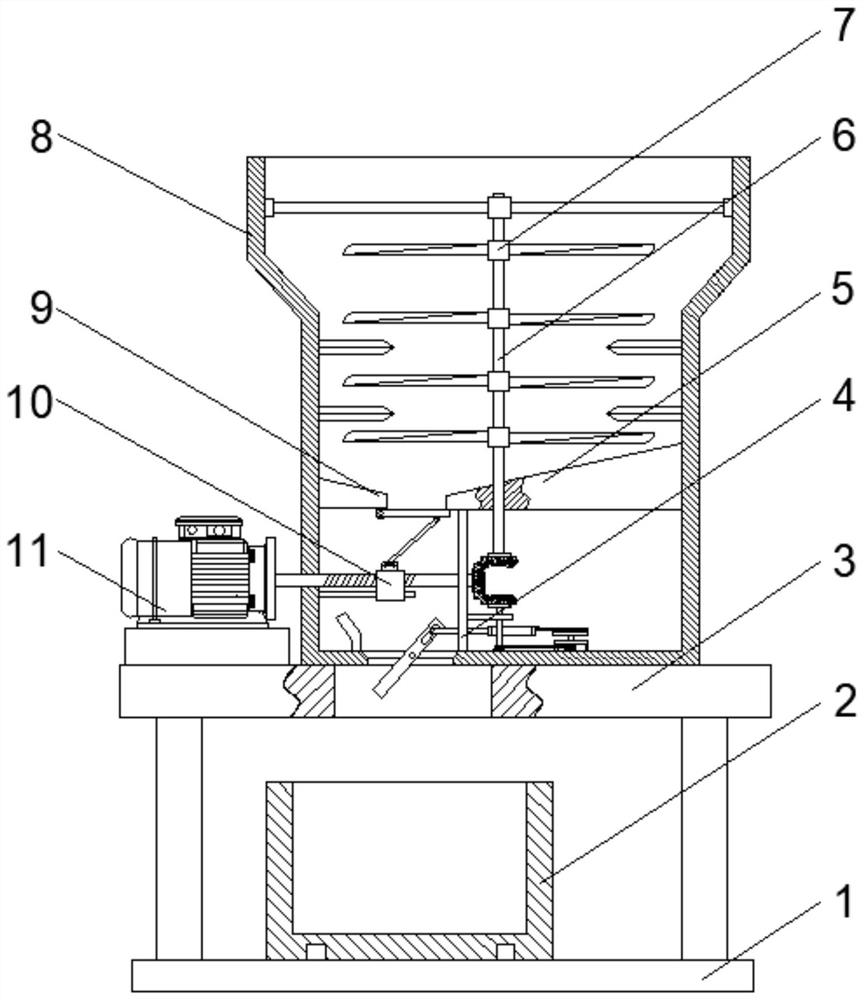

Straw recycling equipment and recycling method thereof

A straw and equipment technology, applied in straw recycling equipment and its recycling field, can solve the problems of uneven accumulation, low recycling efficiency, blockage, etc., and achieve the effect of increasing the storage space and reducing the probability of straw discharge.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

