Patents

Literature

42results about How to "Uniform angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

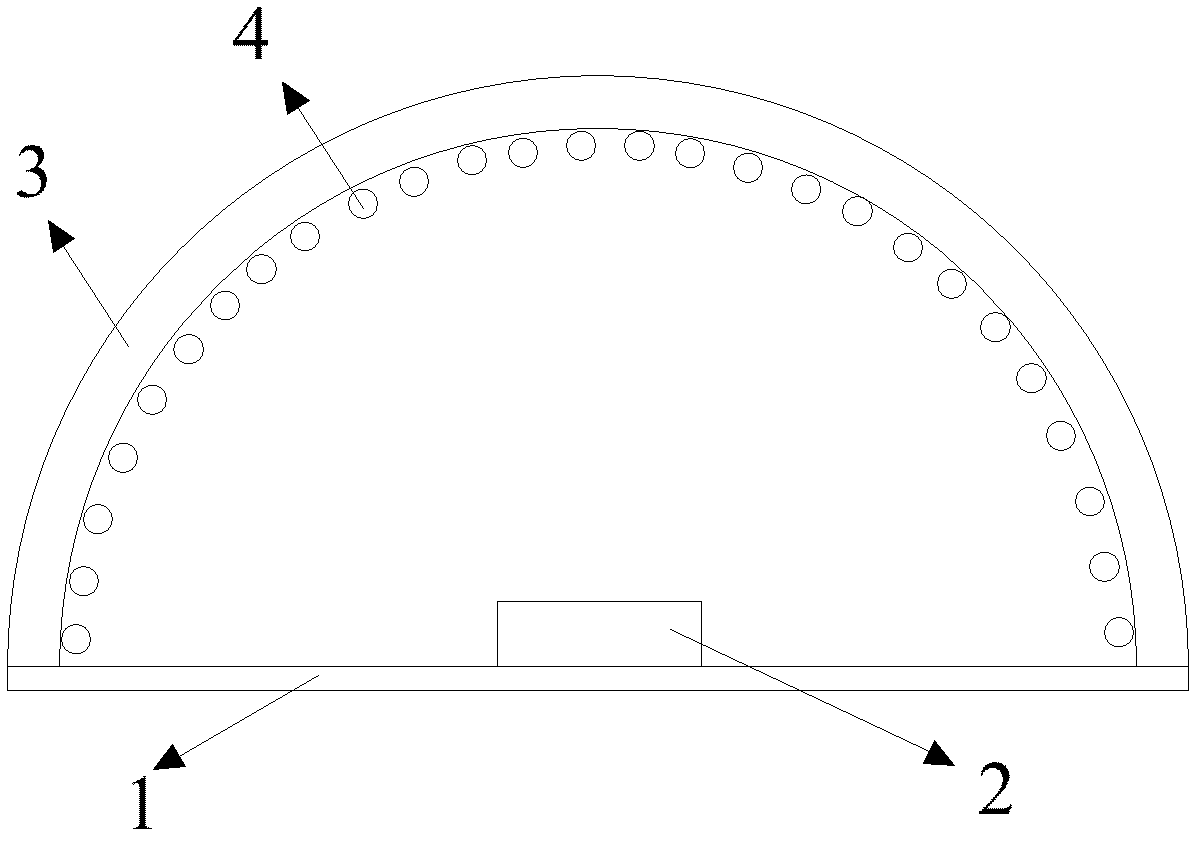

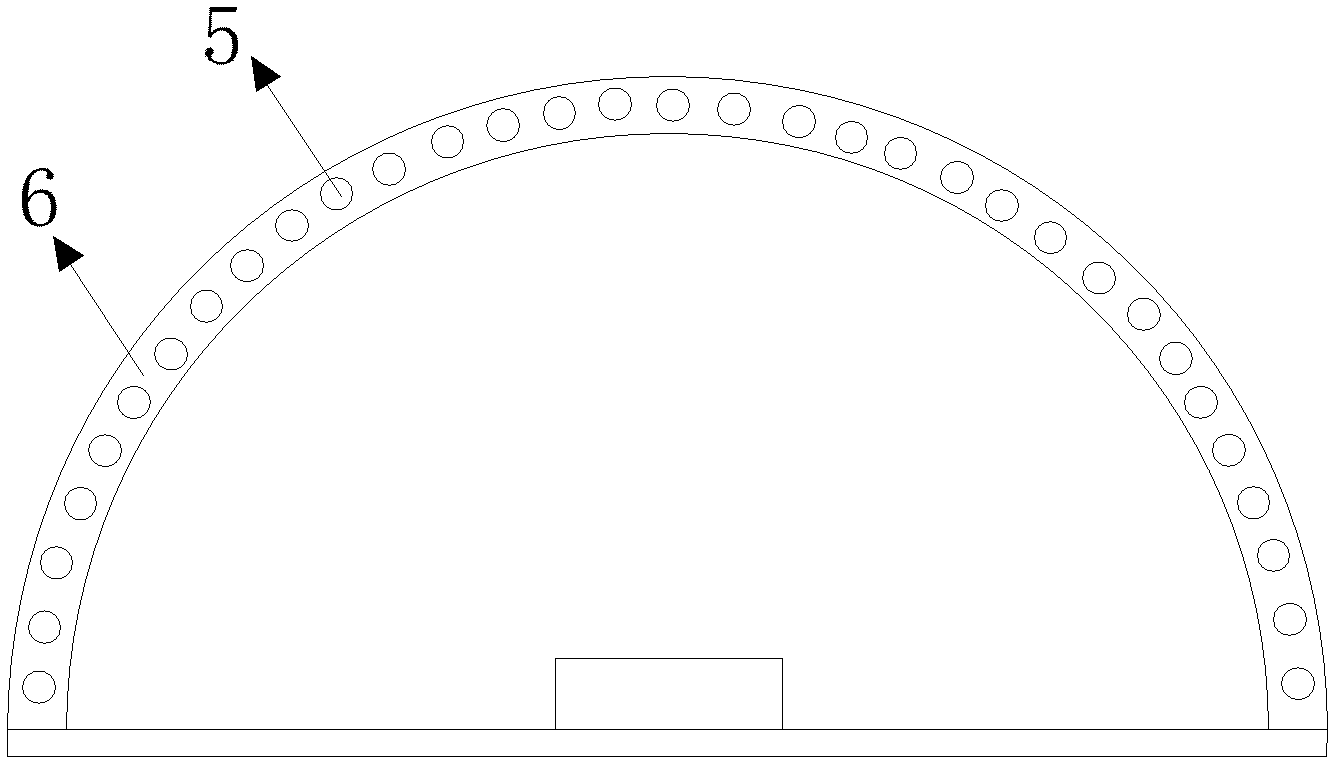

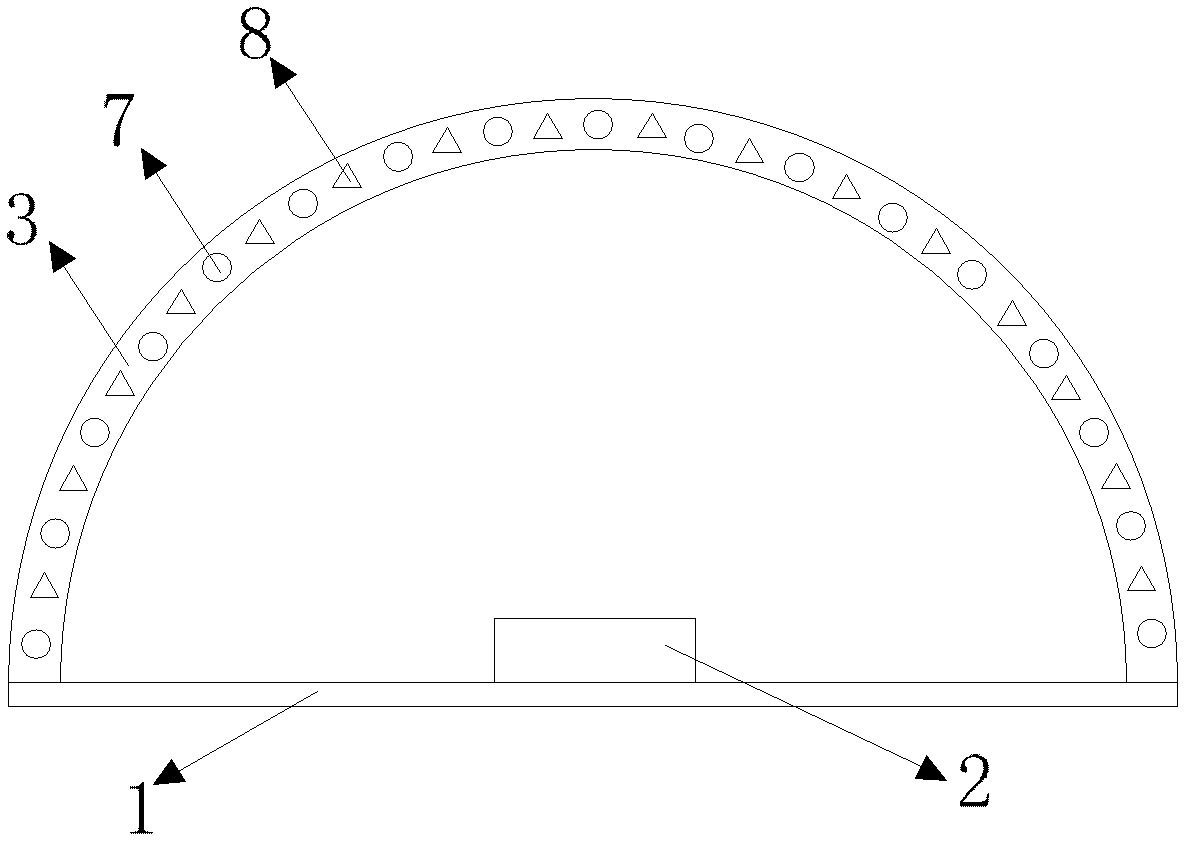

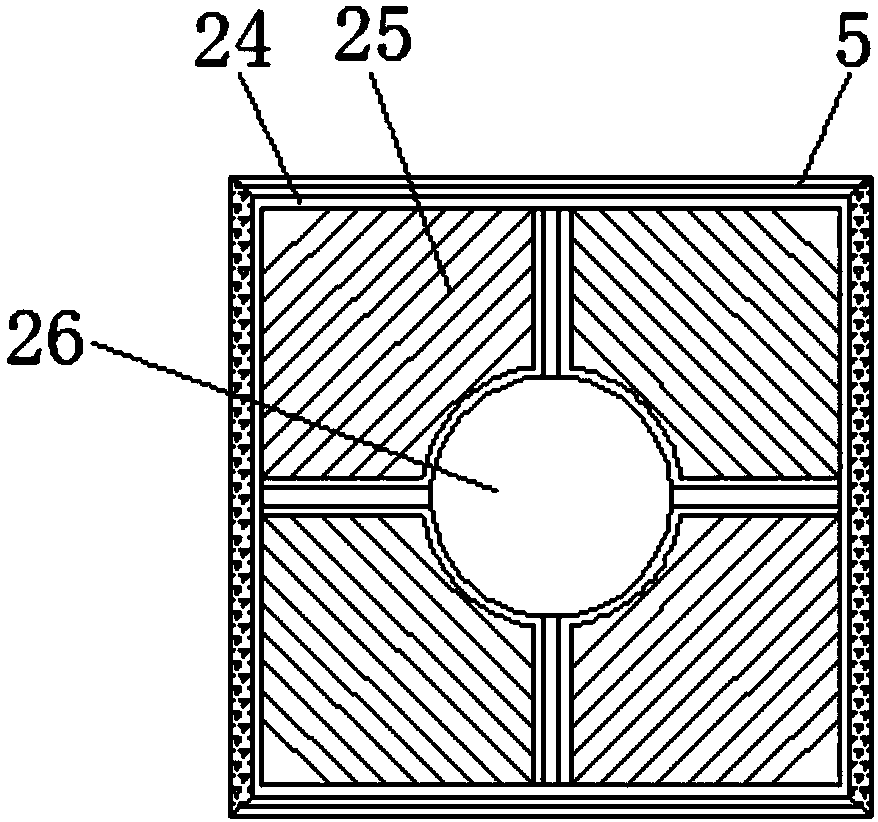

Light emitting diode (LED) device and production method thereof

InactiveCN102437276AUniform distribution of light intensityHigh light efficiencyCoatingsSemiconductor devices for light sourcesLight-emitting diodeDiode

The embodiment of the invention discloses a light emitting diode (LED) device and a production method thereof. The LED device comprises a substrate, a chip, a first lens and a first particle layer, wherein the chip is arranged on the substrate; the first lens is arranged to be opposite to the substrate, and the chip is arranged between the substrate and the first lens; the first particle layer is arranged on the inner surface, on the outer surface or inside the first lens, and the first particle layer comprises fluorescent powder and also comprises light diffusion particles or reflection particles; and the light diffusion particles can scatter the light emitted by the chip and the fluorescent powder, and the reflection particles can reflect the light emitted by the chip. The LED device has high light emitting efficiency, and can solve the problems of the prior art that the LED device has small light emitting angle and non-uniform light.

