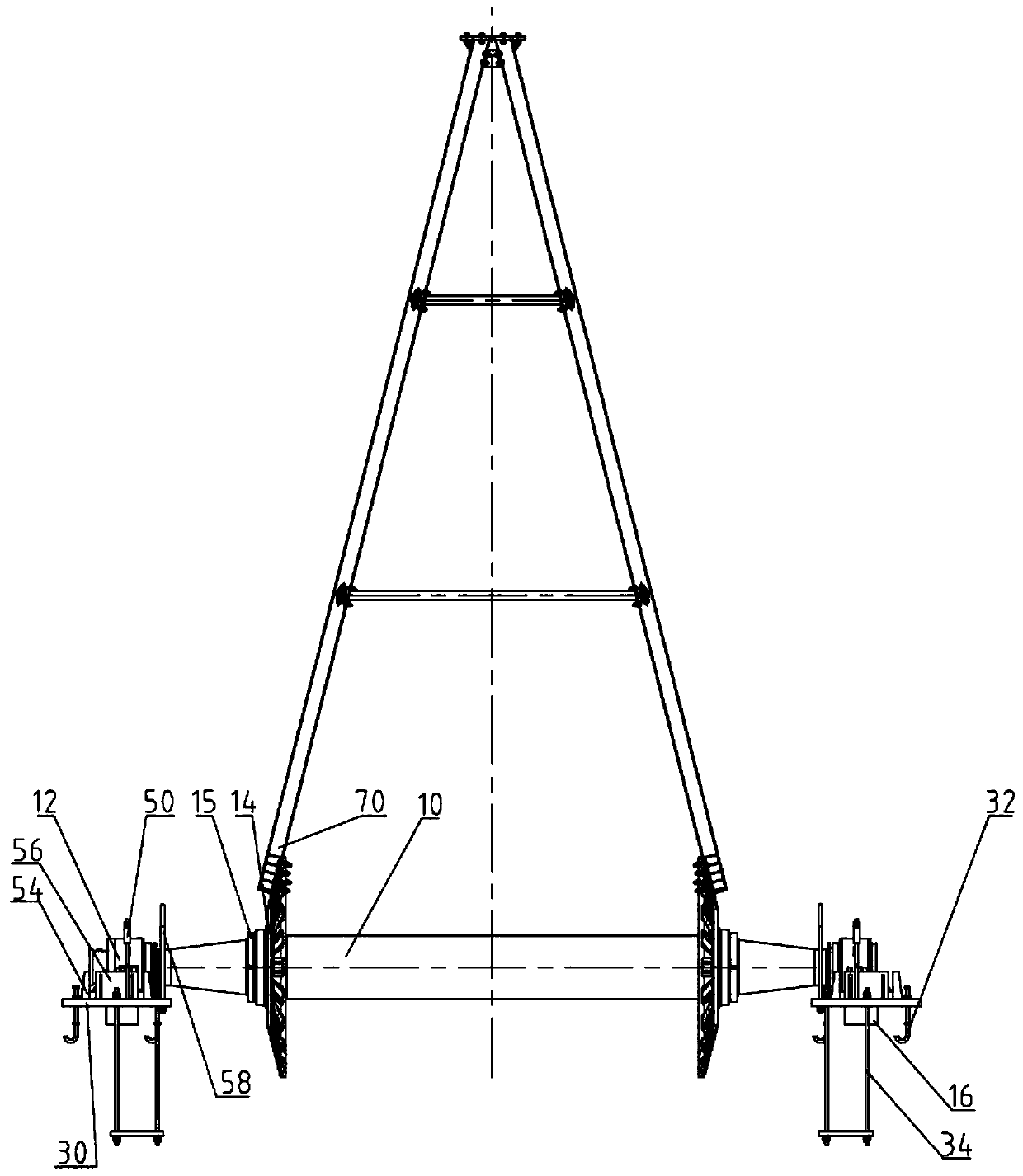

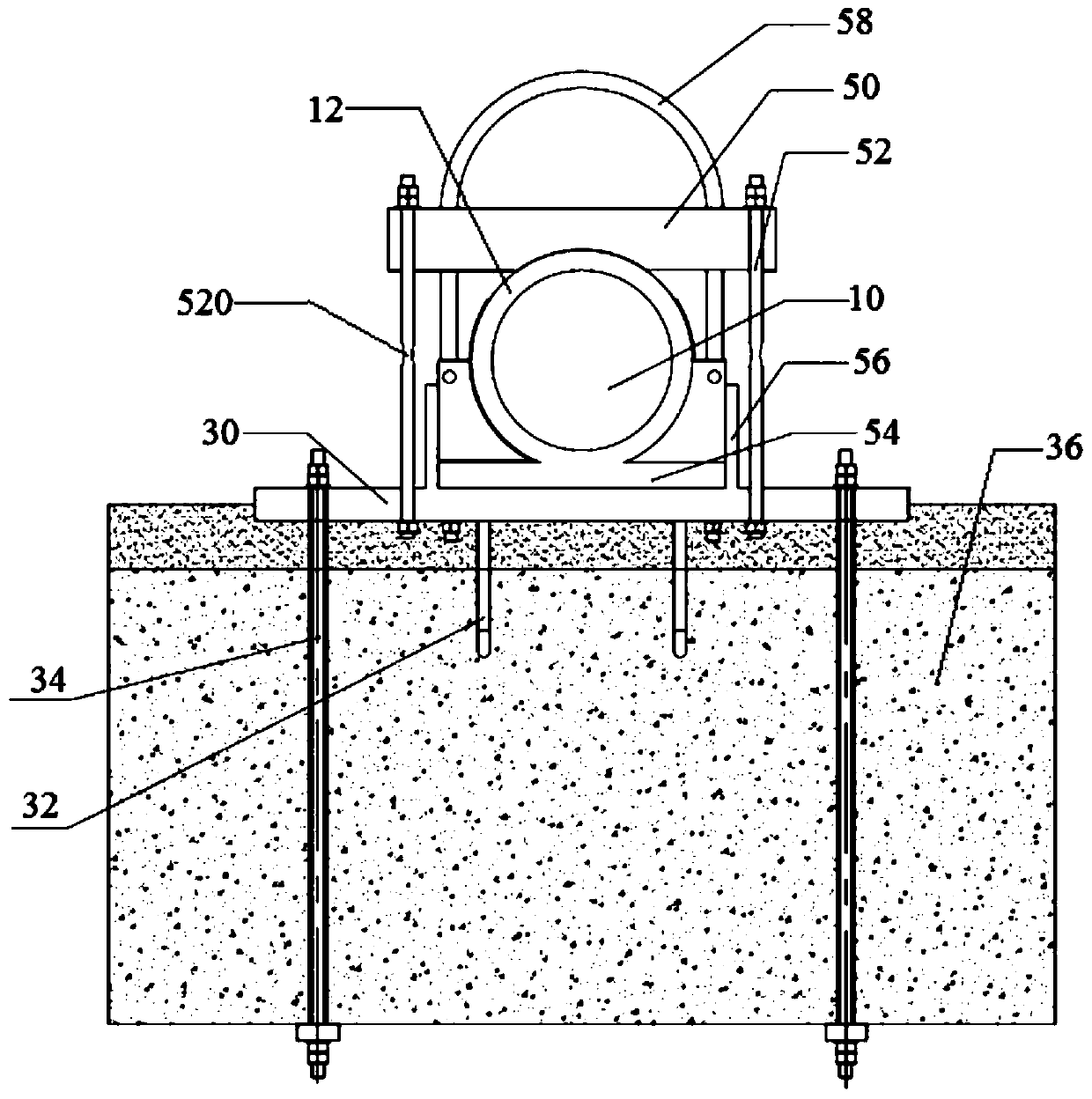

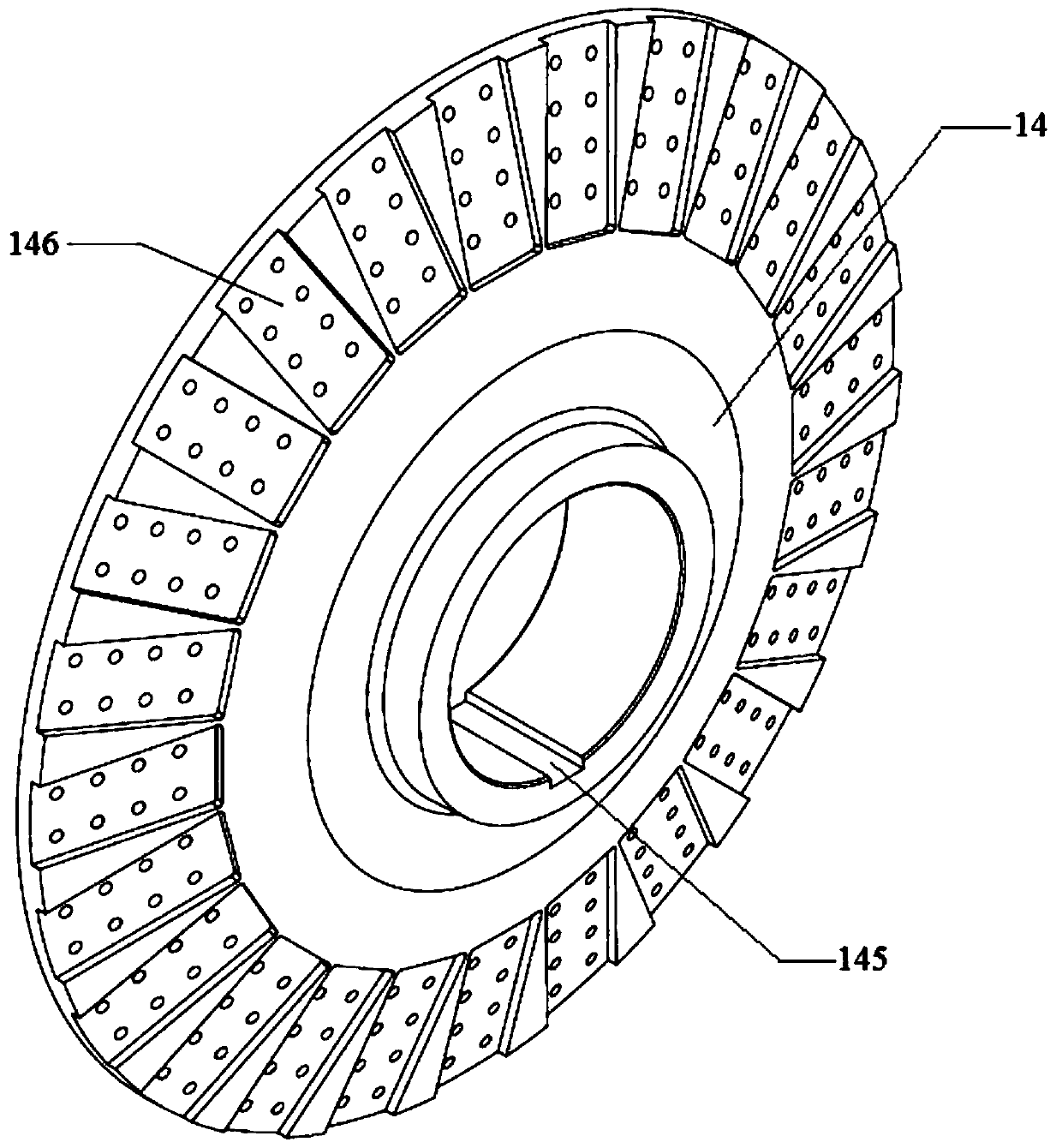

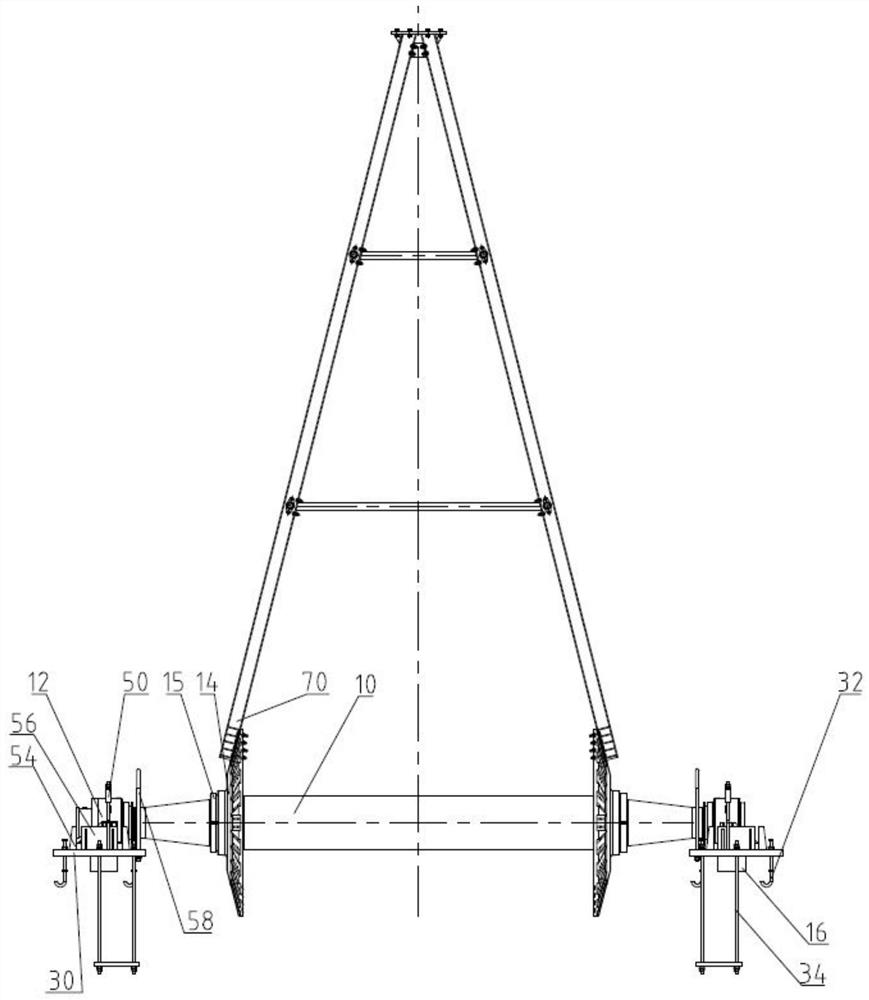

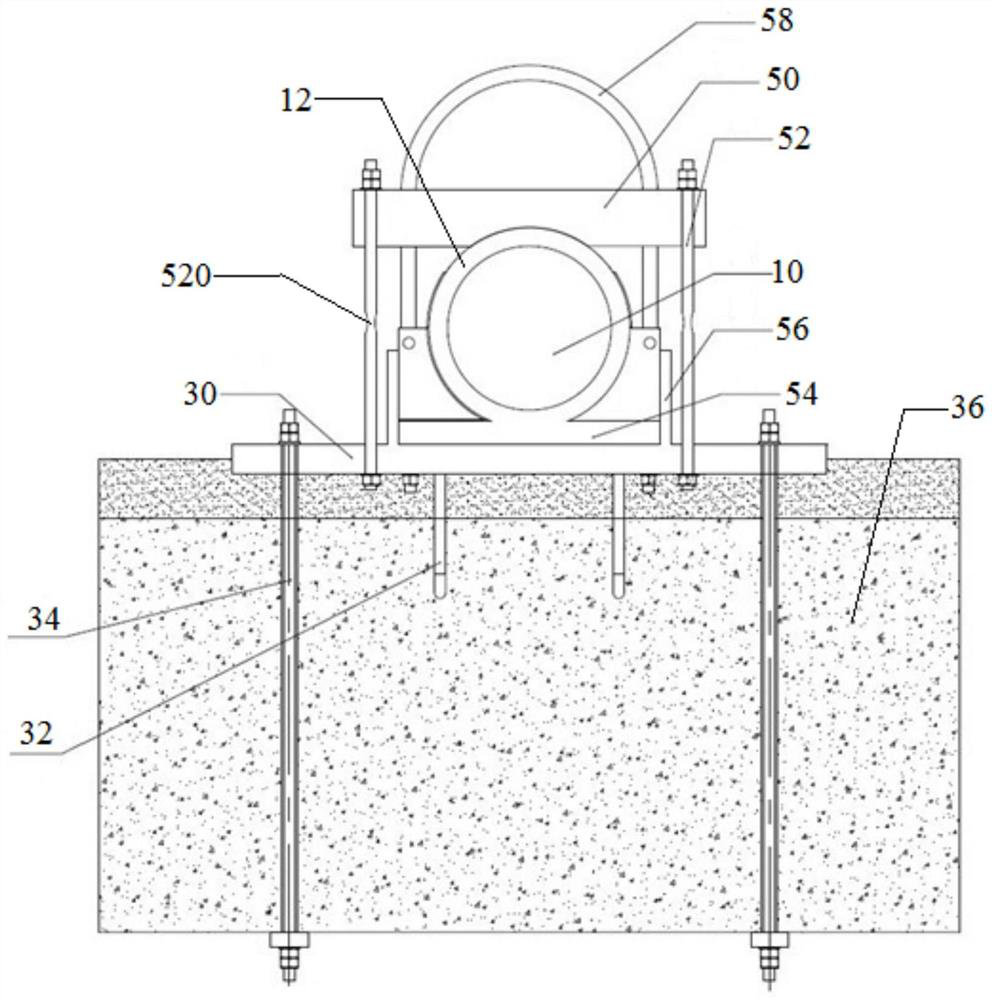

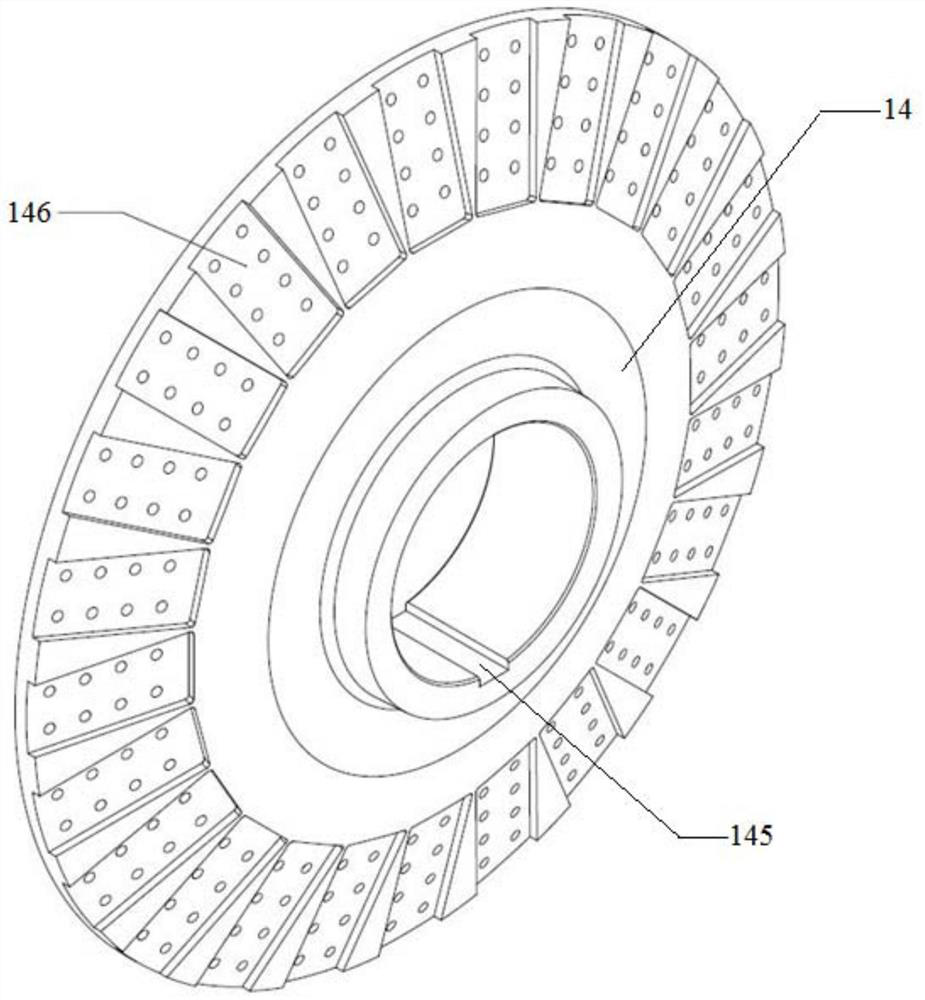

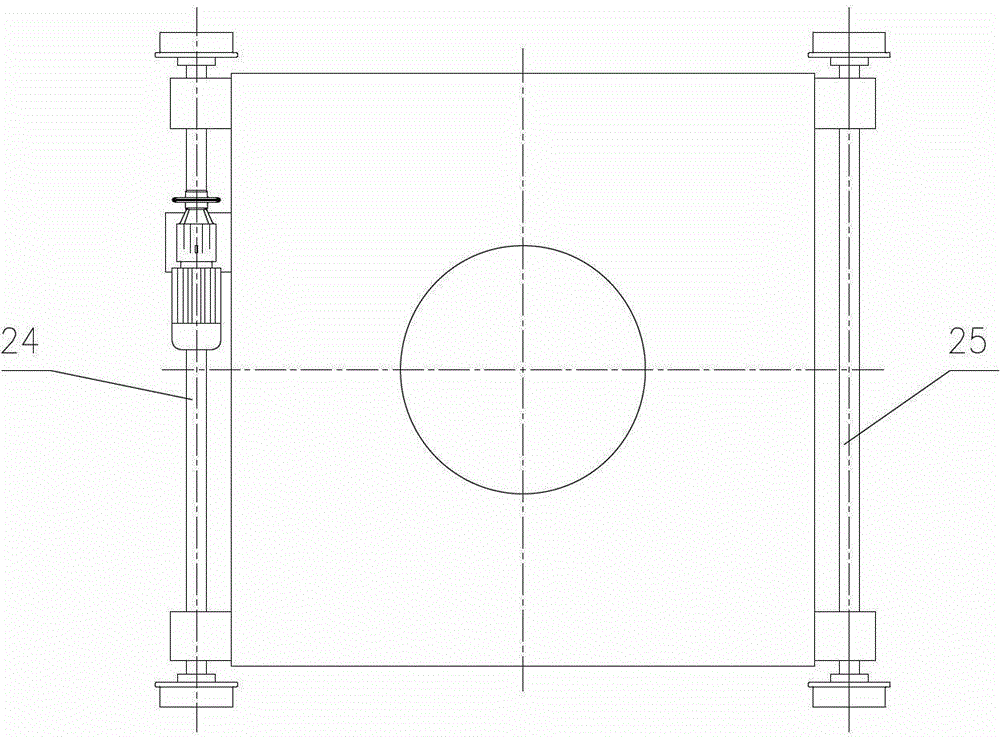

Drum-shaped filter screen support structure in nuclear power plant

ActiveCN110404313APlay a protective effectEnsure safetyStationary filtering element filtersEngineeringBuoyancy

The invention discloses a drum-shaped filter screen support structure in a nuclear power plant. The structure comprises a spindle, a spindle bearing seat, a bearing seat base plate, a drum-shaped filter screen protection device, a hub and spokes, wherein the spindle is mounted in the spindle bearing seat; the hub is mounted on the spindle; the spokes are connected with the hub; the drum-shaped filter screen protection device comprises a protection pressing block and a protection pull rod; the bearing seat base plate is fixed on a concrete floor plate; the spindle bearing seat is connected below the protection pressing block; and the protection pressing block is connected with the bearing seat base plate through the protection pull rod. Before being damaged, a drum-shaped filter screen canbe pulled off through a pull-off load of the protection pull rod, and thus security of the drum-shaped filter screen can be ensured. As the drum-shaped filter screen protection device is arranged on the spindle bearing seat of the structure, the drum-shaped filter screen can be pulled off by the protection pull rod in case of large buoyancy, and a protection function on the drum-shaped filter screen can be achieved. The hub is of a forged piece structure, and the spokes are of H-shaped steel structures.

Owner:中广核工程有限公司 +3

Method for manufacturing imitating jade tap and its product and mould

InactiveCN101104315AGuarantee unimpededReduce manufacturing costMultiple way valvesSlide valveMechanical engineeringSilicon

The invention provides a making method of a jade-like water tap and the product and a die thereof, relating to a water tap, which solves the problem on current water tap that water discharging amount is not agreeable. The making method of the jade-like water tap comprises the following steps: A. assembling the die; B. closing the die; C. injecting; D. assembling. The jade-like water tap comprises a body inside which a circular tube and a valve core seat are arranged. A water inlet pipe and a water outlet pipe are fixedly connected to the body and both are communicated with the valve core seat through respective connecting tubes. The body is made of resin and the connecting tubes are provided with reinforcing structures inside to strengthen the intensity of the connecting tubes. An upper die body and a lower die body of the jade-like water tap are made of plaster and the joint interface of the upper die body and the lower die body is provided with a silicon glue layer; the positioning holes of the valve core seat, the water inlet seat and the water outlet seat are provided with positioning devices. With the method, rate of finished water taps is high and the products are elegant in appearance and good in taste.

