Method and device for producing copper belt

A copper strip and equipment technology, applied in the production of copper strip and its equipment, can solve the problems of copper strip for production, low density of copper strip and poor quality of finished products, etc., and eliminate the problems of air holes and uneven density , Small size, light weight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

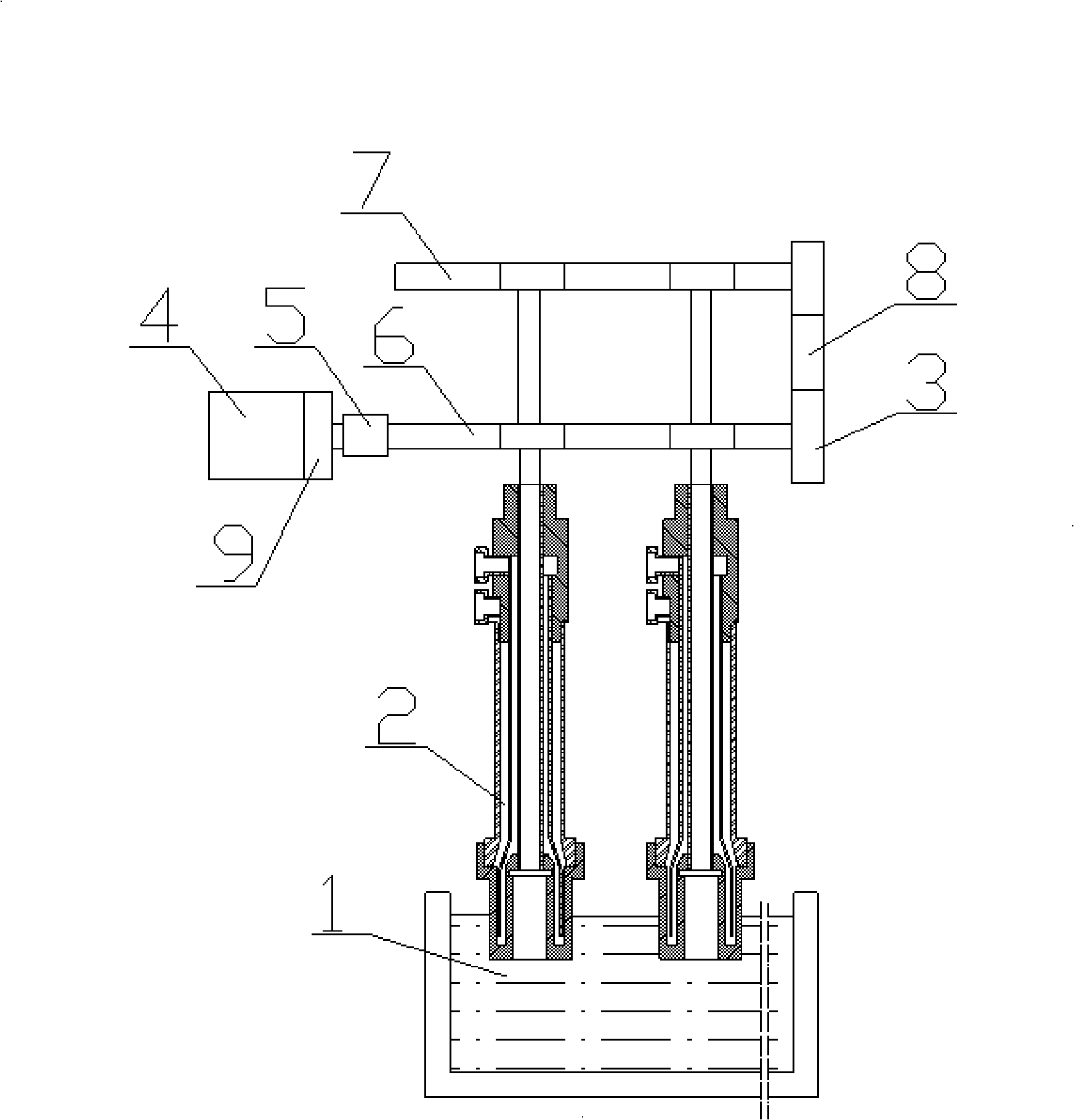

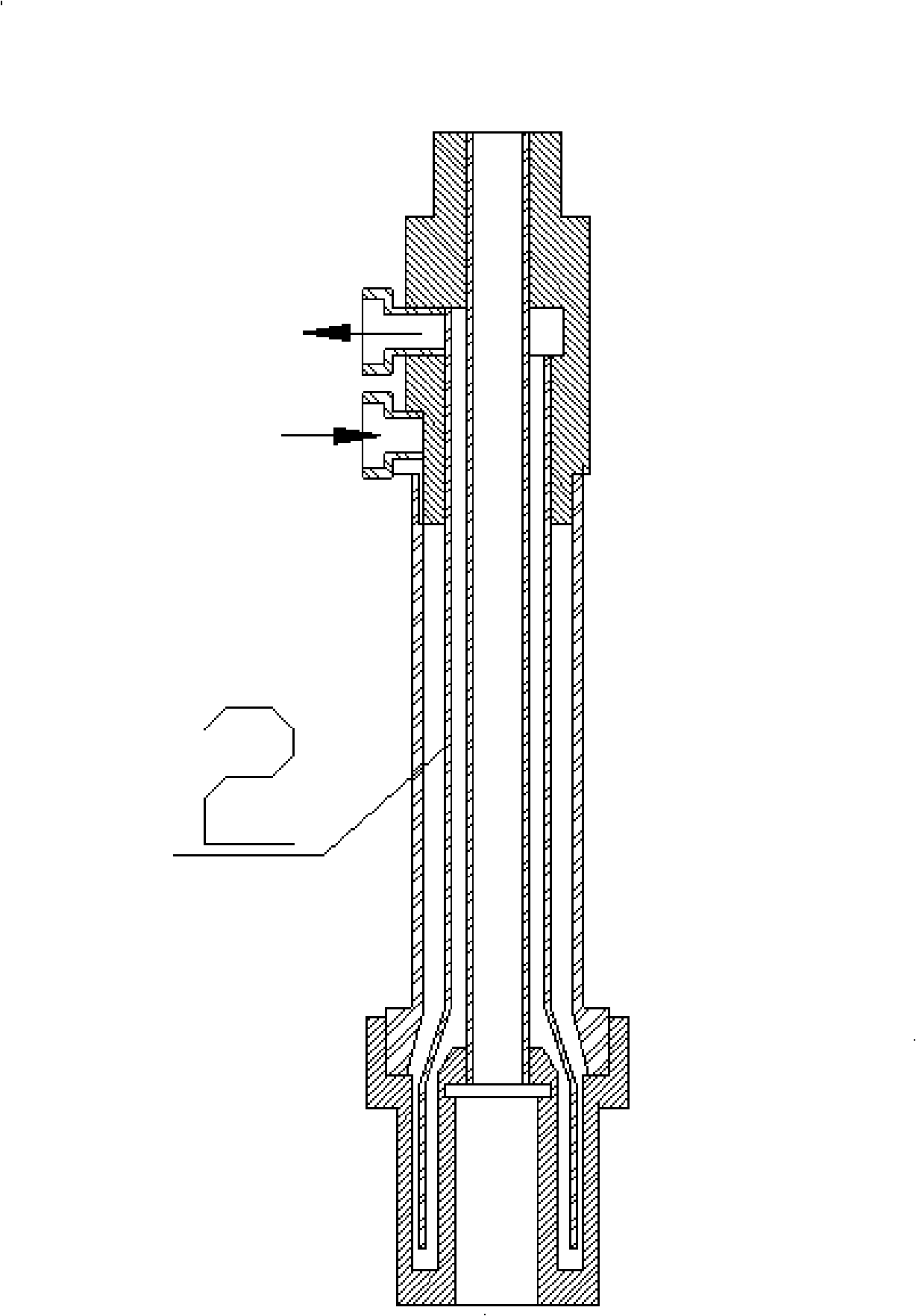

[0016] Embodiments of the present invention: the structure of the present invention is as figure 1 with figure 2 As shown, the melting furnace 1 includes an induction furnace and a holding furnace. A frame is installed on the melting furnace 1, a crystallizer 2 is installed on the frame, and an upward guide mechanism 3 is connected to the crystallizer 2. The mechanical installation of this part The structure and working principle are the same as that of the up-drawing method for producing oxygen-free copper rods; but the transmission device installed on the up-drawing mechanism 3 of the present invention is a servo motor 4, and a reduction box 9 is installed on the servo motor 4, and the reduction box 9 passes through the shaft coupling The device 5 is connected with the main traction shaft 6, and the setting of the reduction box 9 can further increase the torque of the servo motor 4. The auxiliary traction shaft 7 is connected with the main traction shaft 6 through the timin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com