Patents

Literature

39results about How to "Uniform pitch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

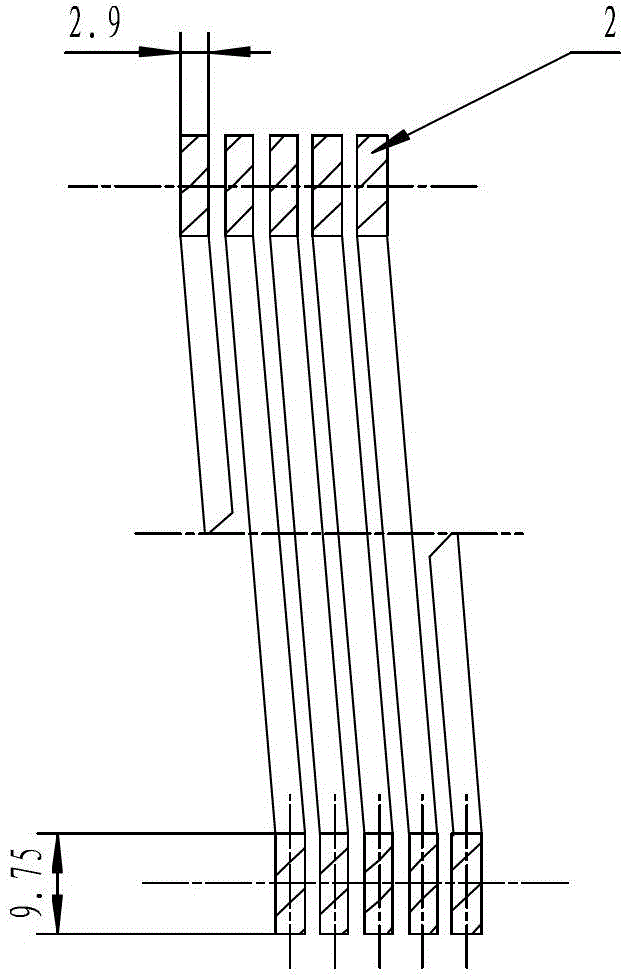

Stranding lead in device of stranding machine

InactiveCN102945713AIncrease profitIncrease productivityCable/conductor manufactureElectrical conductorEngineering

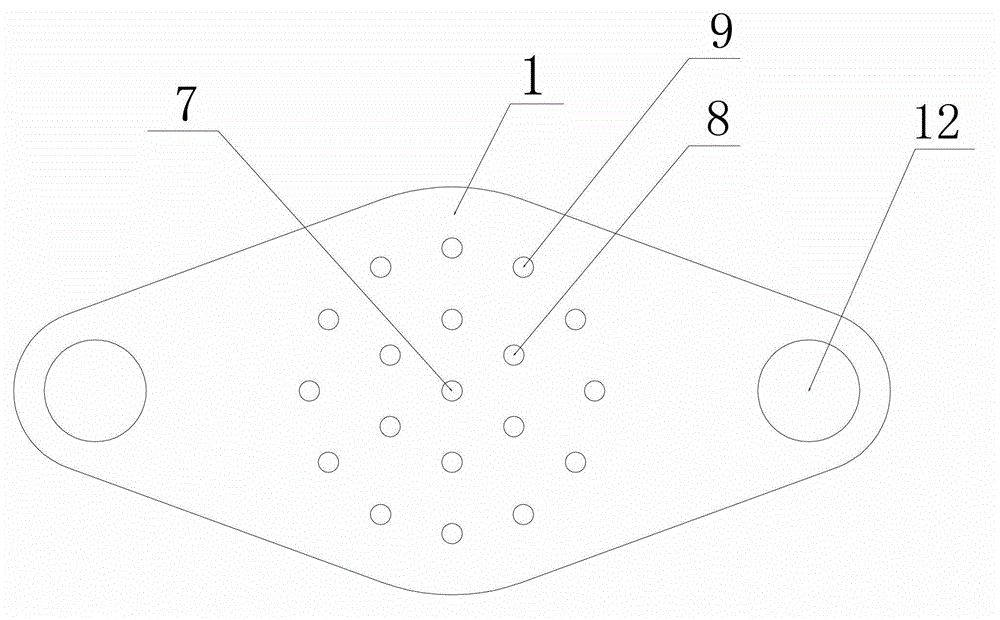

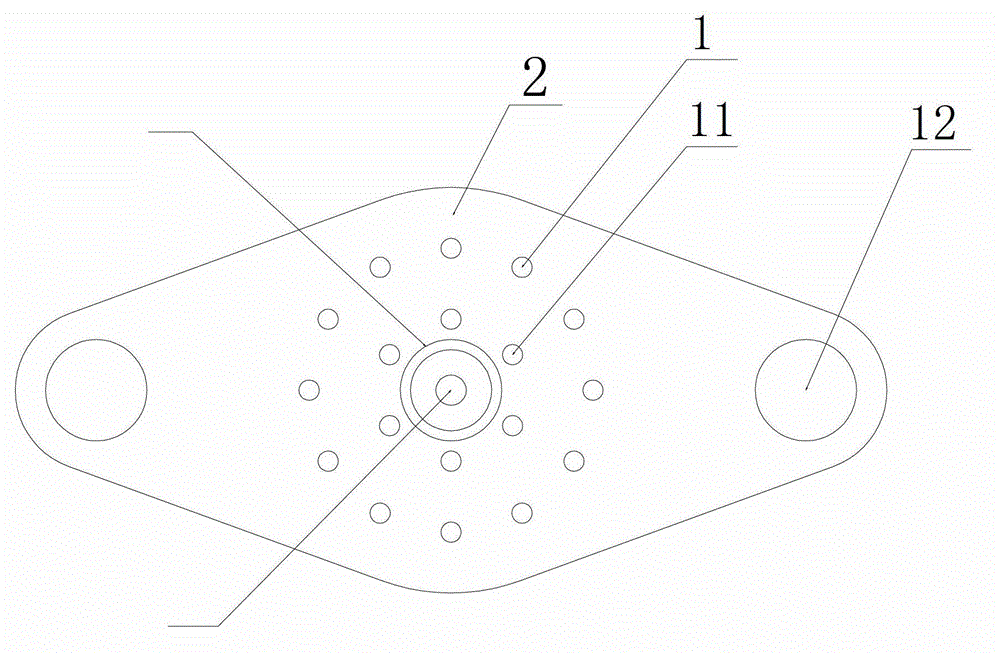

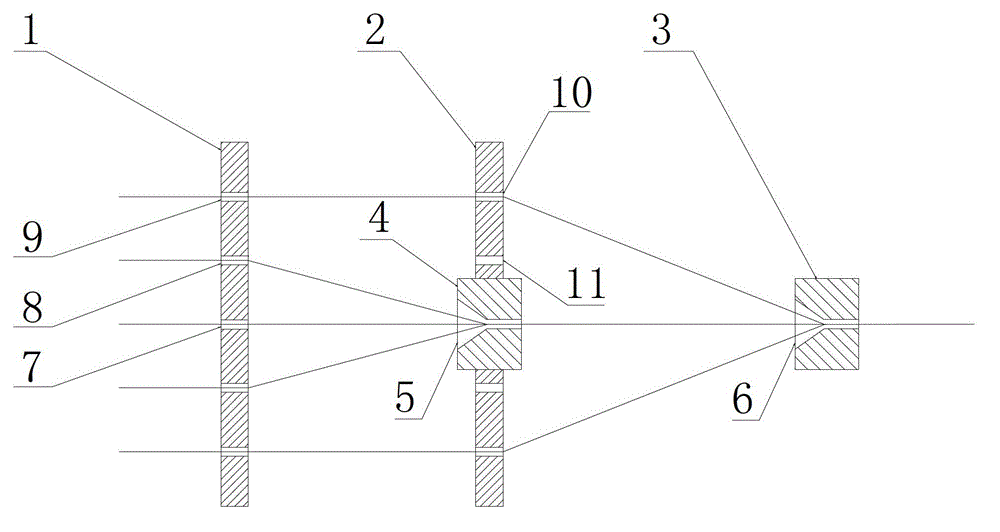

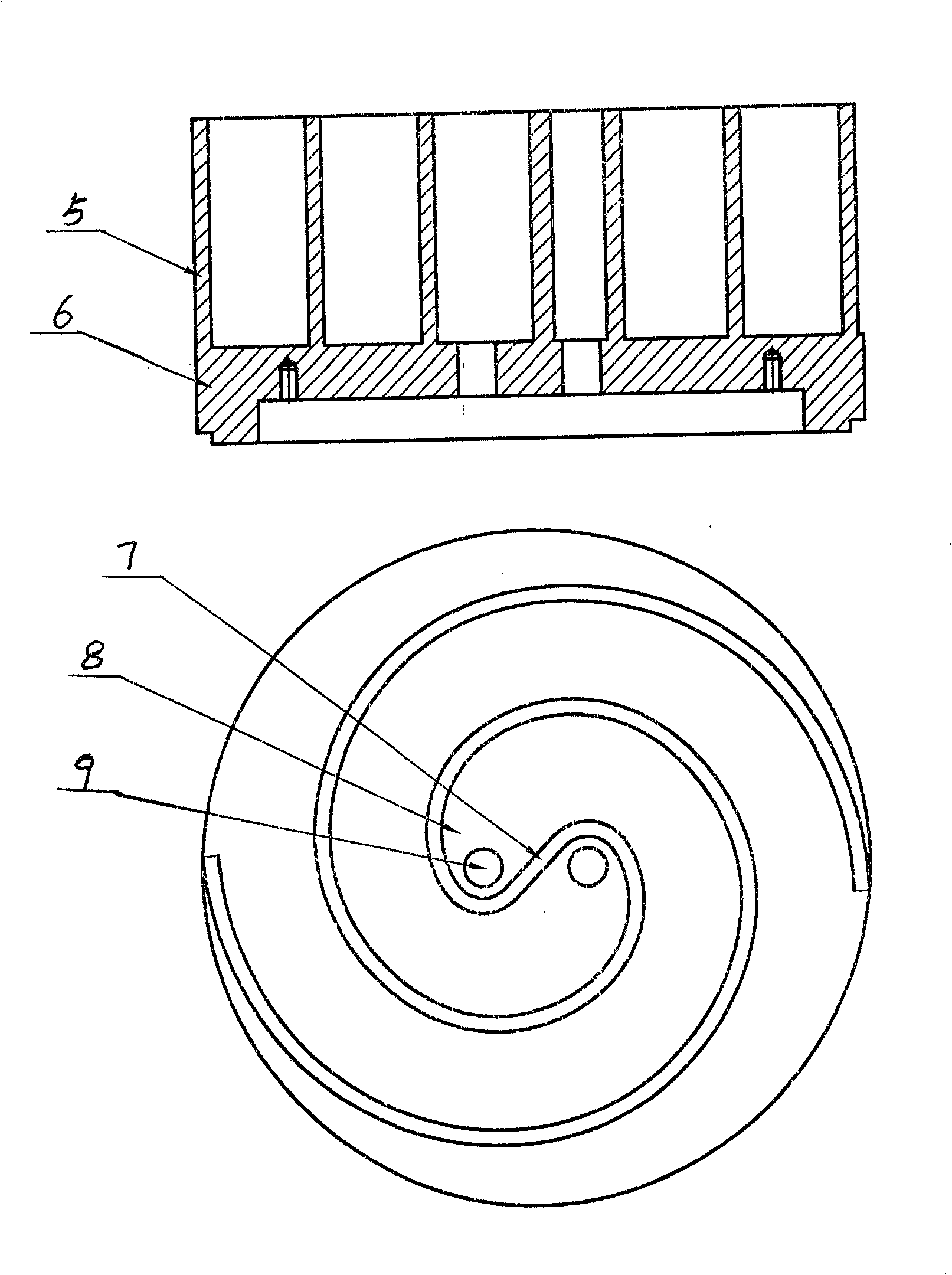

The invention provides a stranding lead in device of a stranding machine. A first wire split die plate, a second wire split die plate and a second wire combining die sleeve are sequentially arranged along the wire feeding direction, a first wire combining die sleeve is arranged at the center of the second wire split die plate, a first wire combining hole and a second wire combining hole are mounted on the first wire combining die sleeve and the second wire combining die sleeve respectively, wire penetrating holes are arranged on the first wire split die plate and the second wire split die plate respectively, and the number of the wire penetrating holes is equal to that of conductors to be required to be stranded. By means of the stranding lead in device of the stranding machine, a stranded body with numerous single strands and two or more than two stranded layers can be stranded once, the production efficiency and applicability of the stranding machine are improved, and the stranding quality of the stranded body can meet technological requirements.

Owner:江苏和和电缆科技有限公司

Automatic winding mechanism

The invention relates to an automatic winding mechanism, comprising a rack, a transverse motor, a winding motor, a spindle and a winding assembly; the transverse motor is arranged on the rack by a motor seat; the winding motor is glidingly arranged on the rack by a sliding seat; the spindle and a motor shaft of the winding motor are fixedly connected; the winding assembly is arranged on the spindle and driven by the winding motor to rotate; the sliding seat and a piston rod of the transverse motor are fixedly connected; the transverse motor drives the sliding seat to reciprocate on the rack, so a winding width of yarns on the winding assembly is realized. The transverse motor drives the sliding seat to drive the whole winding assembly to horizontally reciprocate while the winding motor drives the winding assembly to rotate to realize the automatic winding of the yarns on yarn rods, the winding width of the yarns is realized, distances between the yarn rods are adjustable to adapt to bobbins of different diameters or clews or products of different winding diameters, the operation is stable, the friction is small, and the yarn winding distances are uniform, and the forming quality and production efficiency are improved.

Owner:NINGXIA RUYI SCIENCE & TECHNOLOGY FASHION INDUSTRY CO LTD

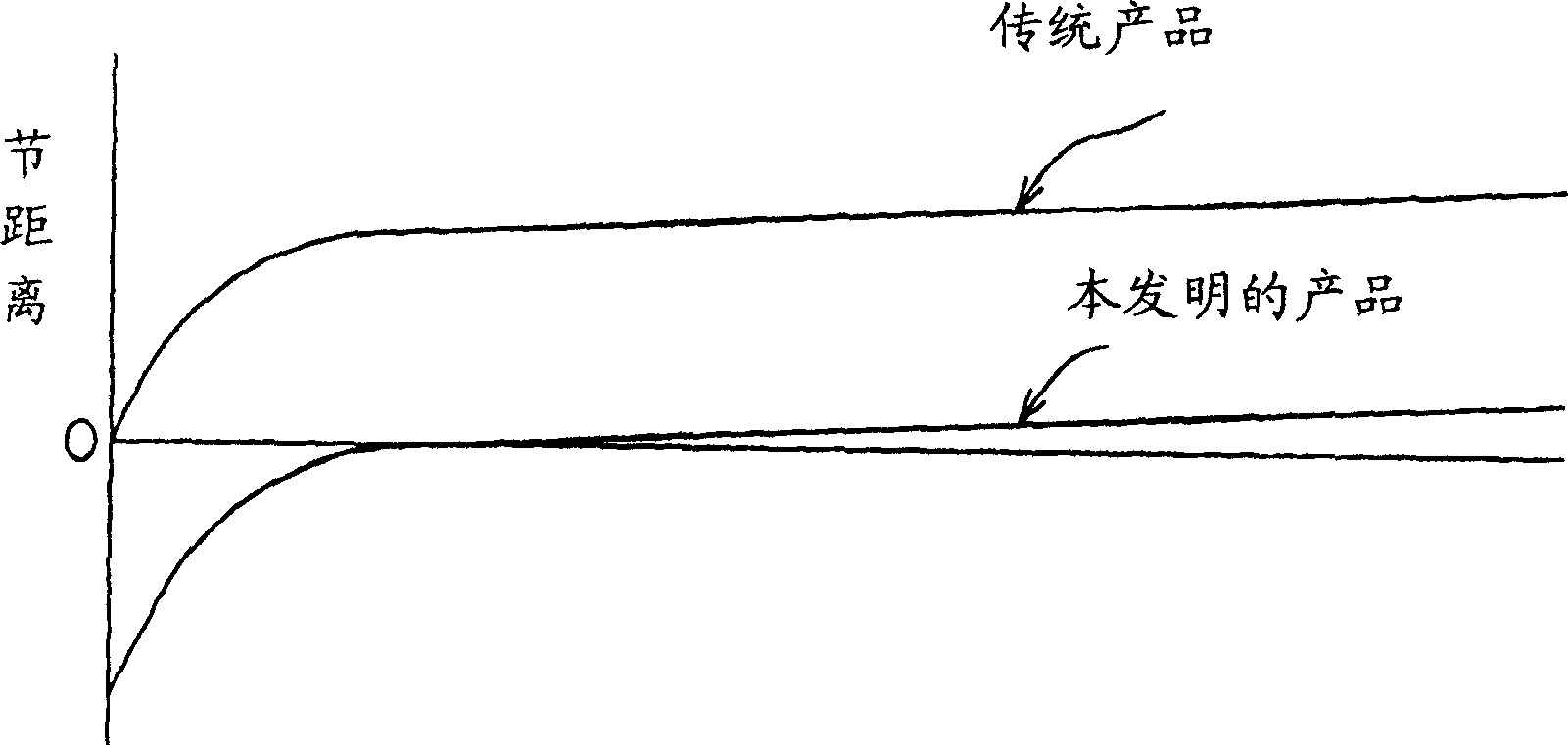

Power transmission chain

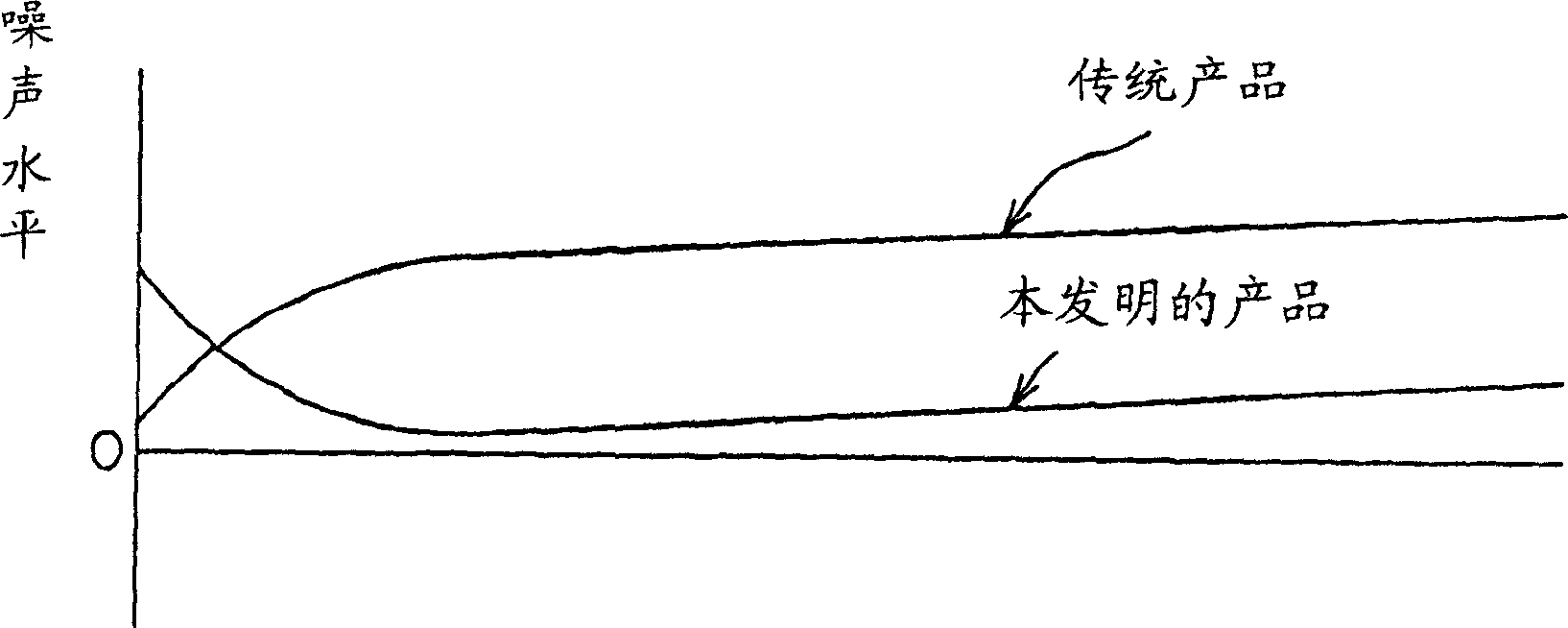

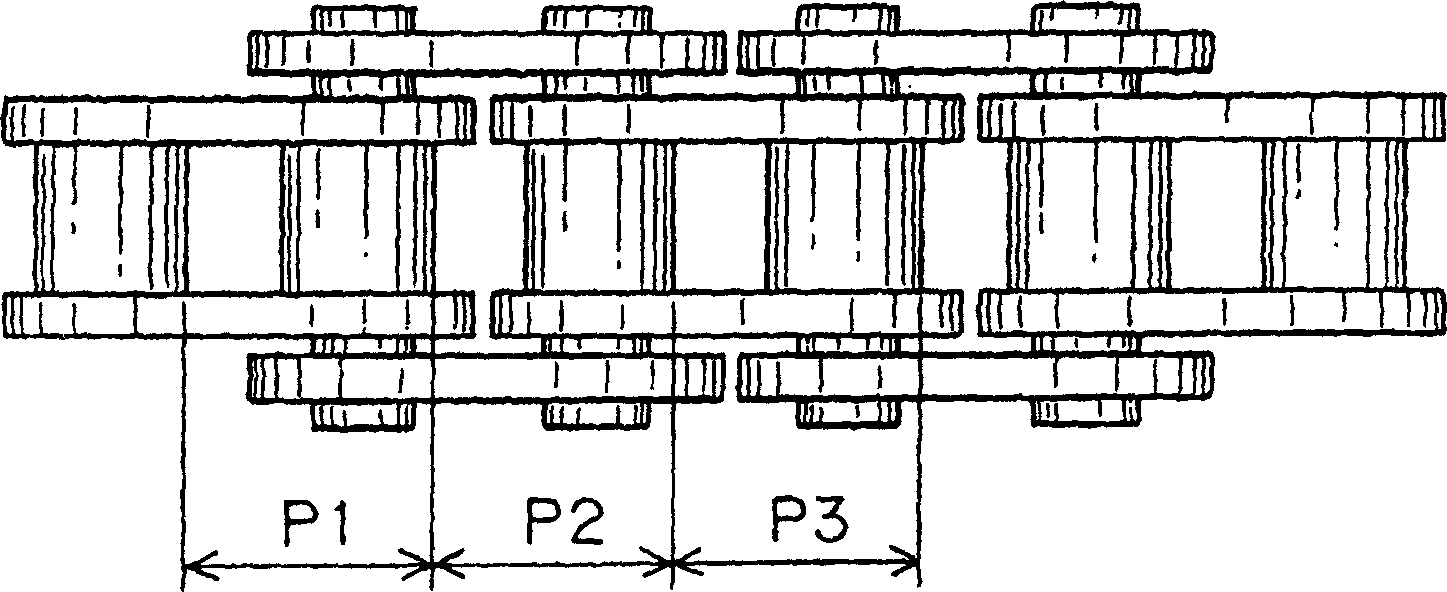

In a newly manufactured roller chain, the pitch measured from one of two adjacent bushings of any two consecutive inner links of the chain to the other is greater than that measured from any of said inner links of the chain The pitch measured from one of the two bushings on one to the other is a small amount corresponding to the initial lengthening of the chain.

