A kind of tire tread layered winding method

A tire tread, tread technology, applied in the direction of tires, other household appliances, household appliances, etc., can solve the problems of research, winding a layer, etc., to achieve the effect of reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

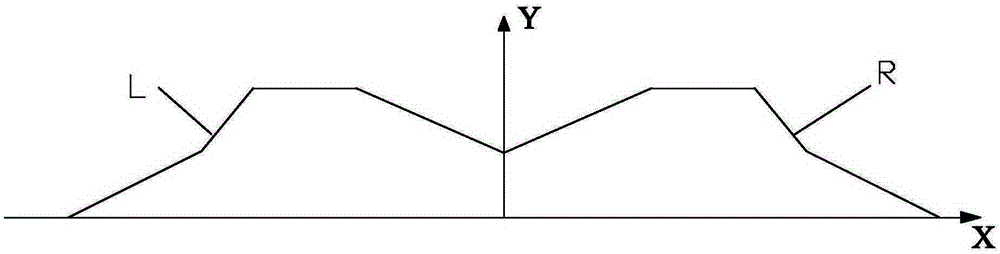

[0022] Such as figure 1 As shown, it is a schematic diagram of the outer profile of the tire tread section to be layered in this embodiment. It can be seen from the figure and the prior art that the tire tread profile is mainly composed of lines, which is a symmetrical structure in the middle, L is the left side, and R is the right side, and the slope of the line may be positive or negative.

[0023] A kind of tire tread layered winding method of the present embodiment is similar to figure 1 The image shown is layered as follows:

[0024] A. Delamination of the tread in the winding machine forming process;

[0025] B. Wrap the tire blank with rubber strips according to the above-mentioned layering method.

[0026] The steps of the layered approach described in Step A are as follows:

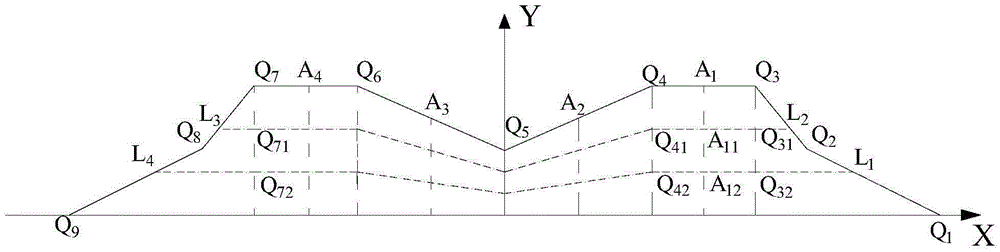

[0027] (1) Establish a coordinate system with the vertical line of the tire tread as the Y axis and the bottom layer of the tread as the X axis; figure 2 shown.

[0028] (2) Select the inf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com