Owner:张长春

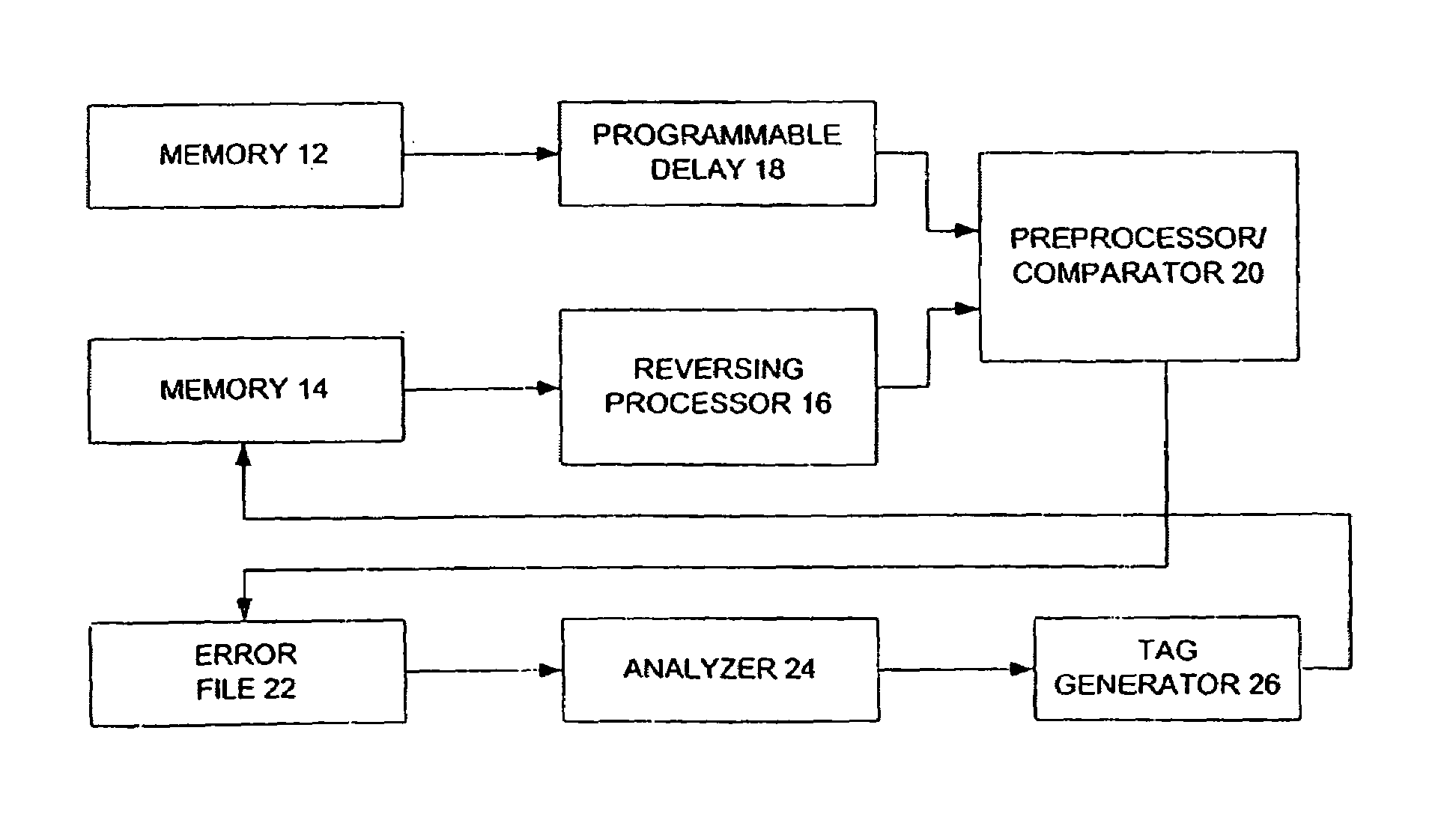

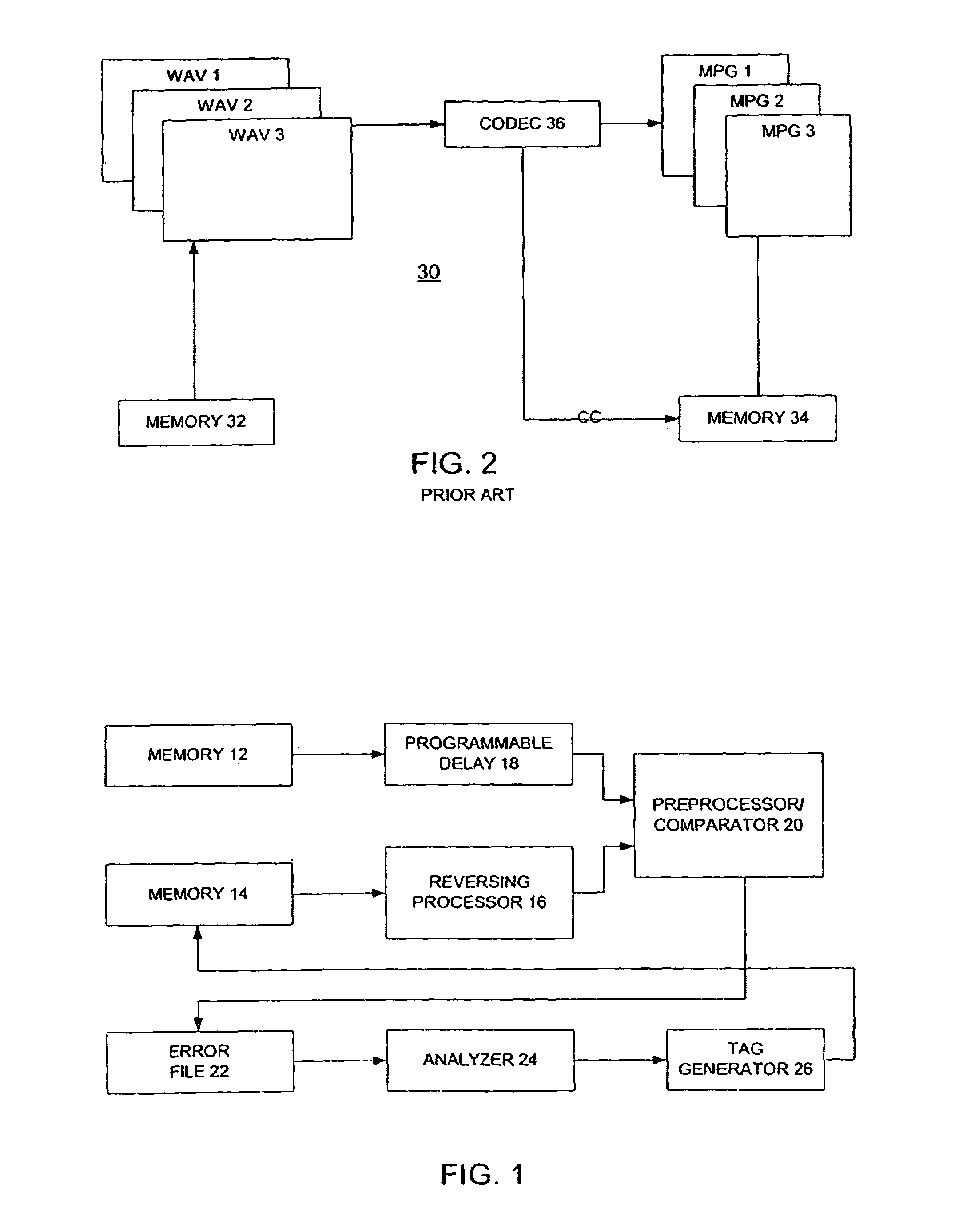

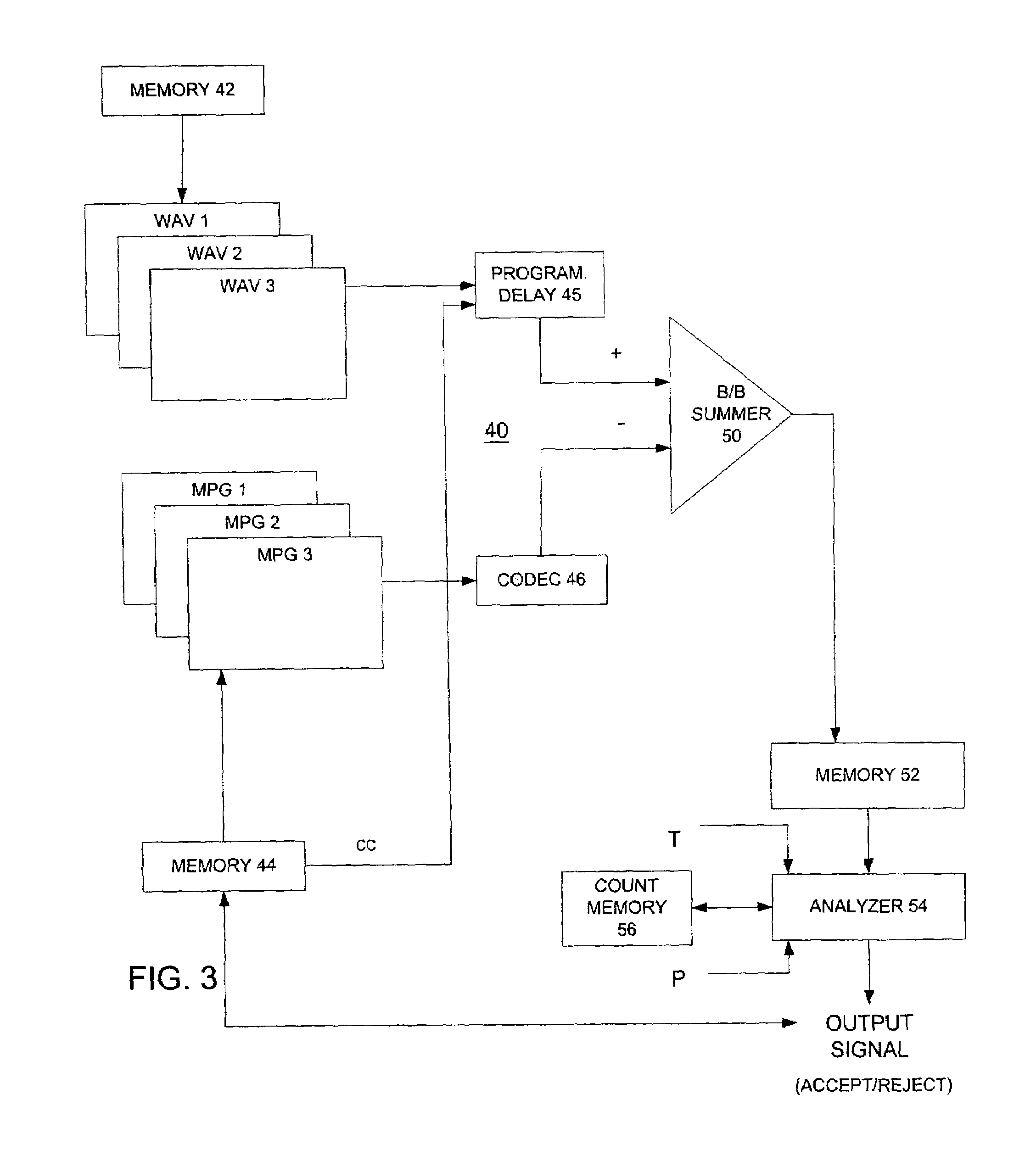

Method and system for verifying derivative digital files automatically

ActiveUS7197458B2Maximum qualityEasy to adaptError preventionBroadcast information characterisationSound qualityDigital file

A method and apparatus for verifying automatically that a plurality of derivative audio (or other multimedia) files have acceptable sound quality. In one embodiment, each derivative file is compared on a byte-by-byte basis to a corresponding original file to generate a difference. The difference is compared a threshold value (that may be determined empirically). If the difference is too large for many bytes, the derivative file is tagged as having an unacceptable sound quality. In another embodiment, segments of the original and derivative files are converted to the frequency domain and analysis is performed in this domain. The resulting signal could be a tag indicating that whether the derivative file is acceptable, or could be a more comprehensive signal indicative what kind of errors were detected and in what temporal and / or spectral region for diagnostic purposes.

Owner:WARNER MUSIC GROUP

Imitated manual dumpling making machine

InactiveCN105145703AEqual weightDough-sheeters/rolling-machines/rolling-pinsDough processingMaterials science

The invention discloses an imitated manual dumpling making machine. The imitated manual dumpling making machine comprises the following processes: putting a dumpling wrapper on a dumpling forming mold; sliding a dumpling wrapper pressing mold device to the front end of the dumpling making machine; pressing the dumpling wrapper into the dumpling forming mold by a dumpling wrapper pressing mold on the dumpling wrapper pressing mold device; sliding the dumpling wrapper pressing mold device to the rear end of the dumpling making machine, and loading filling to the dumpling wrapper in the dumpling forming mold through a dumpling filling device; rotating the dumpling forming mold a circle, and packing a certain number of dumplings to fall into a tray by the dumpling forming mold, so that a certain number of dumplings packed once can be controlled; and dumpling is fast and convenient to make, thin in wrapper, large in filling, juicy, matched in shape, equal in weight and the like.