Owner:SICHUAN SUNFOR LIGHT

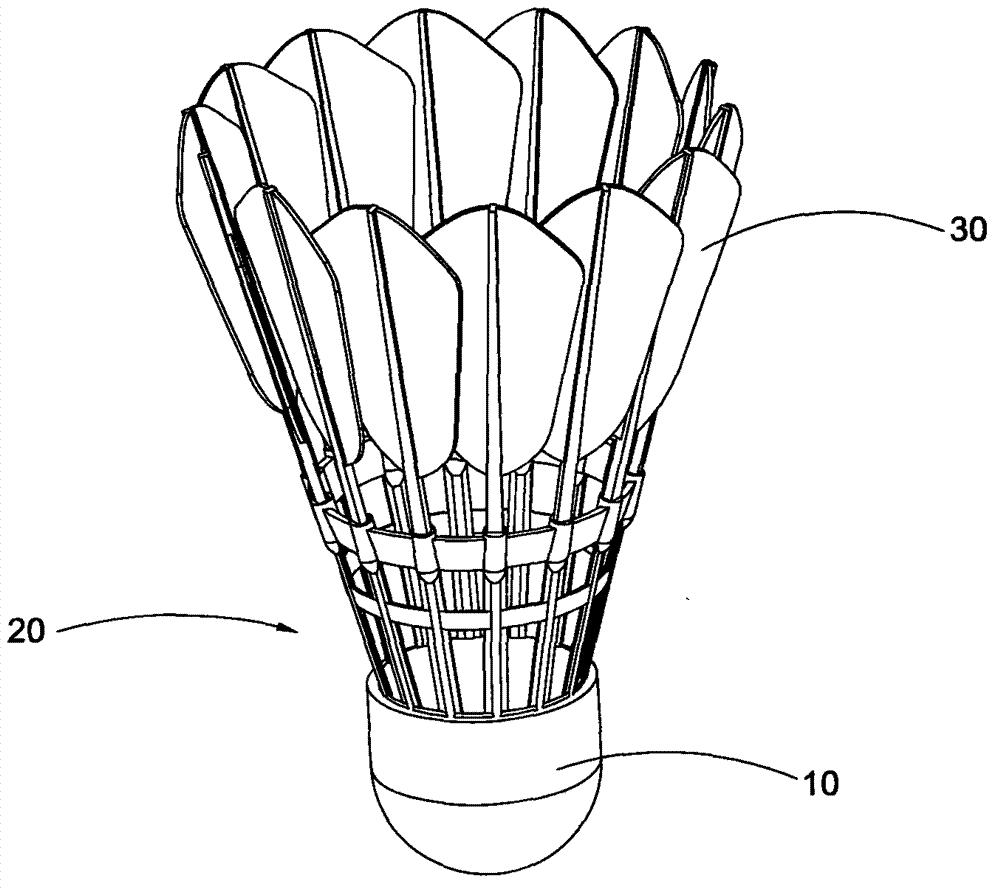

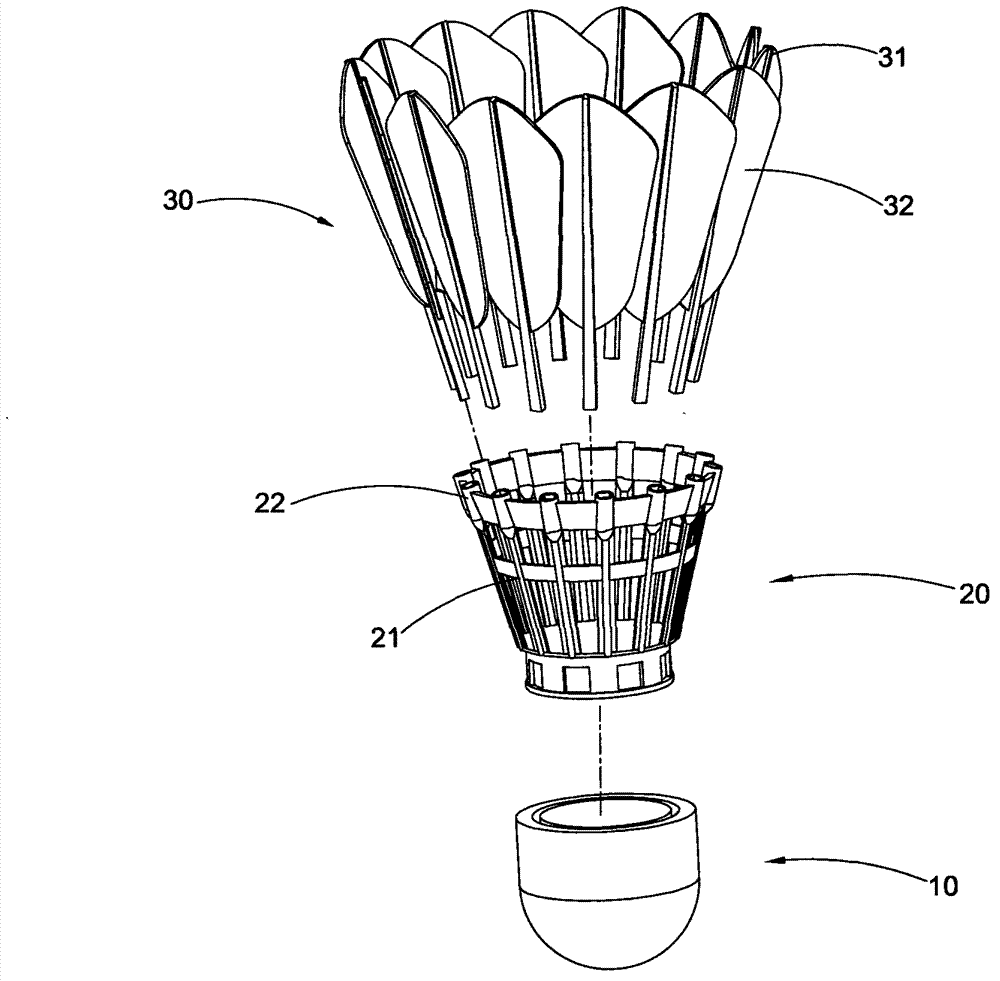

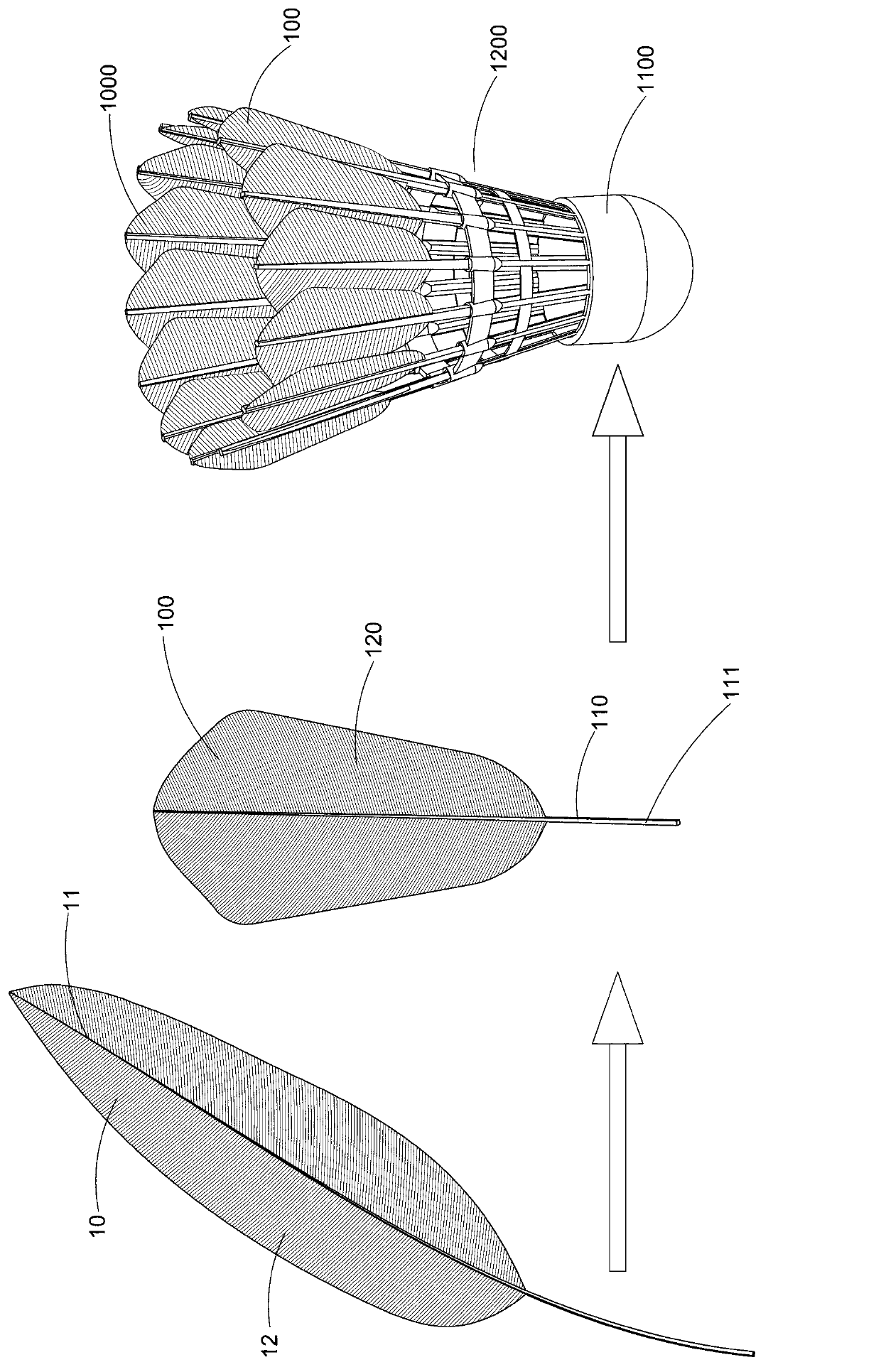

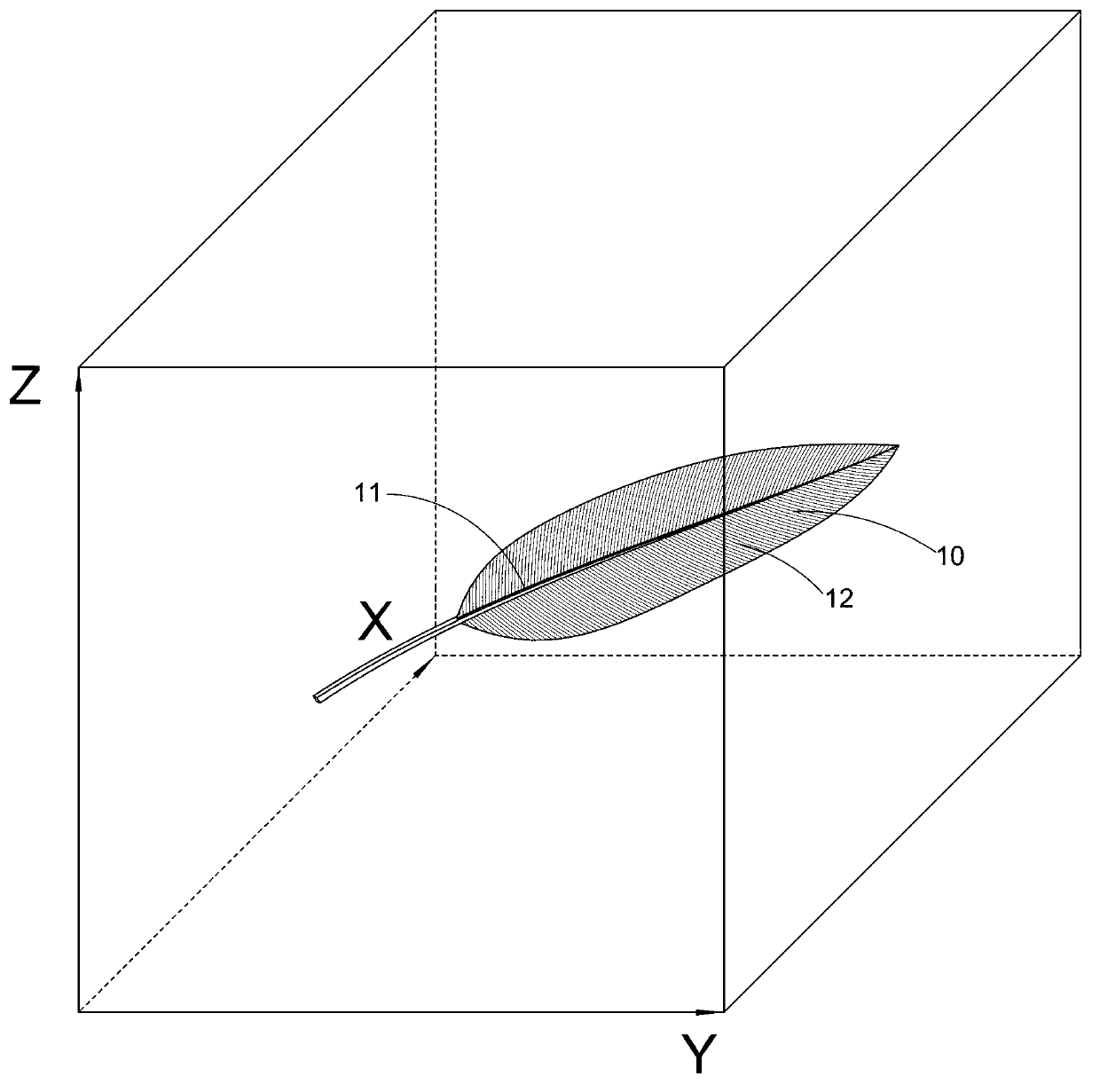

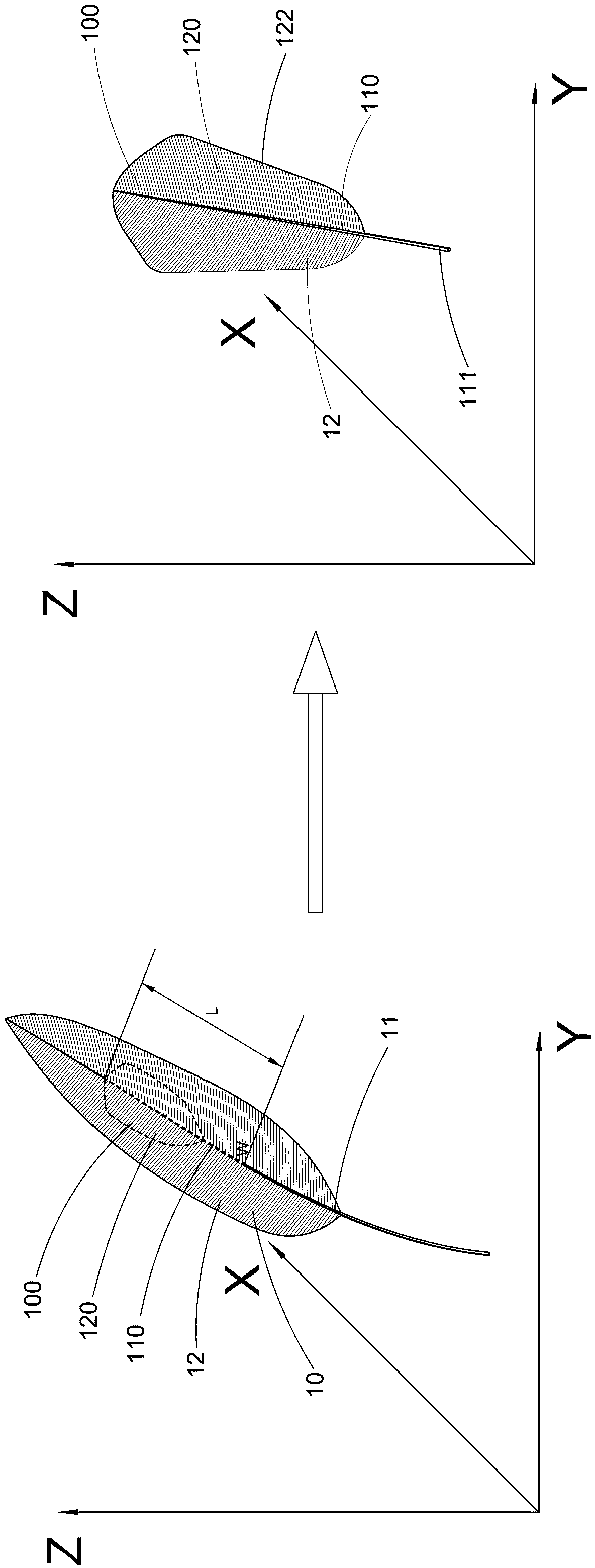

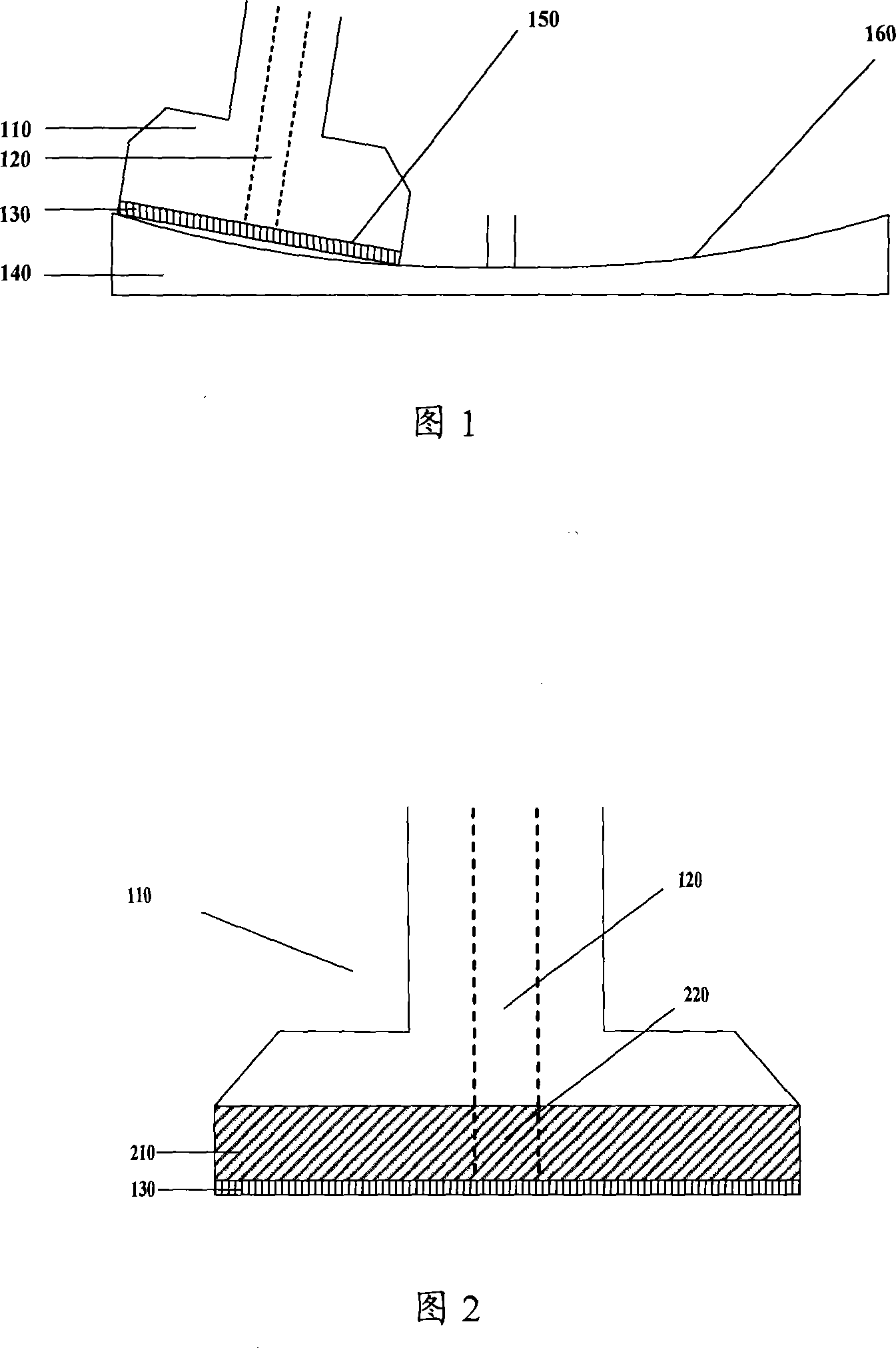

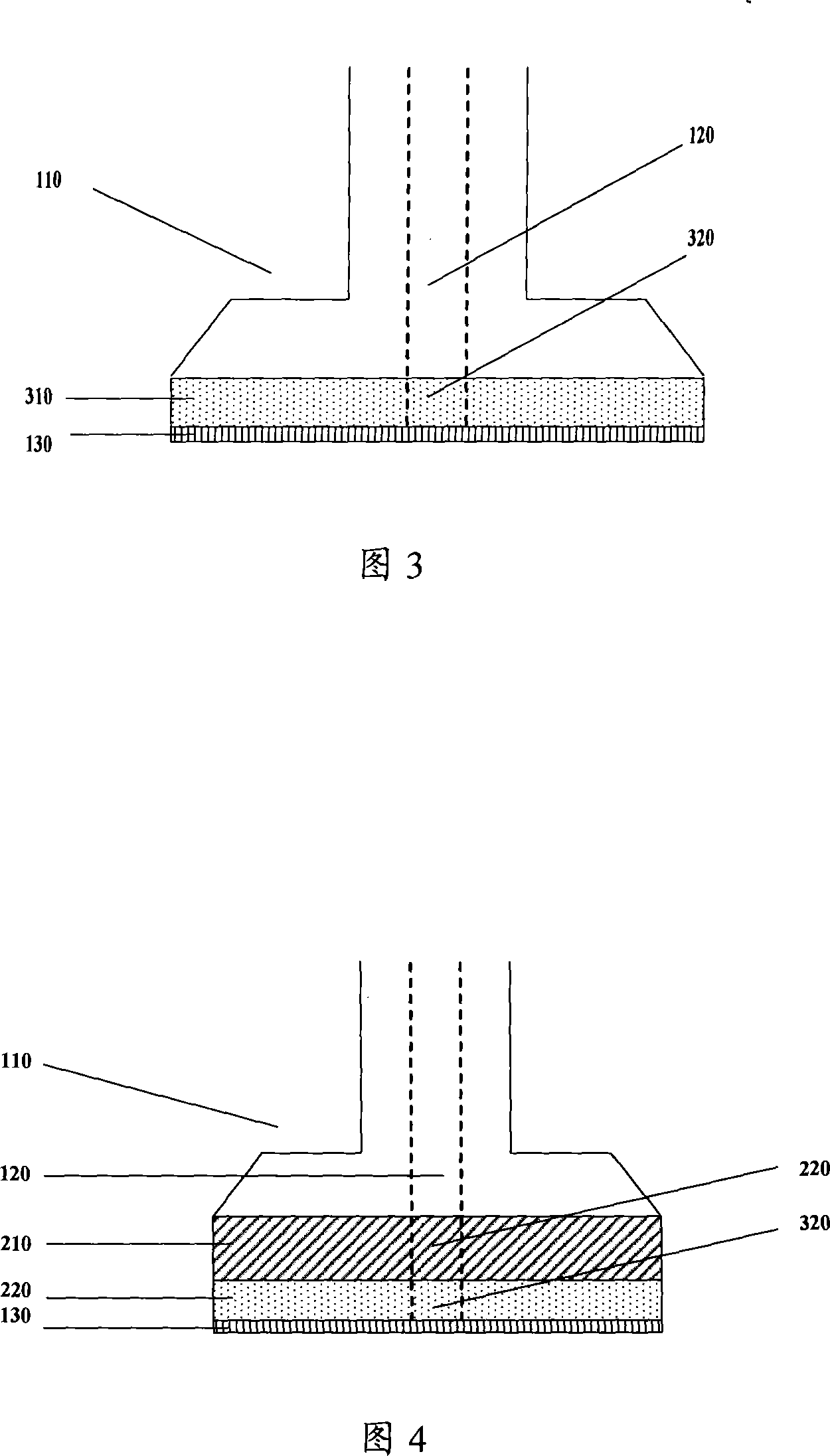

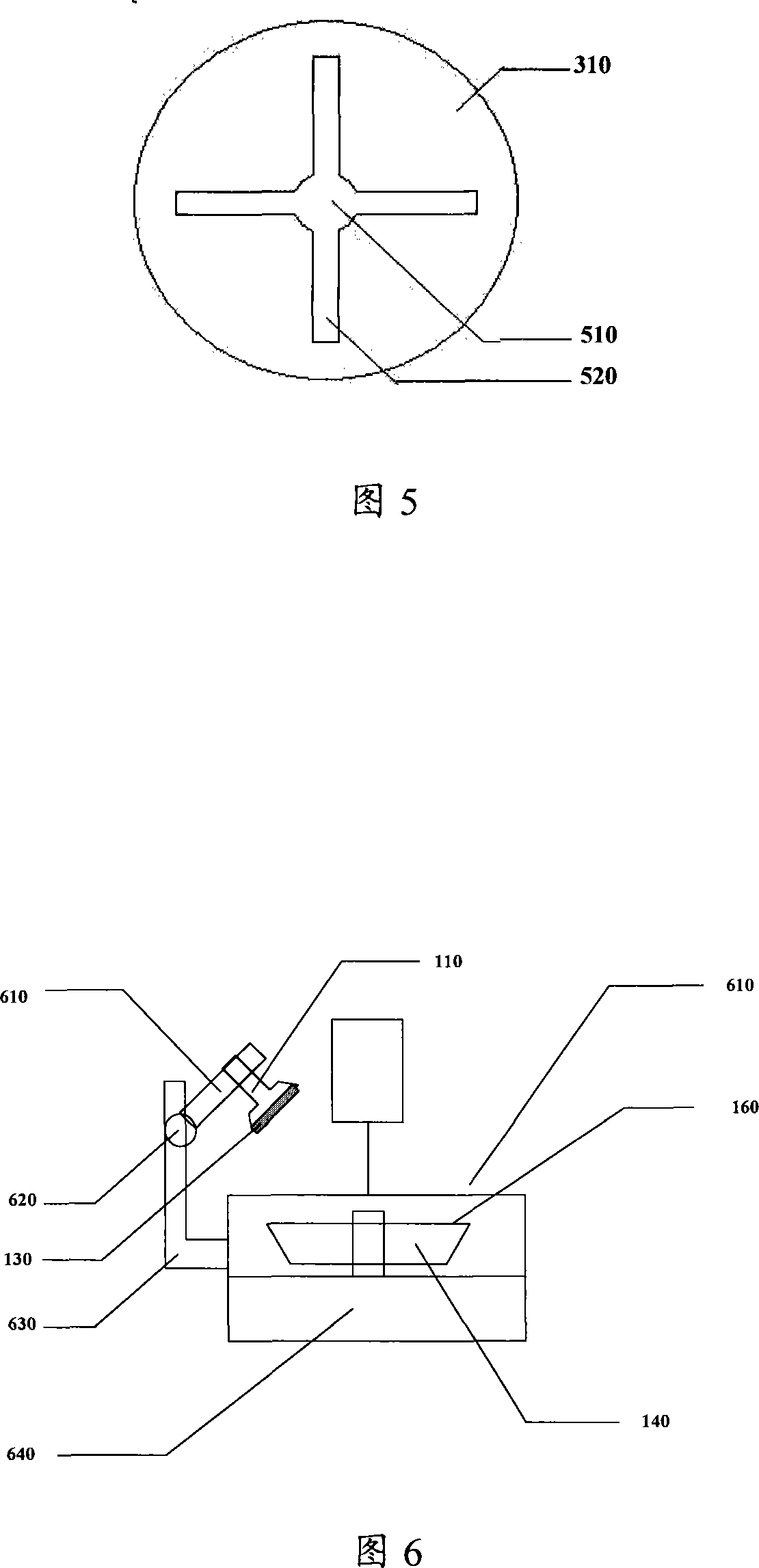

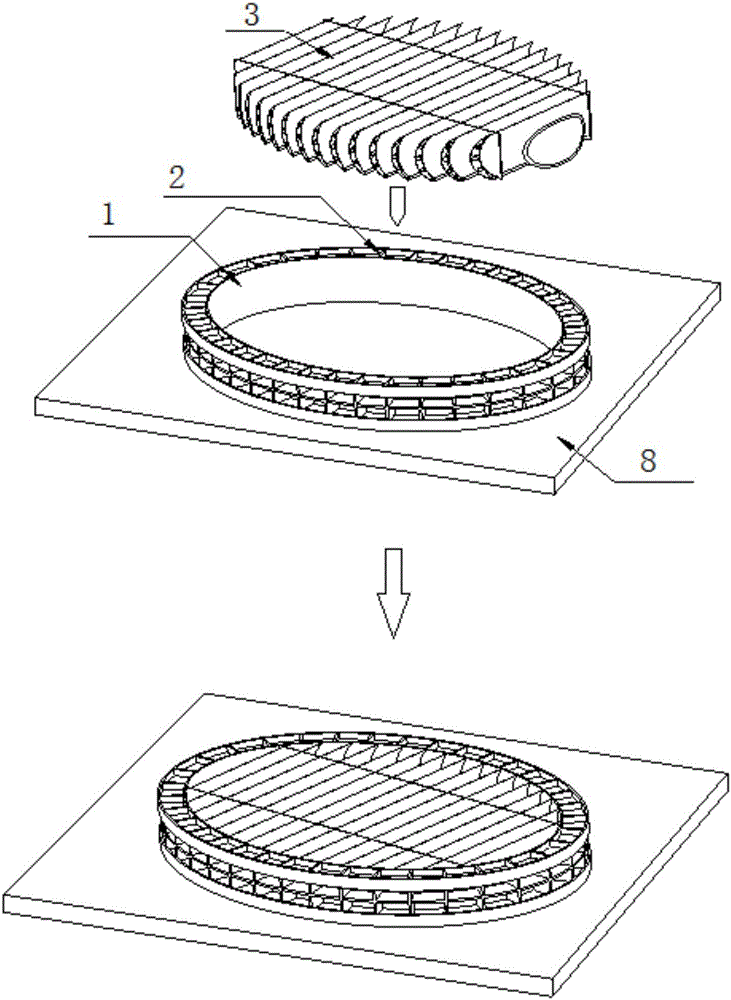

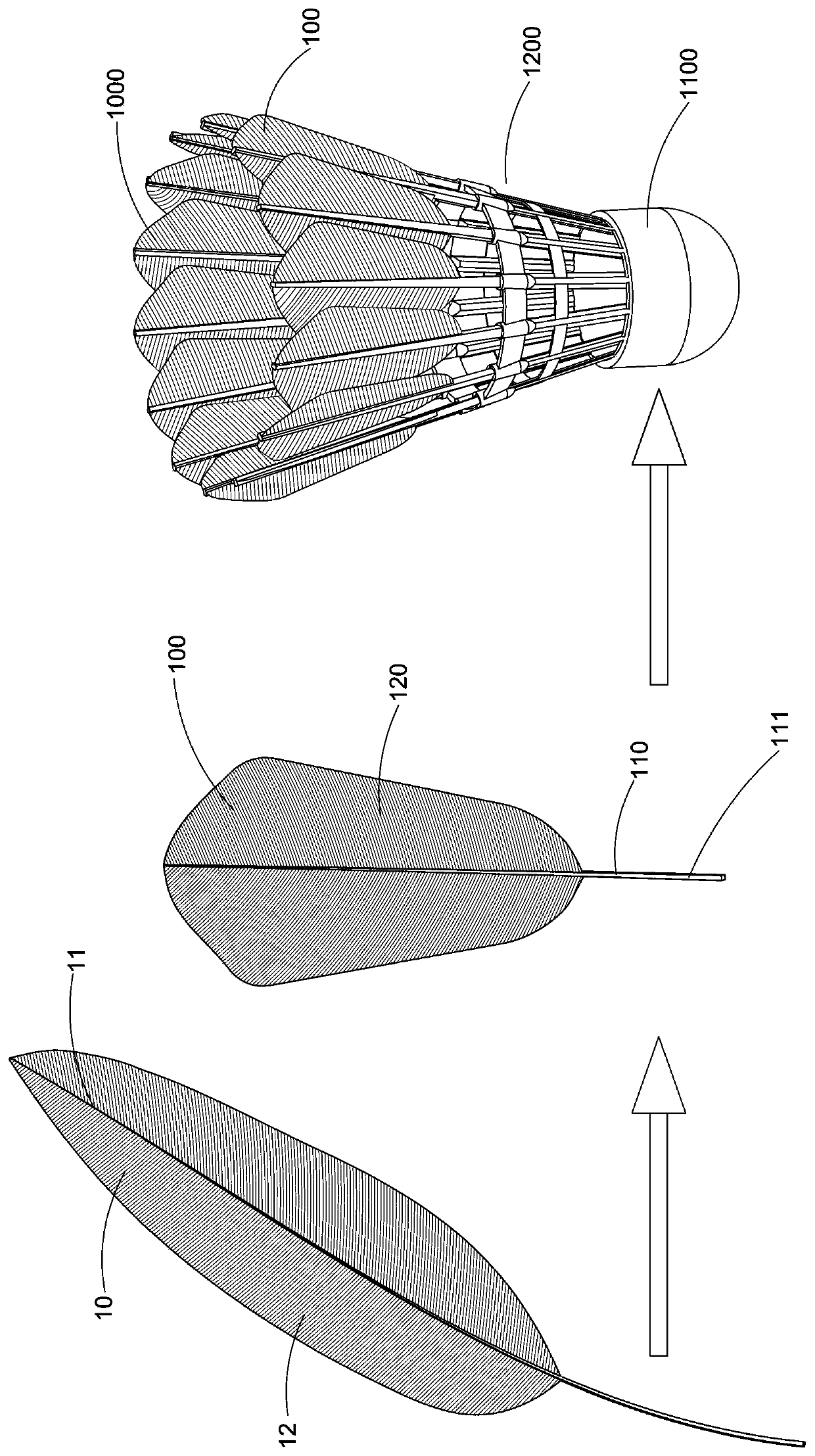

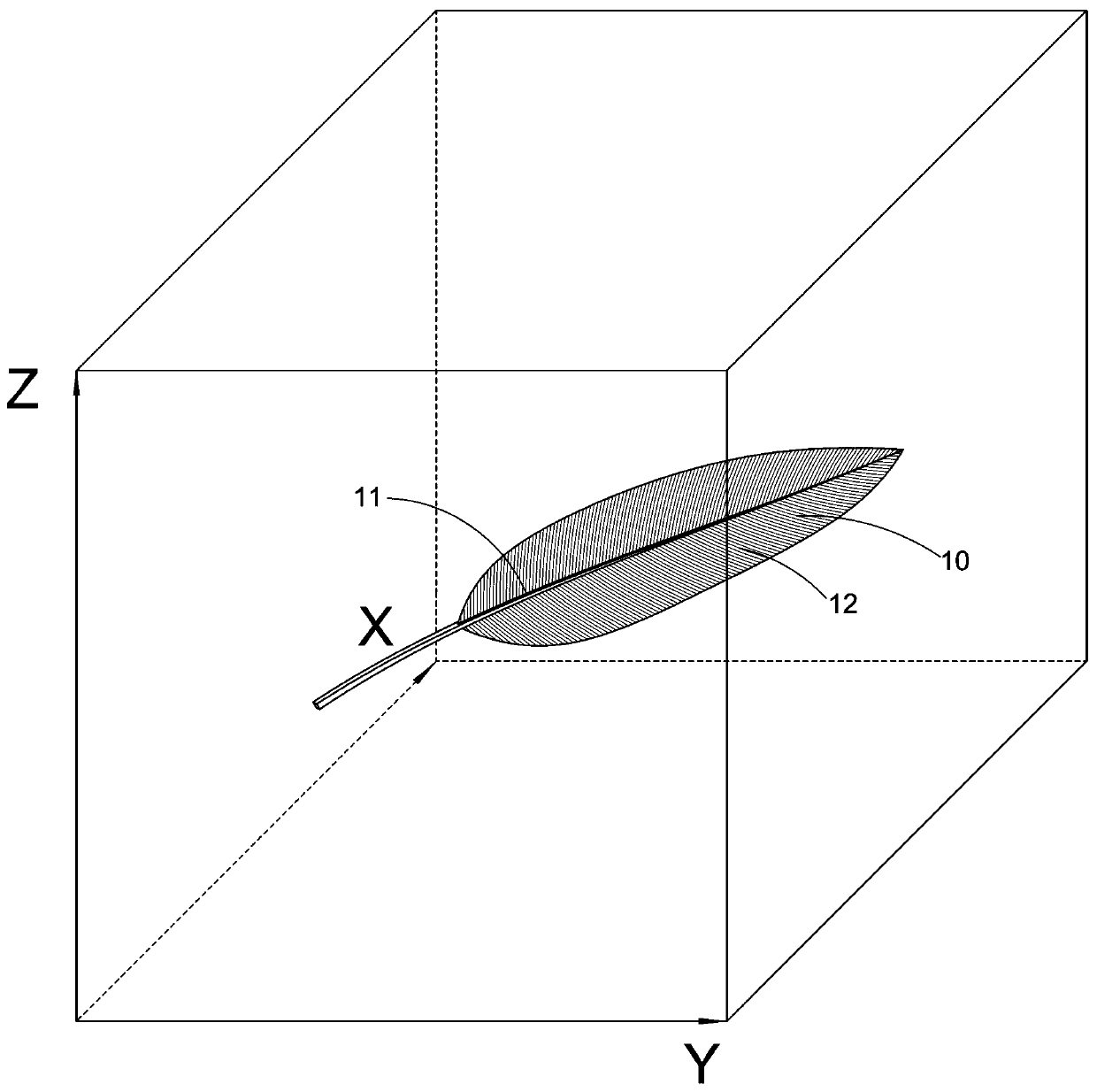

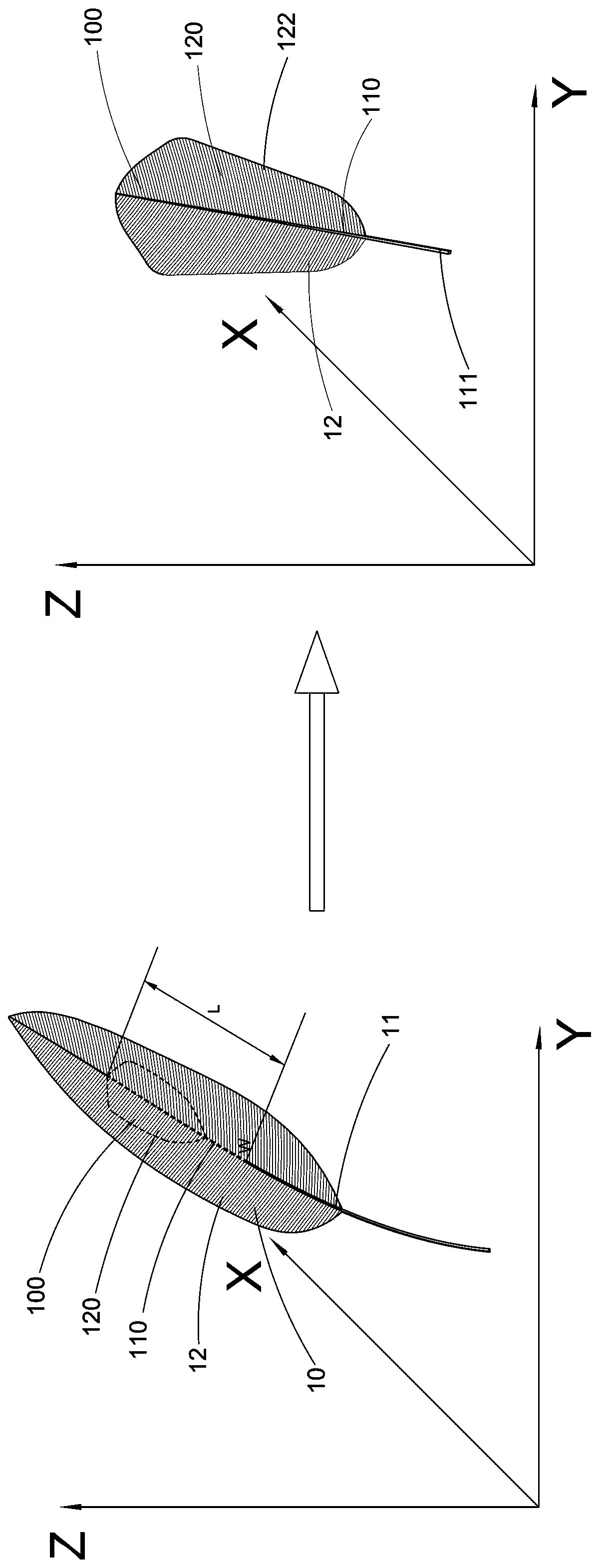

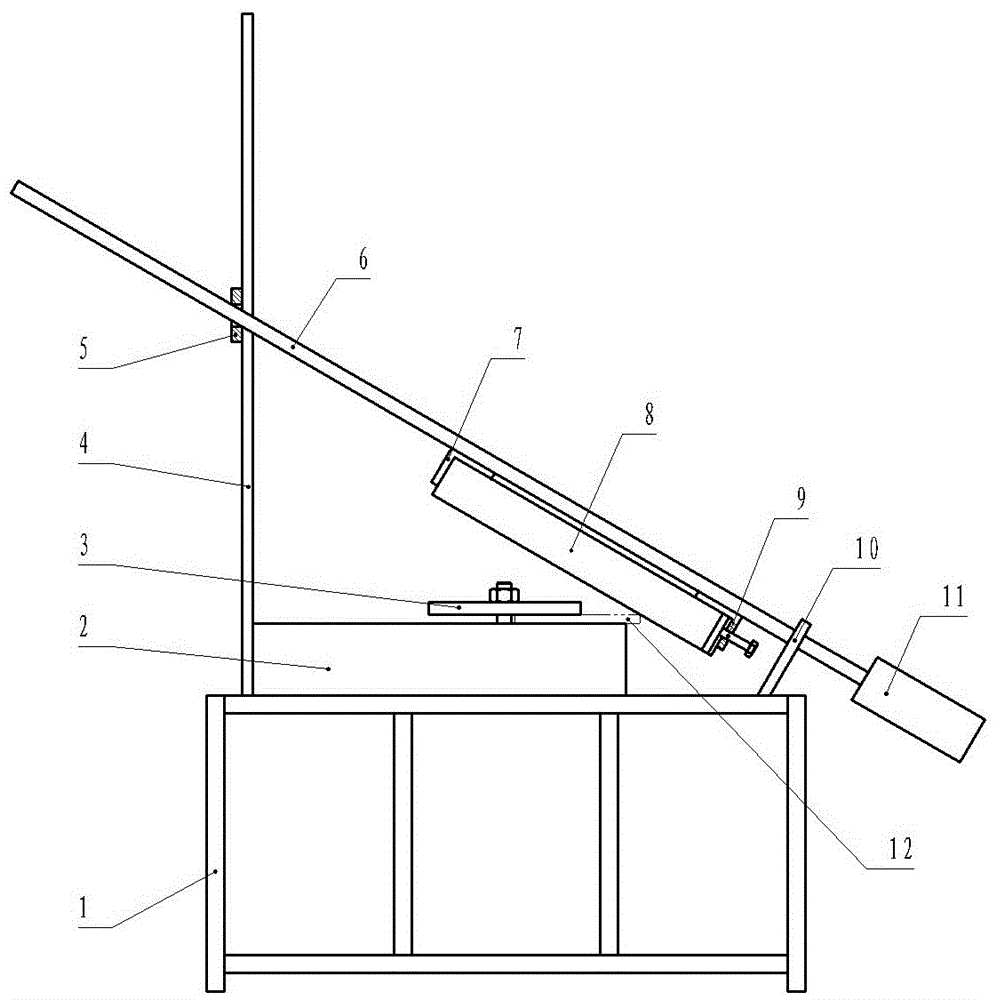

