Automatic Down Filling System of Down Filling Machine Using Weighing Mode

A down filling machine and automatic technology, which is applied in the direction of weighing equipment, weighing, and application of materials with special properties/forms, can solve the problem that the down quantity is difficult to ensure the same weight, the down filling products are uneven, and the down speed Difficult to control and other problems to achieve the effect of avoiding shutdown and rework, avoiding electrical control failures, and accurate cashmere feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

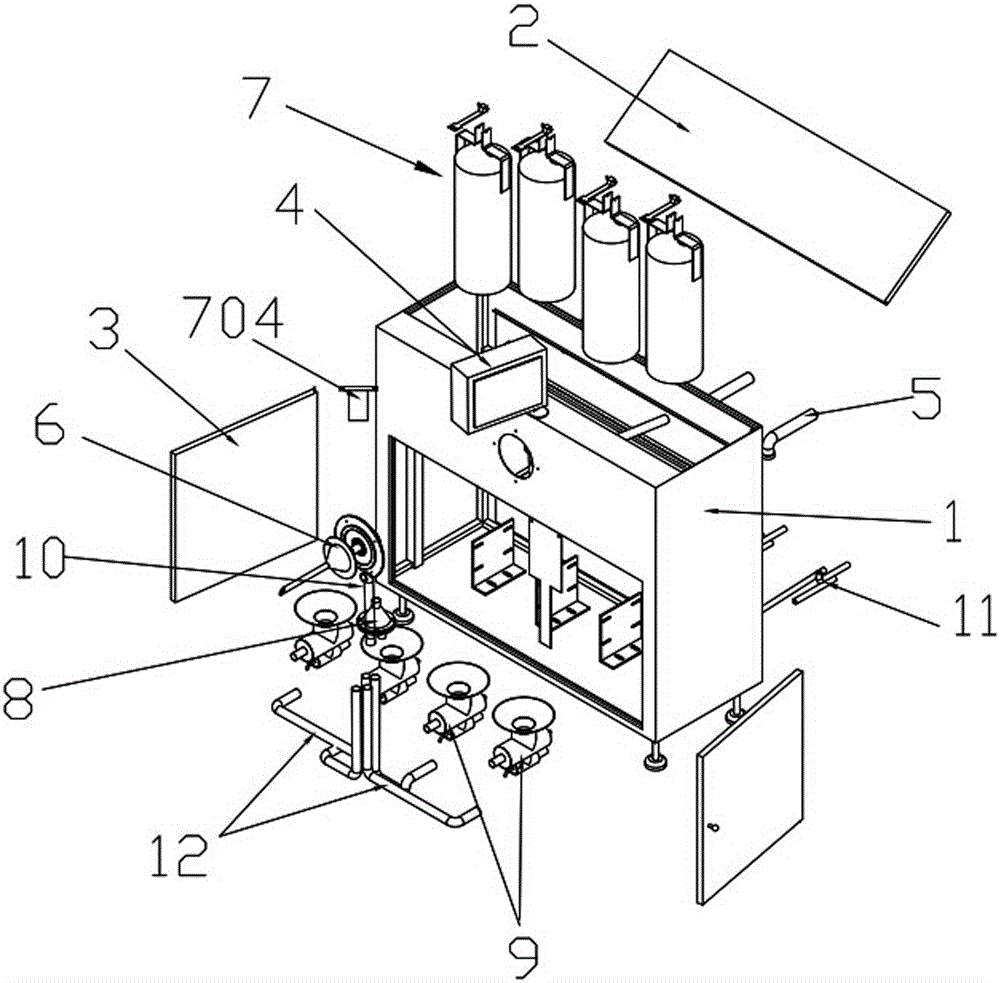

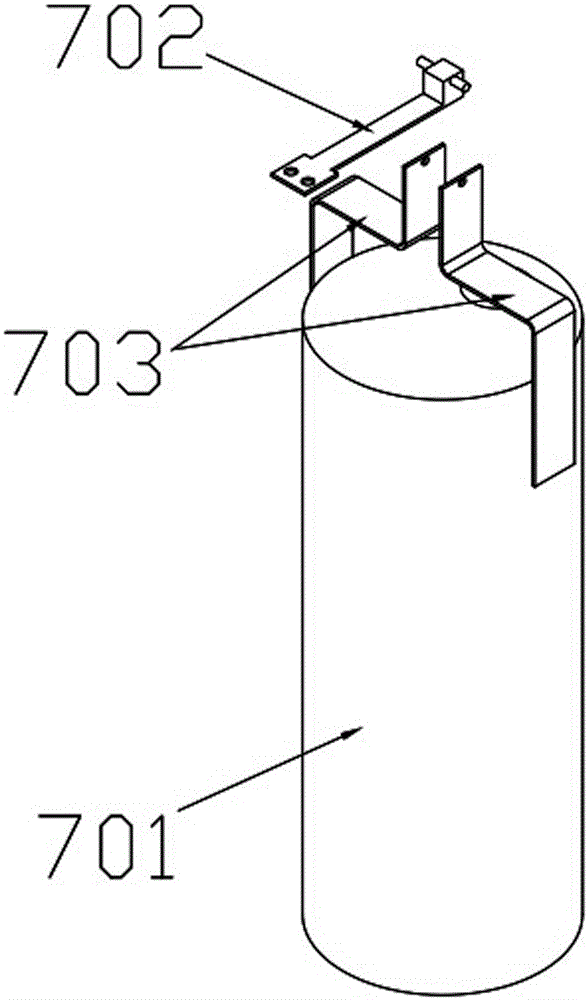

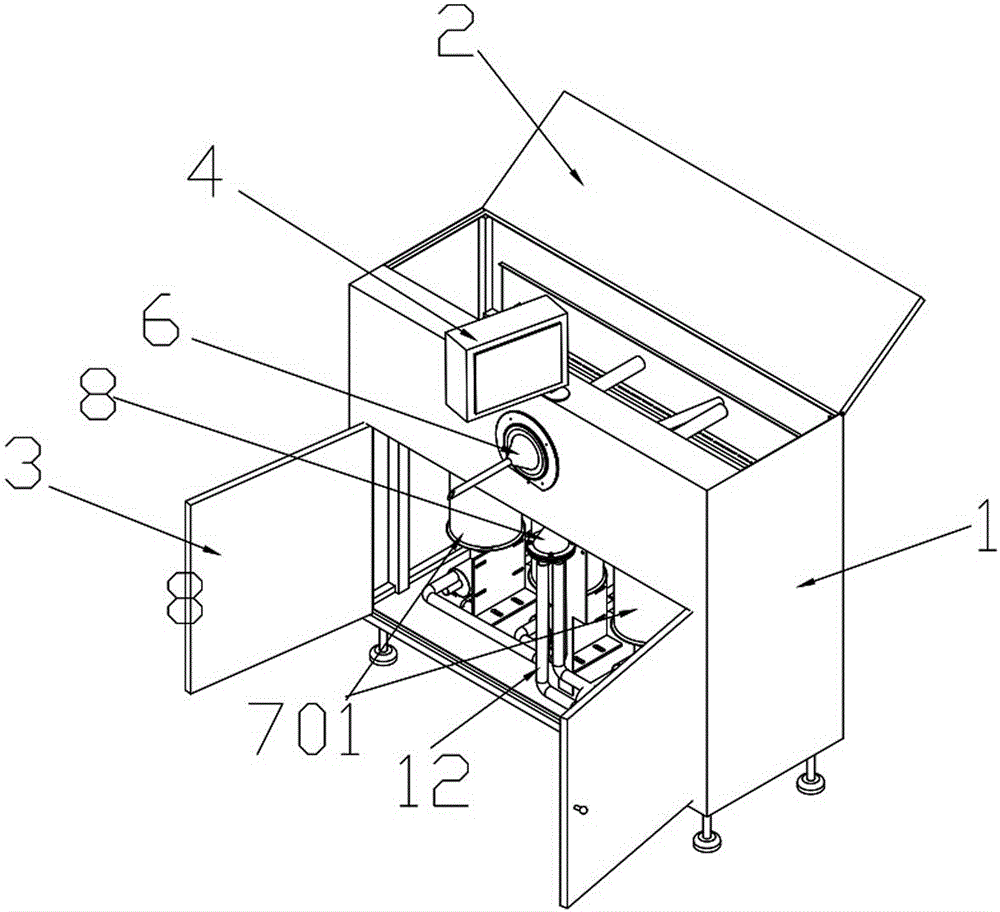

[0036] In this embodiment, refer to Figure 1 to Figure 7 , its specific implementation is as follows:

[0037] like Figure 1 to Figure 5 As shown, the automatic down filling system of the down filling machine includes a case 1 and an automatic down filling mechanism arranged inside the case 1. A controller 4 is also provided outside the case 1, and the controller 4 can set the down filling weight. Depending on the size, you can set different amounts of down filling. By setting the weight of down filling, you can perform accurate down filling. The cabinet 1 includes a top inspection door 2 and a side inspection door 3. The rear end of the cabinet 1 is provided with a storage box for the down filling machine. The velvet inlet pipe 5 connected to the velvet box, the front end of the cabinet 1 is provided with a velvet filling nozzle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com