Owner:TSUBAKIMOTO CHAIN CO

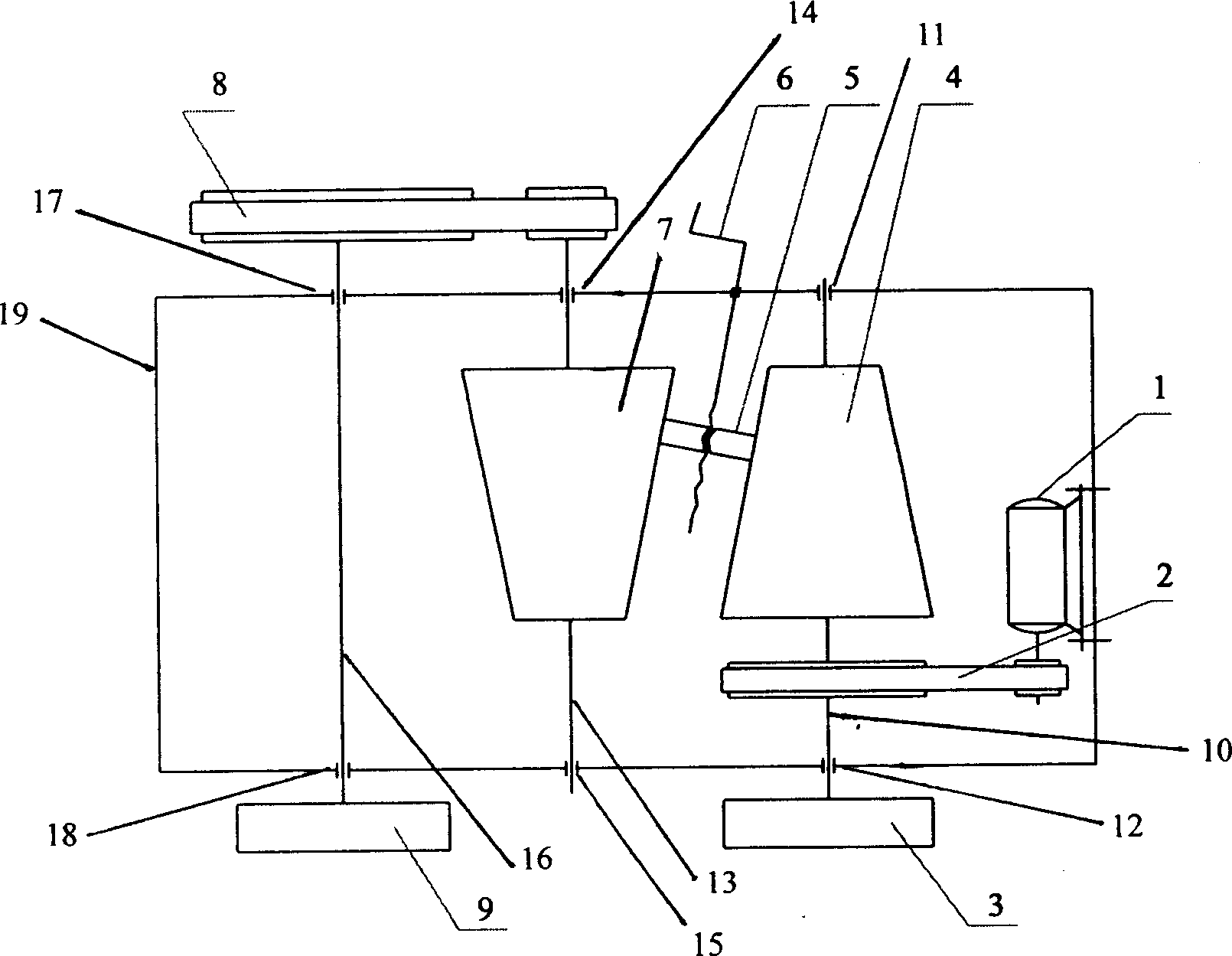

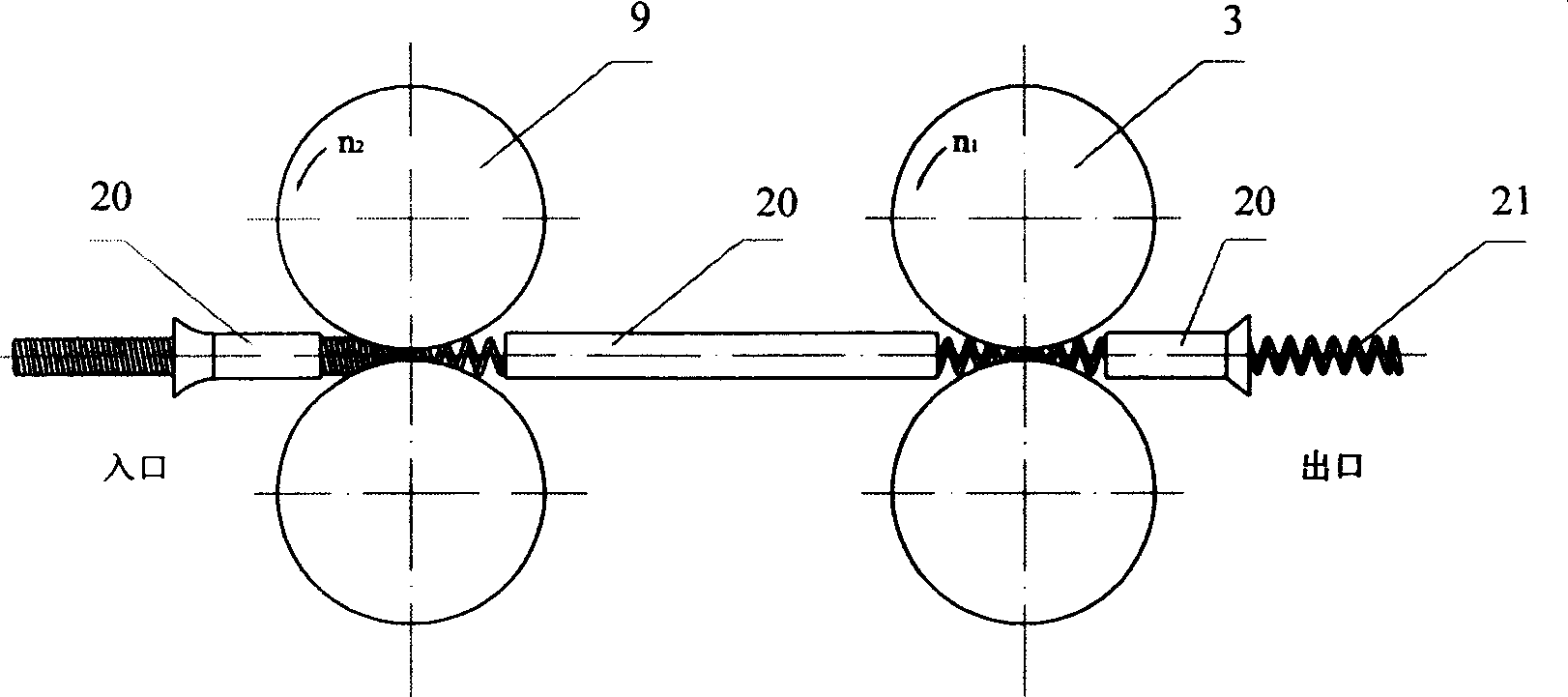

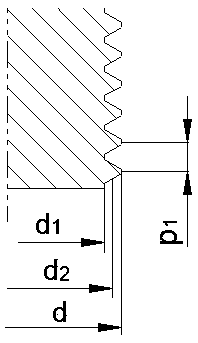

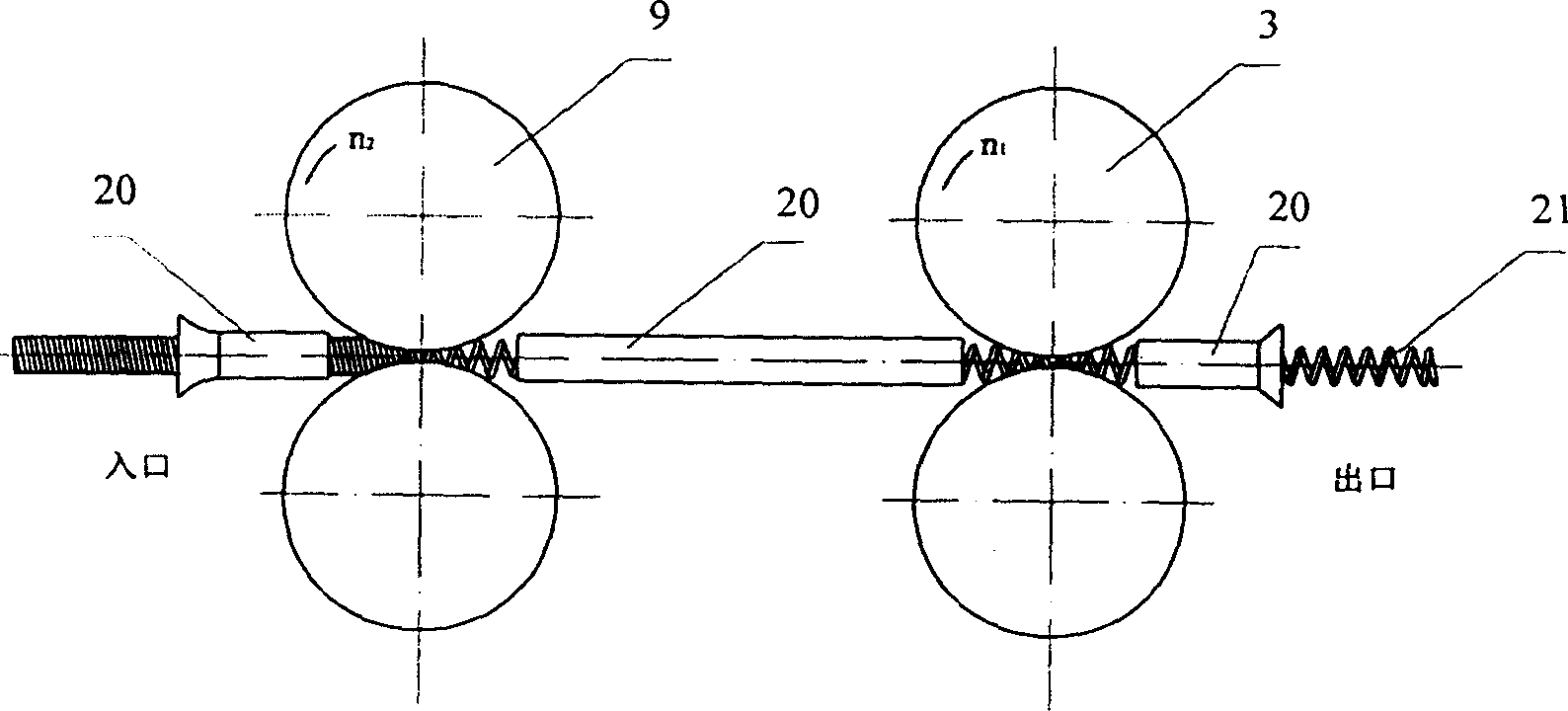

Screw roll fixed pitch stretching device

The screw roll fixed-pitch stretching equipment consists of motor, high-speed belt drive stage, low-speed belt wrive stage, driving rubber roller, differential rubber roller, driving conic roller, driven conic roller, speed-regulating screw, shaft and bearings. The motor drives the small belt pulley of high-speed belt drive stage; the driving conic roller, the large belt pulley of high-speed belt drive stage and the driving rubber roller are on the drive shaft; the driven conic roller and the small belt pulley of low-speed belt drive stage are on the middle shaft; the large belt pulley of low-speed belt drive stage and the differential rubber roller are on the driven shaft; there is speed regulating screw with control handle installed between the driving conic roller and the driven conic roller; and the bearings are mounted on the box.

