Pressing device for floors

A kind of technology of equipment and floor, which is applied in the field of floor pressing equipment, can solve the problem of wasting resources and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

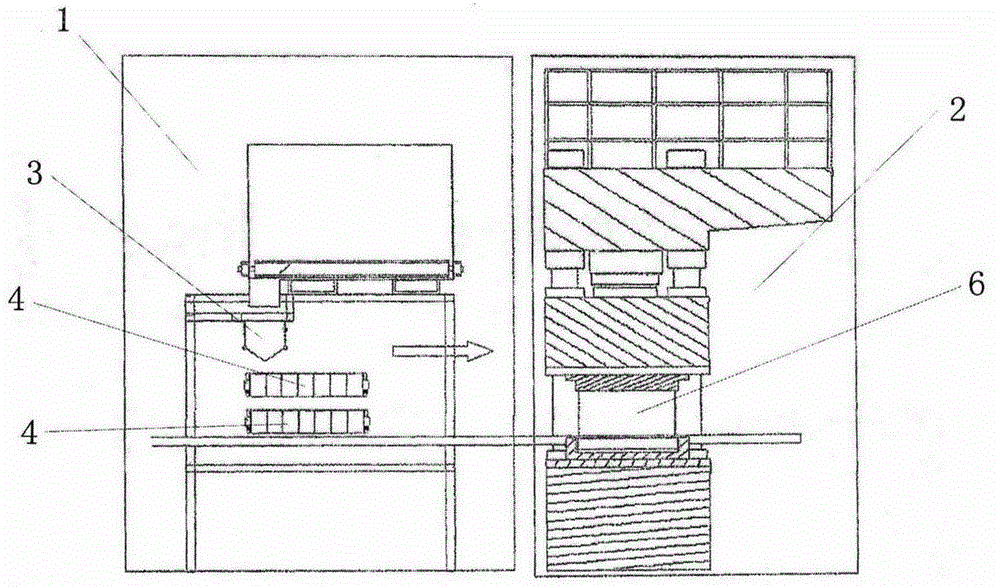

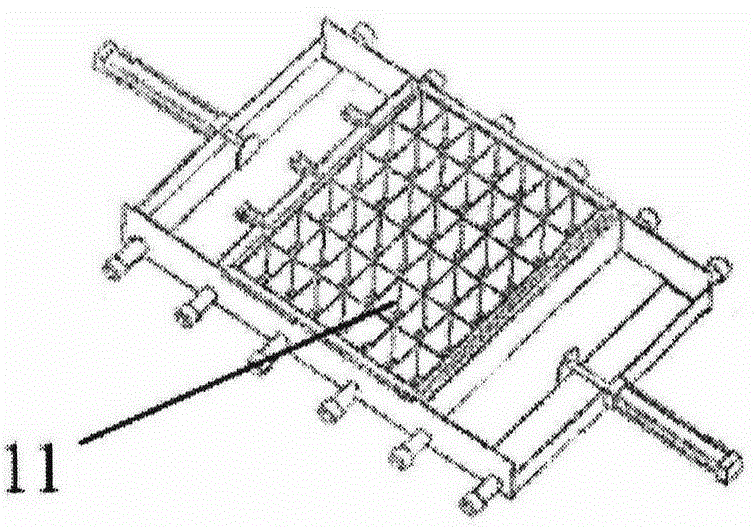

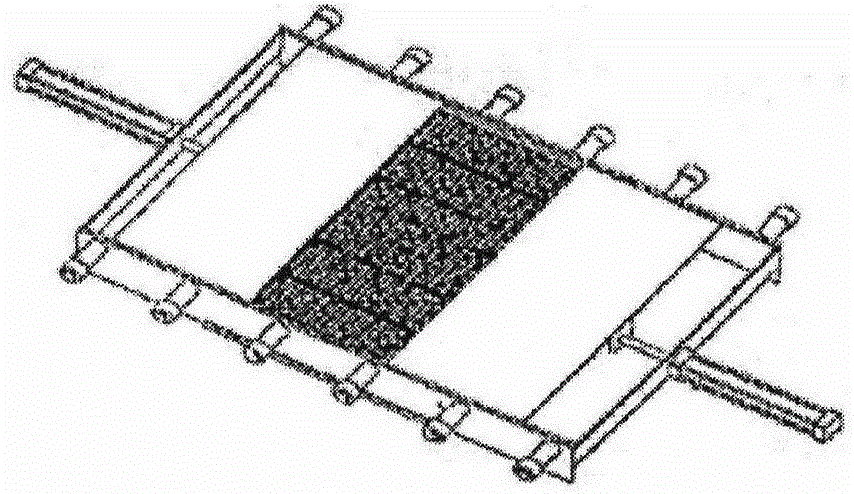

[0023] The present invention provides a kind of floor pressing equipment, comprising a vibrating feeder 1 and a thermoforming machine 2, the vibrating feeder includes a material box for storing raw materials, a weighing funnel 3 and a charging platform, the weighing The funnel is installed at the outlet of the hopper, the charging platform is arranged directly below the weighing funnel, the charging platform is provided with a movable transfer feeding tray 4, and the transferring feeding tray There are a first station and a second station 6, wherein the first station is located on the charging platform directly below the weighing funnel, and the second station is located at the feed port of the thermocompression molding machine , the quantity of the transfer feeding tray is 2, and the 2 transfer feeding trays are arranged up and down, and several vertical spacers arranged horizontally and vertically are arranged in the two transfer feeding trays, and several The inner space of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com