Screw roll fixed pitch stretching device

A stretching device and screw technology, applied in the field of special equipment for preparing metal rubber products, can solve the problems of waste of human resources, difficulty in ensuring the consistency of the spiral coil pitch, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

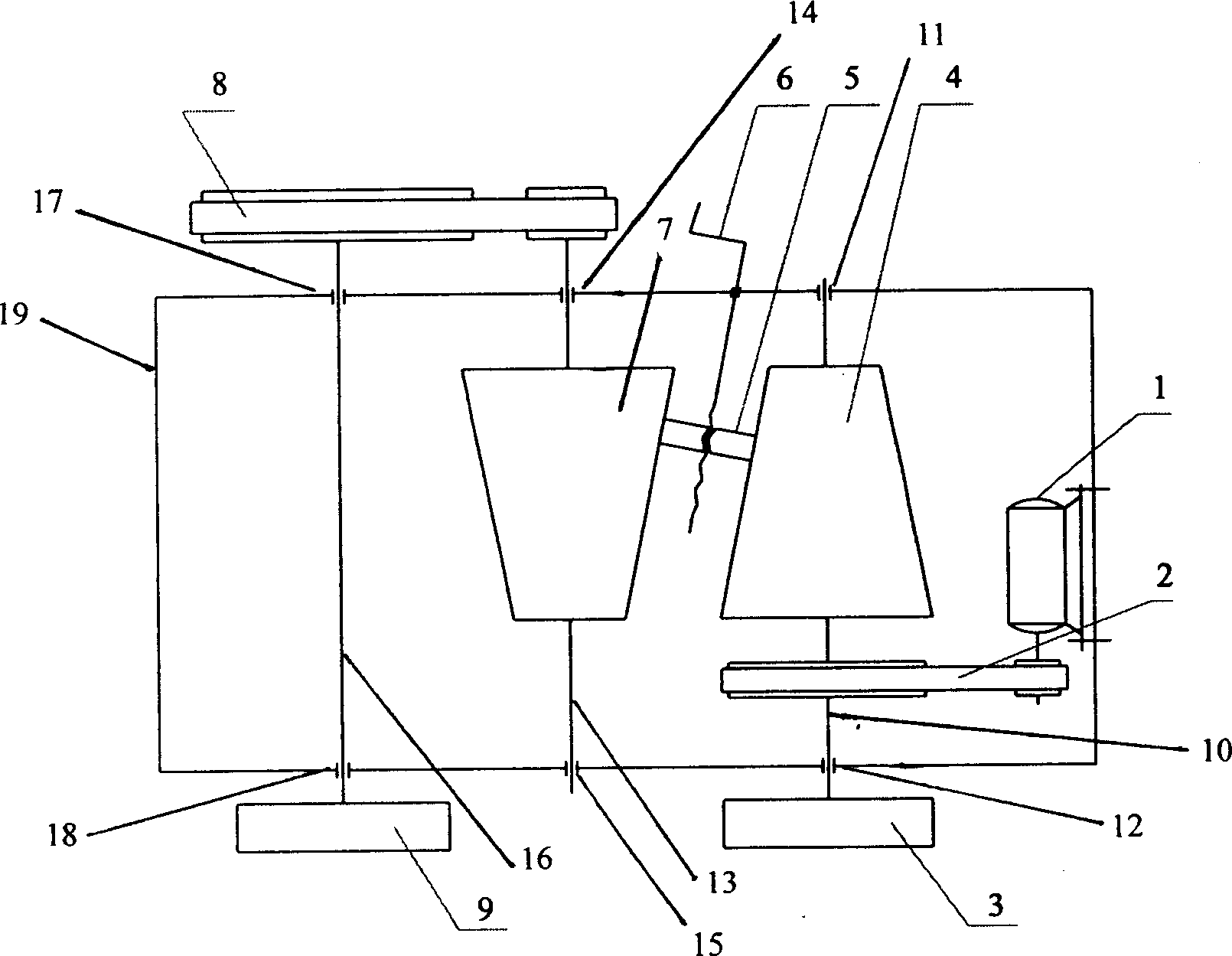

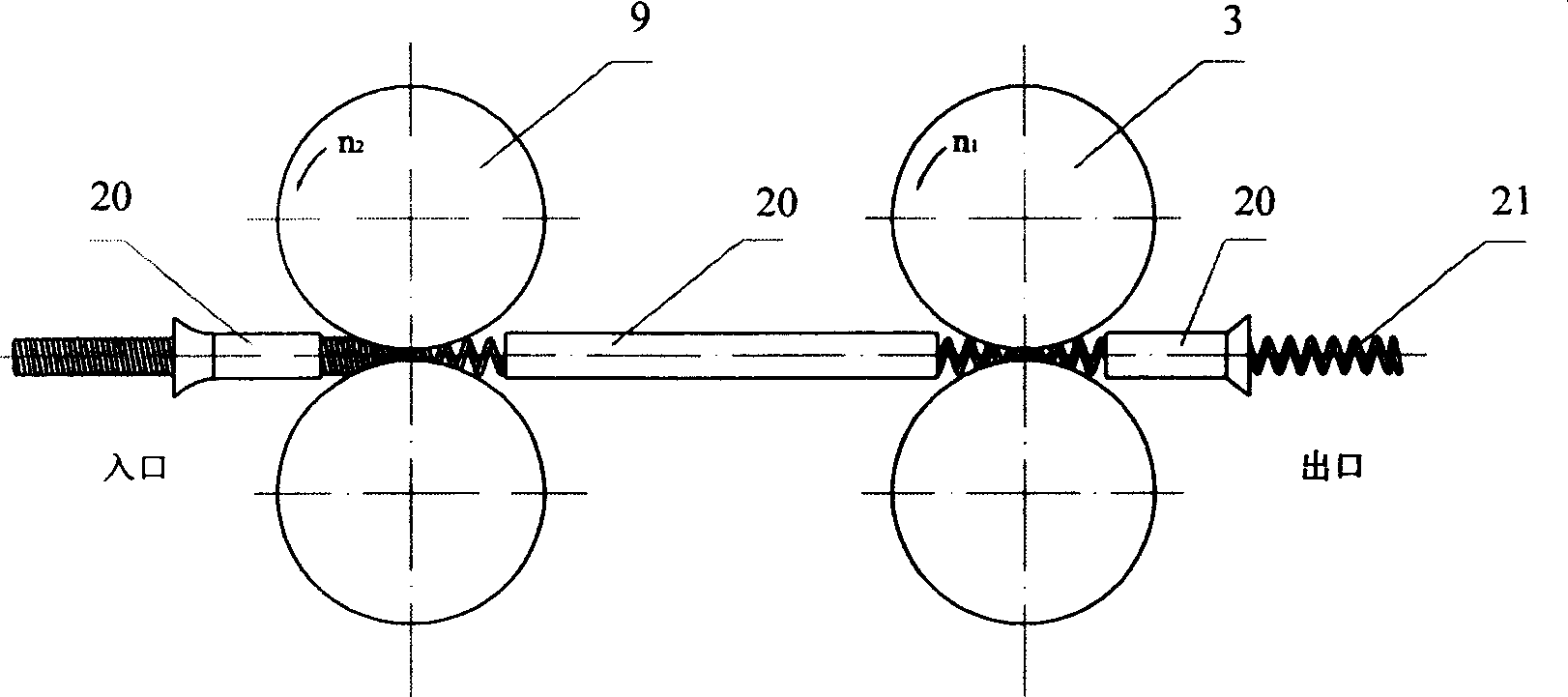

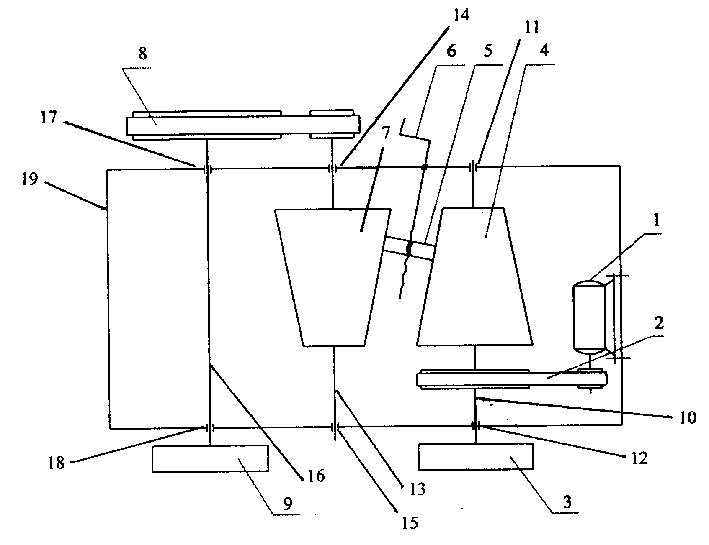

[0006] The length of the box of the present invention × height × width is 300 × 200 × 150 mm, the power of the DC motor of the present invention is 24W, the speed is 1400 rpm, the bearing is a self-aligning ball bearing, the nominal length of the driving transmission belt is 320 mm, and the nominal length of the driven transmission belt is 320 mm. The length is 480 millimeters, the taper of the driving tapered roller and the driven tapered roller is 1: 6, and the pitch of the speed regulating screw is 1 millimeter, and all roller core materials in the present invention are 45 # Steel, roller rim in neoprene, active and differential rubber rollers 32 mm in diameter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com