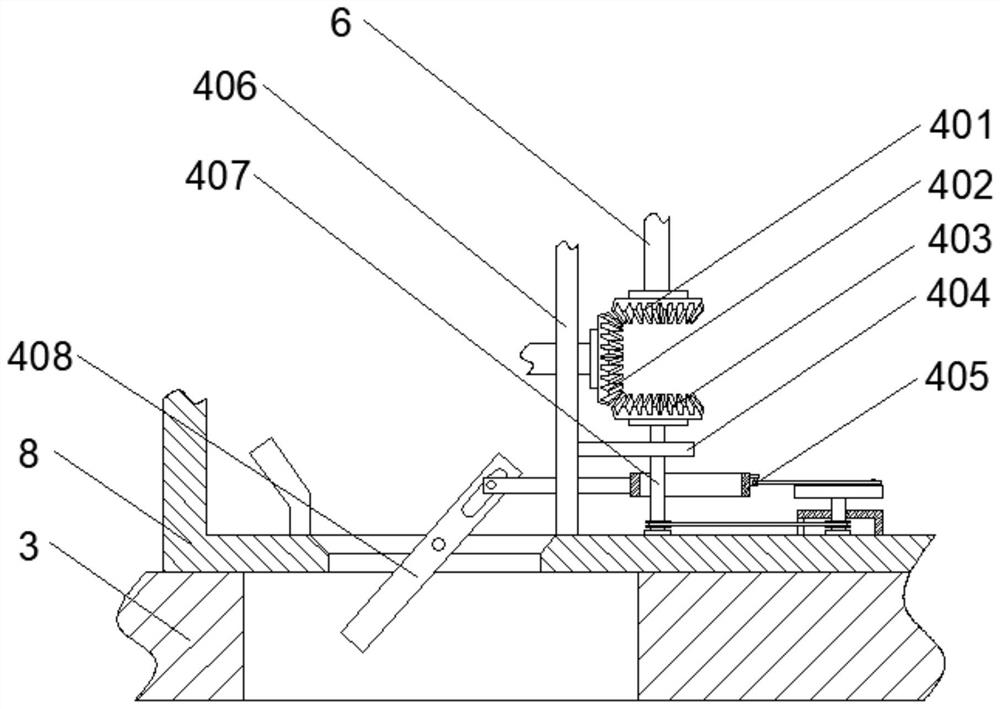

[0034] see figure 2As shown, the above-mentioned adjustment mechanism 4 includes a third partition 406 fixedly connected to the first partition 5, the third partition 406 is arranged vertically, and a first bevel gear 402 is provided on one side of the third partition 406, and the first bevel gear 402 is arranged on the first partition 406. The bevel gear 402 is connected to the first rotating shaft 6 through the second bevel gear 401, the first bevel gear 402 is connected to the second rotating shaft 407 through the third bevel gear 403, and the bottom end of the second rotating shaft 407 is connected to the shell 8 through the bearing. The inner wall is rotatably connected, through the rotation of the first bevel gear 402 and the rotation of the second bevel gear 401 and the third bevel gear 403 to drive the first rotating shaft 6 and the second rotating shaft 407 to rotate respectively, so as to provide power output for the cutter 7 to cut straw, and the third partition 40...

Embodiment 2

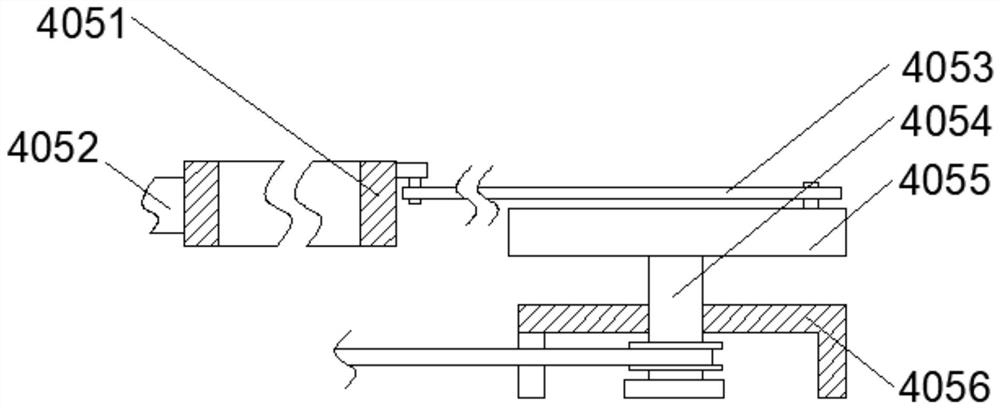

[0038] see Figure 5 and Figure 6 As shown, the above-mentioned opening mechanism 10 includes a threaded screw rod 1005, the middle part of the threaded screw rod 1005 is threadedly connected with an installation sleeve 1003, and the top of the installation sleeve 1003 is movably connected with a push-pull rod 1002 through a rotating seat, and one end of the push-pull rod 1002 is hinged with an opening. Closing the door 1001, one end of the opening and closing door 1001 is hinged with the second partition 9, a guide rod 1004 is arranged below the threaded screw rod 1005, the guide rod 1004 moves through the bottom of the installation sleeve 1003, and the installation sleeve 1003 moves through the guide rod 1004 Limit support is provided, and at the same time, the push-pull rod 1002 is driven to open or close the opening and closing door 1001 through the movement of the installation sleeve 1003, so as to facilitate the control of the amount of straw discharged in a fragmented ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com