Owner:陈茂威

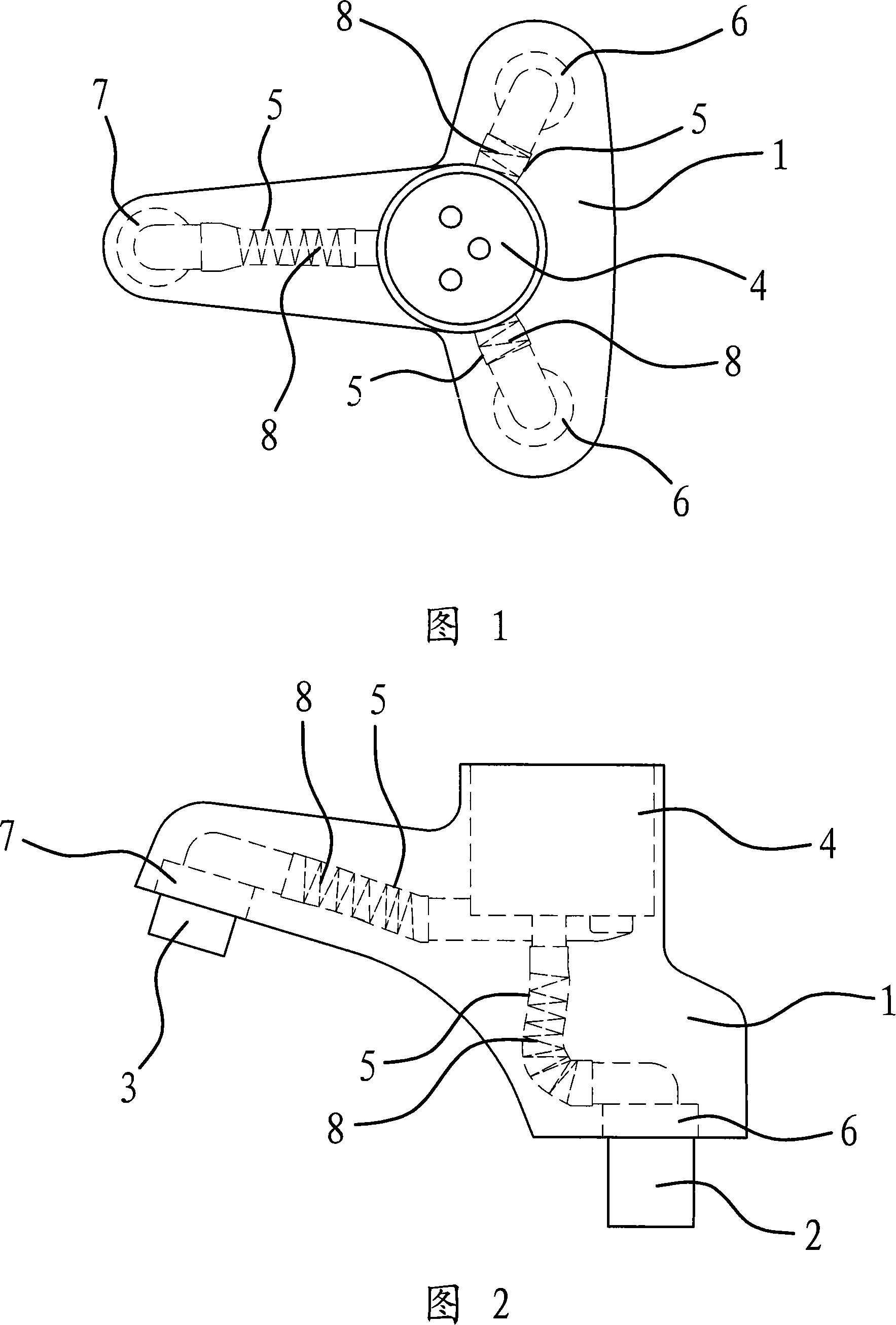

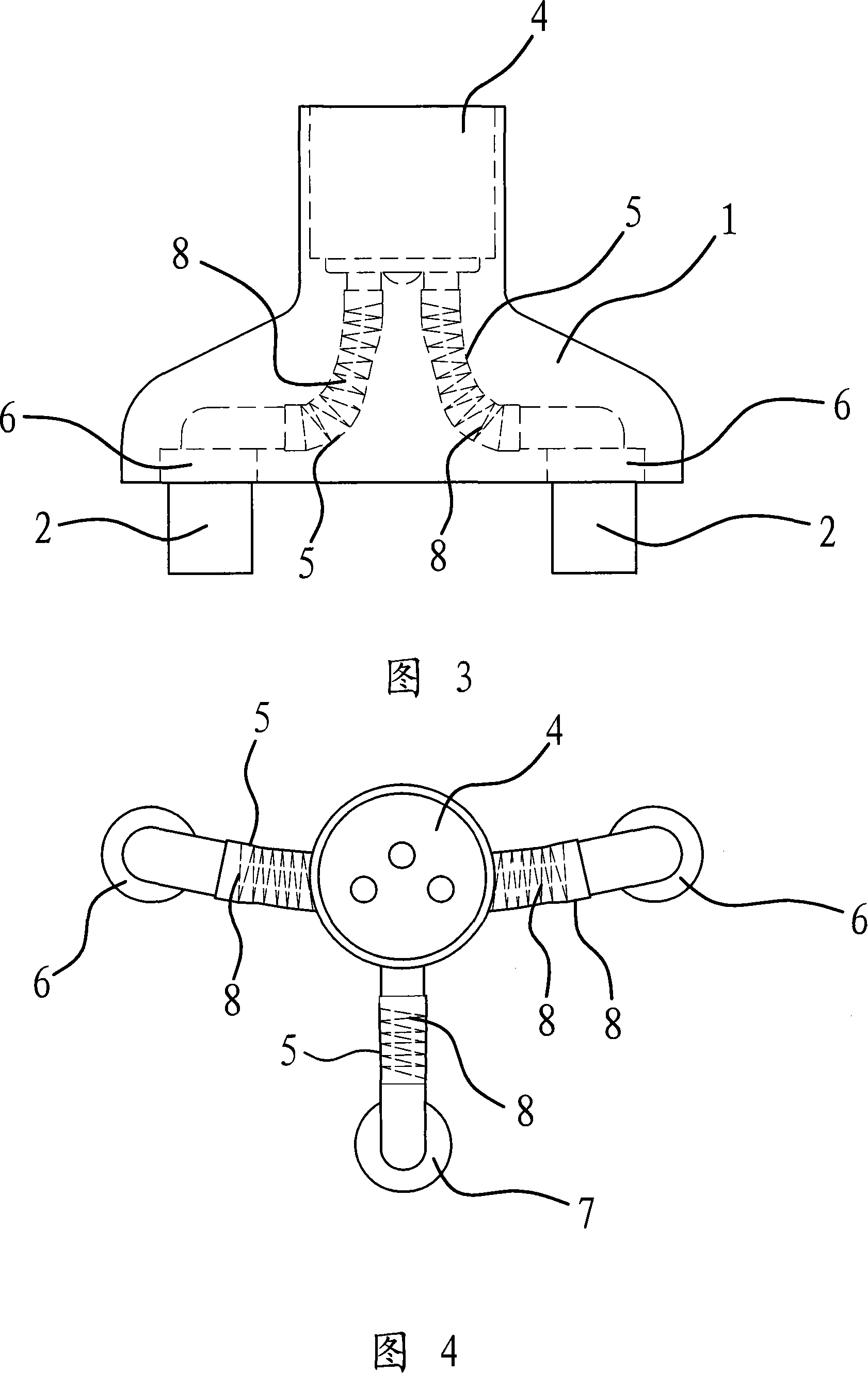

Scale-type schoolbag belt

Owner:SUZHOU INST OF TRADE & COMMERCE

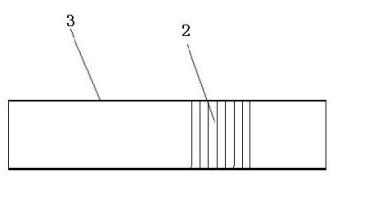

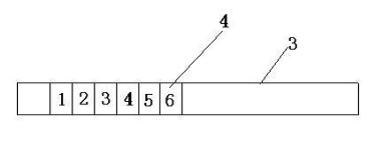

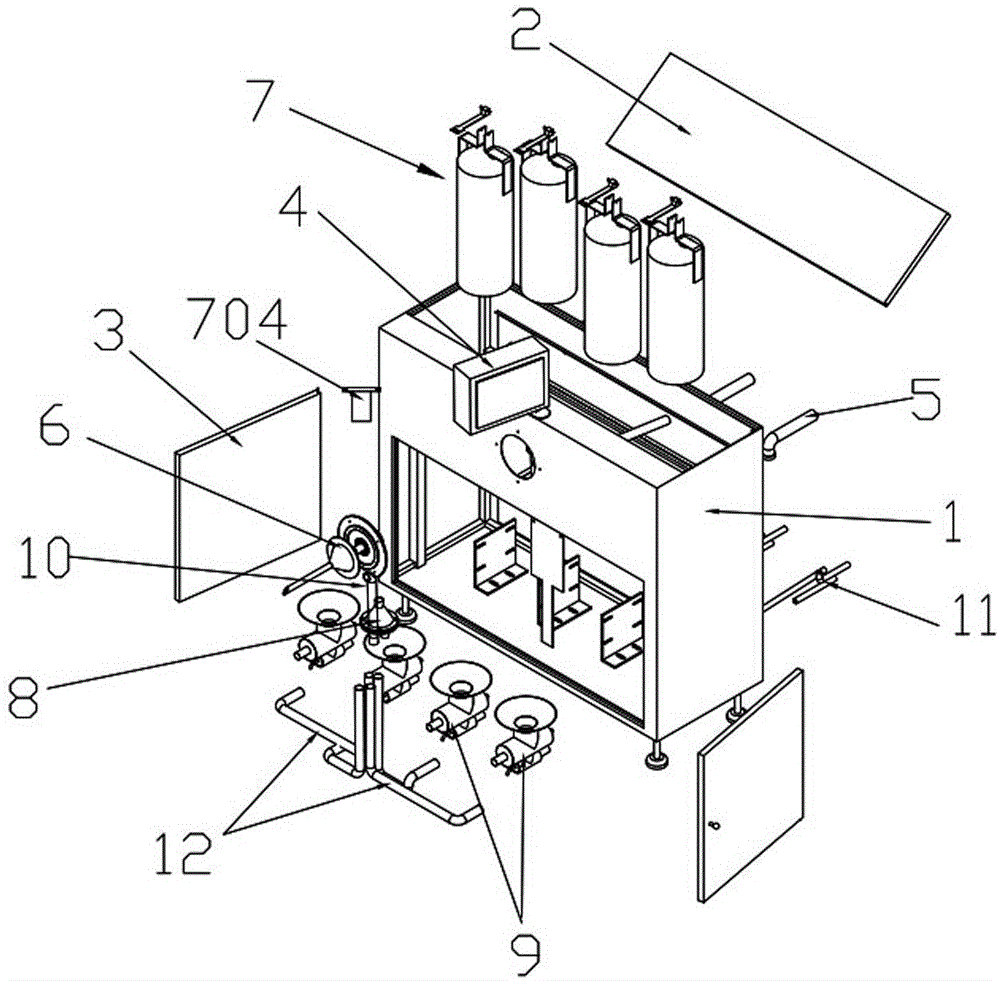

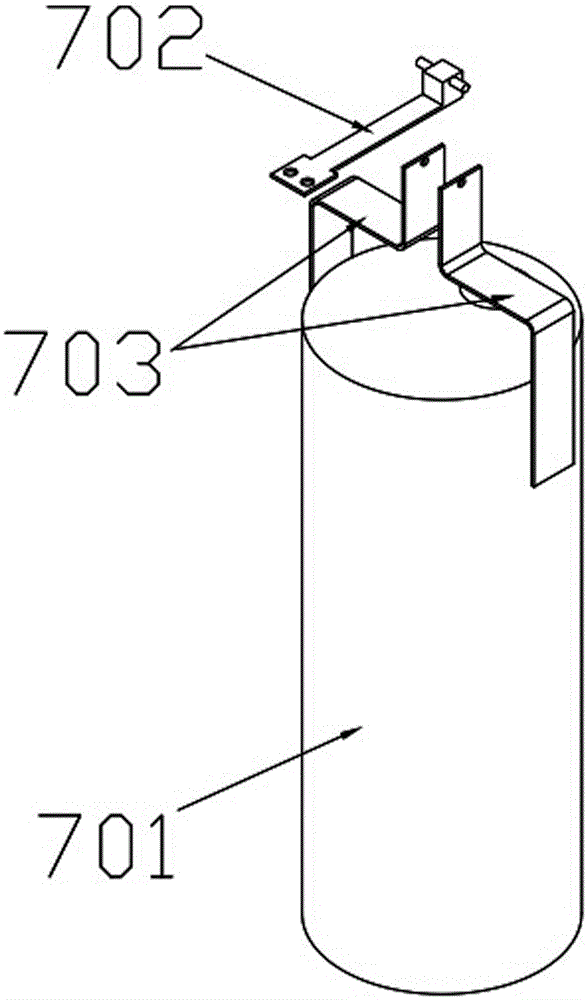

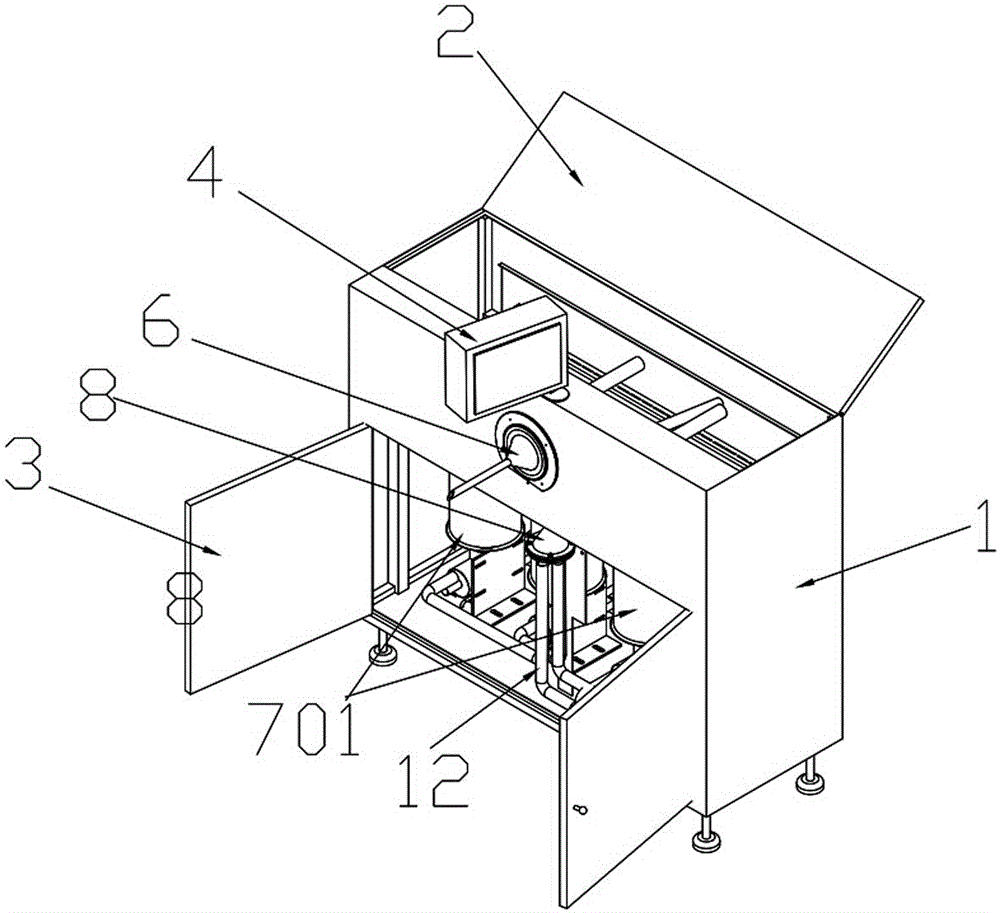

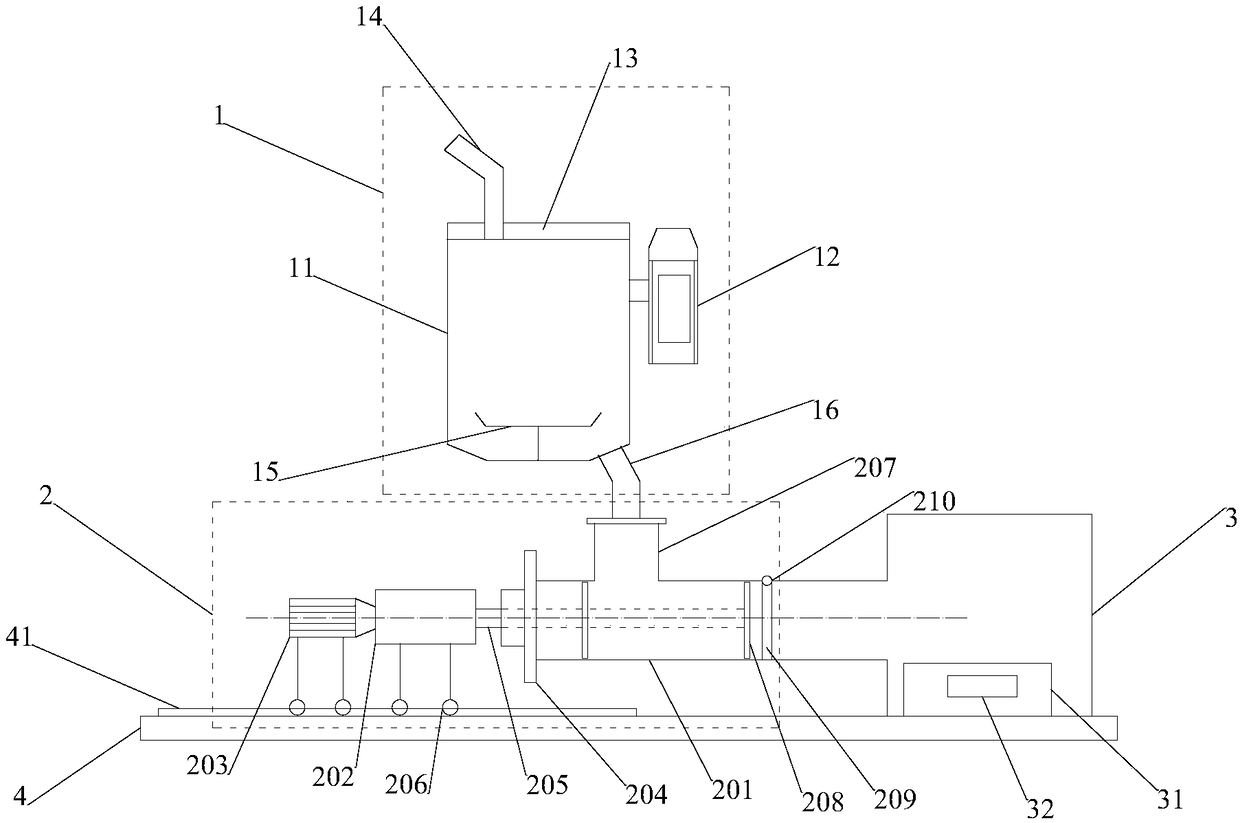

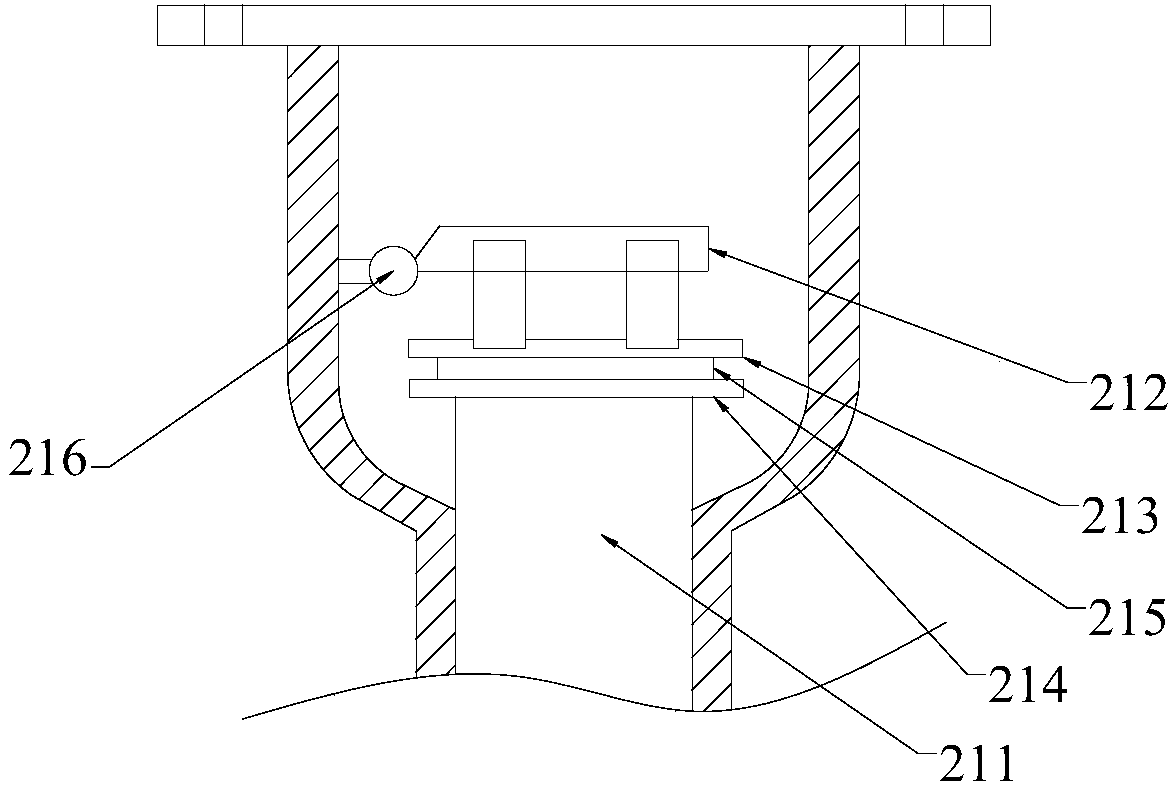

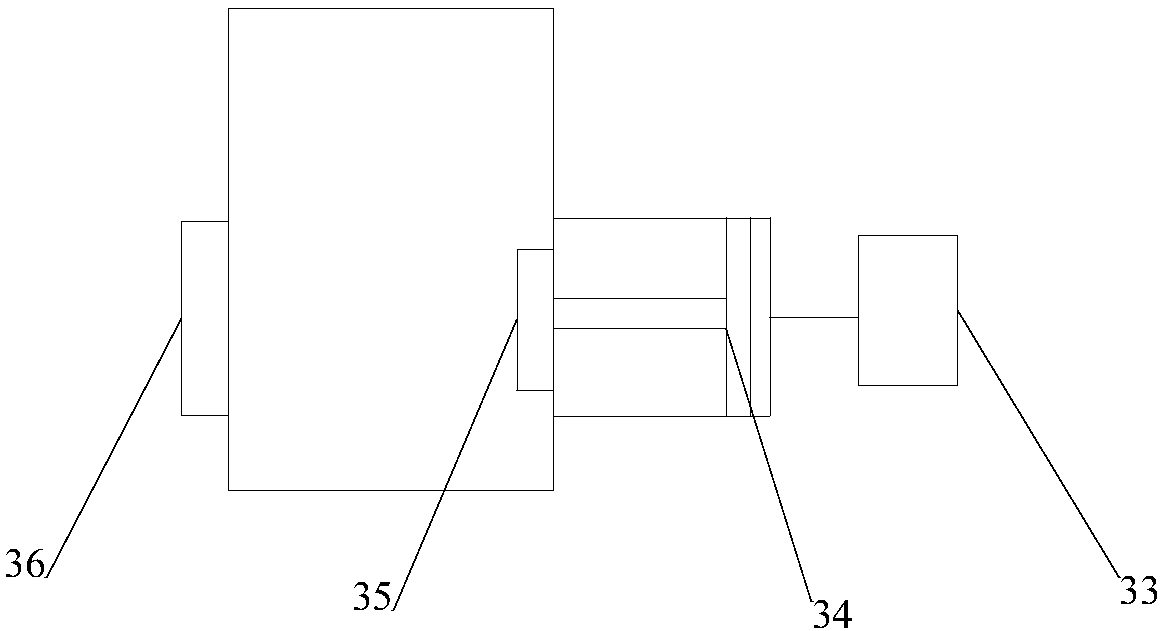

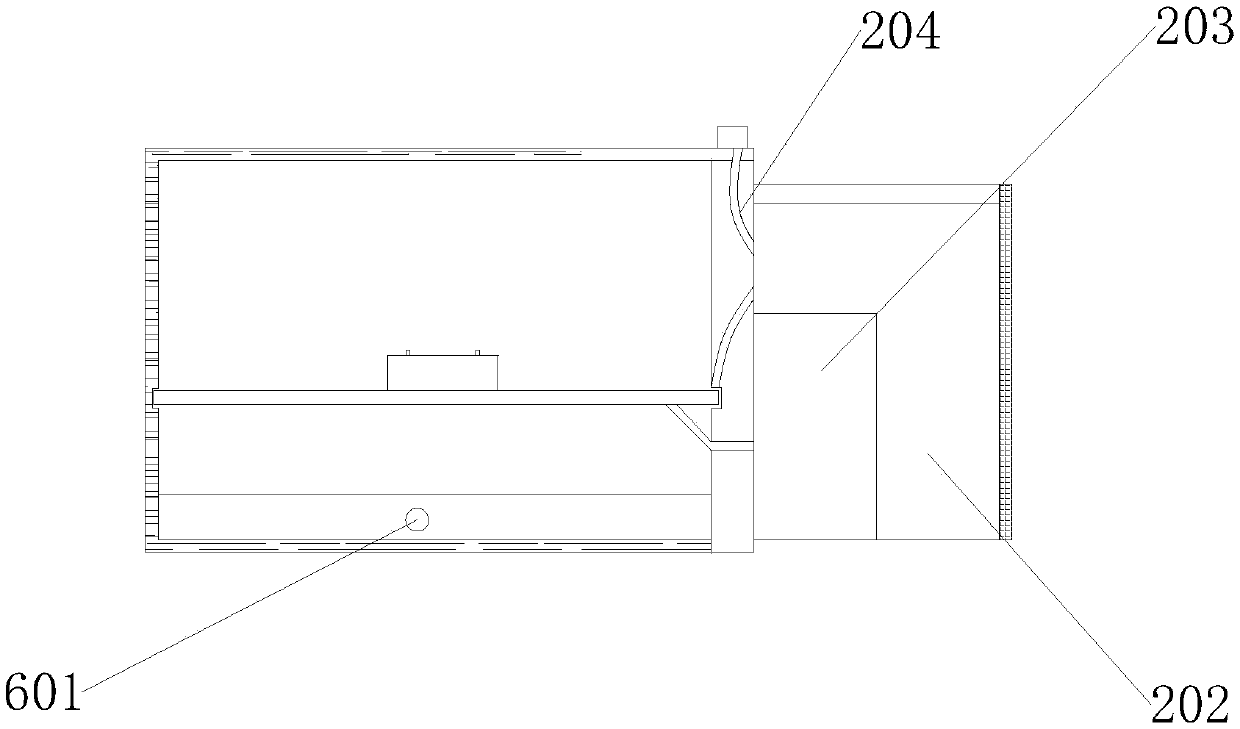

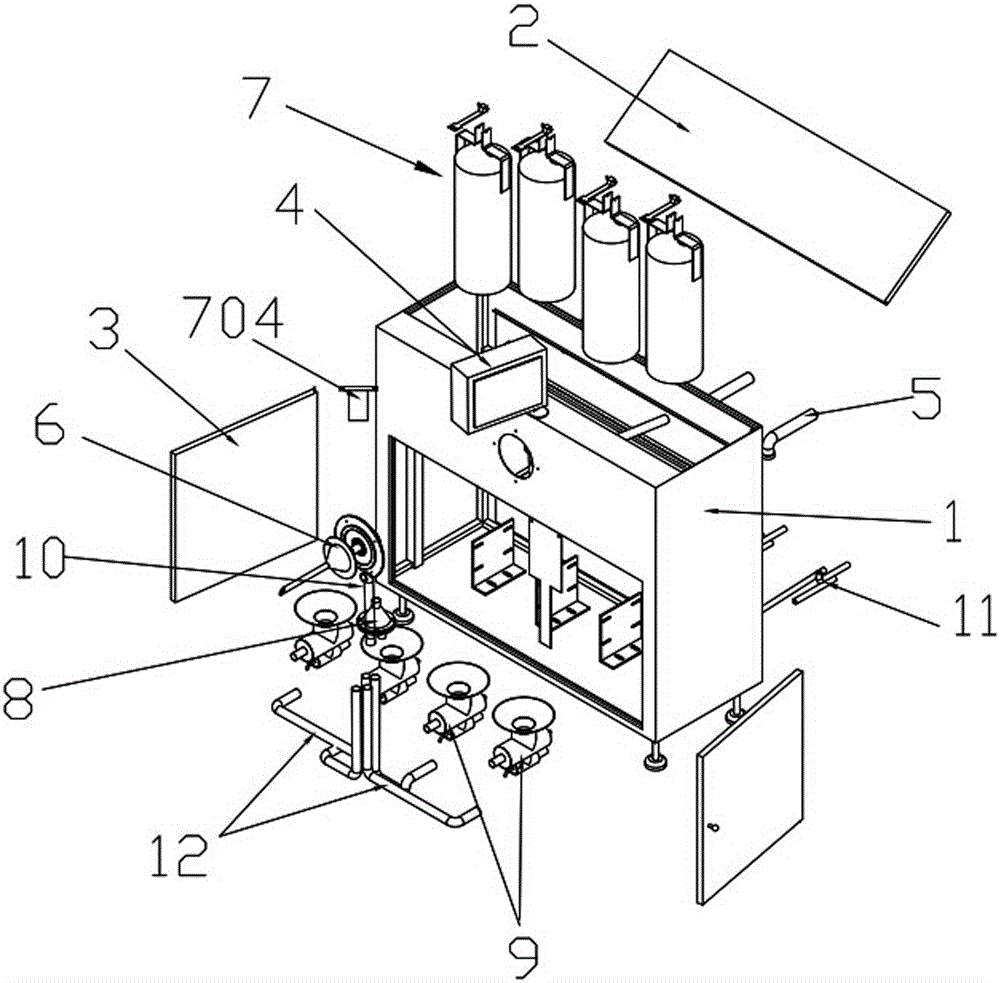

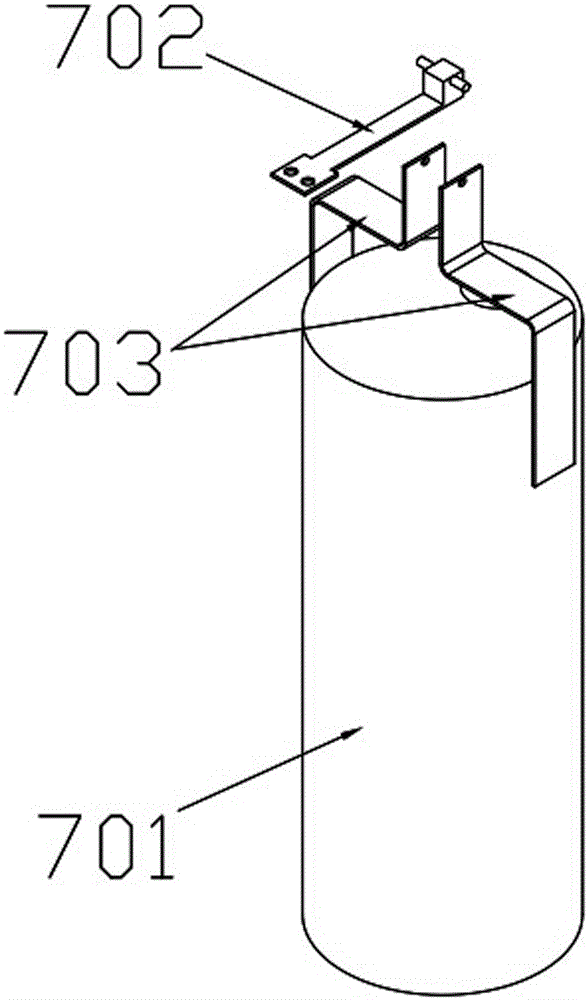

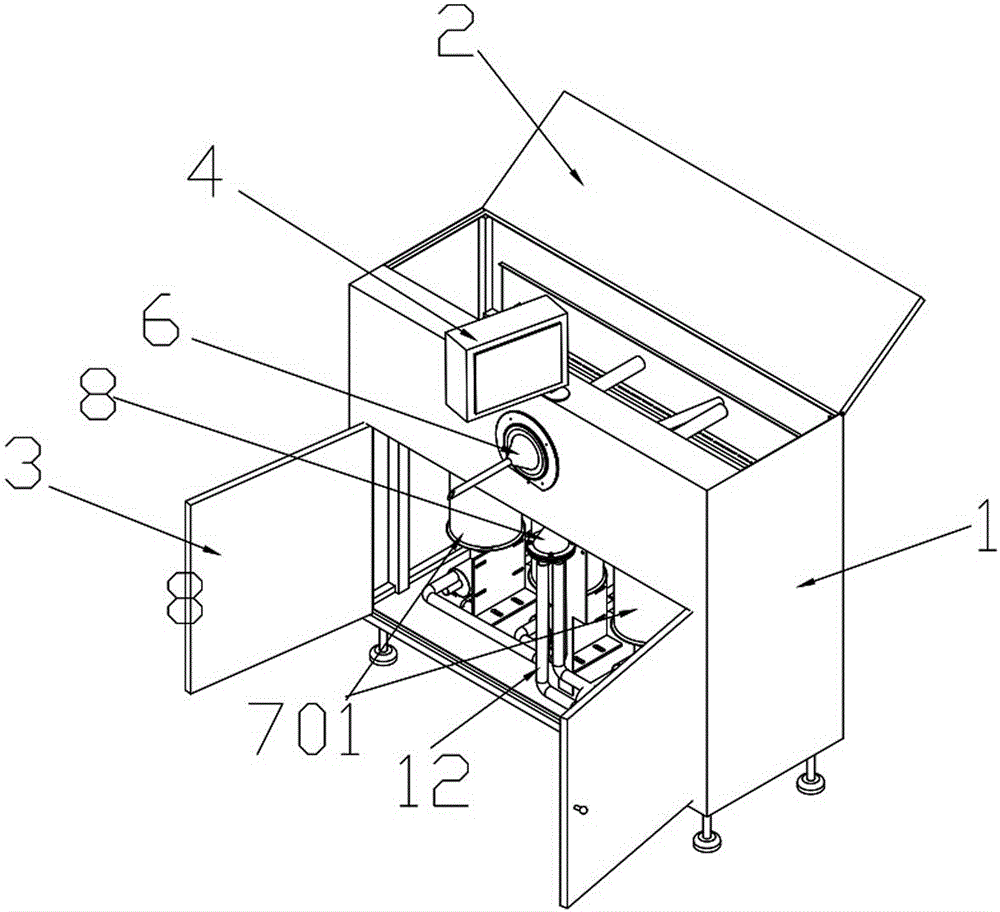

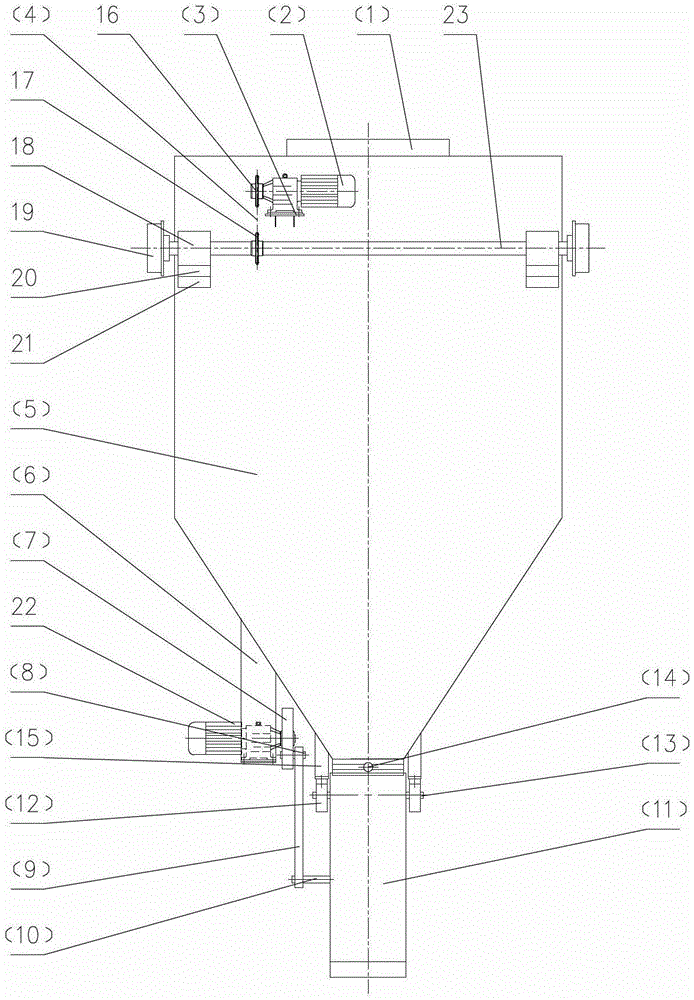

Automatic down filling machine down filling system by means of weighing mode

InactiveCN105110285AThe overall structure is simpleLow costUpholstery manufactureWeighing apparatus for materials with special property/formMechanical engineeringShunting

The invention relates to an automatic down filling machine down filling system by means of a weighing mode, and belongs to the field of down filling equipment. The down filling system comprises a machine box and an automatic down filling mechanism arranged in the machine box, and the automatic down filling mechanism comprises automatic weighing devices, multi-channel jointing devices and multi-channel shunting devices; each automatic weighing device is composed of a weighing box and weighing sensors, all the weighing sensors are jointly connected with a weighing transmitter used for controlling the weighing quantity, each multi-channel jointing device comprises a shunting entrance and a jointing exit, and the number of the multi-channel shunting devices is matched with that of the automatic weighing devices. The automatic weighing devices, the multi-channel shunting devices and the multi-channel jointing devices are additionally arranged, weighing is firstly performed through the automatic weighing mode, then material feeding and down filling are performed through the multi-channel shunting devices and the multi-channel jointing devices respectively, the weighing boxes are designed to be of a suspension type structure, the weighing sensors are arranged on the tops of the weighing boxes, therefore, an the automatic weighing process is not subjected to any influences, and it is guaranteed that the down filling precision is high enough, down filling error is very little and the down filling stability is high.

Owner:周业照

Powder preparing device

InactiveCN108263690AEasy to packEasy maintenanceSolid materialCompression deviceBiomedical engineering

The invention provides a powder preparing device. The powder preparing device comprises a powder stirring device, a compression device, a weighing device and a base. The compression device and the weighing device are fixedly arranged on the base. The compression device and the weighing device are movably connected. Through a discharging port, the powder stirring device is connected with a feedingvalve and the compression device. The powder preparing device has the beneficial effects that the powder size is compressed, packaging is convenient, the weight of packaged powder bags is equivalent,and the error is small.