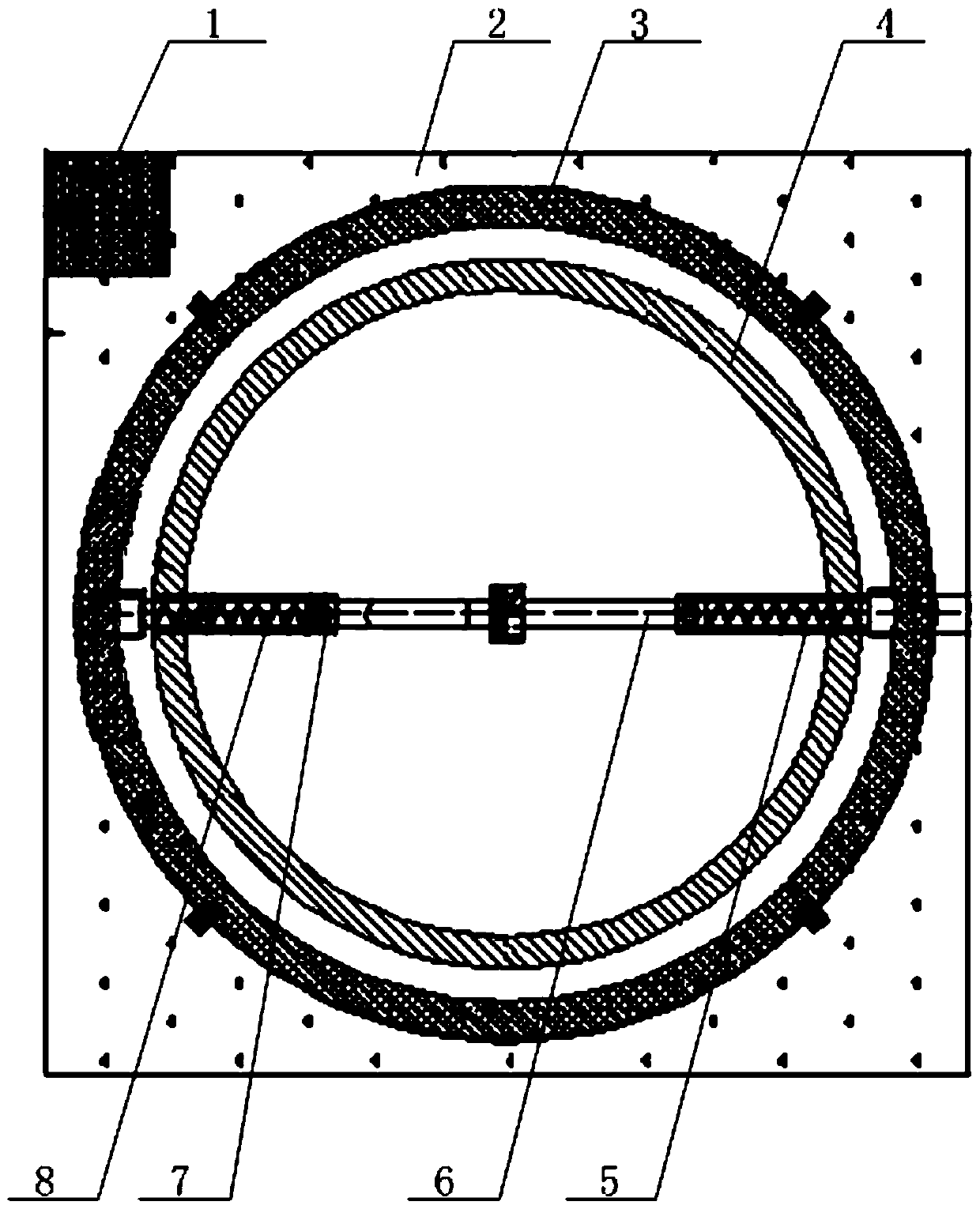

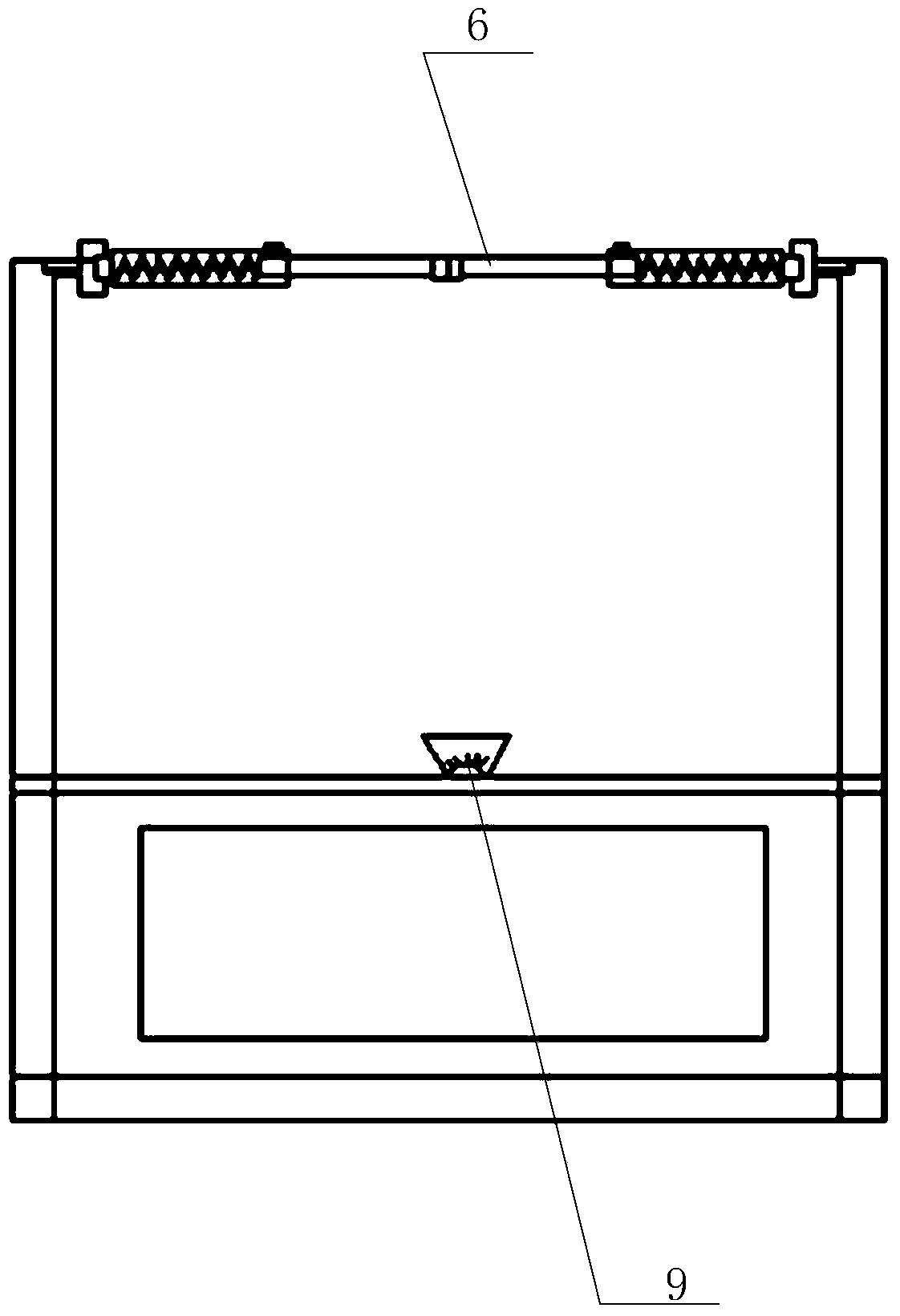

Producing method of shuttlecock

Owner:ANHUI SANCAI SPORTS GOODS

Manufacturing method of badmintons

ActiveCN102989150ARealize automated productionReduce or eliminate manual operationsSport apparatusEngineeringMechanical engineering

The invention discloses a manufacturing method of badmintons. The method comprises the following steps of: (a) molding a flocking shelf with a group of flocking rods and a group of flocking tubes, wherein each flocking tube is respectively and integrally formed at one end of a