Owner:HARBIN INST OF TECH

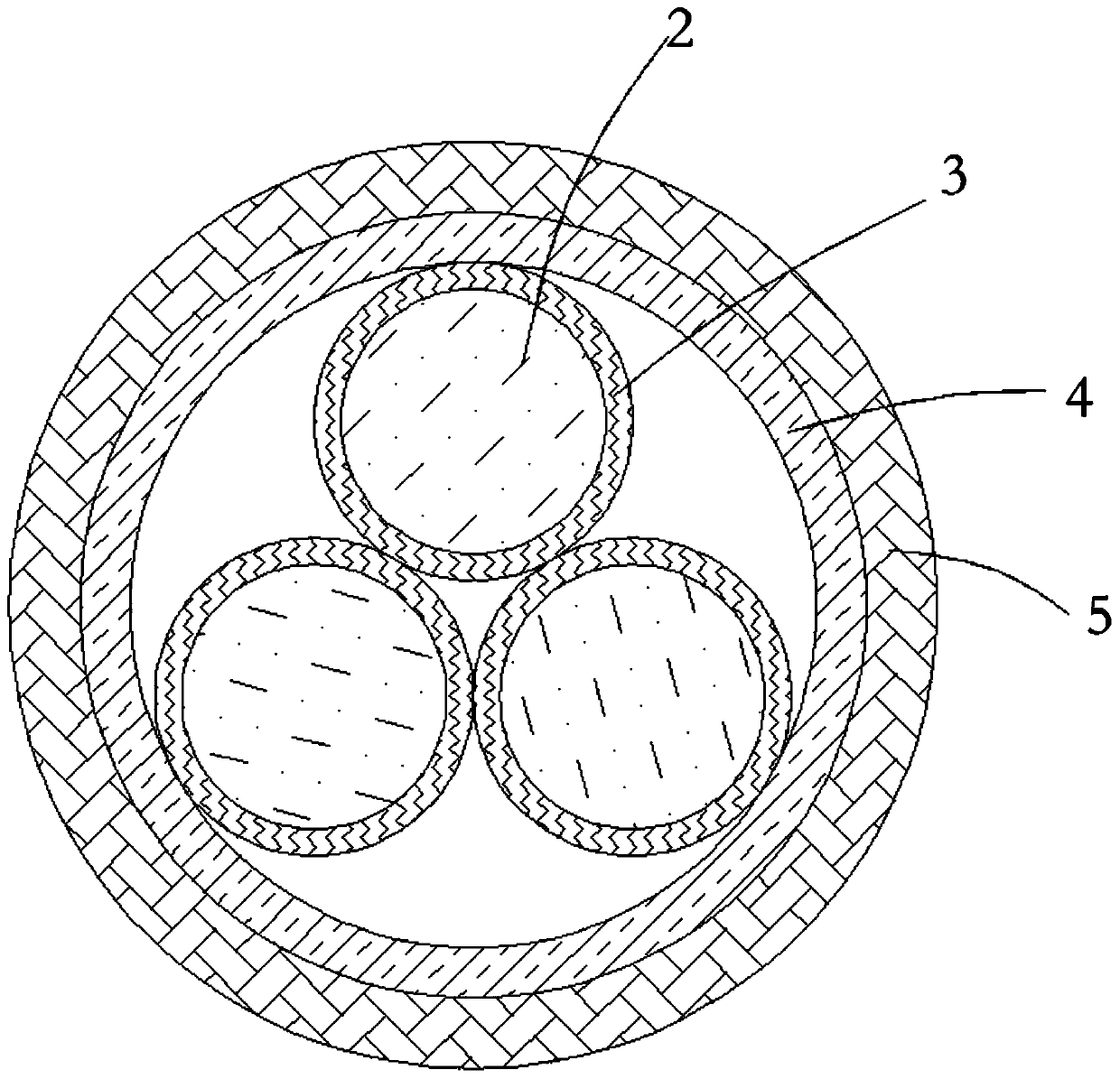

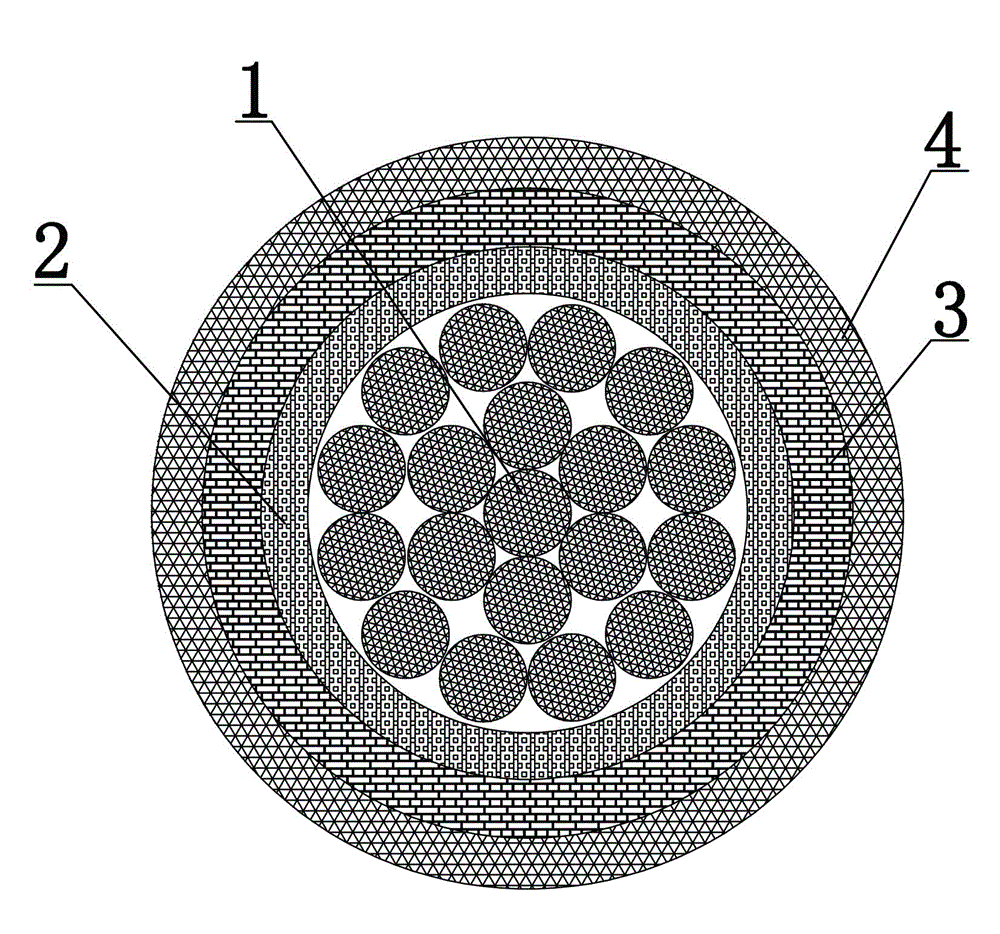

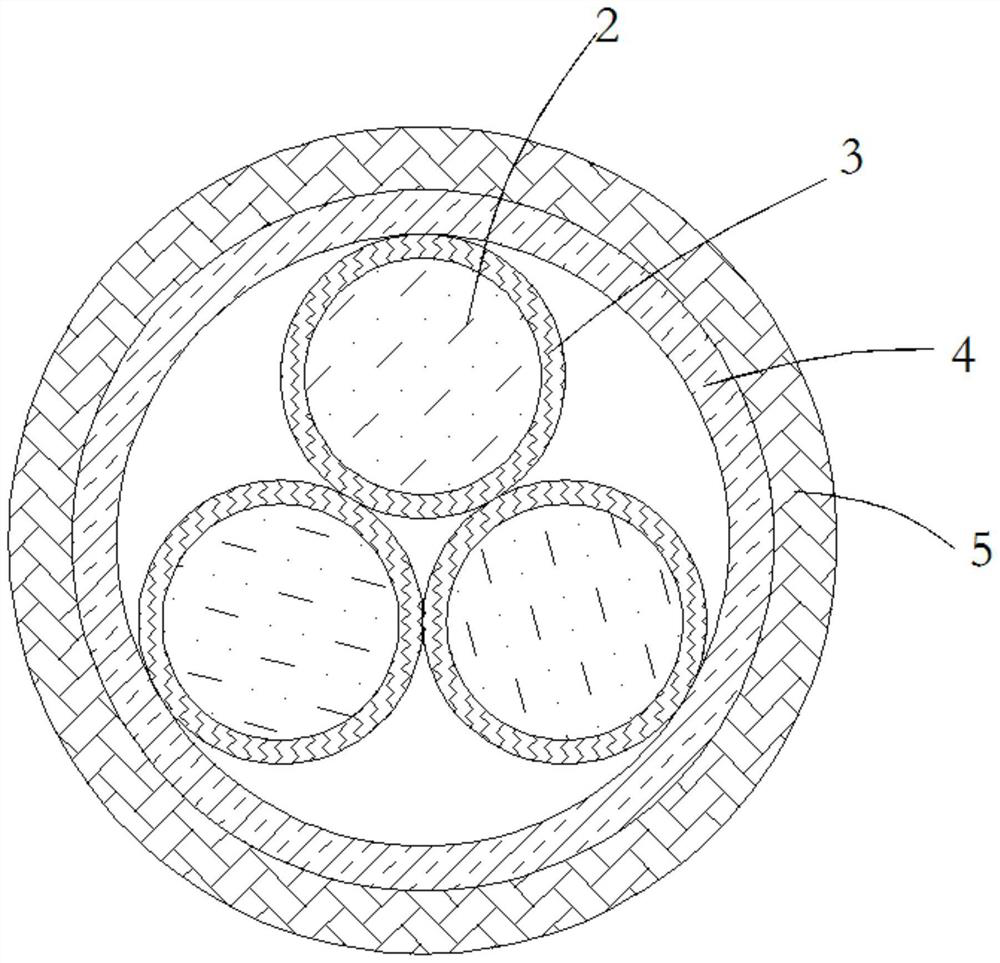

High-flame-retardant cable for oil platform

ActiveCN111540507AImprove flame retardant performanceIncrease ampacityCommunication cablesInsulated cablesThermodynamicsElectrical conductor

The invention relates to the technical field of cables, and discloses a high-flame-retardant petroleum platform cable. The cable comprises a cable body, and is characterized in that the cable body comprises conductors located in the middle, a wrapping layer is connected outside each conductor in a wrapping manner, an insulating layer is coated outside a plurality of conductors, and an outer sheathis coated outside the insulating layer. The high-flame-retardant cable for the oil platform has the advantages that the whole cable is environmentally friendly, high in flame retardance, high in mechanical performance, and resistant to mud, oil and cold.

Owner:ANHUI CABLE

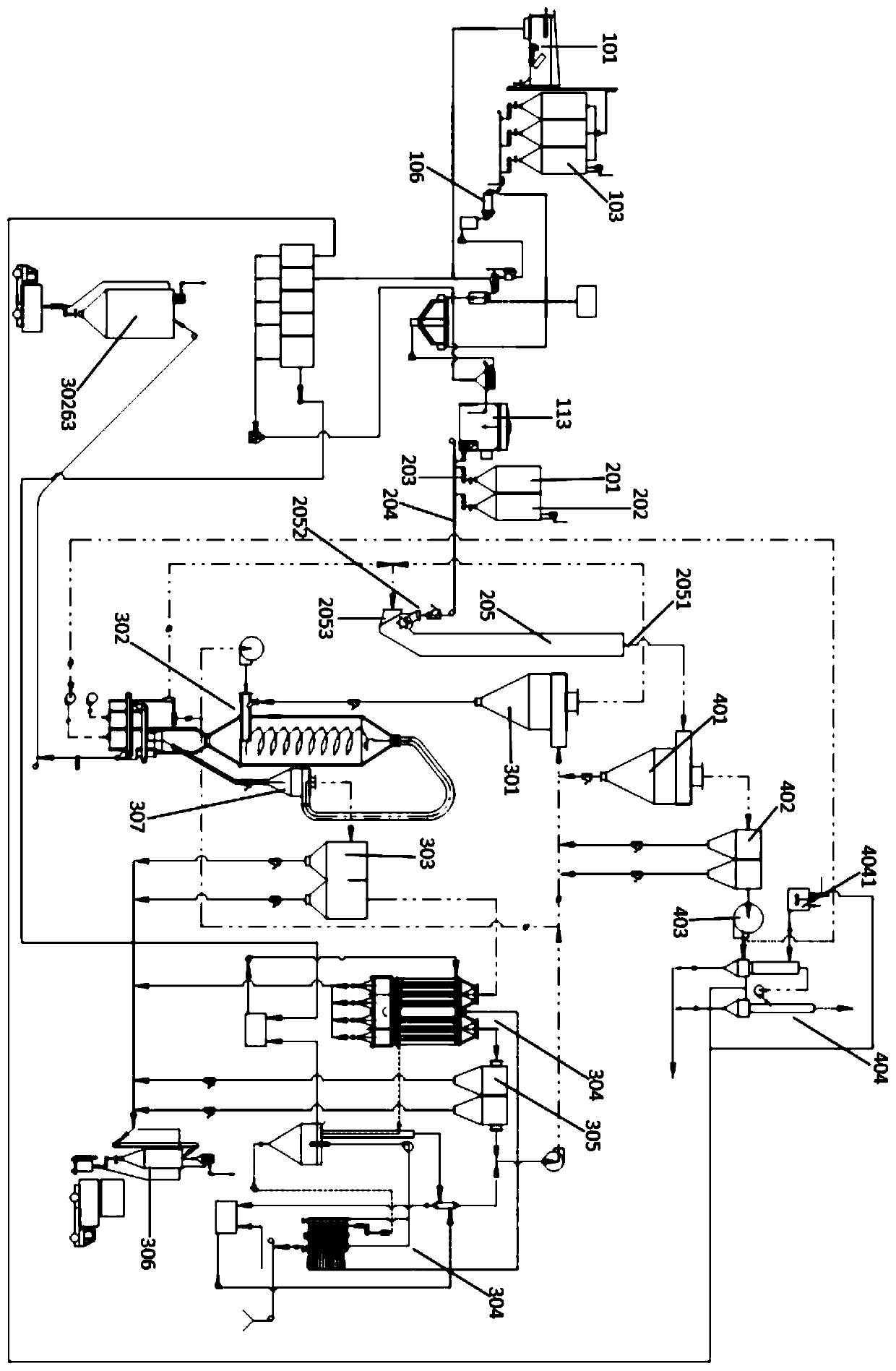

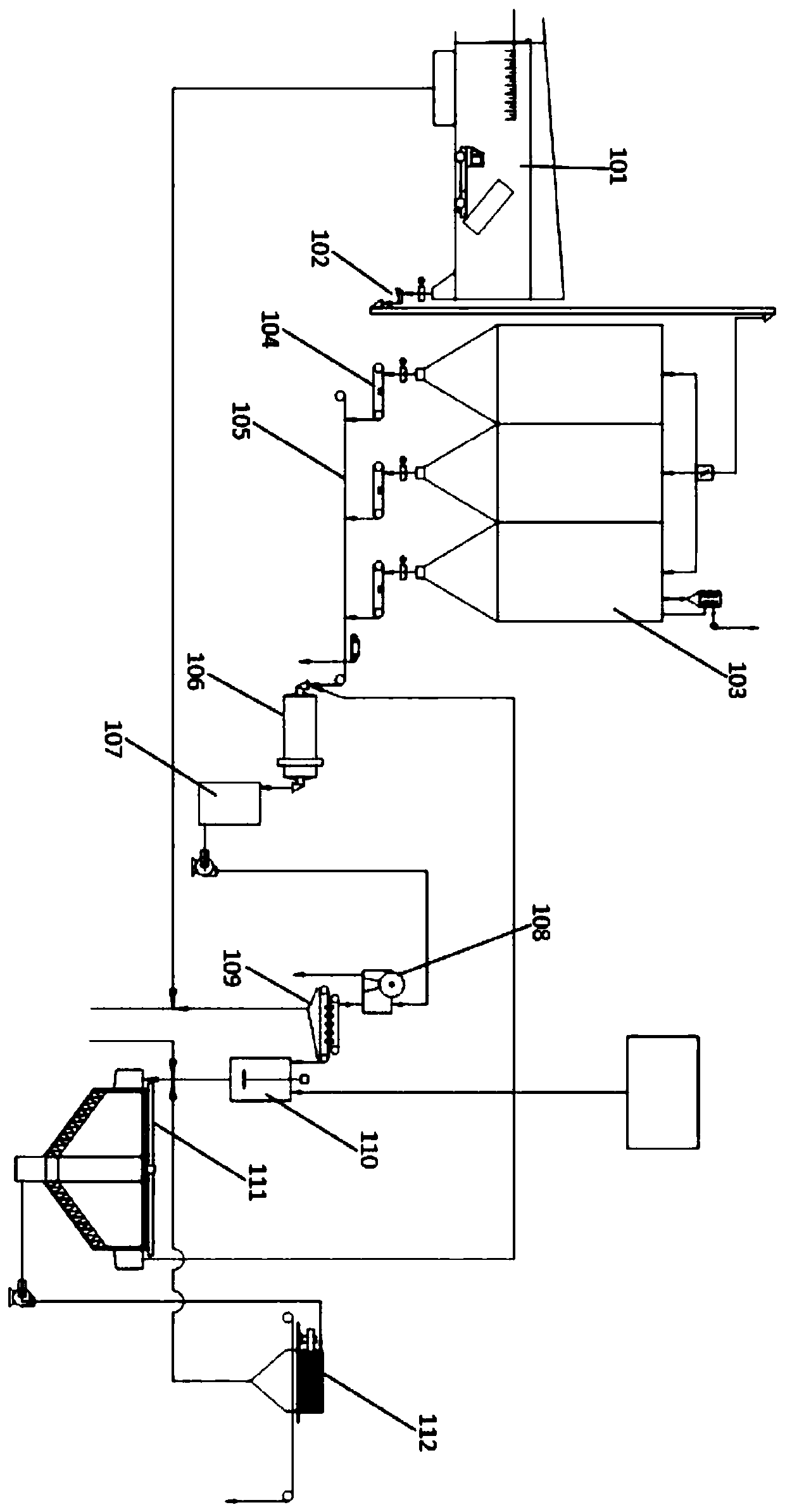

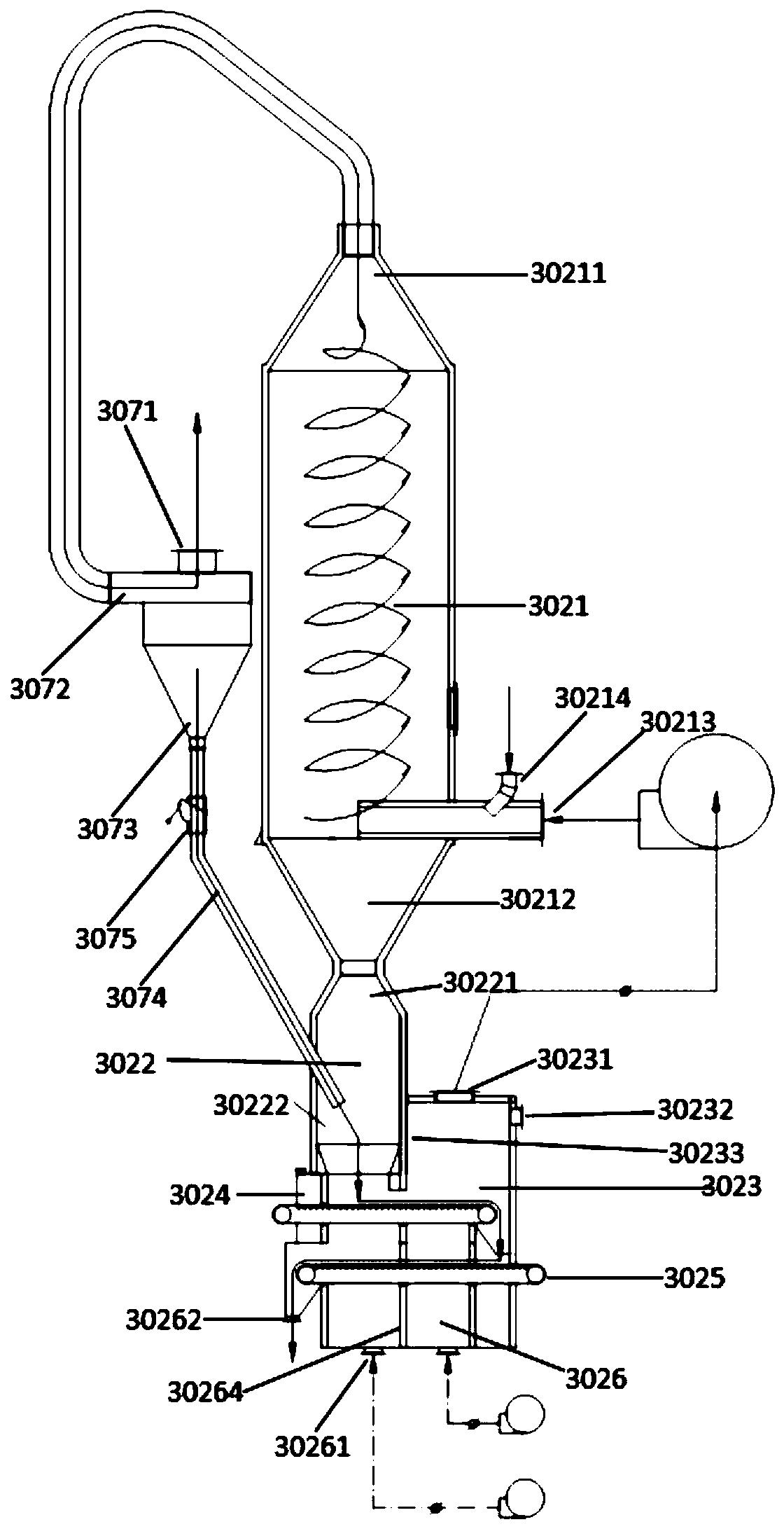

System and method for disposing dust collection ash of iron and steel plant through mesh belt type suspension combined reduction furnace

PendingCN111282961AEnsure complete combustionExtended burn timeCombination devicesTransportation and packagingThermodynamicsFlue gas

The invention discloses a system for disposing dust collection ash of an iron and steel plant through a mesh belt type suspension combined reduction furnace. The system comprises a washing dechlorination system, a drying dehydration system, a volatilization zinc extraction system and a flue gas treatment system, wherein the volatilization zinc extraction system comprises a cyclone preheater, the mesh belt type suspension combined reduction furnace, an oxidation chamber, a saline water evaporation and flue gas sedimentation system, a high-temperature electrostatic dust collector and an exhaustfan which are sequentially connected; the mesh belt type suspension combined reduction furnace is composed of a furnace body and a cyclone separator; and the furnace body comprises a rotational flow part, a boiling part, a cooling chamber, a sealing chamber, a high-temperature mesh belt machine and an inflation chamber from top to bottom. The mesh belt type suspension combined reduction furnace isused as main cremation refining equipment, and the equipment is simple and unique in structure, convenient to operate and low in manufacturing cost.

Owner:长沙中硅环保科技有限公司

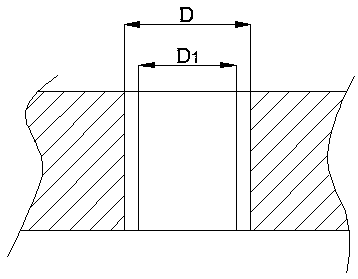

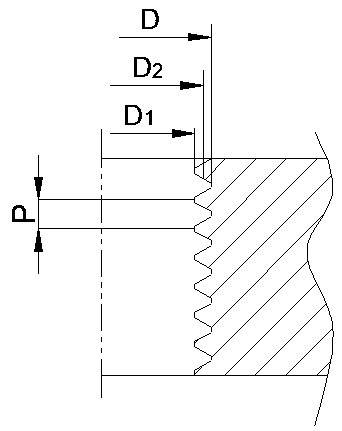

Tapping-free sintering process for internal thread of MIM product

The invention discloses a tapping-free sintering process for an internal thread of an MIM product. The process comprises the following steps (1) preparation of a POM screw mould core: calculating thedimension of the POM screw mould core according to dimension of the internal thread of the MIM product and shrinking percentage of a POM material and manufacturing the POM screw mould core according to corresponding dimension; (2) preparation of an MIM injection molding blank: first, injecting metal powder and a binder to a cavity filled with the POM screw mould core, and then heating and meltingthe POM screw mould core to prepare the MIM injection molding blank with an internal threaded hole; (3) degreasing: degreasing the MIM injection molding blank with the internal threaded hole by usinga catalytic degreasing technology; (4) degreasing the MIM injection molding blank with the internal threaded hole by adopting a vacuum sintering technology; and (5) carrying out inspection. The process not only can solve the problems that the tapping cost is high, the service life of a screw tap is short and tapping is forgotten as the hardness of the sintered product is high thoroughly, but alsocan improve the percent of pass of the product greatly. A reworking condition is avoided.

Owner:QUJING ZHONGMING TECH

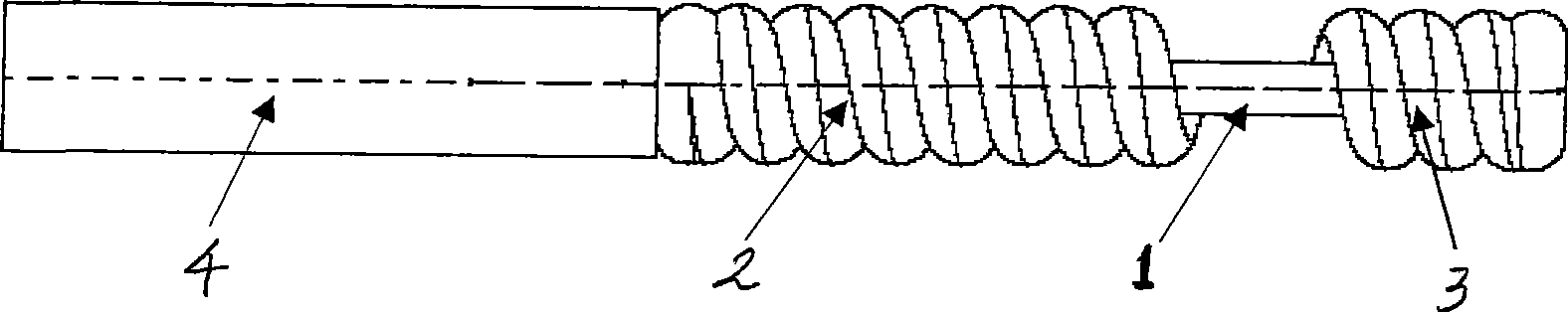

Ceramic metallic halogen lamp electrode

InactiveCN101425446AGuaranteed low current requirementsAvoid shockGas discharge lamp detailsNiobiumCeramic metal

The invention discloses a ceramic metal halogen lamp electrode which comprises a main rod made of thorium-tungsten alloy materials; a yttrium-molybdenum alloy-wire spiral body is wound on one end of the main rod, and a high-purity tungsten wire spiral body is wound on the other end of the main rod; and the main rod end part on which the yttrium-molybdenum alloy-wire spiral body is wound is connected with an outer-lead niobium rod. The invention is a high-effective and environment-friendly ceramic metal halogen lamp electrode and has the advantages of high efficiency, safety, environment protection, even electrode spring, and the like.