Owner:TIANJIN LONGHUA CHENGXIN POWDER TECH

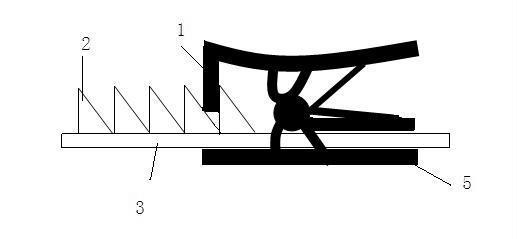

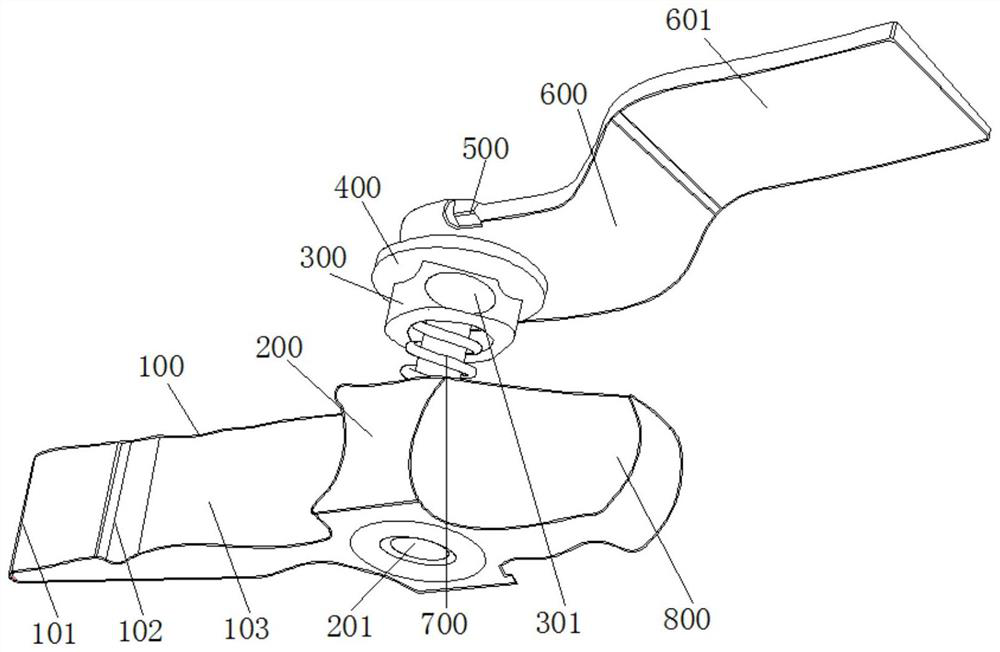

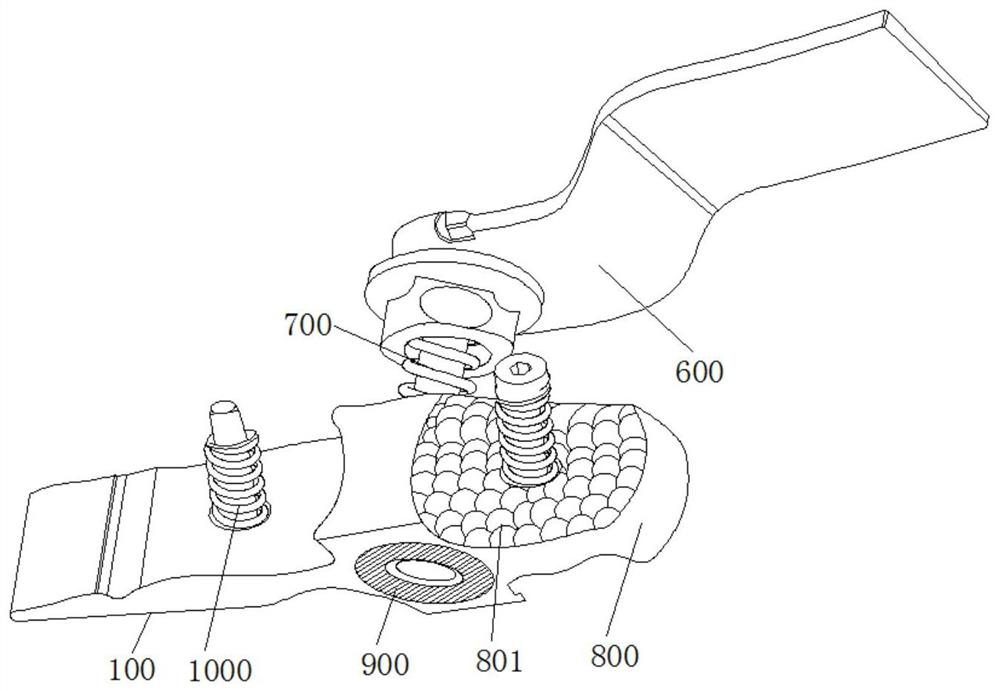

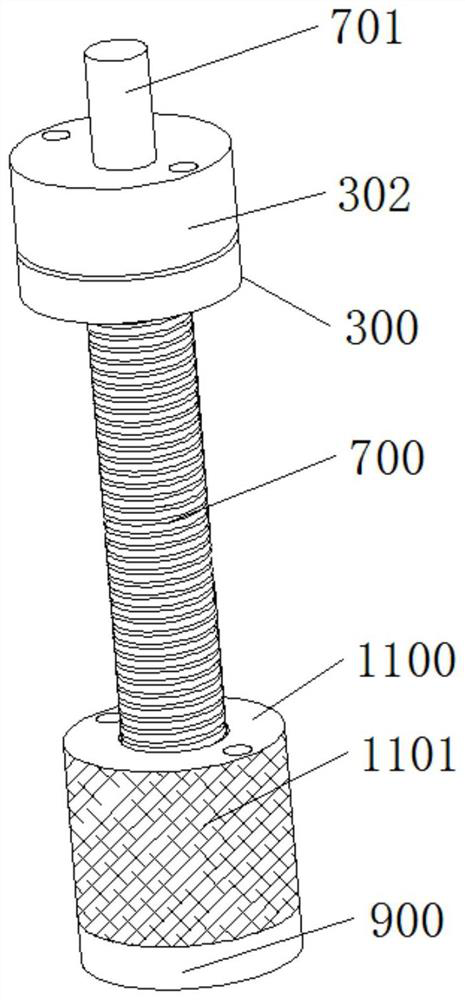

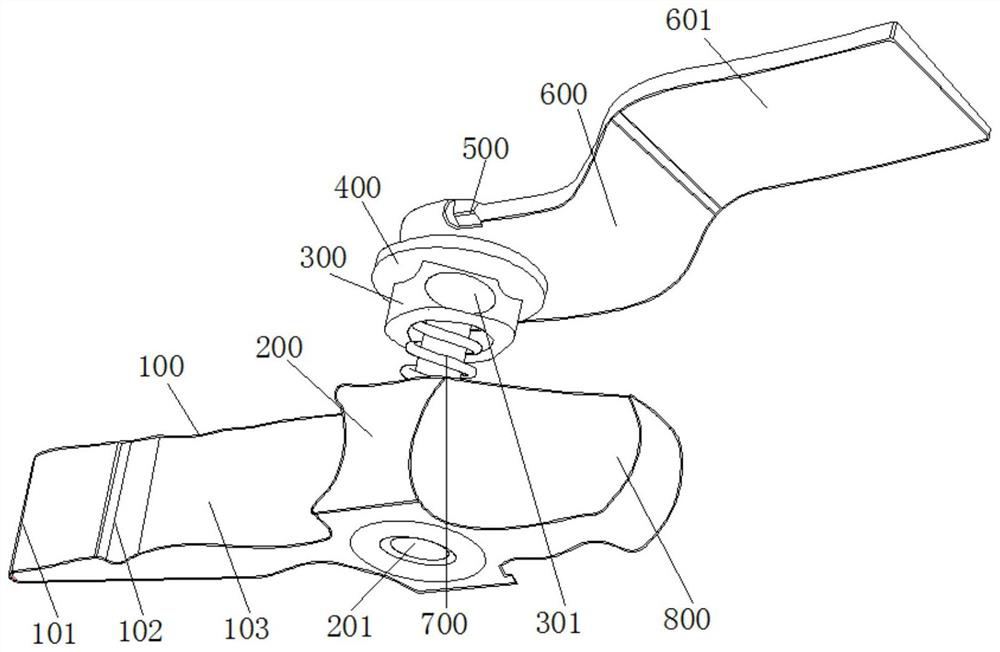

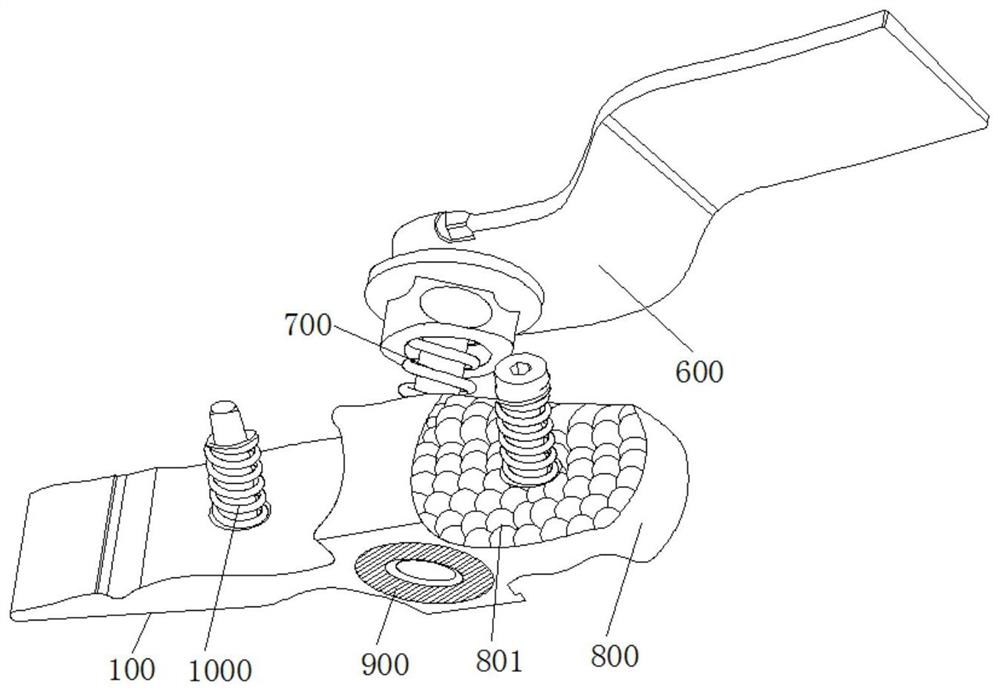

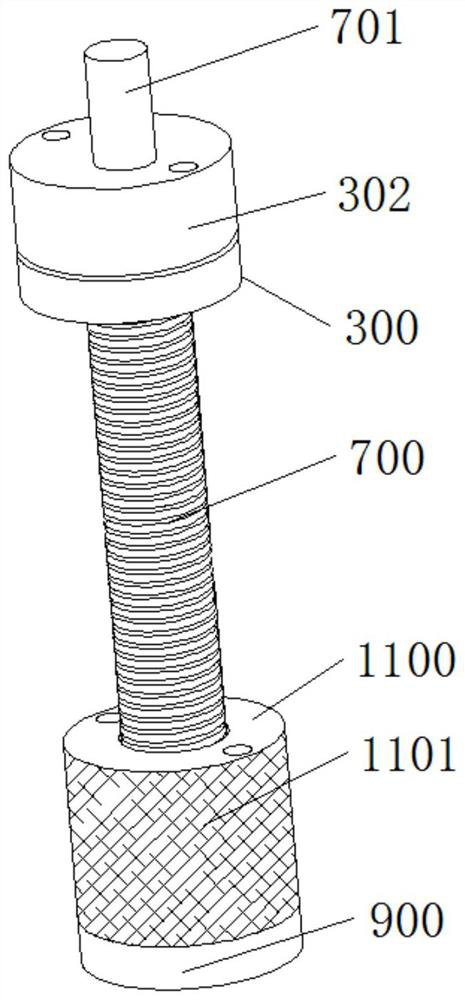

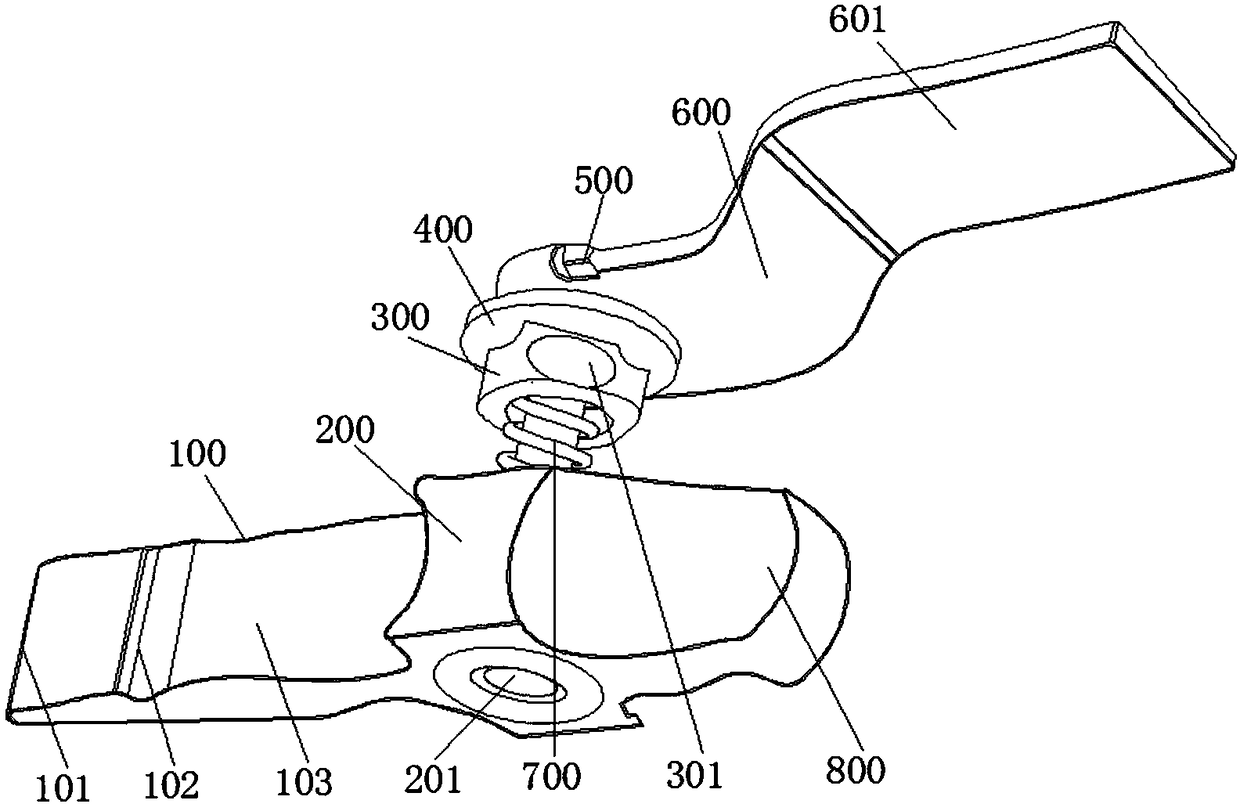

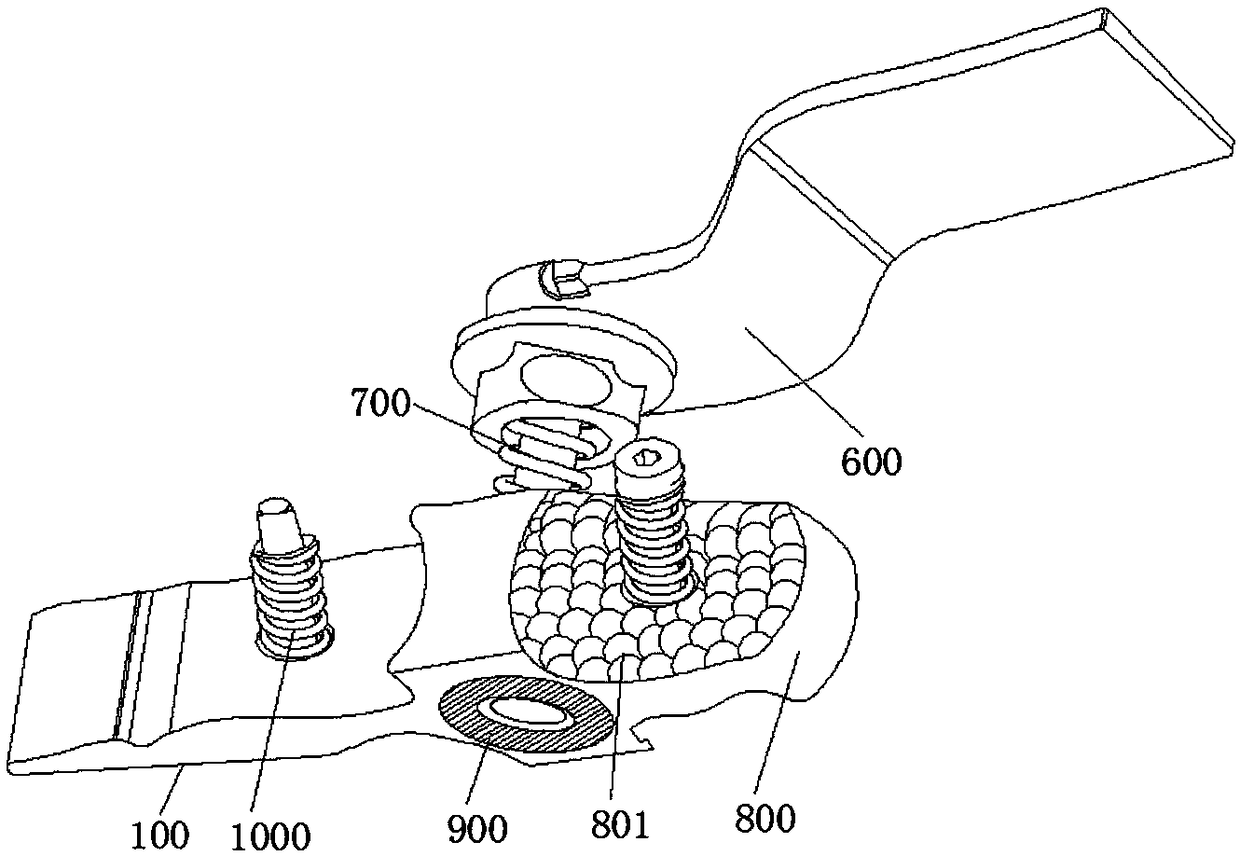

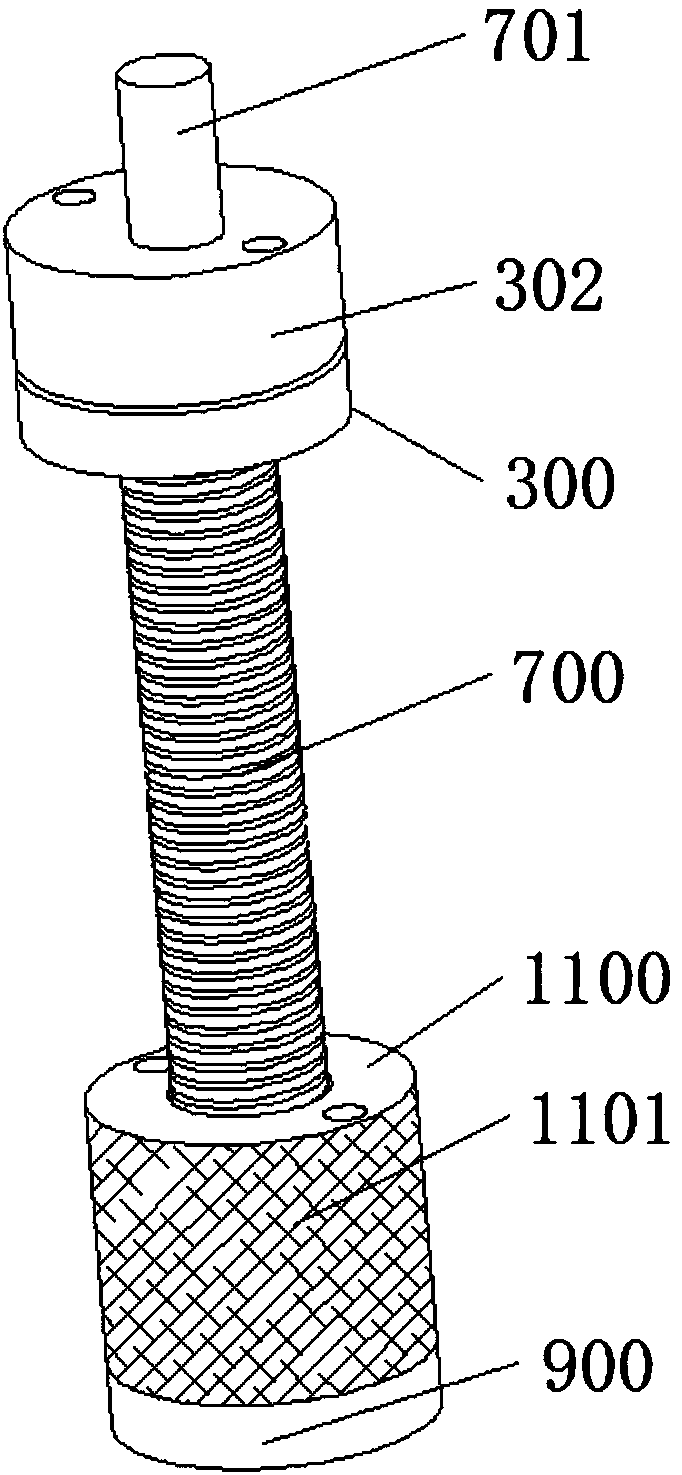

Dust-proof conductive touch body for precise conductive contact mechanism

ActiveCN108447464BEqual weightGood playing feelElectrophonic musical instrumentsMusicPianoDust control

The dust-proof conductive touch body for the precise conductive contact mechanism includes a dust-proof handle, through which the dust infiltrated under the hammer is covered and blocked in a large area, which solves the weight error caused by the difference in the construction of the keys, resulting in The learner’s playing tactility is wrong, and the dust falls to the bottom and gradually accumulates during long-term use, resulting in fluctuations in the touch reflection time. The problem of scrapping the piano is that after the dust enters the bottom of the keys, the dust-proof handle at the bottom of the keys blocks and closes the dust. Through the vibration of the keys, the scale-like dust-removing sheet on the dust-removing table is lifted. The dust is vibrated out, so that the dust does not accumulate inside, and the rebound speed is fast. The conductive screw can enhance the spring speed of the guide core, greatly speeding up the sounding time of the piano and improving the playing efficiency.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Nuclear power plant drum screen support structure

ActiveCN110404313BPlay a protective effectEnsure safetyStationary filtering element filtersNuclear plantIndustrial engineering

The invention discloses a support structure for a drum-shaped filter screen in a nuclear power plant, which comprises a main shaft, a main shaft bearing seat, a backing plate for the bearing seat, a drum net protection device, a wheel hub and spokes, the main shaft is installed in the main shaft bearing seat, and the wheel hub is installed on the main shaft , the spokes are connected to the hub; the drum net protection device includes a protective pressing block and a protective tie rod; the bearing base plate is fixed on the concrete floor, the main shaft bearing seat is connected under the protective pressing block, and the protective pressing block is connected to the bearing seat through the protective pulling rod Backing plate; the breaking load of the protective tie rod enables it to be broken before the drum net is damaged, ensuring the safety of the drum net. In the present invention, a drum net protection device is arranged on the main shaft bearing seat, and when the drum net is subjected to a relatively large buoyancy force, the protection rod is pulled off to protect the drum net. The hub adopts forging structure, and the spokes adopt H-shaped steel structure.