corresponding flocking rod; (b) installing the flocking shelf at a fixed ball head; and (c) respectively implanting the inserting heads of a group feather blades into corresponding flocking tubes; or after inserting the feather blades into the flocking shelf, the flocking shelf with the feather blades is installed on the ball head. The method further comprises a step (d) that natural feather is cut according to the demands of a cutting model to obtain the feather blades. According to the method, machines are engaged to operate, the production efficiency of the badminton is improved, and the manufactured badminton has a molded flocking shelf, so that stable and accordant conical degree is formed for the badmintons, and the badminton quality is ensured.

Owner:ANHUI SANCAI SPORTS GOODS

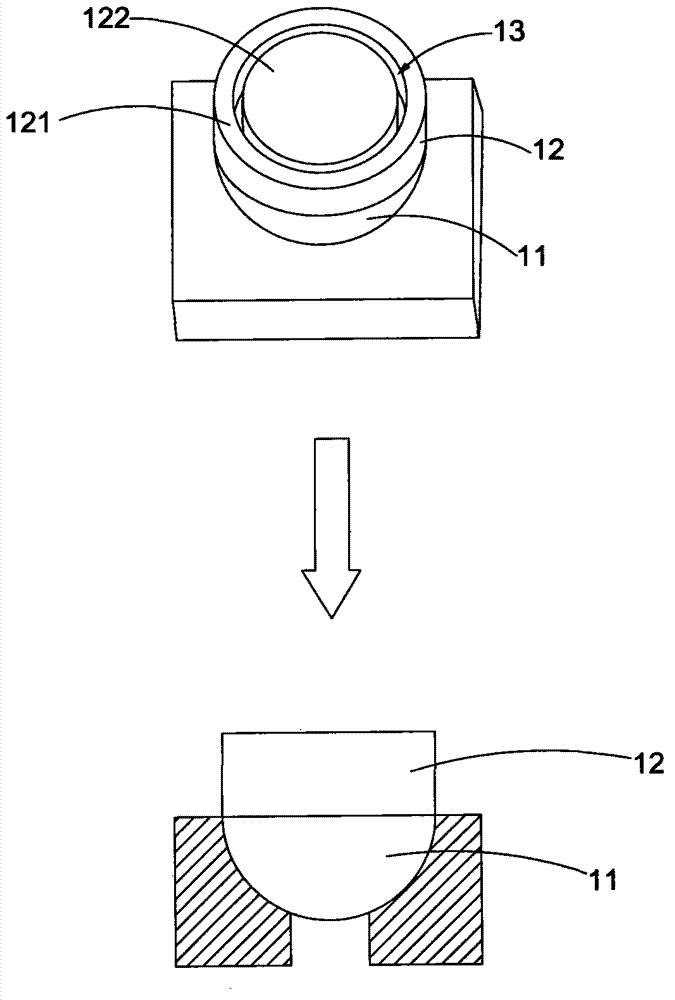

Angle lapping device for silicon chip edge

InactiveCN101214625AAvoid breakage etc.Low costEdge grinding machinesGrinding machine componentsCushioningSilicon chip

The present invention relates to a bevelling device of the edge of a silicon chip. The present invention comprises a wheelhead and an abrading disk; the lower surface of the wheelhead is of a circular plane, and a vacuum pipeline arranged in the wheelhead can absorb the silicon chip on the outer layer of the lower circular surface of the wheelhead; the wheelhead also comprises a magnet layer and a cushioning layer, and the magnet layer and the abrading disk generate magnetic attraction which ensures that the silicon chip is uniformly stressed; the cushioning layer ensures that the silicon chip and the wheelhead are tightly combined together and not injured by collision. The upper surface of the abrading disk is provided with a concave surface, in the process of bevelling, the silicon ship is absorbed by the wheelhead to be contacted with the concave surface of the abrading disk, the wheelhead and the abrading disk relatively rotate, and meanwhile, the edge of the silicon chip is bevelled on the abrading disk. The present invention resolves the problems that the traditional manual bevelling operation process is inaccurate, errors can be easily produced, and the bevelled mesa is uneven, so the present invention ensures that the operation is simple, the accuracy is improved, the cost is greatly saved, and the efficiency is increased.