Owner:佛山宁宇科技股份有限公司

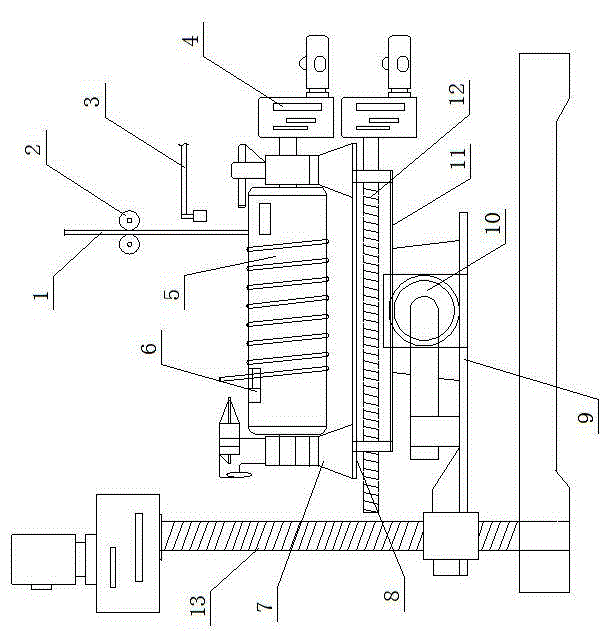

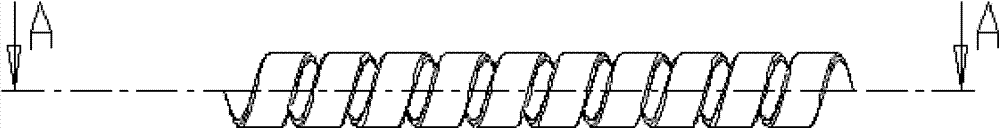

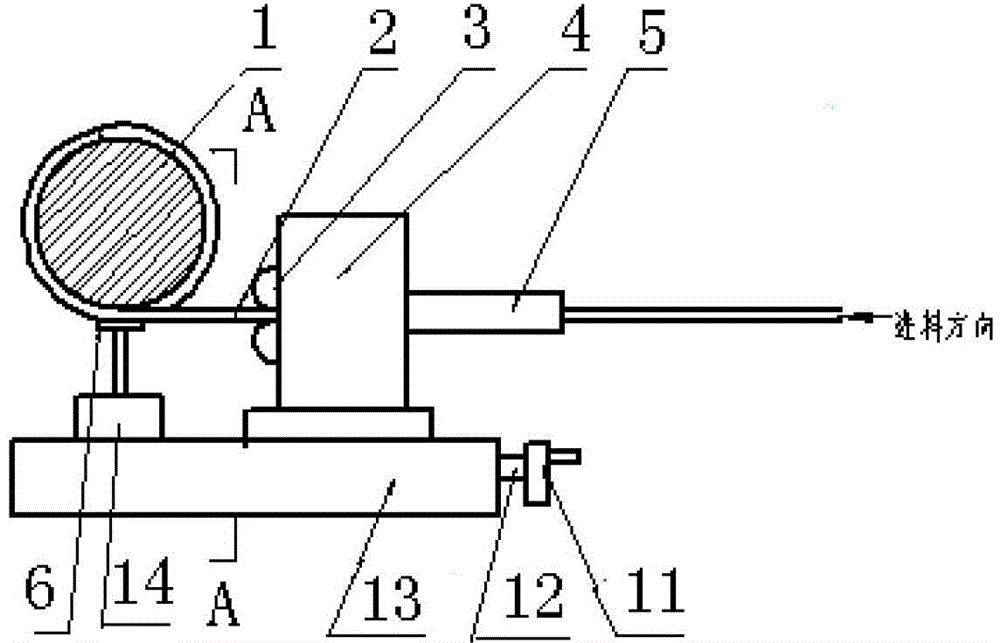

Device for directly drawing helical circular quartz tube by continuous-melt method and drawing method

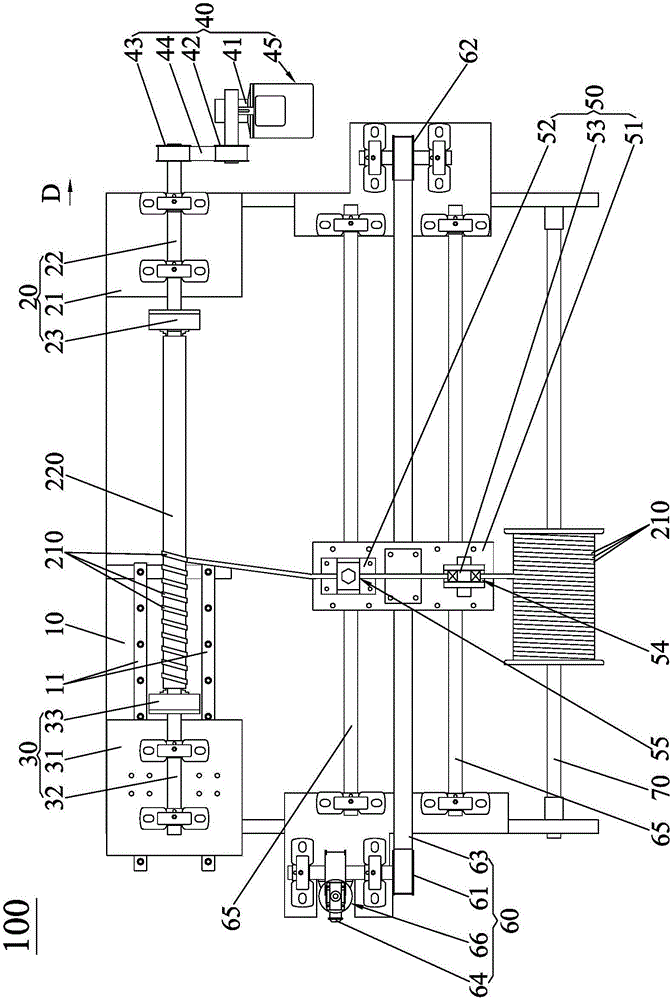

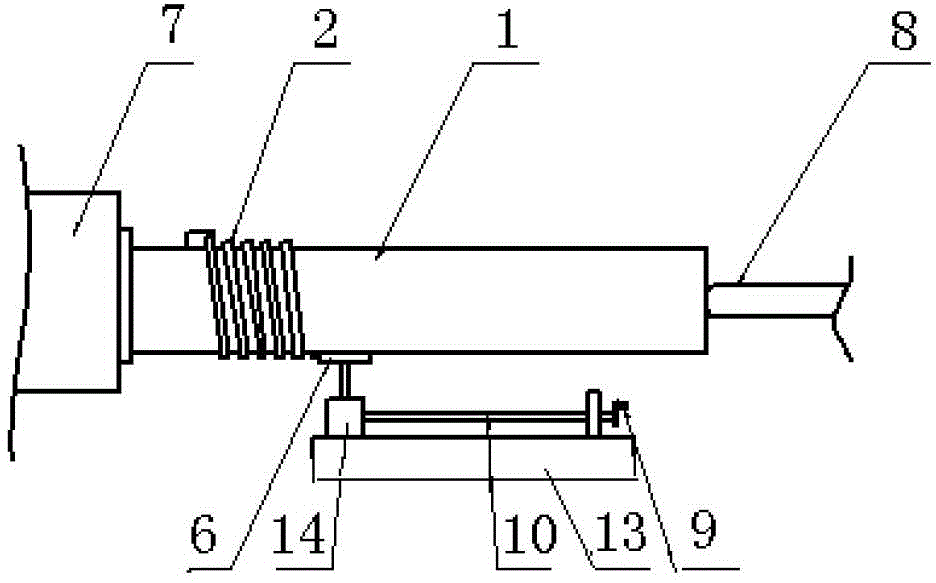

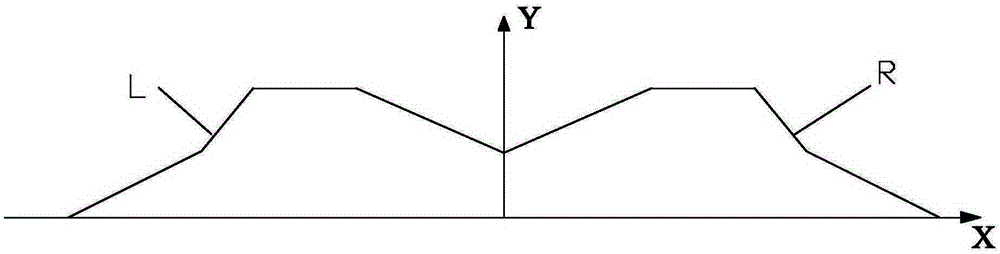

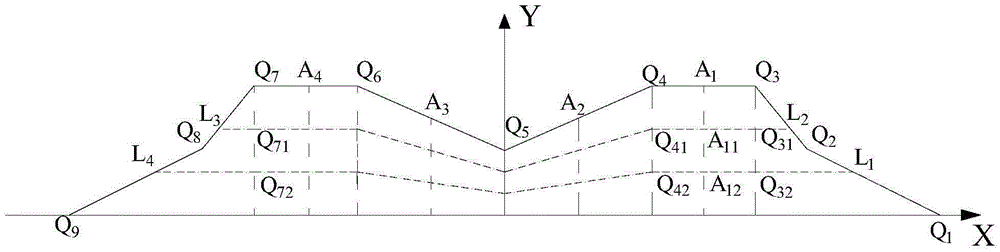

ActiveCN103204621AUniform pitchQuality improvementGlass forming apparatusGlass reforming apparatusWinding machineDrive motor

The invention discloses a device for directly drawing a helical circular quartz tube by a continuous-melt method and a method for drawing the helical circular quartz tube by the device. The device comprises a rotary winding which is arranged below a discharge hole of a continuous-melt furnace; the rotary winding machine is fixed on a support plate through a support frame; a left and right movement mechanism for driving the rotary winding machine to move left and right is arranged at the lower part of the support plate; a front and back movement mechanism is arranged at the lower part of the left and right movement mechanism; the lower end of the front and back movement mechanism is arranged on a lifting mechanism; the rotary winding machine comprises a rotary drum; the rotary drum is fixed on a rotating shaft; the rotating shaft is connected with a drive motor through a drive device; a quartz tube pressing tube is arranged on the rotary drum; a quartz tube descending tractor is arranged between a discharge hole of the continuous-melt furnace and the rotary winding machine; and a quartz tube cutter is arranged between the quartz tube descending tractor and the rotary winding machine. The helical circular quartz tube is formed by molding once; secondary processing is removed; an energy source is saved; time and labor are saved; and the helical circular quartz tube is even in screw pitch and stable in quality.

Owner:LIANYUNGANG HUAYUAN QUARTZ PROD

Method and device for producing copper belt

The invention discloses a method for producing a copper belt and a device thereof, the method adopts the continuous up-casting process for producing the copper belt, meanwhile, a backtrack vibrating process is added to the copper belt, the backtrack vibrating process can lead the incompletely solidified copper belt to vibrate up and down and become dense in a crystallizer, thus the density of the copper belt is increased. The production method adds the backtrack vibrating process in the existing continuous up-casting process, when the up-casting process is used for producing copper belts, the density of the copper belt is increased, the problems of air holes and uneven density are eliminated; the production method can save labor hour and abundant energy, and improve quality of the copper belt. The backtrack vibrating process is completed by a servo motor which has the advantages of small volume, light weight, high power output and torque, convenient speed regulation, and the like, thus accurately controlling the rotating range of a traction shaft and increasing pulling speed.

Owner:浙江郎立电工器材有限公司

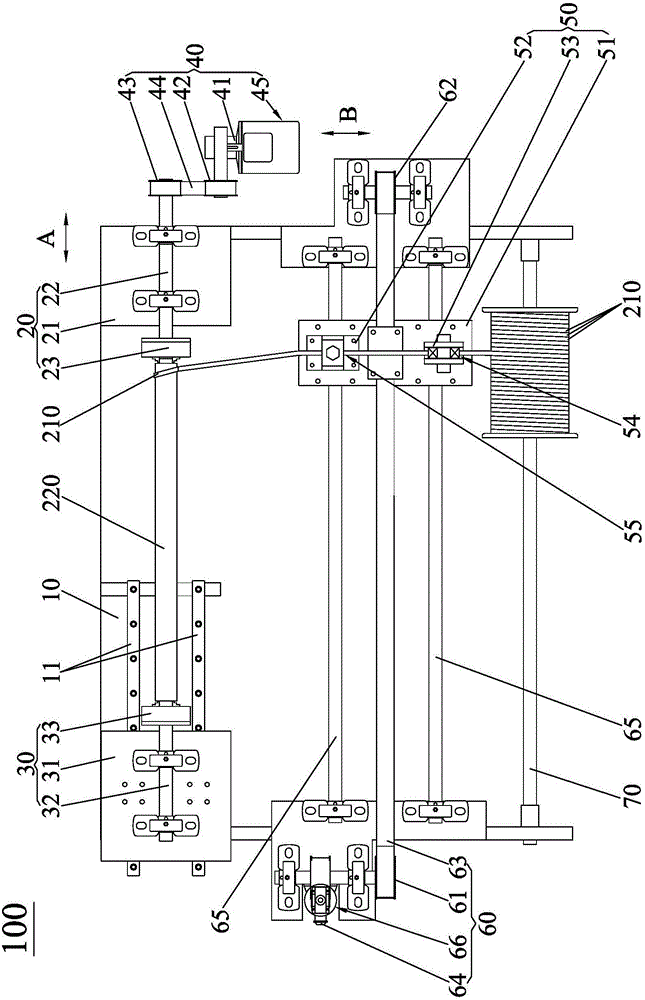

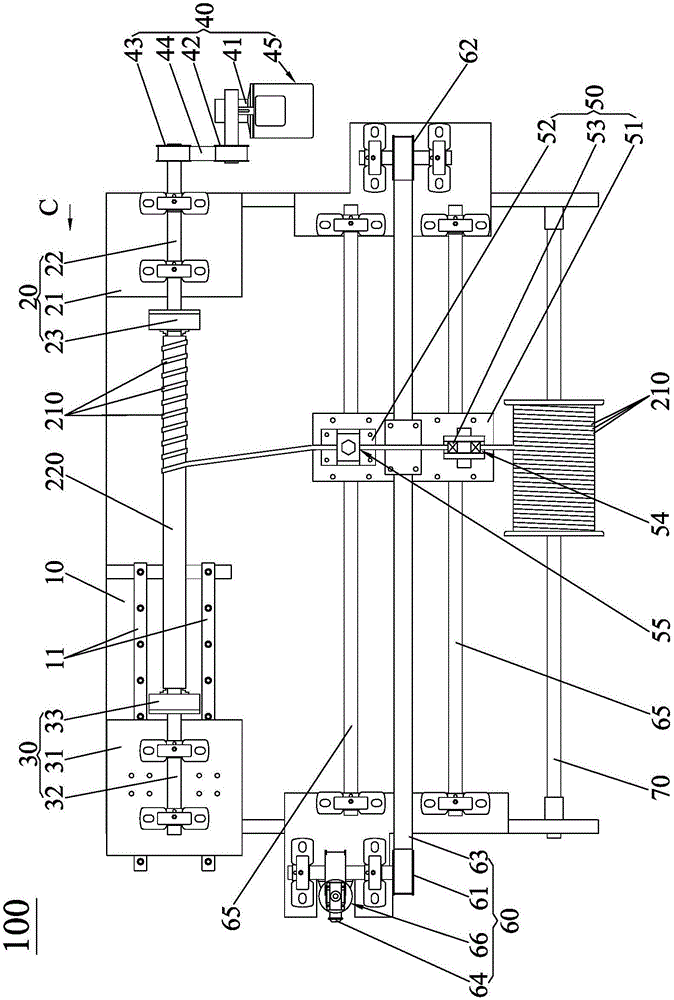

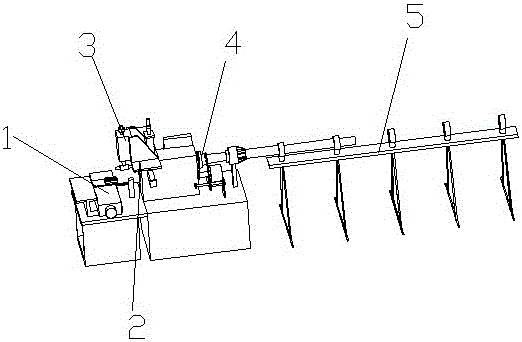

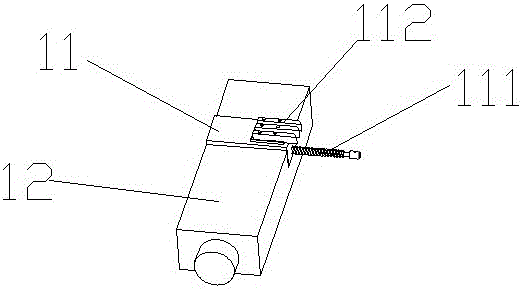

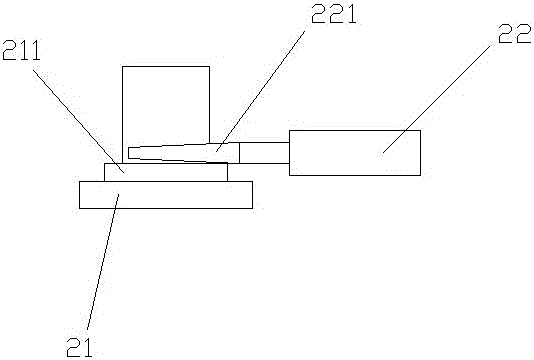

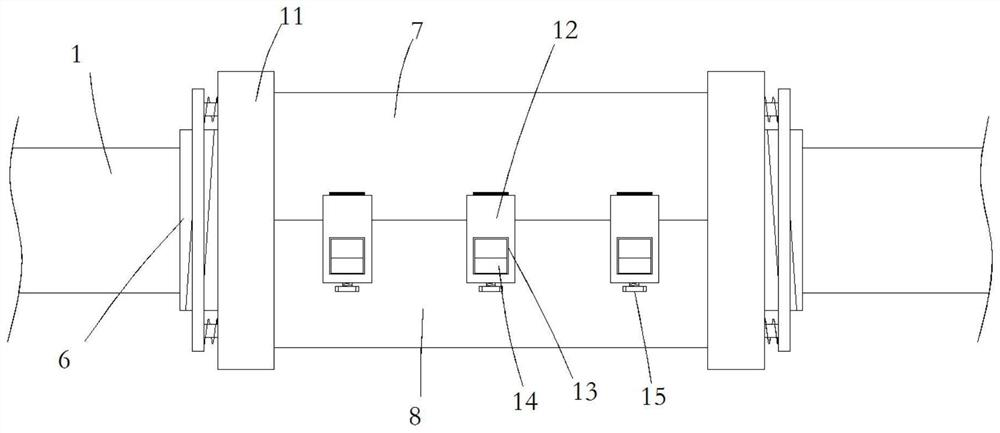

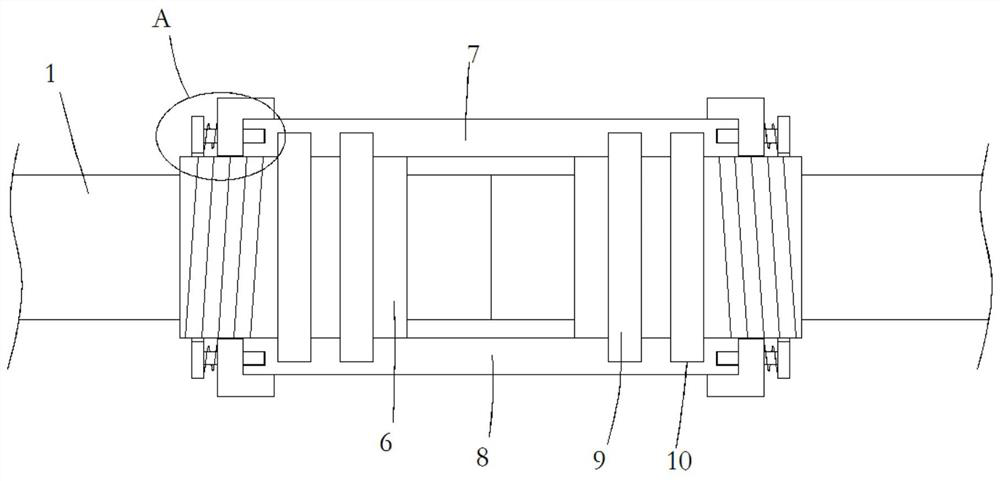

Winding device for tempered transmission rollers

InactiveCN106829625AReduce the burden onUniform pitchFilament handlingEngineeringMechanical engineering

The invention discloses a winding device for tempered transmission rollers. The winding device comprises a framework, a rope guide, a first clamping mechanism, a second clamping mechanism, a first driving mechanism and a second driving mechanism. The first clamping mechanism is arranged at one longitudinal end of the framework, and one end of each tempered transmission roller is clamped by the first clamping mechanism; the second clamping mechanism is arranged at the other longitudinal end of the framework, the other end of each tempered transmission roller is clamped by the second clamping mechanism, and the tempered transmission rollers can rotate relative to the framework under the condition that the tempered transmission rollers are clamped by the first clamping mechanism and the second clamping mechanism; the tempered transmission rollers can be driven by the first driving mechanism to rotate; the rope guide is slidably arranged on the framework along the longitudinal direction of the framework, and starting ends of tempered auxiliary ropes penetrate the rope guide and then are fixed onto the tempered transmission rollers; the second driving mechanism is arranged on the framework, and the rope guide can be driven by the second driving mechanism to slide in a reciprocating manner. The winding device has the advantage that the tempered auxiliary ropes led out of the rope guide can be wound on the tempered transmission rollers along the axial arrangement of the tempered transmission rollers in a thread pitch manner under the matching effects of the first driving mechanism and the second driving mechanism and accordingly can be uniformly and reliably wound on the tempered transmission rollers.

