Winding device for tempered transmission rollers

A technology of winding device and driving roller, which is applied in the direction of transportation and packaging, thin material handling, and delivery of filamentous materials, etc. It can solve the problems of easy shedding, low winding efficiency, and different stress on the glass surface to meet the production quality requirements , Improve winding efficiency and ensure winding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

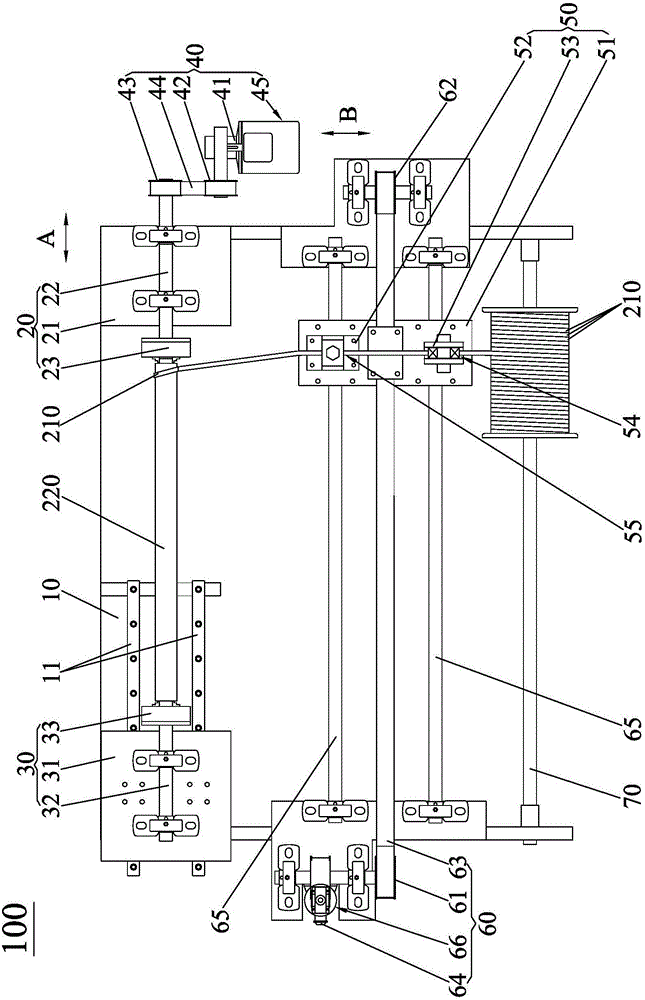

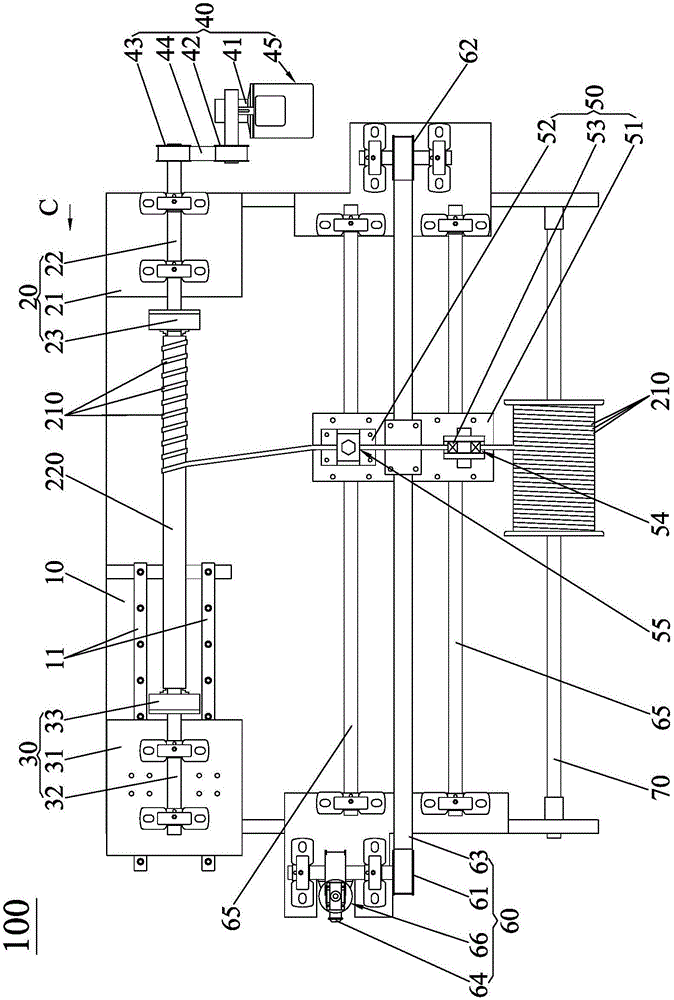

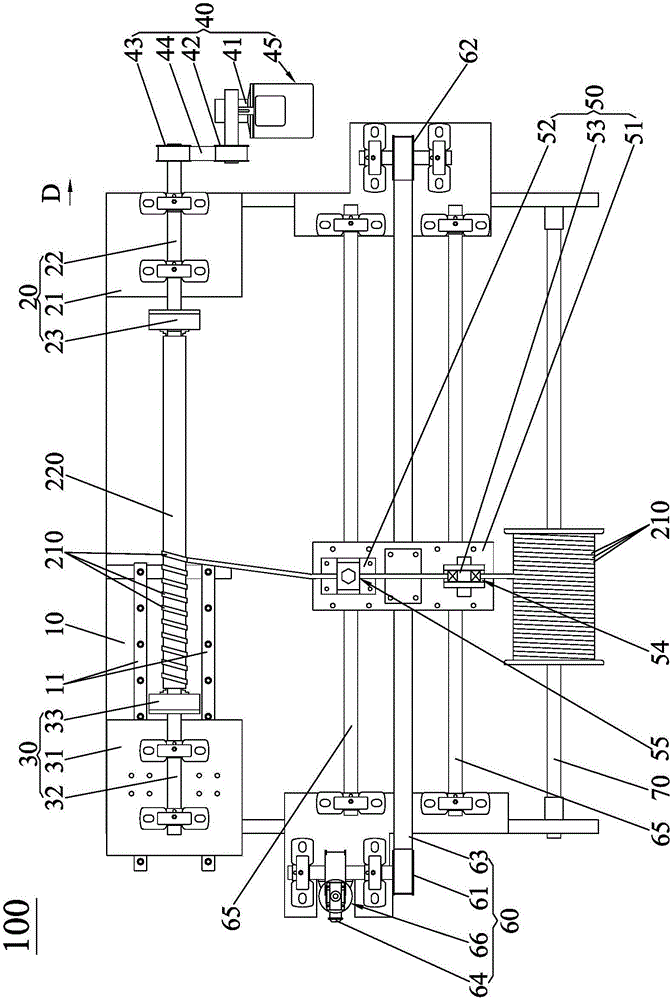

[0021] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

[0022] see figure 1 , the winding device 100 for the tempered driving roller of the present invention is suitable for automatically winding the tempered auxiliary rope 210 (such as aramid rope or asbestos rope) on the tempered driving roller 220, so that the tempered auxiliary rope wound on the tempered driving roller 220 The 210 has the same pitch.

[0023] Wherein, the winding device 100 for tempered drive rollers of the present invention includes a frame 10 , a first clamping mechanism 20 , a second clamping mechanism 30 , a first driving mechanism 40 , a rope guide 50 and a second driving mechanism 60 . The first clamping mechanism 20 is set at one end of the longitudinal direction of the frame 10, and the first clamping mechanism 20 clamps one end of the tempered drive roller 220; the second clamping mechanism 30 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com