Owner:中广核工程有限公司 +3

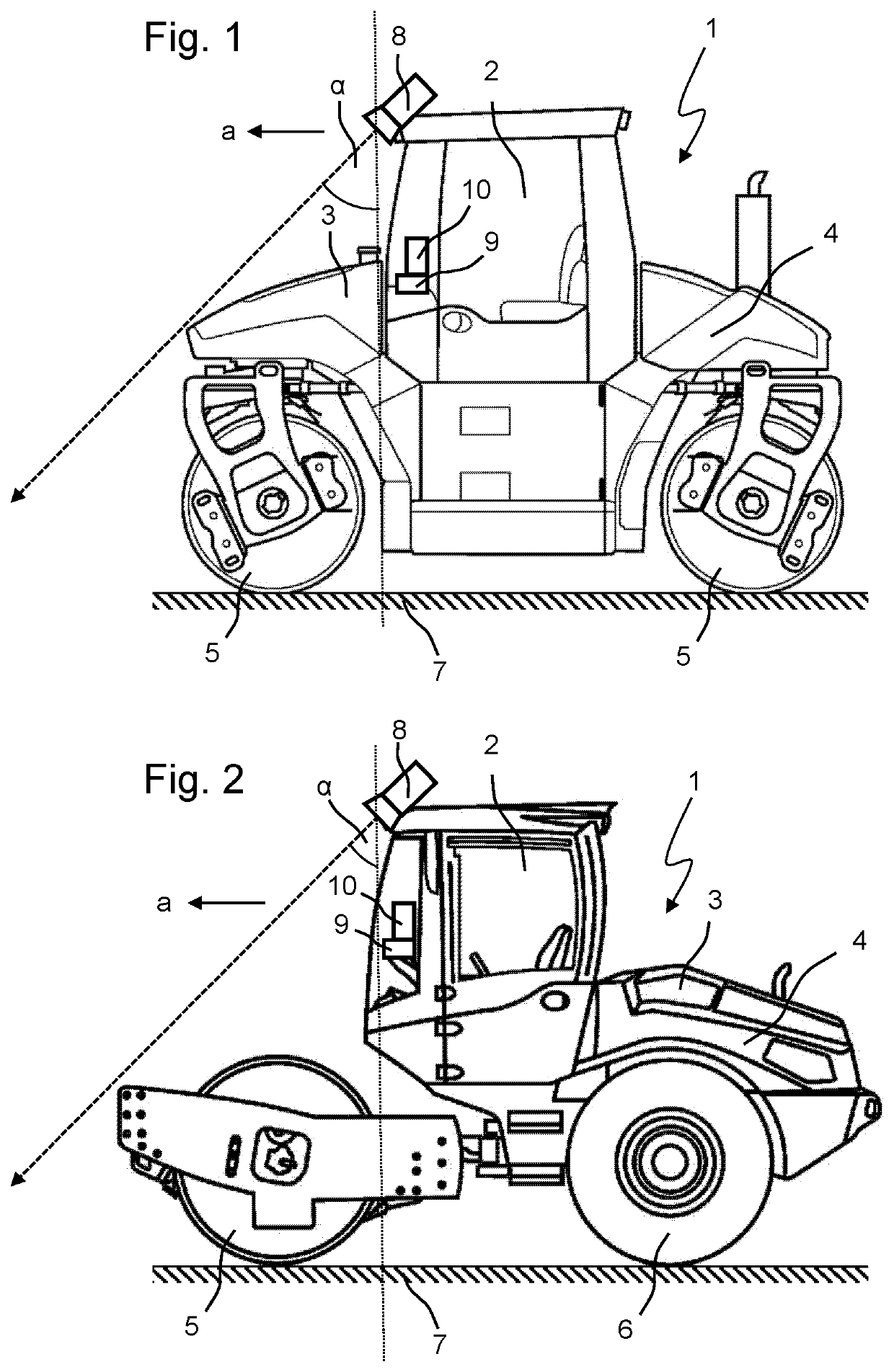

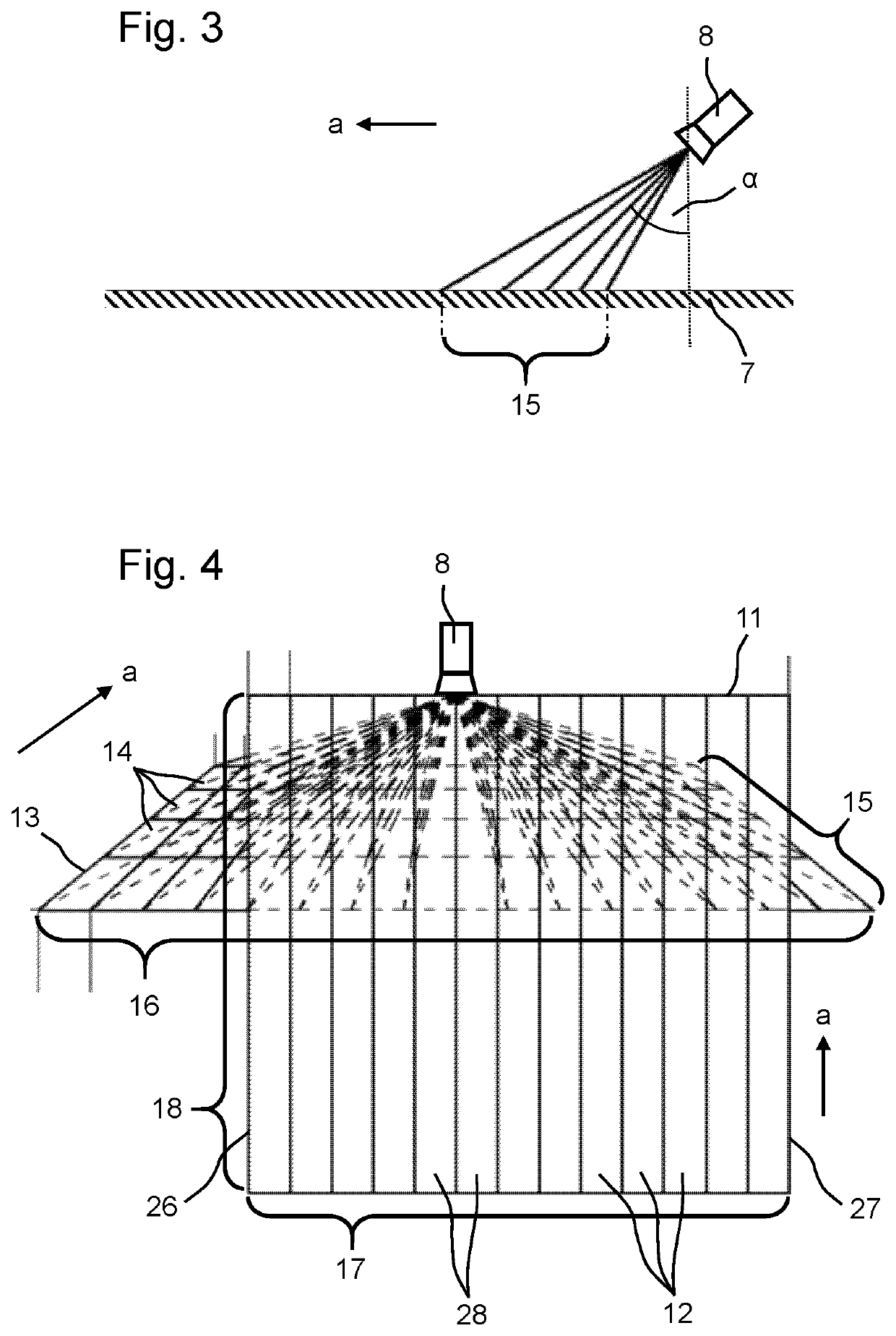

Method for monitoring compaction process in road construction and road roller

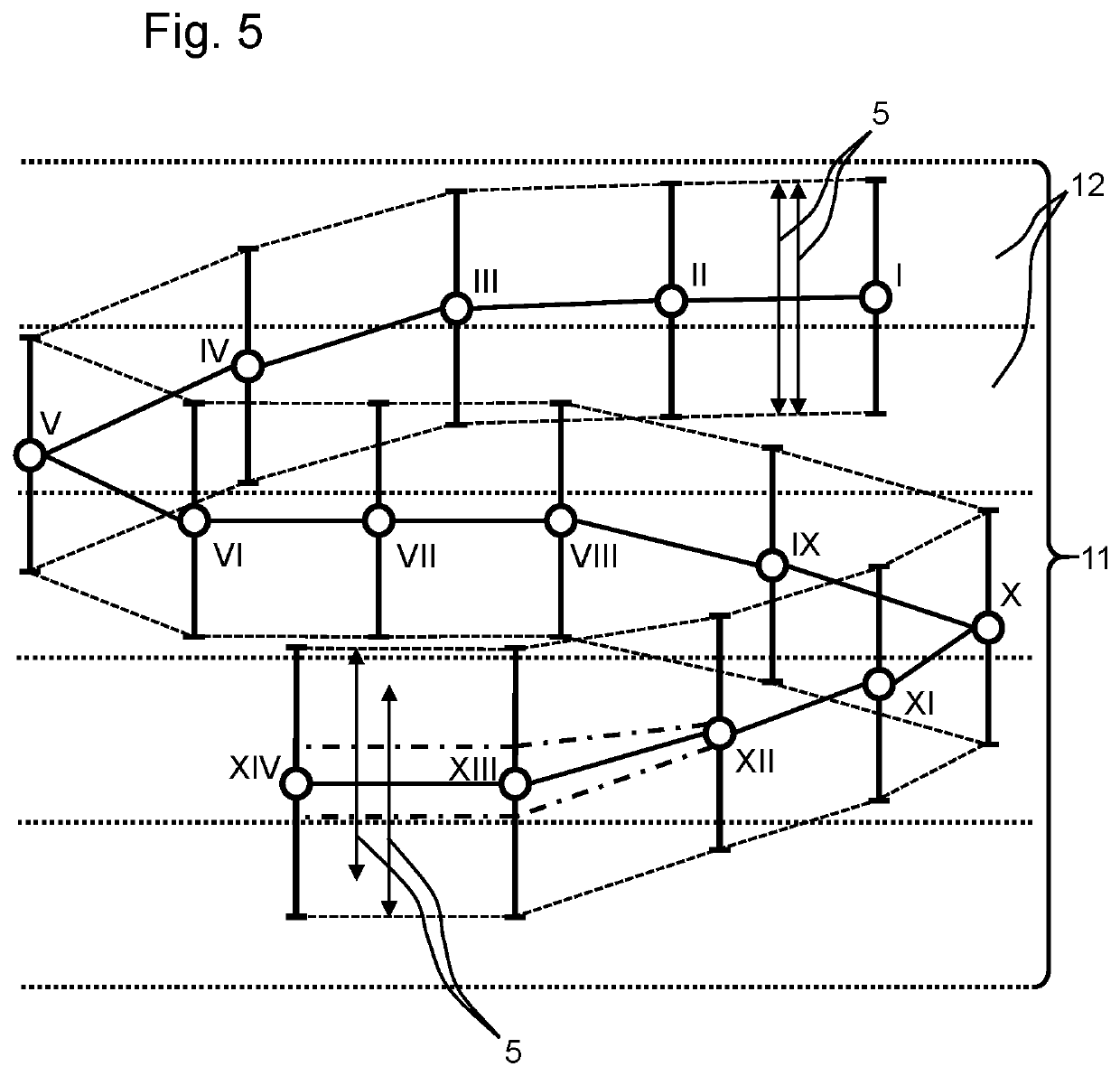

ActiveUS10676879B2Sure easyHigh resolutionRoads maintainenceArchitectural engineeringStructural engineering

A method for monitoring the compaction process of an asphalt layer to be compacted in road construction is provided comprising the steps: detecting the edges limiting the hot asphalt layer transversely to the road pathway by means of a temperature sensor arranged on a road roller compacting the asphalt layer, and dividing the detected asphalt layer into at least two width segments across the road pathway, wherein the position of the road roller on the asphalt layer transversely to the road pathway is determined from the measurement of the temperature sensor and is assigned to one of the width segments, the working operation of the road roller on the width segment is quantified via an operating parameter and stored, and the quantified working operation for each width segment is displayed to the operator for at least one past working interval. A road roller for carrying out the method is also provided.

Owner:BOMAG

Dust-proof conductive touch body

The dust-proof conductive touch body includes a dust-proof handle, through which the dust infiltrated under the hammer is covered and blocked in a large area, which solves the weight error caused by the difference in the construction of the keys, which causes the learner's playing touch to appear Mistakes, as well as dust falling to the bottom and gradually accumulating during long-term use, resulting in fluctuations in the touch reflection time. The piano has always been poorly protected against dust on the touch body, and the internal dust cannot be dealt with, leading to the scrapping of the piano. After the dust enters the bottom of the keys, the dust-proof handle at the bottom of the keys blocks and closes the dust. Through the vibration of the keys, the scale-like dust removal sheet on the dust removal table is lifted, and the dust is vibrated out through multiple rapid vibrations to prevent dust from accumulating. Internally, the rebound speed is fast, and the conduction screw can enhance the bounce speed of the guide core, greatly speeding up the sounding time of the piano and improving the playing efficiency.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

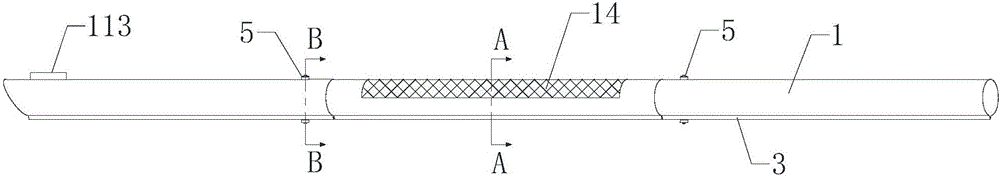

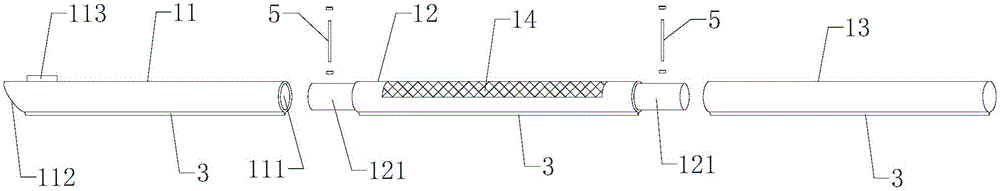

Bamboo canoe drifting sport apparatus

InactiveCN105080104AThickness is easy to controlUniform thicknessSport apparatusSports equipmentVolumetric Mass Density

The invention provides a bamboo canoe drifting sport apparatus. The bamboo canoe drifting sport apparatus comprises a rod part and a filling core, wherein an accommodating cavity is formed in the rod part and filled with the filling core; the filling core adopts a light material, and the density of the light material is smaller than that of water; a water parting line is formed on the outer side surface of the rod part; a weight adding area is arranged on the inner side surface of the rod part and corresponds to the water parting line. According to the bamboo canoe drifting sport apparatus, the thicknesses of all parts of the rod part are controllable, the outer diameters of all part are uniform, the weight is equal, the buoyancy force is balanced, the linetype is smooth, and standardizing set of a game apparatus is facilitated; the water parting line is formed on the outer side surface of the rod part, the weight adding area is arranged on the inner side surface of the rod part and corresponds to the water parting line, the weight of the rod part at the water parting line is increased by the aid of the weight adding area, the water parting line is downwards, and the stability of the rod part on the water surface is enhanced by the aid of the water parting line.