Owner:东莞南玻工程玻璃有限公司 +1

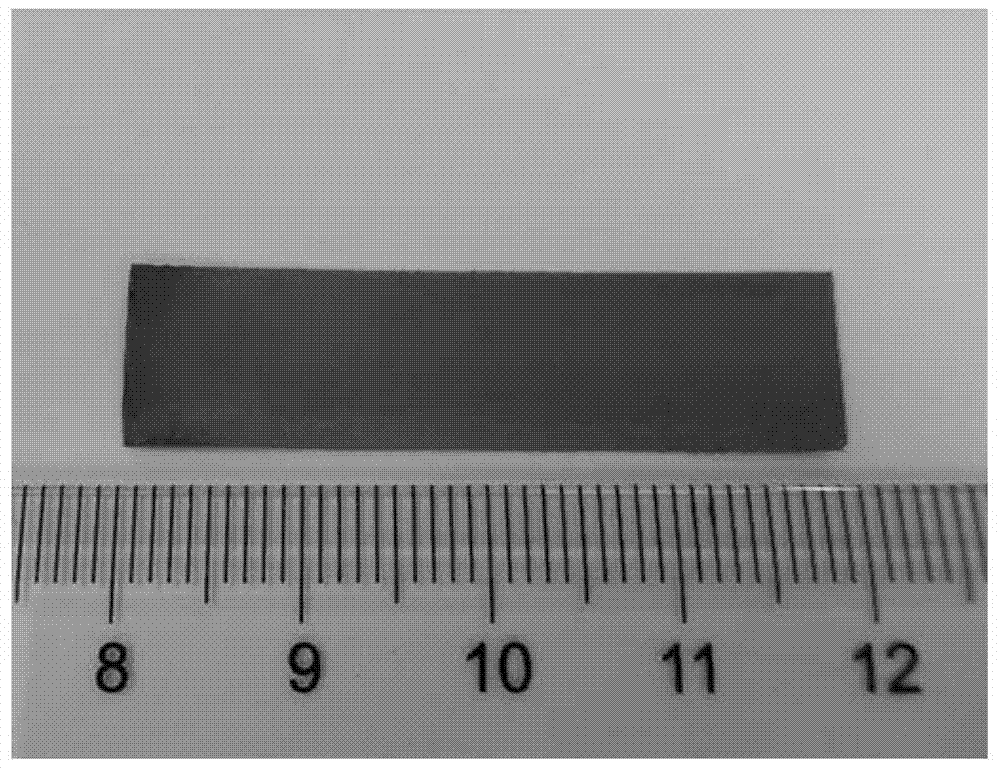

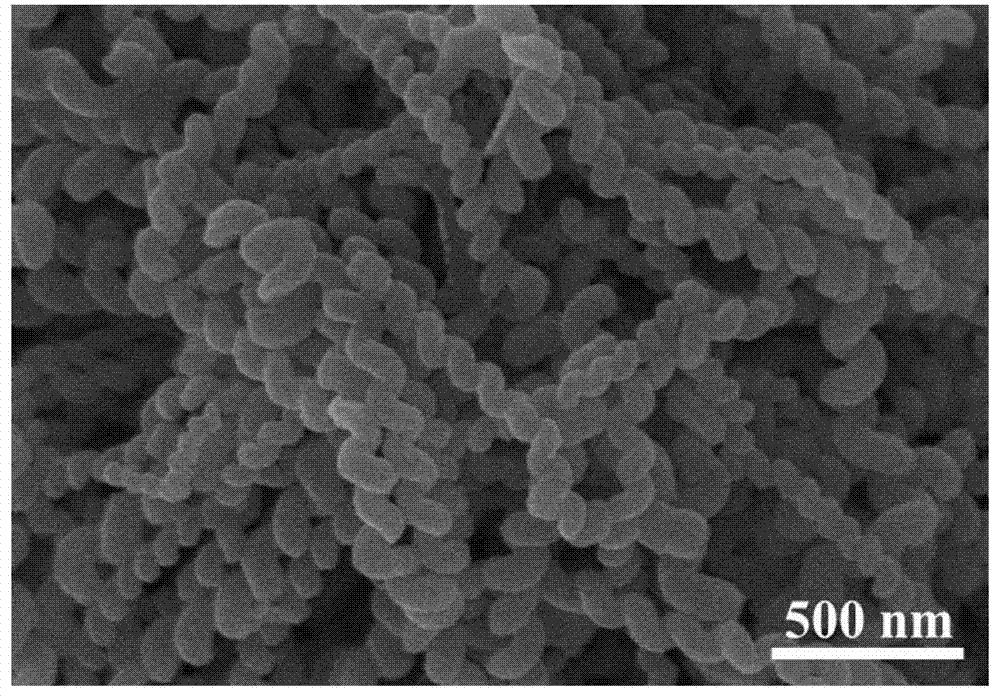

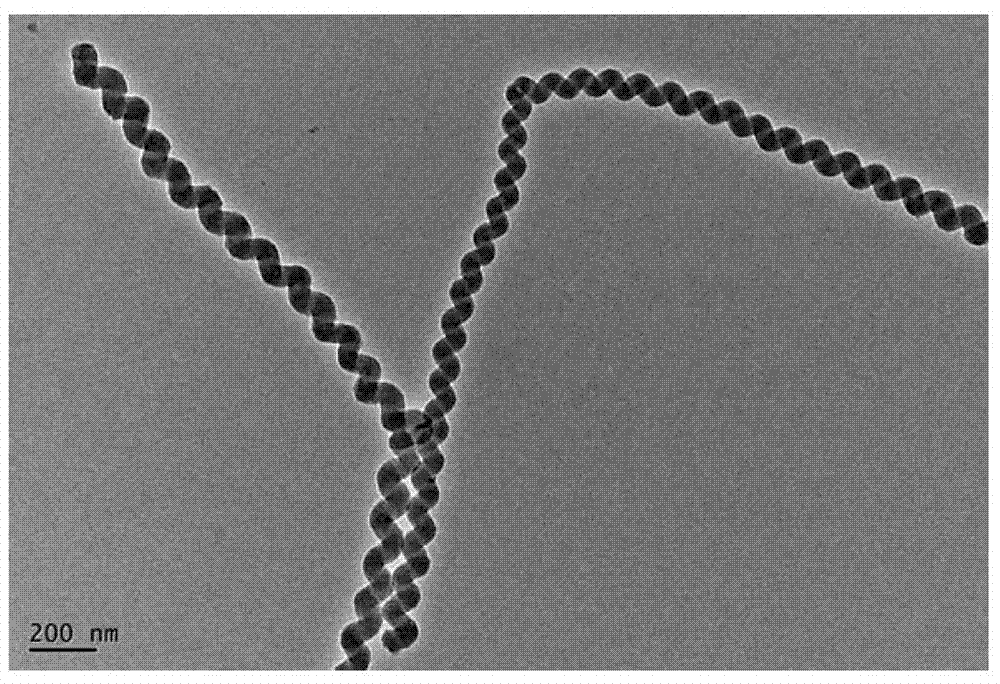

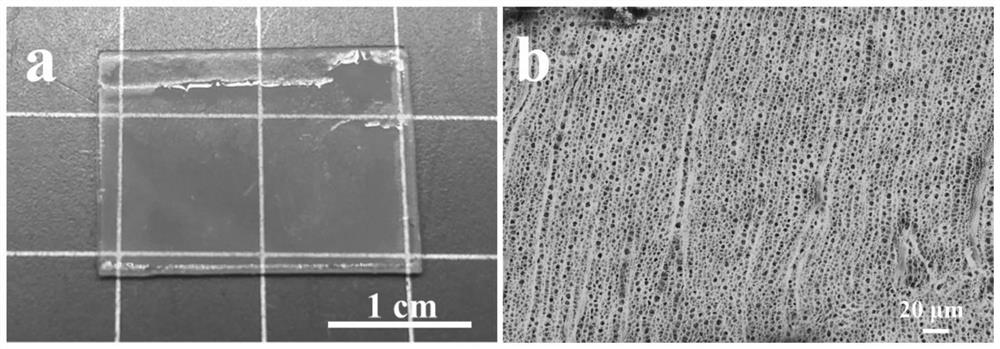

Chiral poly alkyne nano-fiber preparation method

ActiveCN107488243ARaw materials are cheap and easy to getGreat industrial production valueMaterial nanotechnologyMonocomponent synthetic polymer artificial filamentFiberRoom temperature

The invention relates to a chiral poly alkyne nano-fiber preparation method, which comprises: adding an alkyne monomer solution into a hydrothermal kettle liner with a catalyst in a dropwise manner until the catalyst is completely immersed by the alkyne monomer solution; and adding a structure inducing agent into the hydrothermal kettle liner, standing for a certain time at a room temperature, carrying out a hydrothermal reaction at a temperature of 50-250 DEG C, cooling, and washing to obtain the chiral poly alkyne nano-fiber. According to the present invention, the chiral poly alkyne nano-fiber is prepared by using the novel homogeneous hydrothermal method, such that the method has advantages of simpleness, economy, cheap and easily available raw materials, no requirement of special equipment, and great industrialized production value.

Owner:中科西卡思(苏州)科技发展有限公司

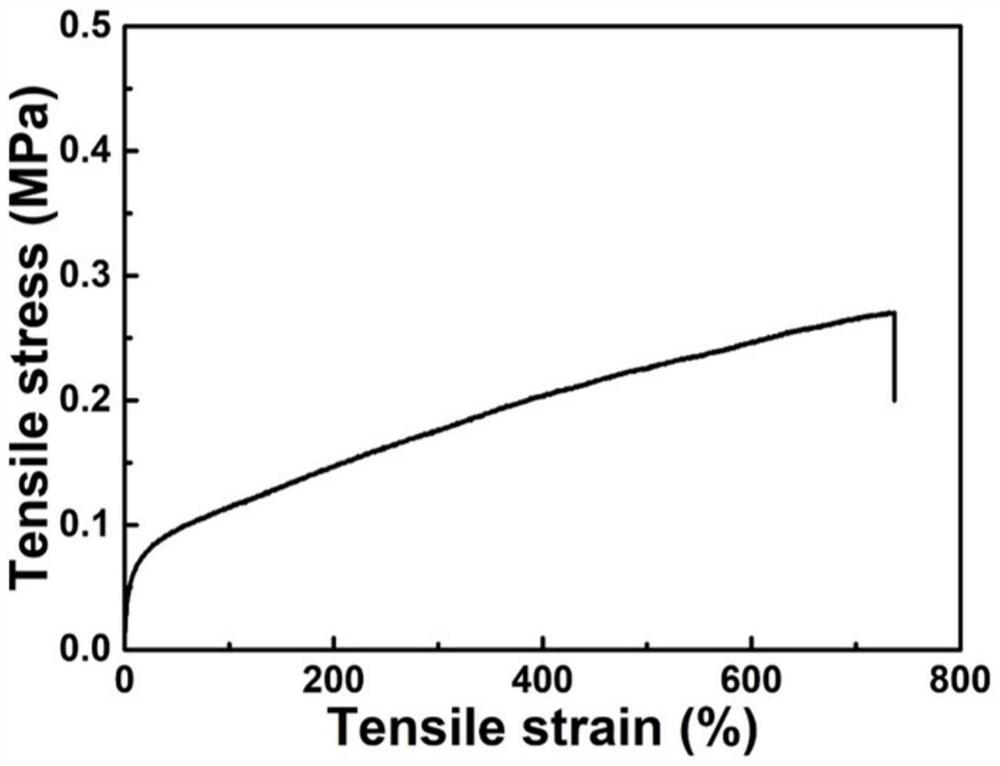

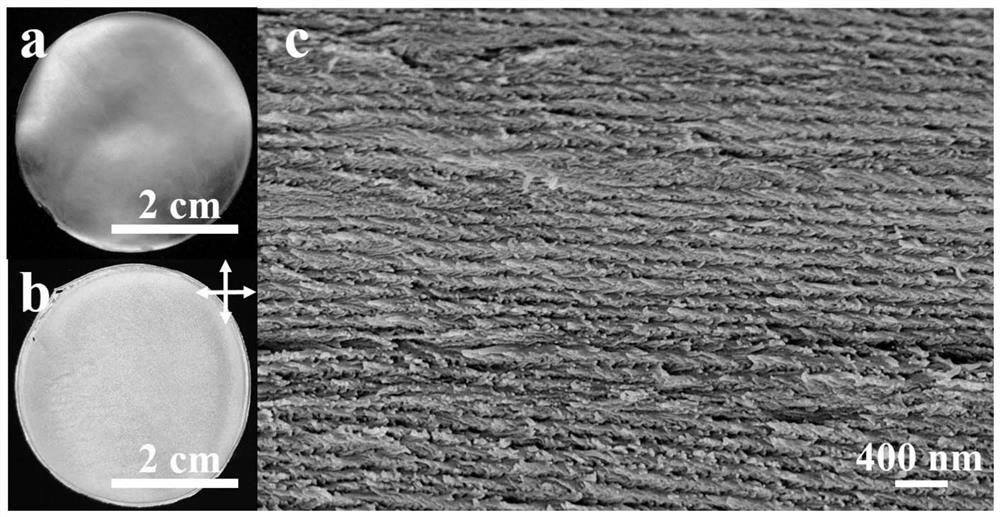

Stress response type optical hydrogel as well as preparation method and application thereof

The invention relates to stress response type optical hydrogel as well as a preparation method and an application thereof. The hydrogel is obtained by swelling a chiral cellulose nanocrystal film obtained by suction filtration of a cellulose nanocrystal suspension with a precursor solution containing acrylamide and acrylic acid and then carrying out ultraviolet polymerization compounding. The stress response type optical hydrogel provided by the invention takes the natural polymer cellulose nanocrystal as a color developing component, the raw materials can be recycled and regenerated, the biodegradability is good, the hydrogel has good tensile property and uniform color development, and the stress response type optical hydrogel has good stress sensing performance and information storage and display functions; and the screw pitch of the chiral cellulose nanocrystalline film can be adjusted by adjusting preparation process conditions, so that the mechanical response range and the color development degree of the optical hydrogel are controlled.

Owner:WUHAN UNIV

Mineral high-strength compact chain production technology

The invention relates to a mineral high-strength compact chain production technology. The mineral high-strength compact chain production technology comprises the following steps of 1, vertical ring blanking; 2, vertical ring heating; 3, vertical ring single ring weaving; 4, vertical ring welding; 5, vertical ring burr removing; 6, vertical ring extrusion forming; 7, flat ring blanking; 8, flat ring heating; 9, chain weaving; 10, flat ring welding; 11, flat ring burr removing; 12, heat treatment; and 13, stretching. In the process of chain weaving, each vertical ring is sleeved with one flat ring to form a compact chain with the flat rings serving as circular rings and the vertical rings serving as compact rings. Generally, the mineral high-strength compact chain production technology has the advantages of being simple, excellent in mechanical property and high in material utilizing rate.

Owner:鹤壁链条有限责任公司

Device for directly drawing helical circular quartz tube by continuous-melt method and drawing method

ActiveCN103204621BUniform pitchQuality improvementGlass forming apparatusGlass reforming apparatusQuartzRotating drum

Disclosed are an apparatus for directly drawing a helical annular quartz tube using a continuous smelting method and a method for drawing a helical annular quartz tube using the apparatus. The apparatus comprises a rotating coiler arranged below a material outlet of a continuous smelting furnace, wherein the rotating coiler is fixed onto a support plate via a support frame, a lower part of the support plate is provided with a left / right moving mechanism driving the rotating coiler to move to the left and right, a lower part of the left / right moving mechanism is provided with a front / rear moving mechanism, and a lower end of the front / rear moving mechanism is arranged on a lifting mechanism. The rotating coiler comprises a rotating drum, wherein the rotating drum is fixed on a rotary shaft, the rotary shaft is connected to a driving electric motor via a transmission, and a quartz tube pressing plate is provided on the rotating drum. A quartz tube descent traction machine is provided between the material outlet of the continuous smelting furnace and the rotating coiler, and a quartz tube cutter is provided between the quartz tube descent traction machine and the rotating coiler.

Owner:LIANYUNGANG HUAYUAN QUARTZ PROD

Low-smoke zero-halogen flame-retardant photovoltaic cable and manufacture method thereof

InactiveCN103337283AIncrease lossIncreased risk of short circuitInsulated cablesPower cablesInsulation layerUltraviolet

The invention provides a low-smoke zero-halogen flame-retardant photovoltaic cable which comprises a conductive wire core, insulating layers, an insulation layer, and a sheathing layer, wherein the conductive wire core is formed by twisting a plurality of tinned copper monofilaments; the insulating layers made of low-smoke zero-halogen flame-retardant glass fabric are wrapped on the conductive wire core in an overlapped manner; the insulation layer is extruded outside the insulating layers; the sheathing layer is extruded outside the insulation layer. The invention further provides a manufacture method of the low-smoke zero-halogen flame-retardant photovoltaic cable. The low-smoke zero-halogen flame-retardant photovoltaic cable and the manufacture method thereof have the advantages of scientific design, environmental protection, zero contamination, and wind, rain, ultraviolet and ozone corrosion resistance, and can bear temperature variation in a larger range.

