Double-mold automatic casting machine capable of rotating by 90 degrees to pour aluminum piston blank and using method of double-mold automatic casting machine

A casting machine and piston technology, applied in foundry workshops, casting equipment, manufacturing tools, etc., can solve the problems of slow cooling of the head of the piston blank, coarse grain structure, low production efficiency, etc., to avoid pores, trachoma, and grain structure The effect of fineness and porosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

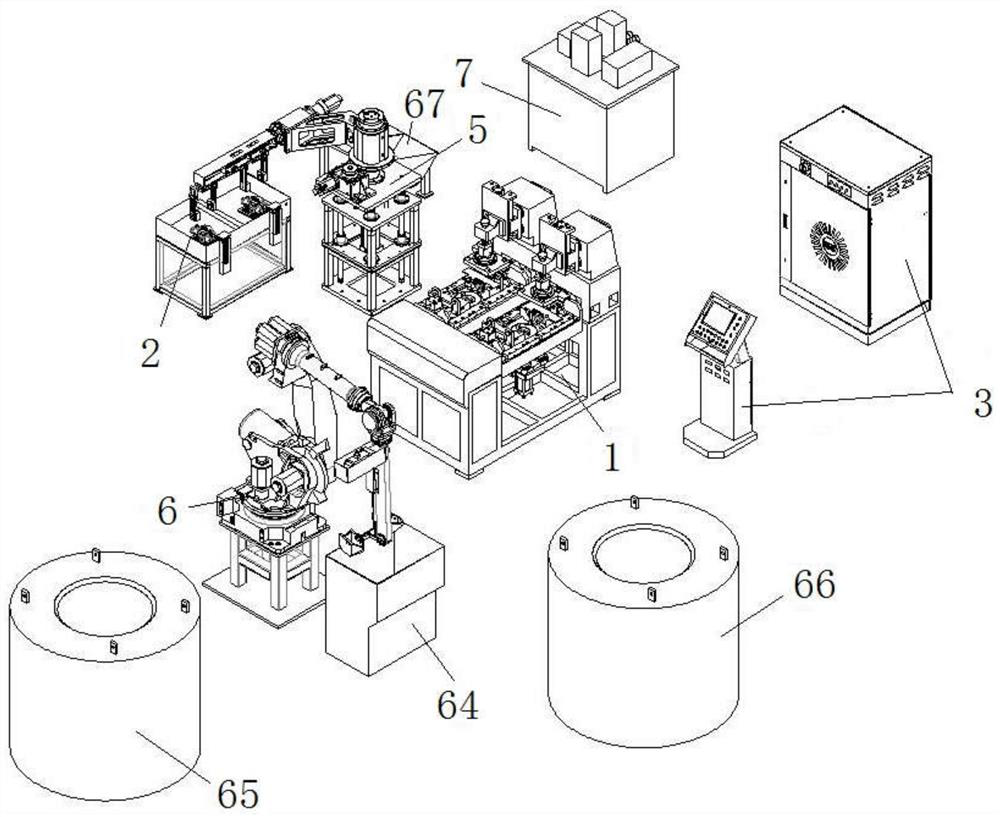

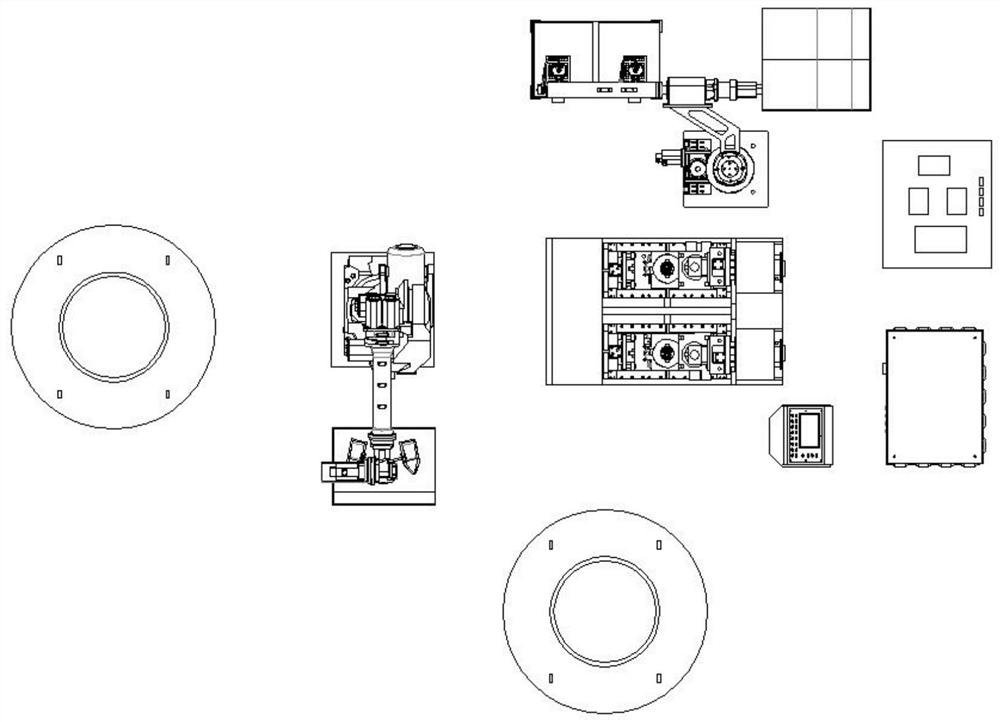

[0048] Such as Figure 1-13 As shown, this embodiment provides a dual-mode automatic casting machine for pouring aluminum piston blanks by rotating 90°, including a pouring system 1, a pick-up manipulator 5, a joint pouring robot 6, a hydraulic system 7, an electrical operating system 3, and a quenching and cooling box 2, of which,