Owner:HANGZHOU FUYANG XIANGRUI WATERBORNE SPORTS EQUIP CO LTD

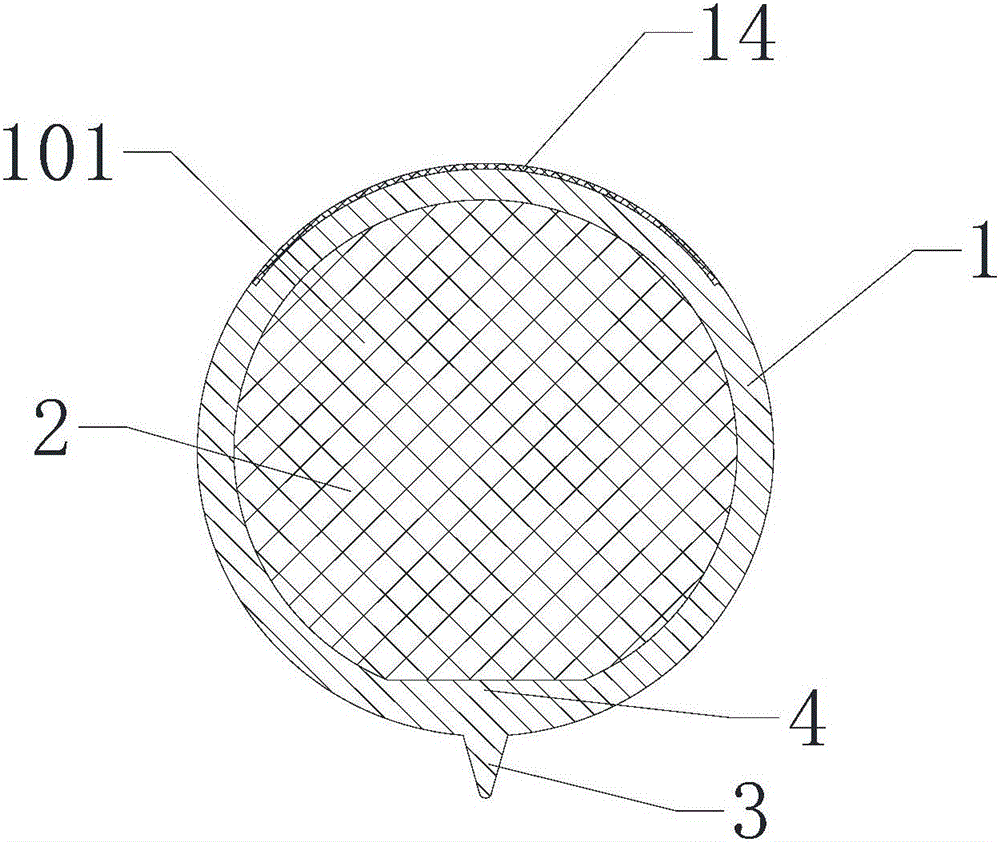

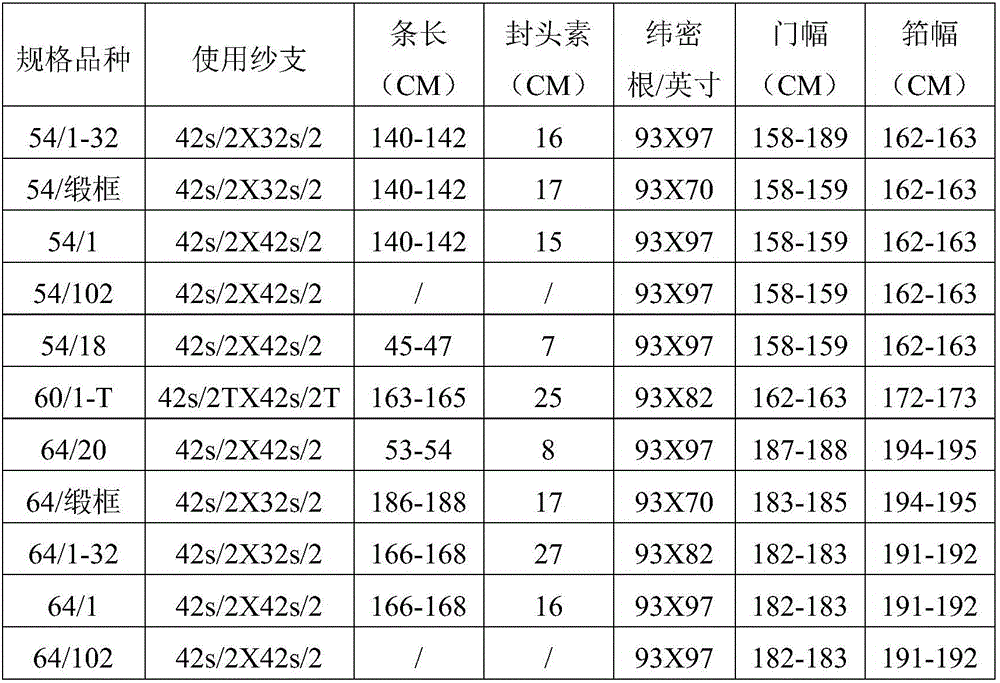

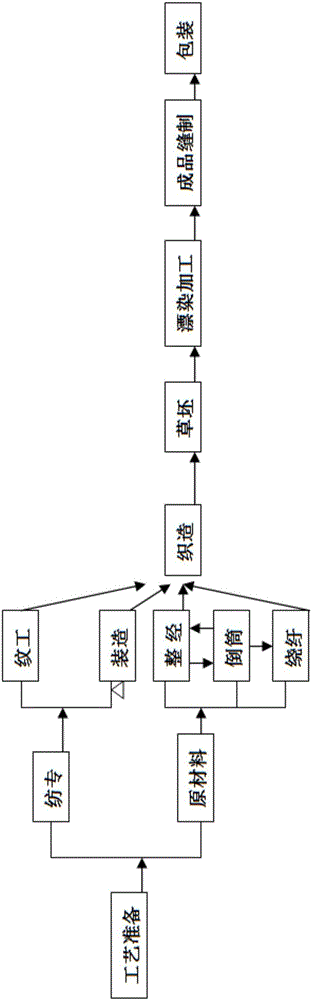

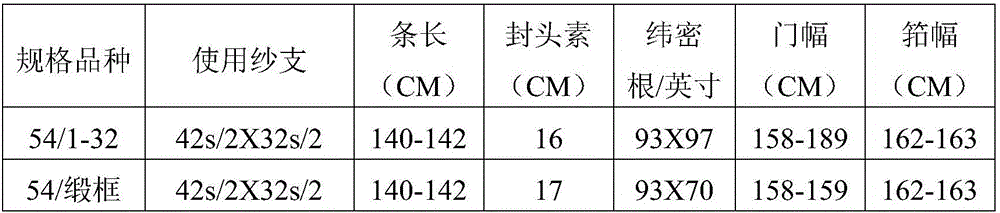

Textile method for jacquard table cloth

InactiveCN106757638AImprove production and maintenance efficiencyImprove product qualityJacquardsWarping machinesDyeingEngineering

The invention discloses a textile method for a jacquard table cloth, and belongs to the field of textiles. The textile method for the jacquard table cloth is used for solving the problems that in the prior art, the production and maintenance efficiency, the product quality and the precision are low. The spinning method for the jacquard table cloth comprises the following steps that 1 process preparation before spinning is conducted, wherein process preparation comprises the steps of textile machine preparation and raw material preparation, textile machine preparation comprises the steps of pattern work preparation and textile machine installation, and raw material preparation comprises the steps of warping, rewinding and quill winding preparation; 2, prepared raw materials are woven on the textile machine; 3, a grey jacquard cloth is obtained; 4, bleaching and dyeing processing is conducted on the grey jacquard cloth, and the needed color is obtained according to the demand; 5, finished product sewing is conducted on the grey jacquard cloth obtained after bleaching and dyeing, and the needed finished product is obtained; 7, the finished product is packaged. The textile method can achieve the advantages of high production and maintenance efficiency, high product quality and high precision.

Owner:MAANSHAN JINZI TEXTILE OMAMENT

Pressing device for floors

InactiveCN105171889AEase of Controlling EmissionsImprove work efficiencyWood working apparatusFlat articlesEngineeringMaterial supply

The invention relates to a pressing device for floors. The pressing device comprises a vibration unloader and a hot-pressing forming machine. The vibration unloader comprises a material box for storing raw materials, a material weighing funnel and a loading platform. The material weighing funnel is installed on an outlet of the material box. The loading platform is arranged under the material weighing funnel. The loading platform is provided with movable transfer material feedback discs. Each transfer material feedback disc is provided with a first station and a second station. Each first station is located on the loading platform under the material weighing funnel. Each second station is located on a material supply opening of the hot-pressing forming machine. The two transfer material feedback discs are arranged up and down. The floors can be prepared through raw materials such as straw, and therefore timber resources are saved.

Owner:CHINA NAT DECORATION

A kind of production technology of pentaprism

The invention discloses a pentaprism production process which solves the problem that a pentaprism does not meet requirements as an existing machining process is complicated and softening temperature is improperly controlled. The pentaprism production process includes the steps: (1) cutting raw materials into small glass blanks by a cutting machine; (2) grinding corners of the glass blanks; (3) coating boron nitride powder on the surfaces of the glass blanks; (4) feeding the coated glass blanks into a softening furnace for softening; (5) profiling the softened glass blanks in a profiling mould to form an initial product; (6) annealing the initial product. The annealing temperature is 10-20 DEG C lower than a glass softening point. The cutting machine is used for cutting the raw materials, the same sizes and weights of the glass blanks are effectively ensured, so that division and rolling procedures are decreased, manpower cost is greatly saved, and machining time is shortened.

Owner:成都恒达光学有限公司

Spinning method of spinning machine

InactiveCN106835421AImprove production and maintenance efficiencyImprove product qualityJacquardsWarping machinesState of artRaw material

The invention discloses a weaving method for a weaving machine, which belongs to the field of weaving. Aiming at the problems of low production and maintenance efficiency, low product quality and insufficient precision existing in the prior art, the present invention provides a jacquard tablecloth weaving method, 1) the textile machine needs to be disassembled and prepared, and the required work The disassembly and assembly of the textile machine includes the following steps: A, dismantling: remove the original loom parts, retain the wall panels and frame, disassemble the loom parts in turn, and repair the worn shafts after disassembly; B, loading: Install the loom components that need to be installed on the frame in turn; C. Calibration: Correct each component after installation to ensure that it is installed at the required position; D. Test run: Conduct a test run of the newly installed loom. 2) Textile machine preparation: Texture preparation and textile machine assembly; 3) Raw material preparation: Warping, rewinding and winding preparation. It can achieve the effects of high production and maintenance efficiency, high product quality and high precision.

Owner:MAANSHAN JINZI TEXTILE OMAMENT

A restaurant-oriented robot mobile platform

ActiveCN112171689BMeet installation needsEasy loadingProgramme-controlled manipulatorRobotic armReduction drive

The invention discloses a restaurant-oriented robot mobile platform, comprising a mobile platform, a chassis, a vehicle cover, first to fourth synchronous pulleys, first to fourth couplings, first to fourth solid load-bearing rubber wheels, And the first to fourth permanent magnet servo motors, the first to fourth reducers, the first to fourth vertical bearings with seats and counterweights fixed on the chassis; and the permanent magnet servo motor drivers fixed inside, Manipulator driver and industrial computer, first to second ultrasonic sensors, first to second infrared sensors fixed on the platform, long manipulator, short manipulator and support frame fixed on the car cover; fixed on the manipulator The torque sensor is fixed on the support frame for the first to second RGB‑D depth cameras. The robot mobile platform provided by the present invention has flexible control, large working range, and functions of walking, grasping, and cooking, and can quickly complete the work of ordering and picking dishes, thereby reducing the burden on canteen staff.

Owner:HANGZHOU DIANZI UNIV

Anti-mildew tea leaf filling device

InactiveCN107826364APrevent mildewWith low temperature processing environmentSolid materialMildewMobile station

The invention discloses a mildew-proof tea filling equipment, which comprises a filling machine body and an electric equipment box, the front of the filling machine body is provided with an electric equipment box, and the electric equipment box is fixed in the filling machine body by screws , there is a rotating shaft on the upper left of the filling mechanical body, and the rotating shaft is embedded in the filling mechanical body, an electronic scale is installed on the left side of the rotating shaft, and the electronic scale is welded in the rotating shaft, and a filling machine is installed above the filling mechanical body. The filling funnel is embedded in the filling machine body. This kind of anti-mildew tea filling equipment has a low-temperature processing environment and its own dehumidification function. In addition, it is automatic filling during filling. The cooling of the cooler can provide a low-temperature environment for the tea, and the drying room is dehumidified for the filling machinery. It can prevent the tea leaves from being attached to moisture during the filling process, resulting in tea mildew after filling, and the braking equipment will vibrate when it is running. The braking equipment and the mobile placement table are close to each other, driving the mobile placement table to vibrate.

Owner:WUXI KING MO MACHINERY

Automatic Down Filling System of Down Filling Machine Using Weighing Mode

InactiveCN105110285BHigh precisionReduce mistakesUpholstery manufactureWeighing apparatus for materials with special property/formEngineeringLoad cell

The invention relates to an automatic down filling machine down filling system by means of a weighing mode, and belongs to the field of down filling equipment. The down filling system comprises a machine box and an automatic down filling mechanism arranged in the machine box, and the automatic down filling mechanism comprises automatic weighing devices, multi-channel jointing devices and multi-channel shunting devices; each automatic weighing device is composed of a weighing box and weighing sensors, all the weighing sensors are jointly connected with a weighing transmitter used for controlling the weighing quantity, each multi-channel jointing device comprises a shunting entrance and a jointing exit, and the number of the multi-channel shunting devices is matched with that of the automatic weighing devices. The automatic weighing devices, the multi-channel shunting devices and the multi-channel jointing devices are additionally arranged, weighing is firstly performed through the automatic weighing mode, then material feeding and down filling are performed through the multi-channel shunting devices and the multi-channel jointing devices respectively, the weighing boxes are designed to be of a suspension type structure, the weighing sensors are arranged on the tops of the weighing boxes, therefore, an the automatic weighing process is not subjected to any influences, and it is guaranteed that the down filling precision is high enough, down filling error is very little and the down filling stability is high.

Owner:周业照

A kind of anode paste feeding device and feeding method

ActiveCN103847022BUniform clothImprove uniformityLarge containersFeeding arrangmentsMolding machineMaterials science

The invention relates to the electrolytic aluminum field and particularly relates to an anode paste feeding device and a feeding method in production of anode carbon blocks through a vibration molding method. The anode paste feeding device and the feeding method aim at providing anode paste for a plurality of vibration molding machines through a feeding device and enabling feeding to be uniform. The anode paste feeding device comprises a feed box system, a running system and a distributing system; sensors are arranged above number four supports to meter the weight of the anode paste in the anode paste feeding device to enable weight of every produced anode carbon block to be equal and meanwhile to achieve automation. The anode paste feeding device has the advantages of achieving discharging of the plurality of vibration molding machines, enabling anode paste distribution to be uniform and improving uniformity of the intensity of molded anode carbon blocks.

Owner:SHENYANG ALUMINIUM MAGNESIUM INSTITUTE

Dustproof conductive touch body

ActiveCN108364630AEqual weightGood playing feelElectrophonic musical instrumentsPianoComputer science

A dust-proof conductive touch body including a dust-proof handles. The dust that has penetrated into the hammer is blocked by a wide range of coverings by the dust-proof handle, and the weight error due to the difference in the construction of the keys is solved. The weight error causes the learner's playing touch to be erroneous, and the dust falls into the bottom and gradually accumulates duringlong-term use, and causes the touch reflection time to fluctuate. The piano has been poorly dustproof for the touch body, and the internal dust cannot handle the problem of the piano being scrapped.After the dust enters the bottom of the key, the dust handle at the bottom of the key blocks and dust is closed. Through the shock of the keys, the fish scale-like dust-removing pieces on the dust-removing table are lifted. The dust is vibrated by multiple quick oscillations, so that the dust does not accumulate inside with fast rebound. The conductive screw can enhance the spring speed of the guide core, greatly speed up the piano's sound time and improve the playing efficiency.

Owner:UNIV FOR SCI & TECH ZHENGZHOU

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com