Owner:HENAN KAIQI POWER IND

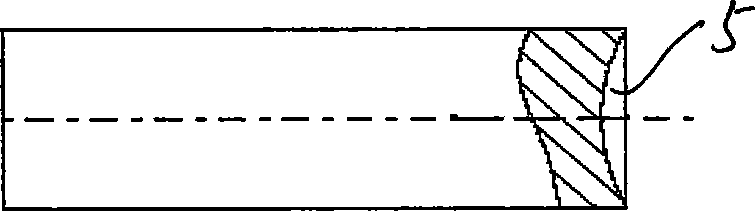

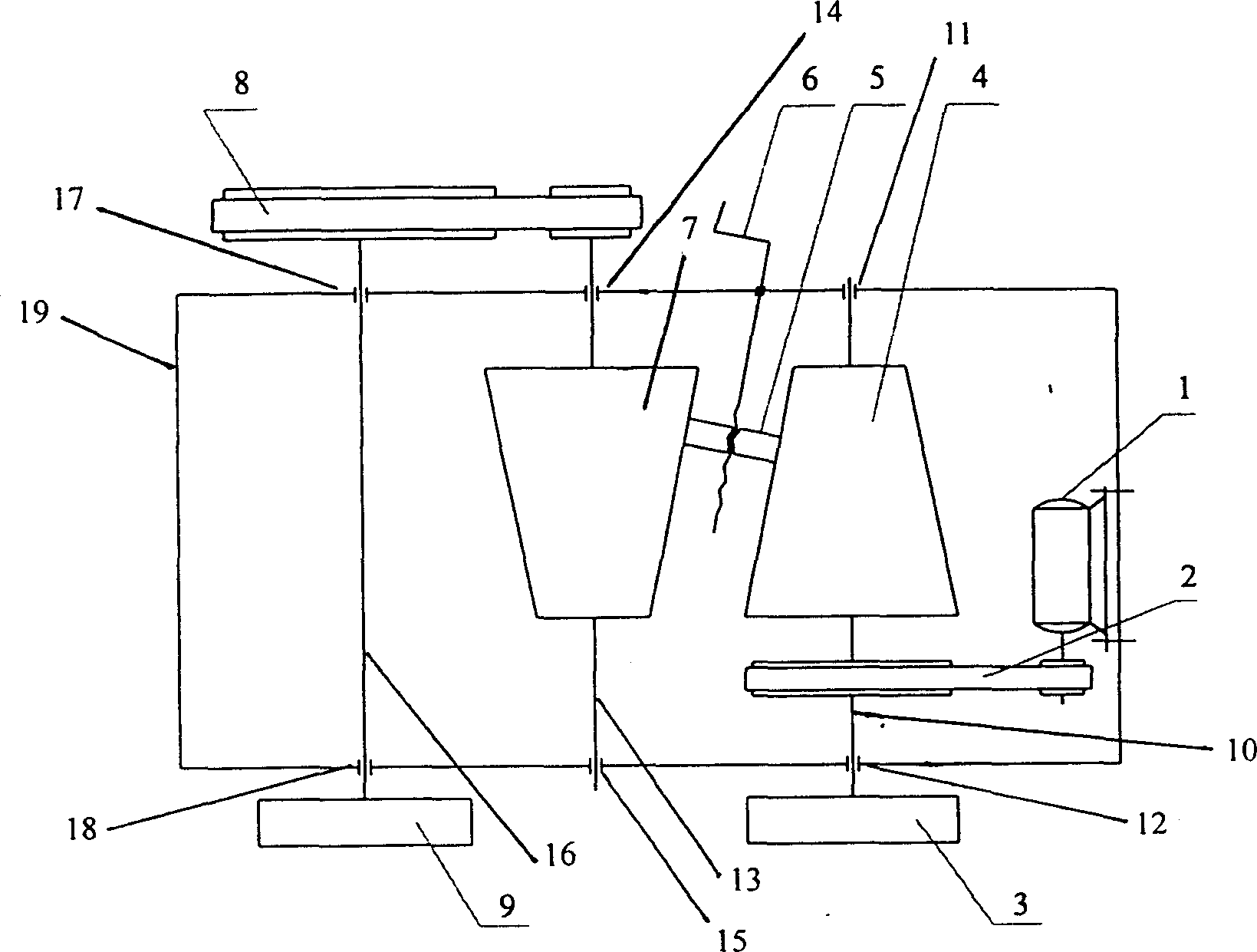

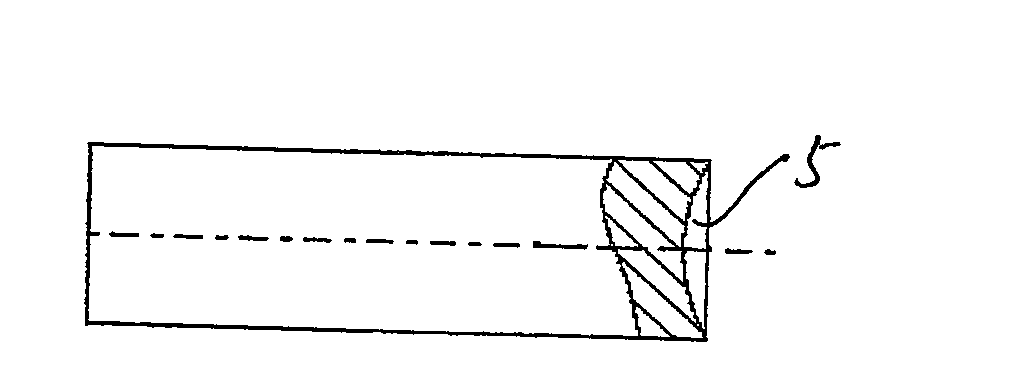

An all-in-one machine for processing parts with internal threads

InactiveCN103934516BFast processingRich choiceThread cutting machinesMechanical engineeringWell control

The invention relates to the technical field of machines, in particular to an all-in-one machine for machining components with internal threads. The an all-in-one machine comprises a rack, wherein the rack comprises a cutting mechanism, a clamping mechanism, a measuring and positioning mechanism and a rotating mechanism, the measuring and positioning mechanism is arranged above the clamping mechanism, and the rotating mechanism is arranged in front of the clamping mechanism. Due to the fact that the all-in-one machine is provided with the cutting mechanism, the clamping mechanism, the measuring and positioning mechanism and the rotating mechanism, pipes can be accurately and rapidly machined, a cutting component comprises a transversely-adjustable workbench and a longitudinally-adjustable workbench so that a tool can reach the required position on the same horizontal plane, three longitudinal tool installation positions are arranged on a tool installation frame so that the tool can have more choices, and efficiency is improved. Due to the fact that the all-in-one machine is further provided with a speed measuring component, when the internal threads are machined, the rotating speed can be well controlled, and thread pitches of the machined internal threads can be uniform.

Owner:吕江源

Manufacturing method of sprockets of alloy zipper

The invention provides a manufacturing method of the sprockets of an alloy zipper, in particular to a manufacturing method of the sprockets of an alloy zipper, which forms the sprockets by a pouring mode, fixes the sprockets on a fabric tape of the zipper and then plates the sprockets. The invention can ensure the problem of the rate of finished products with a certain height. The manufacturing method comprises the following steps of: weaving the fabric tape of the zipper and a static wire; pouring the sprockets; separating the sprockets from a sprue and a pouring gate; and electroplating thesprockets. The invention has the following advantages that: (1) because of adopting a pouring die for forming, the surfaces of the sprockets formed in the pouring die are also smooth and round; (2) when the sprockets are formed, the sprockets are fixedly connected with the fabric tape of the zipper into a whole, the combination is firm and reliable, and the condition that the phenomenon of sprocket fall can not occur is ensured; (3) the rate of finished products is ensured; (4) the accurate positioning of the sprockets and the static wire is ensured, the stability of the point connection between tens of respectively independent sprockets during electroplating is ensured, the success rate of electroplating is ensured, and the fraction defective of the electroplating is greatly lowered; and(5) the appearance is bright, attractive and smooth, the smoothness during pull and combination is increased, and the service life of the alloy zipper is prolonged.

Owner:施天程

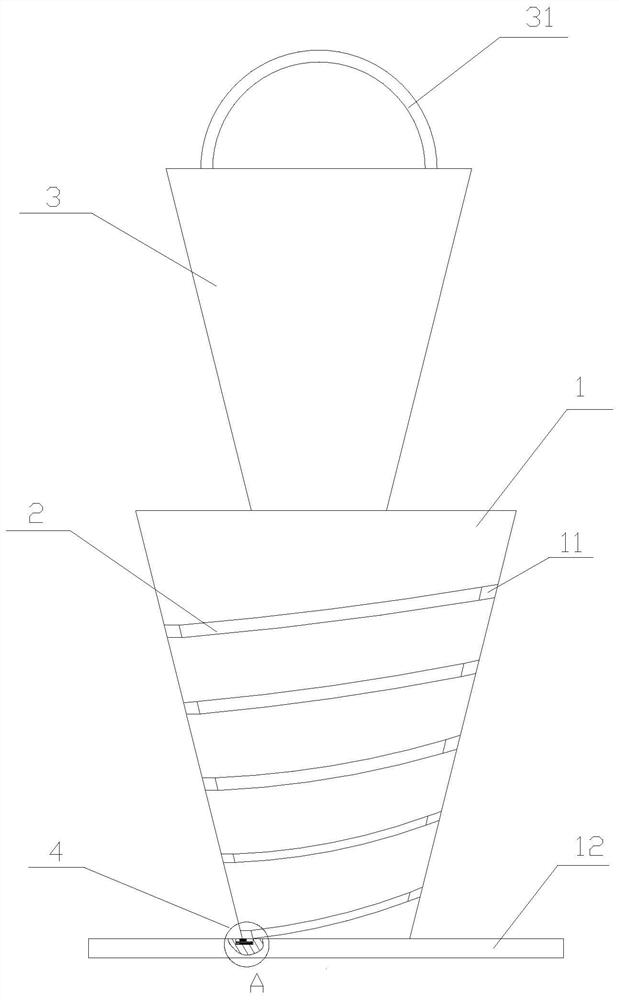

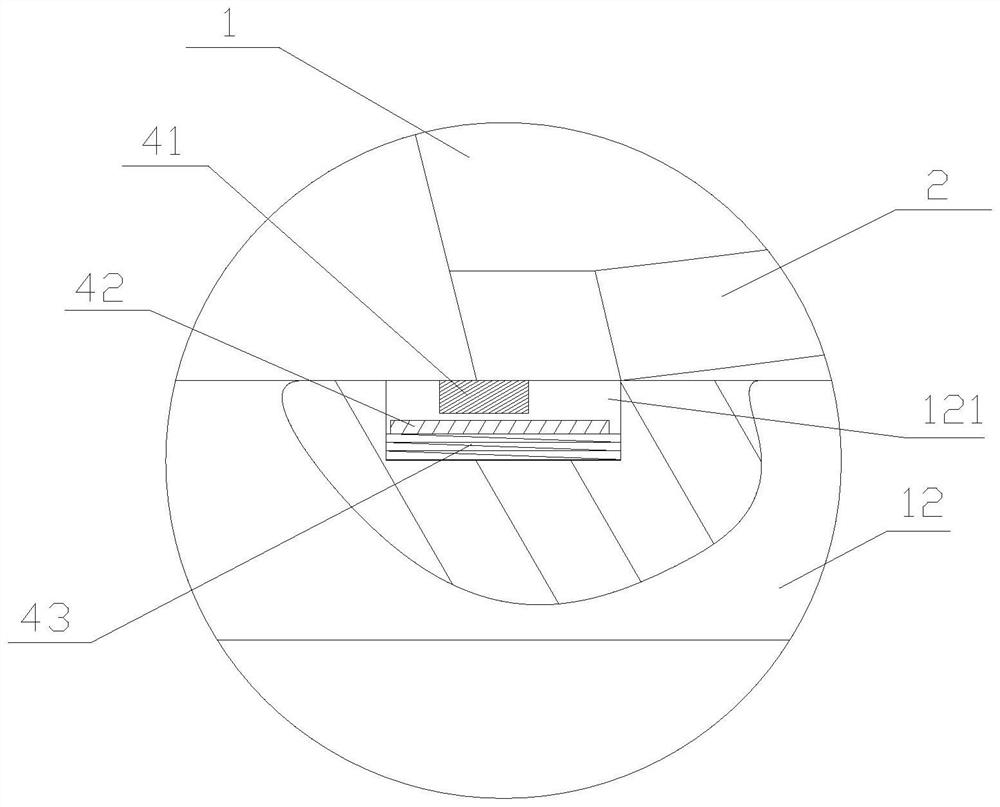

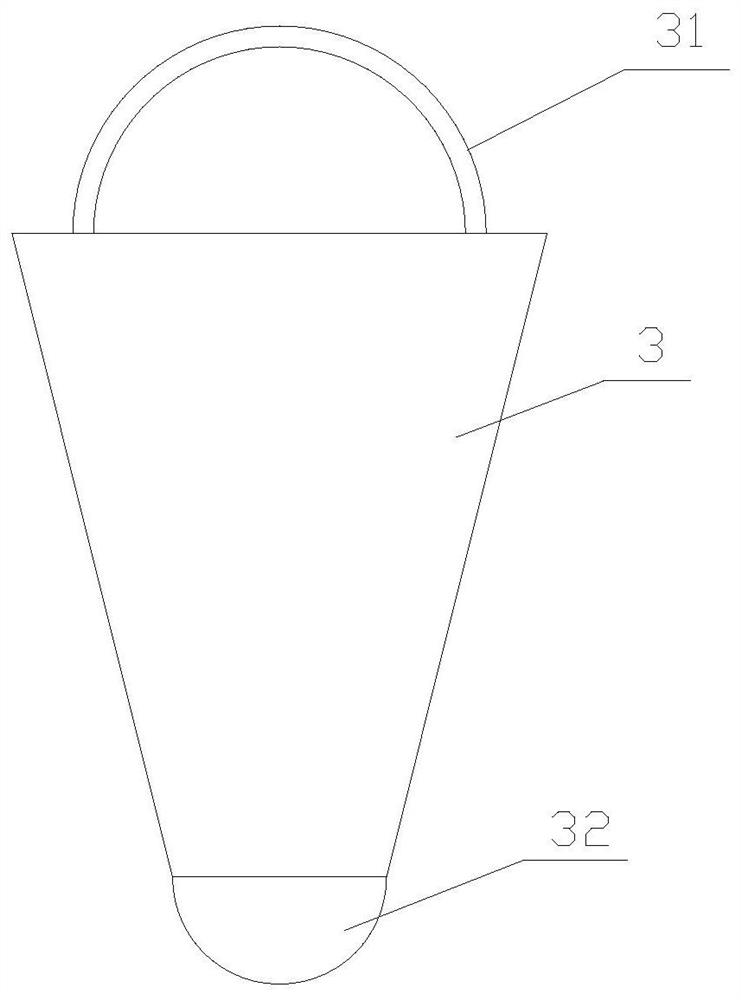

IC card annular coil winder

PendingCN112820534AReduce wasteWind evenlyInductances/transformers/magnets manufactureToroidal coilWire wrap

The invention provides an IC card annular coil winder which comprises a conical winding body, a tip cone used in cooperation with the winding body and a spiral column installed on the winding body, the interior and the exterior of the winding body are both of a conical structure, and a tip cone hole used for allowing the tip cone to be inserted is formed in the center line of the winding body. A spiral hole of a spiral structure is formed in the winding body, the screw pitch of the spiral hole is the same as that of the spiral column, the winding body, the spiral column and the tip cone are detachably installed, a take-up plate used for wire unwinding is installed at the bottom of the winding body, and elastic contraction gaskets are installed at the joint position of a stepped hole of the spiral hole. Opposite surfaces of the contraction gaskets are respectively connected with the spiral hole and the spiral column; according to the invention, the production process and the production precision are improved, the precise and fine copper ring is more stably used in the IC card chip, the design precision is improved, the material waste is reduced, the service life of the product is prolonged, and the quality of precise production is improved.