[0049] The pouring system 1 is set on the ground, the pick-up manipulator 5 is set on the ground on one side of the pouring system 1, the joint pouring robot 6 is set on the opposite side of the pouring system 1, the joint pouring robot 6 picks up the aluminum liquid and pours it into the pouring system, and the pick-up manipulator 5 is on the side Set up the quenching and cooling box 2, and the pick-up manipulator 5 clamps the piston blank poured by the pouring system to the quenching and cooling box. The pouring system 1 is connected to the hydraulic system 7, and the hydraulic system, pick-up manipulator and joint pouring robot are all connecte...

Embodiment 2

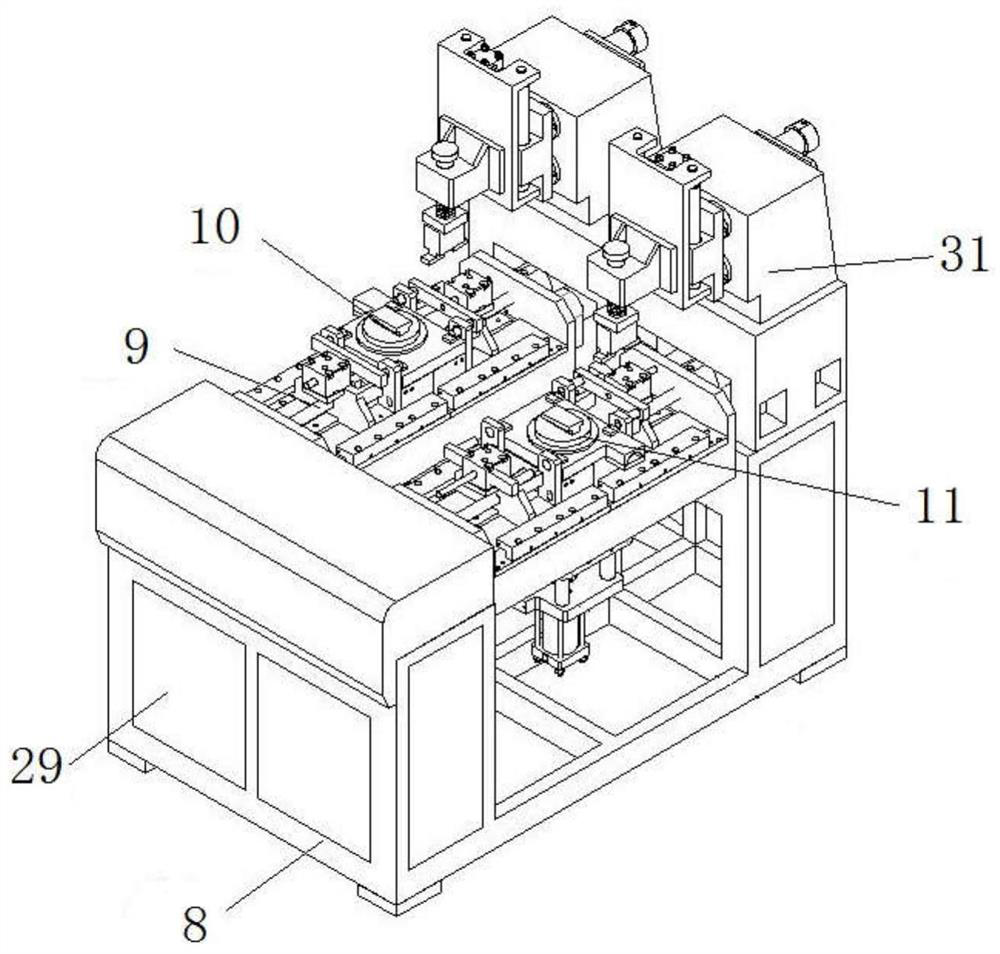

[0065] A double-mode automatic casting machine for pouring aluminum piston blanks by rotating 90°, the structure is as described in Embodiment 1, the difference is that an air suction device 29 is arranged on the frame 8, and the air suction device 29 is connected to the salt core support rod, The gas generated by the heating of the salt core is absorbed by the suction device to reduce the porosity of the piston blank.

Embodiment 3

[0067] A double-mode automatic casting machine for pouring aluminum piston blanks by rotating 90°, the structure is as described in Embodiment 1, the difference is that the top mold clamping device 31 includes a bracket 32, a cylindrical guide rail 33 for the top mold to move up and down, and a carriage 34. Top die upper and lower oil cylinders 35, top die advance and retreat cylindrical guide rails 36, top die advance and retreat oil cylinders 37, fixed seats 38 and pneumatic fingers A39, top die advance and retreat movement cylindrical guide rails are set on the upper side of the support, and top die advance and retreat movement cylindrical guide rails One side is connected to the top mold advancing and retreating oil cylinder, and the other side is connected to the carriage. On the carriage, a cylindrical guide rail is set for the top mold to move up and down. One end of the top mold moves up and down. The slide plate 40 moves up and down through the cylindrical guide rail o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com