Owner:安徽新兆科技有限公司

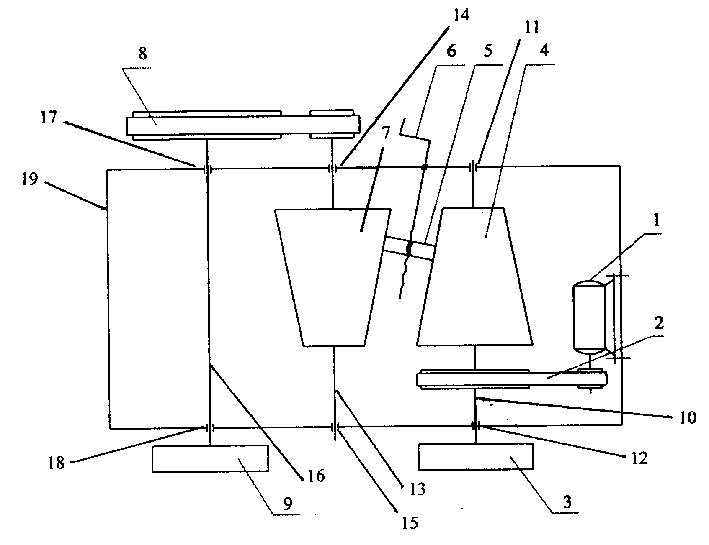

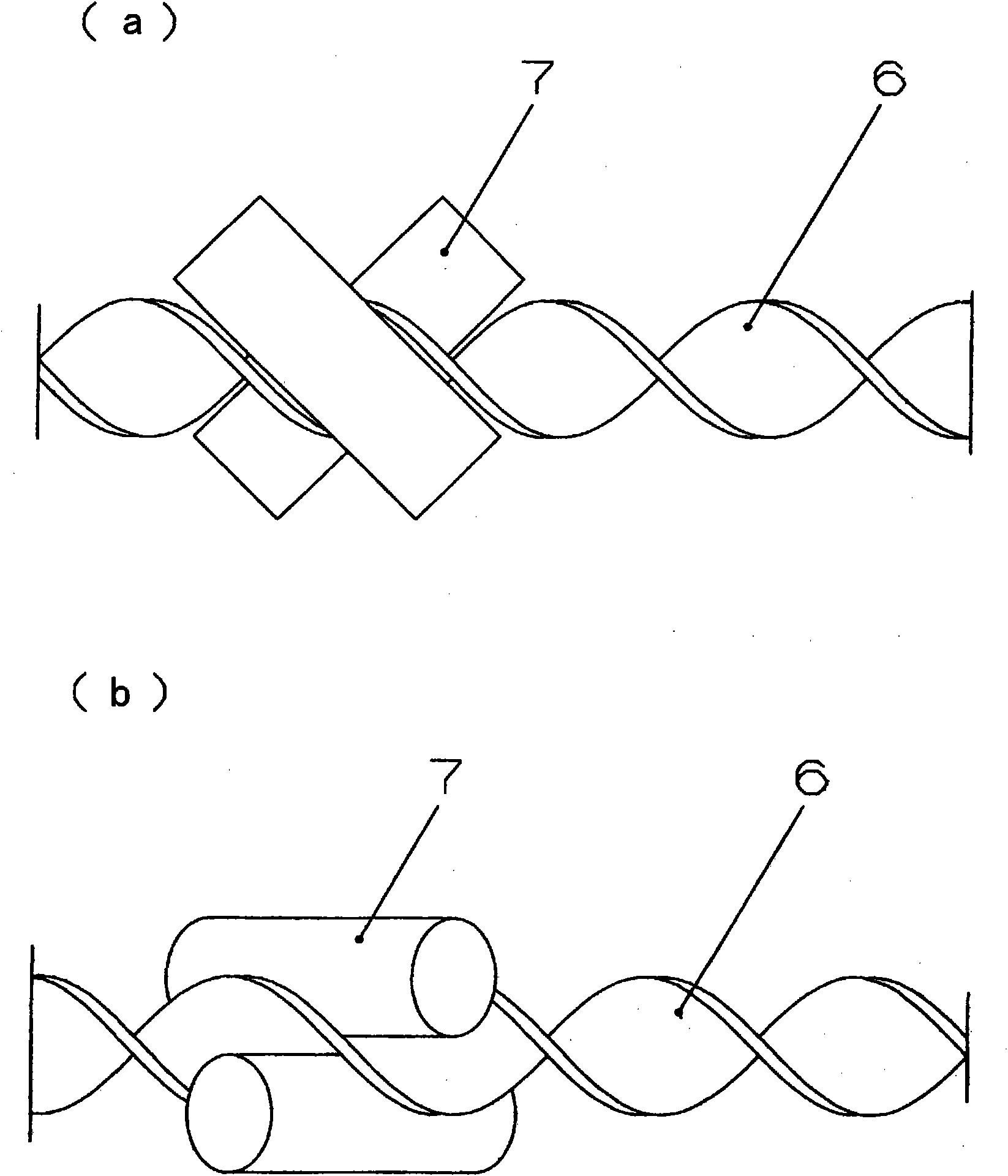

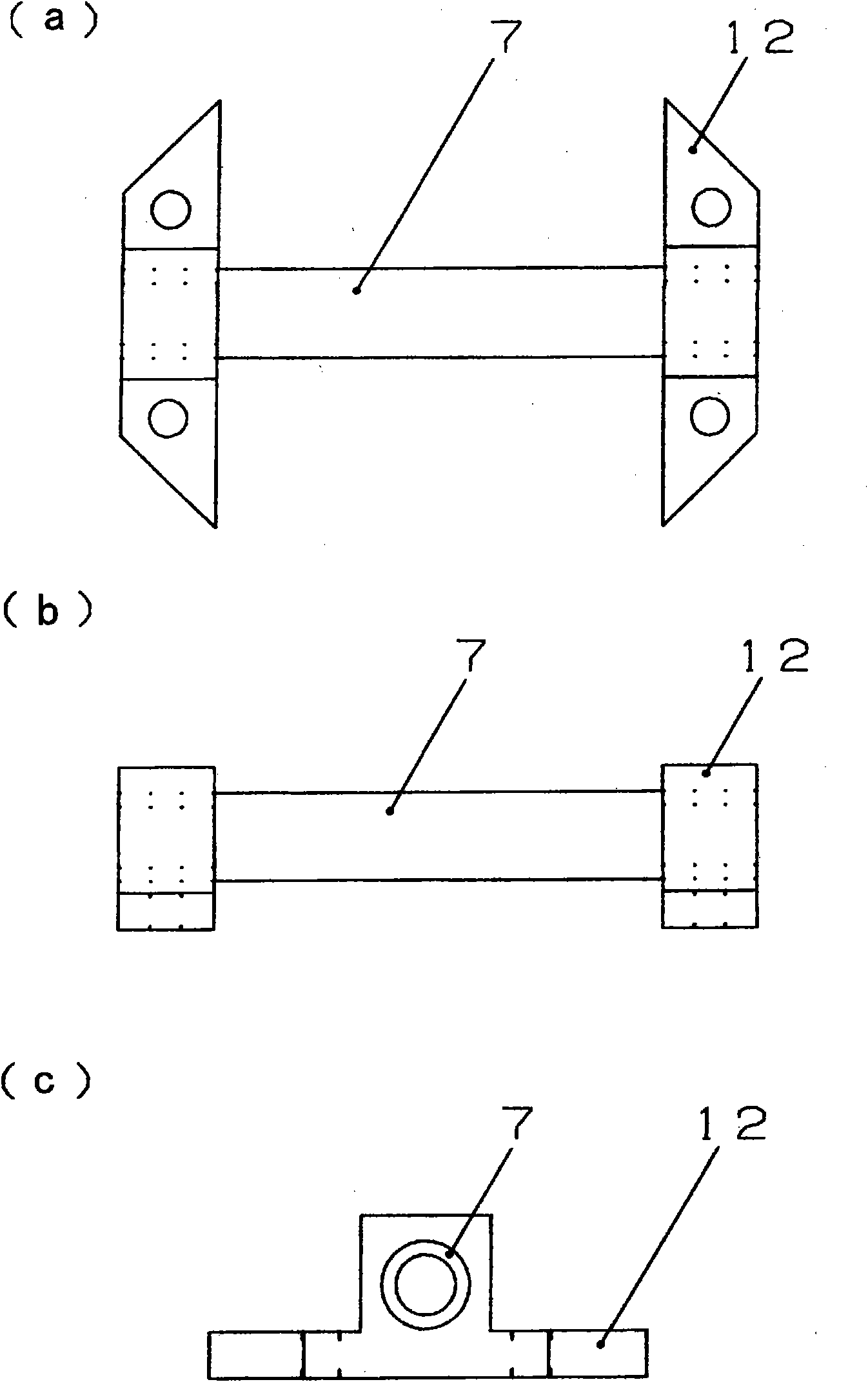

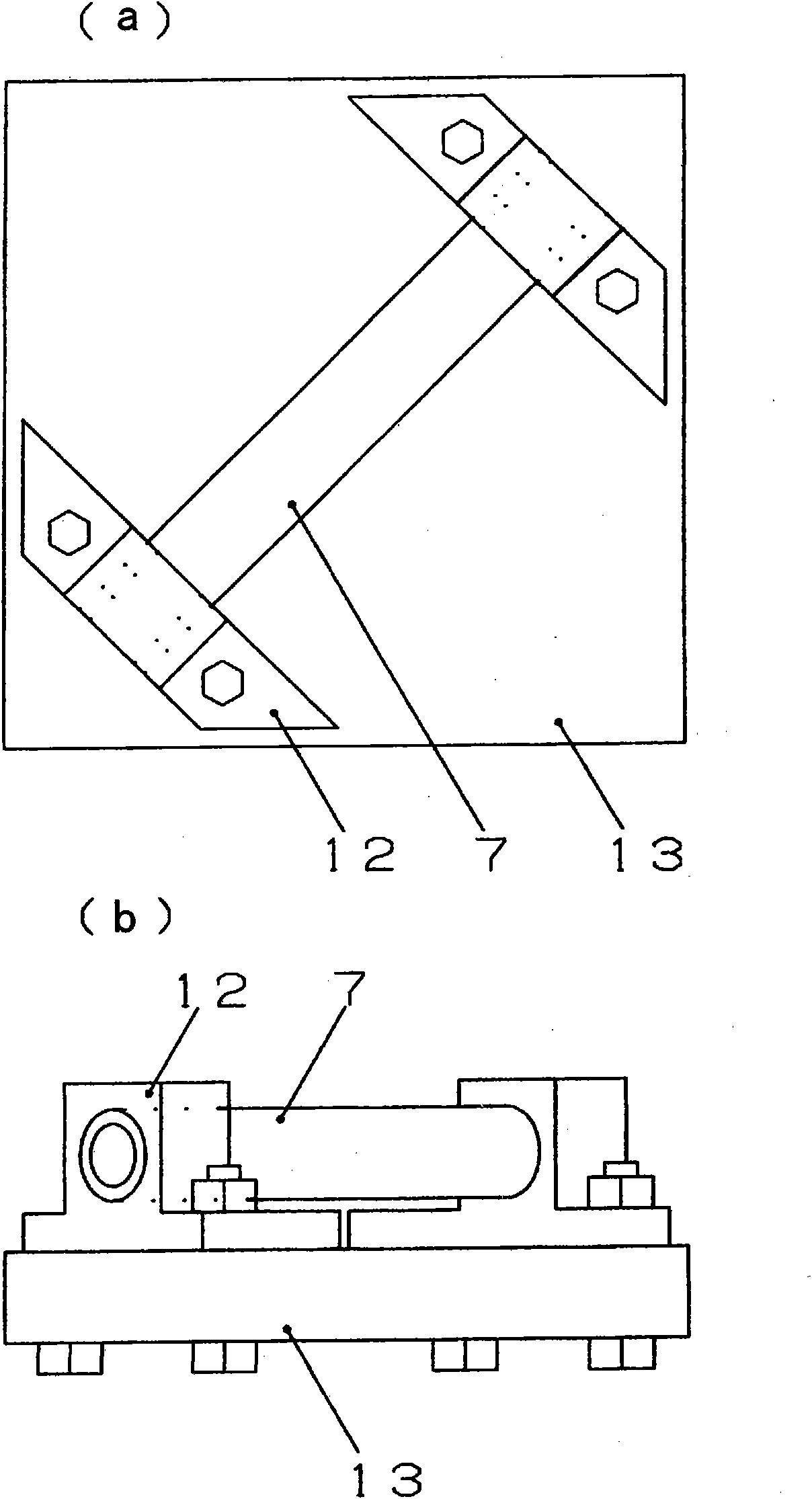

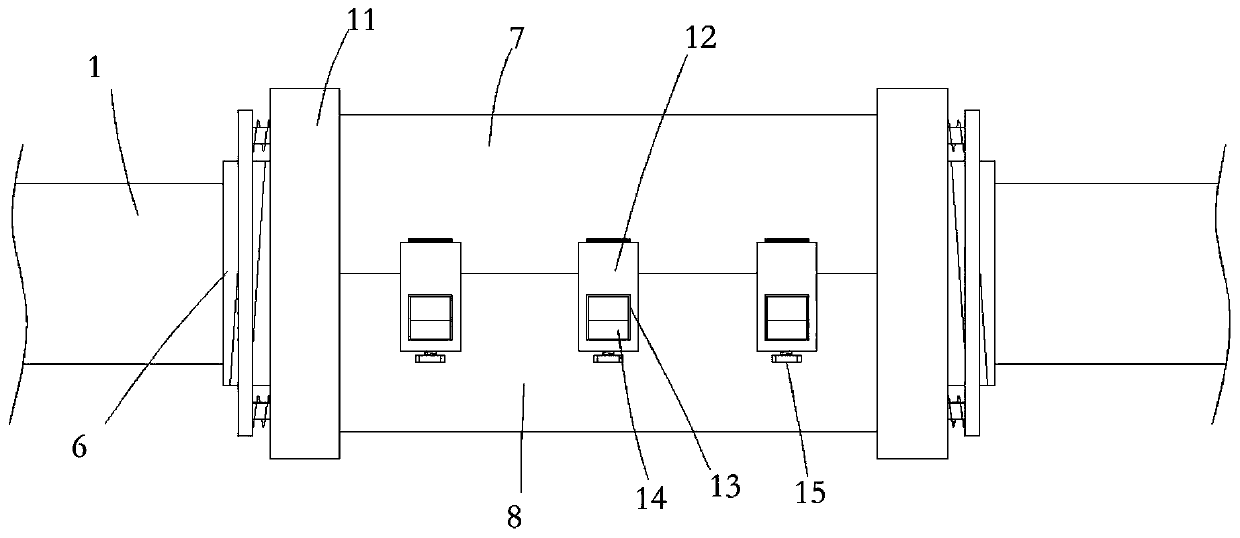

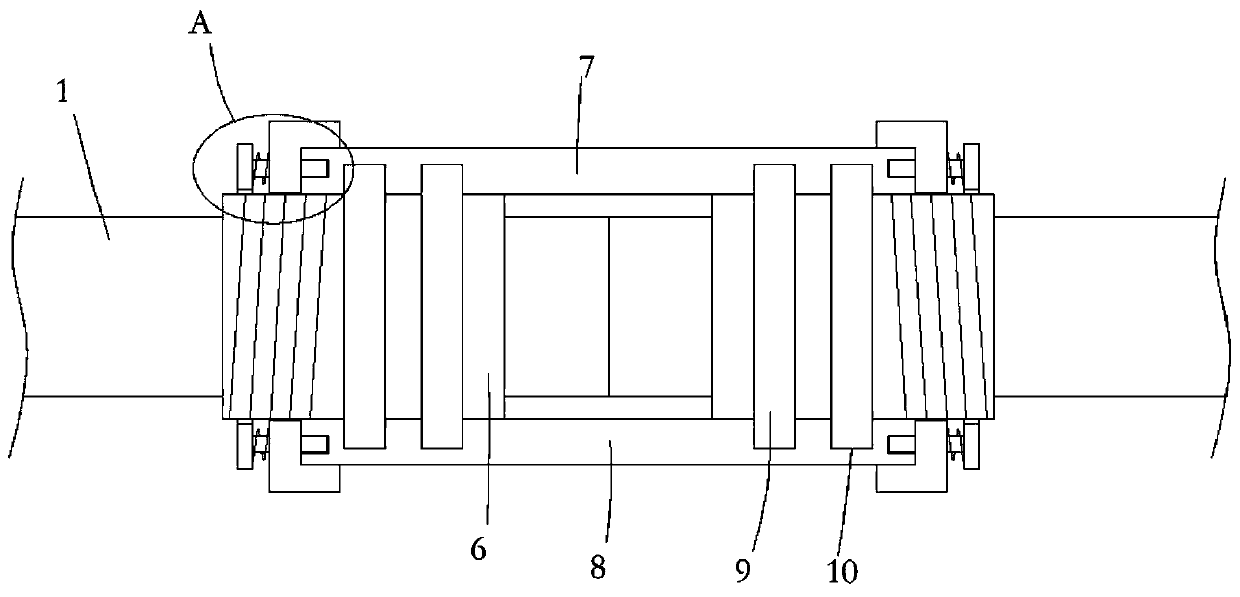

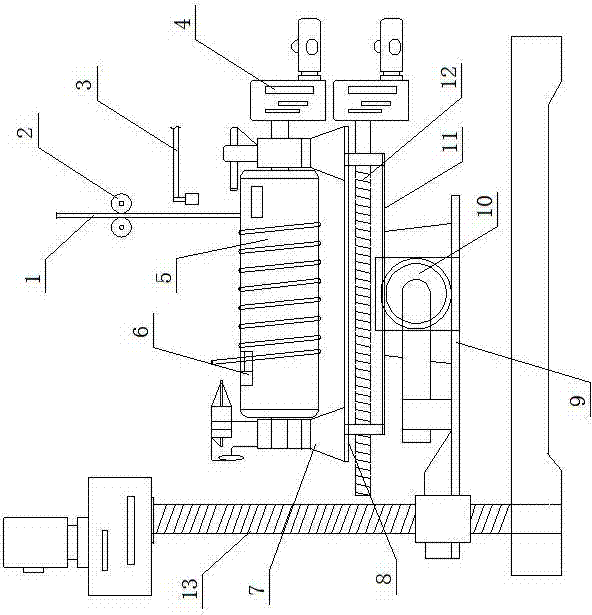

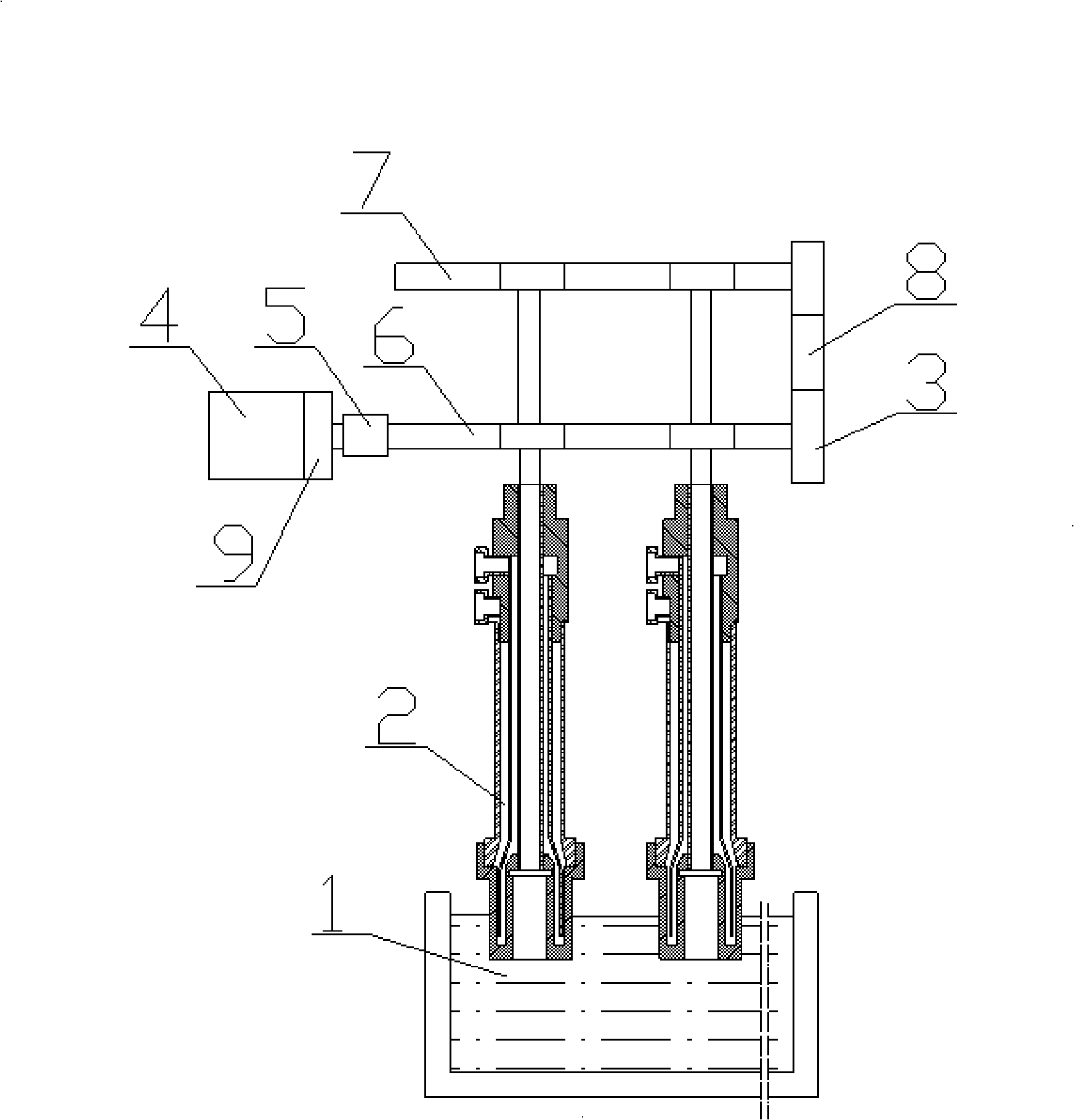

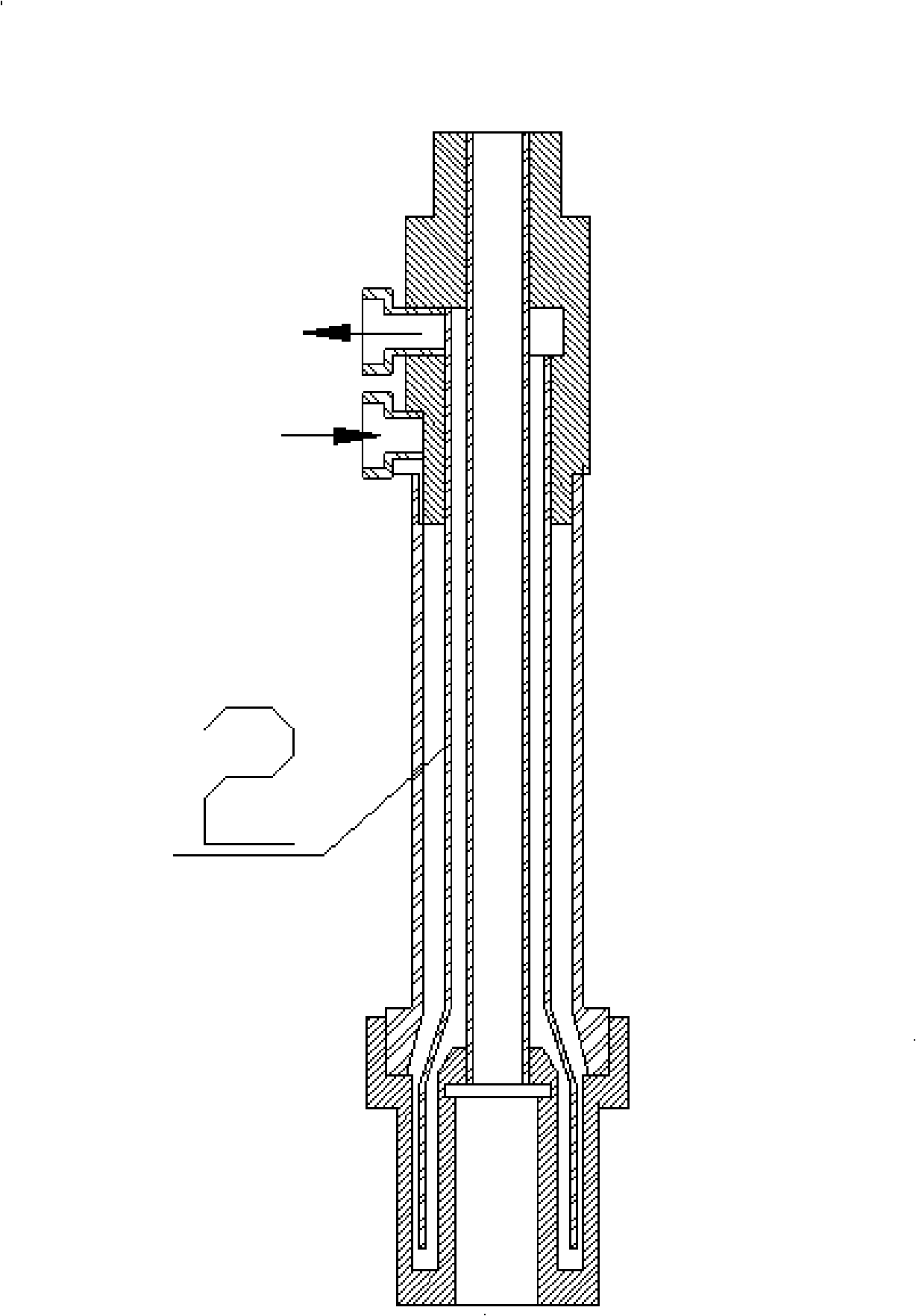

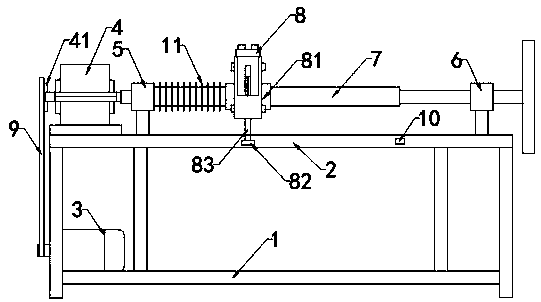

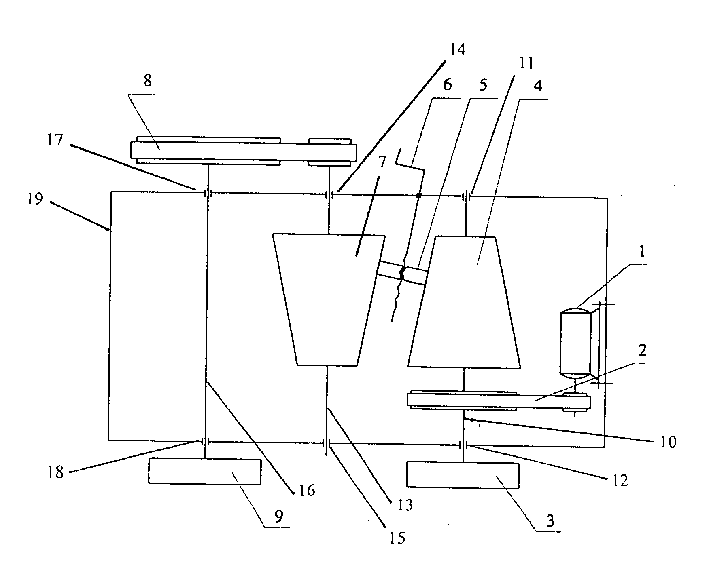

Metal spiral belt winding machine

A metal spiral belt winding machine is characterized in that the upper surface of a machine base (1) is provided with a workbench (2); a driving device (3) is arranged below the workbench (2), and a shaft seat (4), a bearing bracket I (5) and a bearing bracket II (6) are arranged on the workbench (2) and connected through a winding shaft (7); a movable material clamping mechanism (8) is arranged on the winding shaft (7); one side of the shaft seat (4) is provided with a driven wheel (41), the driving device (3) is connected with the driven wheel (41) through a driving belt (9); the driven wheel (41) is connected with a gear arranged in the shaft seat (4); and the driving device (3) drives the driven wheel (41) to rotate and drives the winding shaft (7) to rotate through the gear, and thusthe movable material clamping mechanism (8) on the winding shaft (7) moves to conduct winding operation of a metal sheet belt (11). Through the metal spiral belt winding machine, the production efficiency is greatly improved.

Owner:丹阳市协昌合金有限公司

A winding method of a twist pin

The invention discloses a winding method of a twist pin. The specific steps are as follows: step 1, a plurality of winding coils are arranged in a set area of the twist pin, a rewinding coil is arranged below each winding coil, a wire hole is connected with a wire take-up mechanism and a wire take-up mechanism is arranged on the wire take-up mechanism; step 2 the winding speed of each bobbin, therotating direction of the bobbin, the rewinding speed of the corresponding rewinding bobbin, the wire take-up speed of the wire take-up mechanism and the wire arranging speed of the wire arranging mechanism are set on the controller; step 3, winding is performed to obtain that finished product. By winding the wire of the twist pin on the winding coil and winding the wire back on the winding coil at the same time, the tension frame and the guide device are used for guiding, and then the thread taking-up mechanism and the thread arranging mechanism are used to take-up and arrange the thread, sothat the twisted twist pin wire is uniform in pitch, good in density and smooth in shape, people can set the wire pitch according to their own needs, and the wire pitch can be adjusted, and the wirepitch can be combined with a plurality of wires and a plurality of wire diameters.

Owner:贵阳市博爻科技有限公司

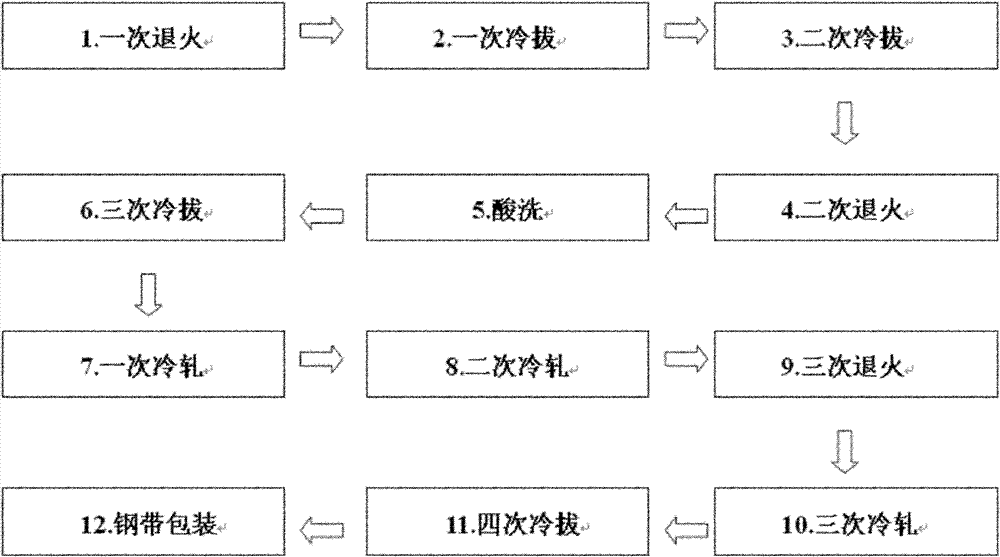

Method for manufacturing steel strip for central cooling tube and method for winding cooling tube

ActiveCN102172813BGood lookingNo side reverse curveHeat exchange apparatusAcid washingConductor Coil

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI +2

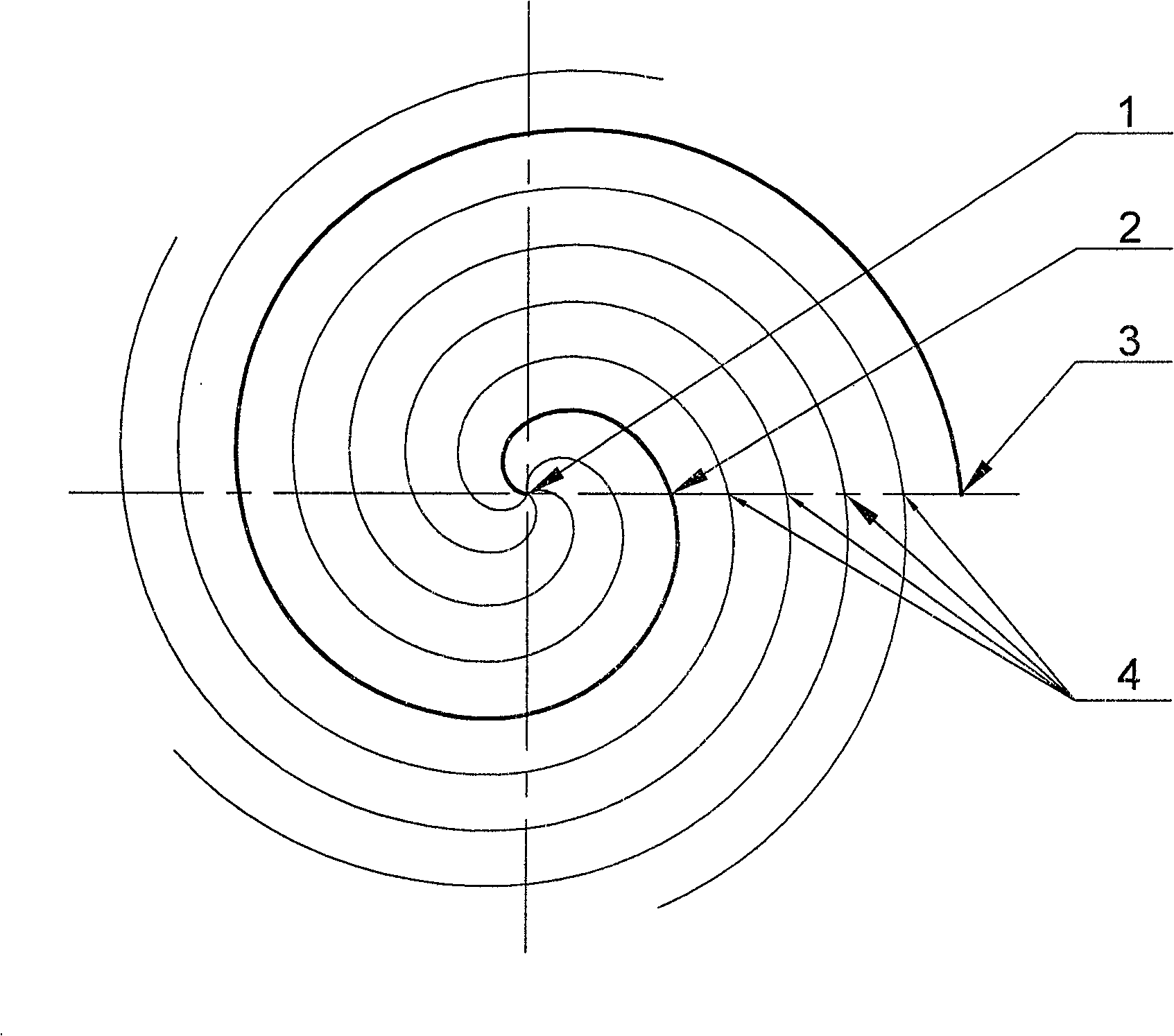

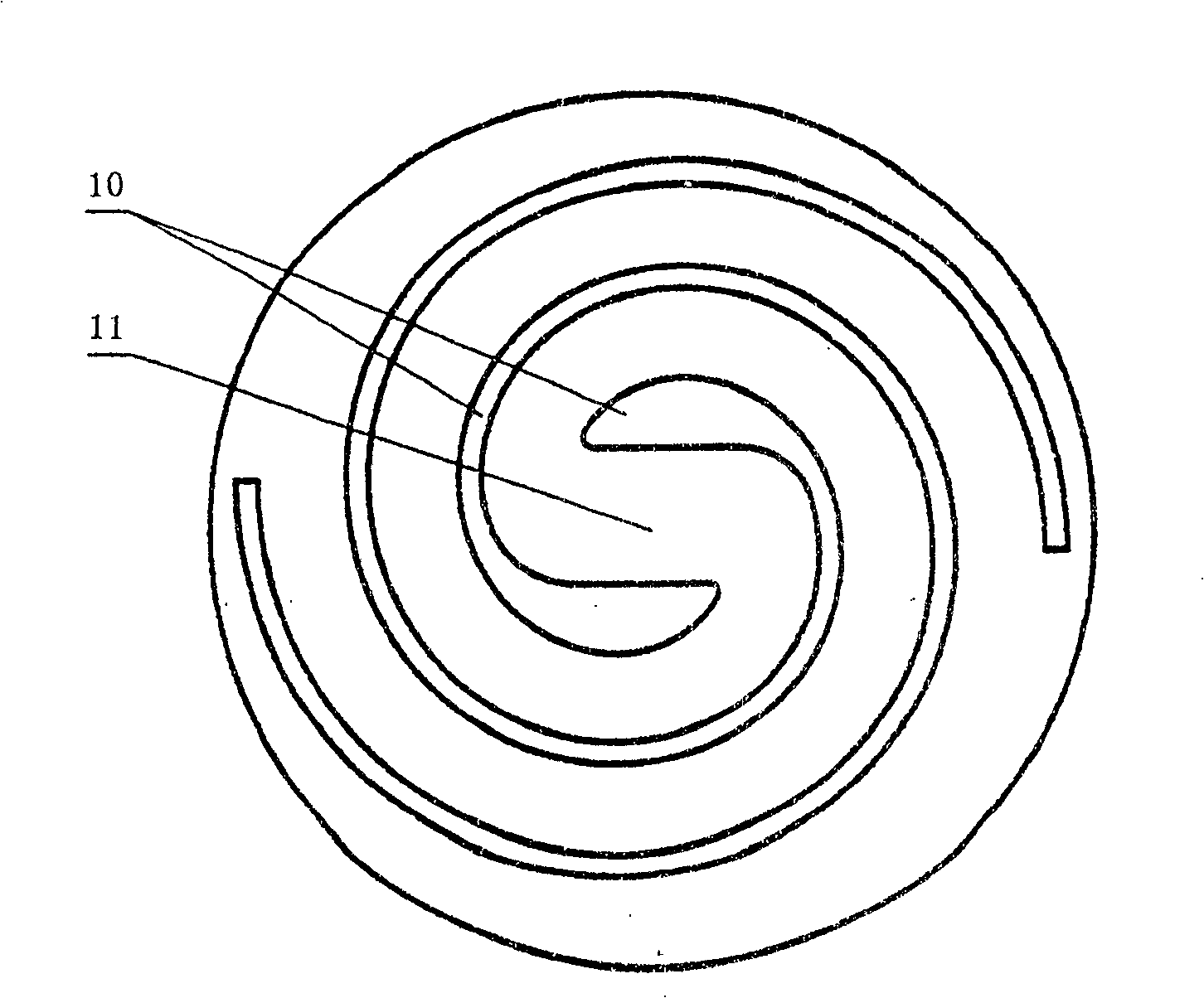

Multi-line whirl disc of whirl compressor and discharge device thereof

InactiveCN100529408CImprove stress conditionAvoid uneven forceRotary piston pumpsRotary piston liquid enginesEngineeringMechanical engineering

Owner:曹宇

Fixture and method for winding rectangular-section wire torsional springs

The invention relates to a fixture for winding rectangular-section wire torsional springs. The fixture comprises a bed plate and a guide support arranged above the bed plate. The guide support is connected with the bed plate in a matched manner by a first screw rod, a support moving handle is connected with one end of the first screw rod in a matched manner, and the support can move from left to right on the bed plate by turning the support moving handle. A correction clamp plate is arranged on the right side of the guide support, a groove type guide wheel is arranged on the left side of the guide support, and a wire with a rectangular section sequentially penetrates through the correction clamp plate and the groove type guide wheel to be wound on a torsion mandrel. The invention further provides a method for winding the rectangular-section wire tensional springs. By the aid of the method, appearance quality of the torsional springs can be guaranteed, sizes of outer diameters of the torsional springs are consistent, and pitches are uniform. By the aid of the fixture and the method, accuracy of guiding can be guaranteed, deflection of feeding is effectively prevented, distance between a feeding outlet and the torsion mandrel can be adjusted, consistency and reliability of winding torsional spring forming are guaranteed, deflection and lodging of the torsional springs can be further avoided during winding.

Owner:CHONGQING WANGJIANG IND

A kind of tire tread layered winding method

Owner:日新集创(新兴)科技有限公司

A cable with high flame retardancy for oil platforms

ActiveCN111540507BImprove flame retardant performanceIncrease ampacityCommunication cablesInsulated cablesThermodynamicsElectrical conductor

The invention relates to the technical field of cables, and discloses a cable for oil platforms with high flame retardancy, comprising a cable body, wherein the cable body includes a conductor located in the middle, the conductor is wound with a wrapping layer, and a plurality of The conductor is covered with an insulating layer, and the insulating layer is covered with an outer sheath. The oil platform cable with high flame retardancy has the advantages of environmental protection, high flame retardancy, strong mechanical performance, mud resistance, oil resistance and cold resistance.

Owner:ANHUI CABLE

The production process of hni65-5 nickel brass tube with heavy plate

The invention relates to a production process for a heavy-coil HNi65-5 nickel brass pipe and belongs to the technical field of metal rolling. According to the production process, the heavy-coil HNi65-5 nickel brass pipe is prepared through preparation of a horizontal continuous casting hollow cast ingot, preparation of a planetary mill rolled heavy-coil coiled pipe, bigeminal pull continuous drawing, recrystallization annealing, coil drawing and the like. The production process solves the problems that a pipe produced through an extrusion method is low in weight, low in yield and high in cost. The production process is simple in manufacturing procedure, high in yield and short in product circulation period, the temperature and speed are easy to control, batched production is facilitated, and the heavy-coil HNi65-5 nickel brass pipe with the weight being 200 kg and above can be produced.

Owner:江苏隆达超合金股份有限公司

Screw roll fixed pitch stretching device

The screw roll fixed-pitch stretching equipment consists of motor, high-speed belt drive stage, low-speed belt wrive stage, driving rubber roller, differential rubber roller, driving conic roller, driven conic roller, speed-regulating screw, shaft and bearings. The motor drives the small belt pulley of high-speed belt drive stage; the driving conic roller, the large belt pulley of high-speed belt drive stage and the driving rubber roller are on the drive shaft; the driven conic roller and the small belt pulley of low-speed belt drive stage are on the middle shaft; the large belt pulley of low-speed belt drive stage and the differential rubber roller are on the driven shaft; there is speed regulating screw with control handle installed between the driving conic roller and the driven conic roller; and the bearings are mounted on the box.

Owner:HARBIN INST OF TECH

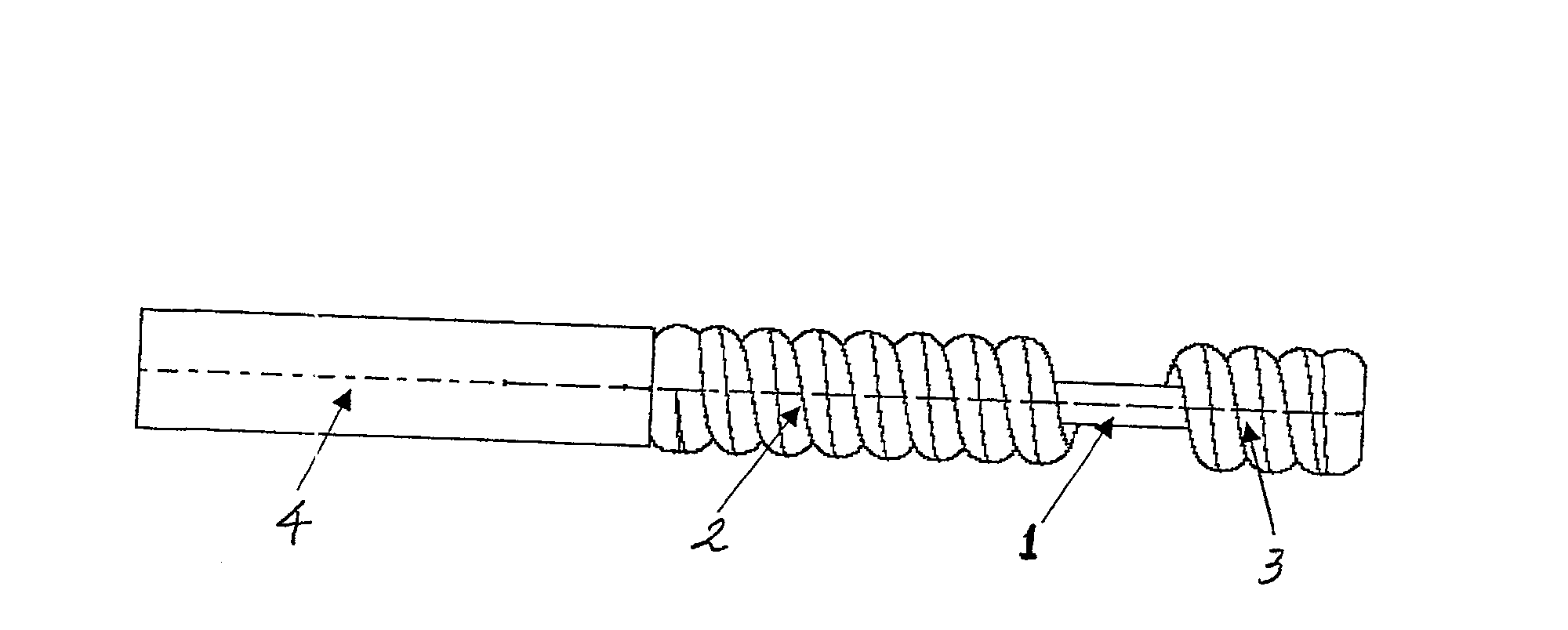

Ceramic metal halide lamp electrode

InactiveCN100585789CGuaranteed low current requirementsAvoid shockGas discharge lamp detailsNiobiumCeramic metal

The invention discloses a ceramic metal halogen lamp electrode which comprises a main rod made of thorium-tungsten alloy materials; a yttrium-molybdenum alloy-wire spiral body is wound on one end of the main rod, and a high-purity tungsten wire spiral body is wound on the other end of the main rod; and the main rod end part on which the yttrium-molybdenum alloy-wire spiral body is wound is connected with an outer-lead niobium rod. The invention is a high-effective and environment-friendly ceramic metal halogen lamp electrode and has the advantages of high efficiency, safety, environment protection, even electrode spring, and the like.

Owner:佛山宁宇科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com