Owner:ZHUZHOU CSR TIMES ELECTRIC CO LTD

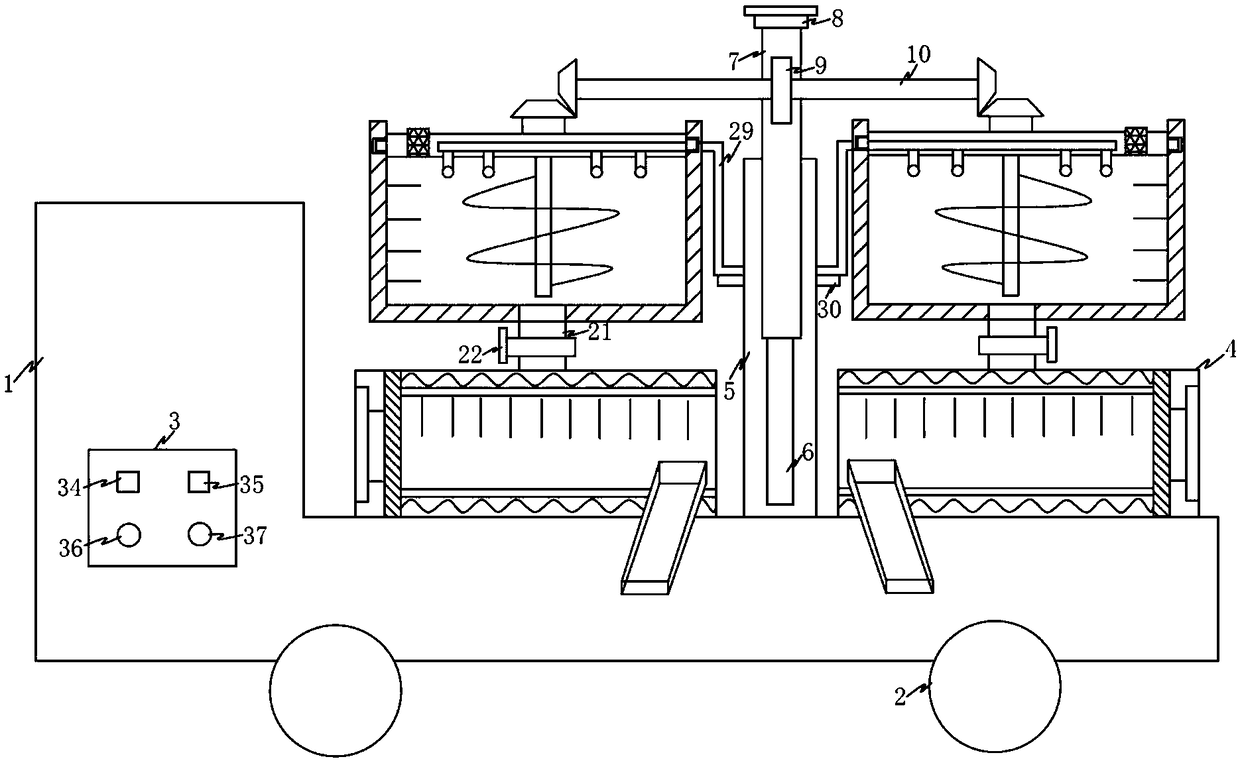

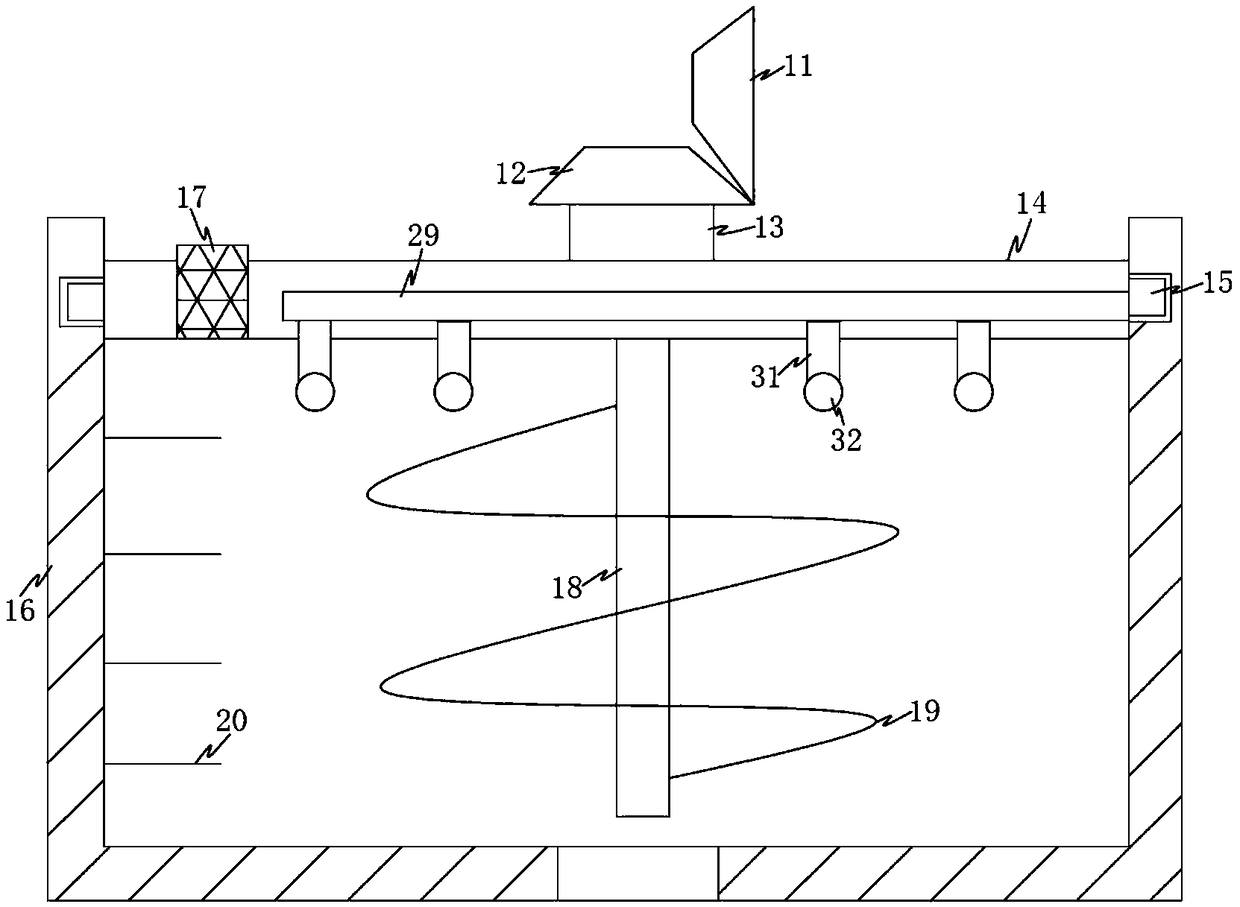

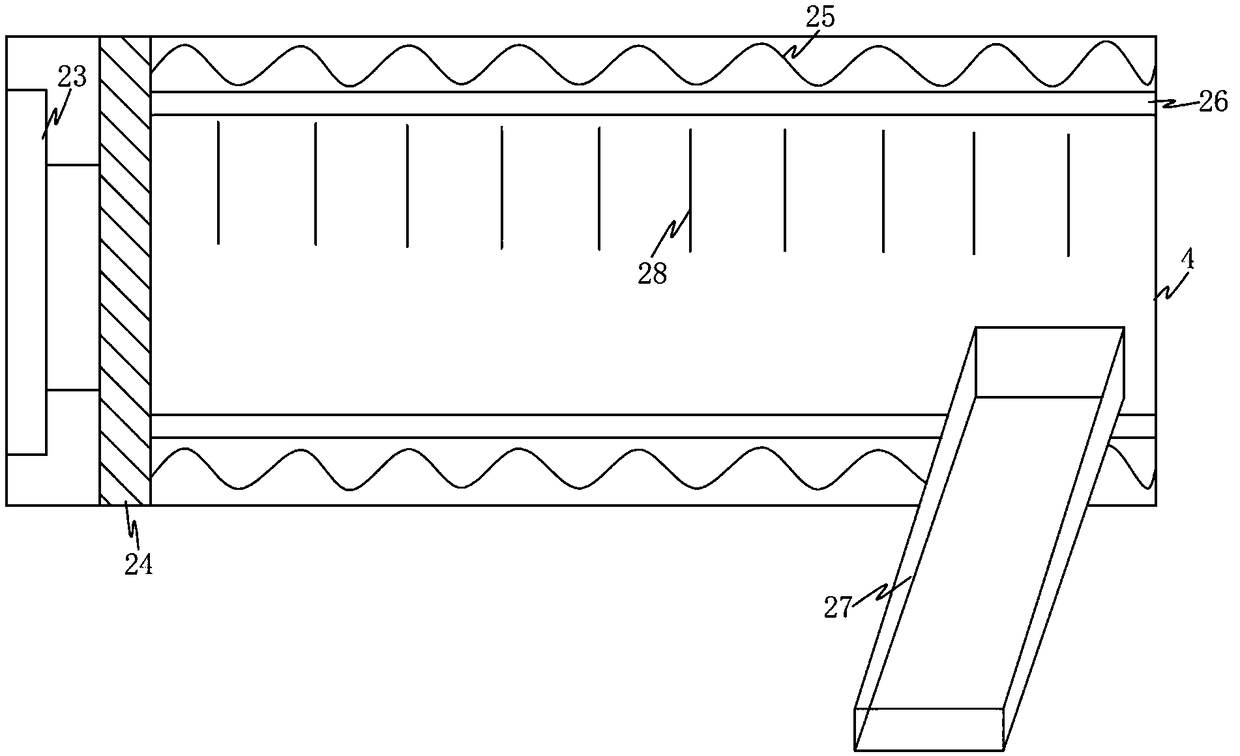

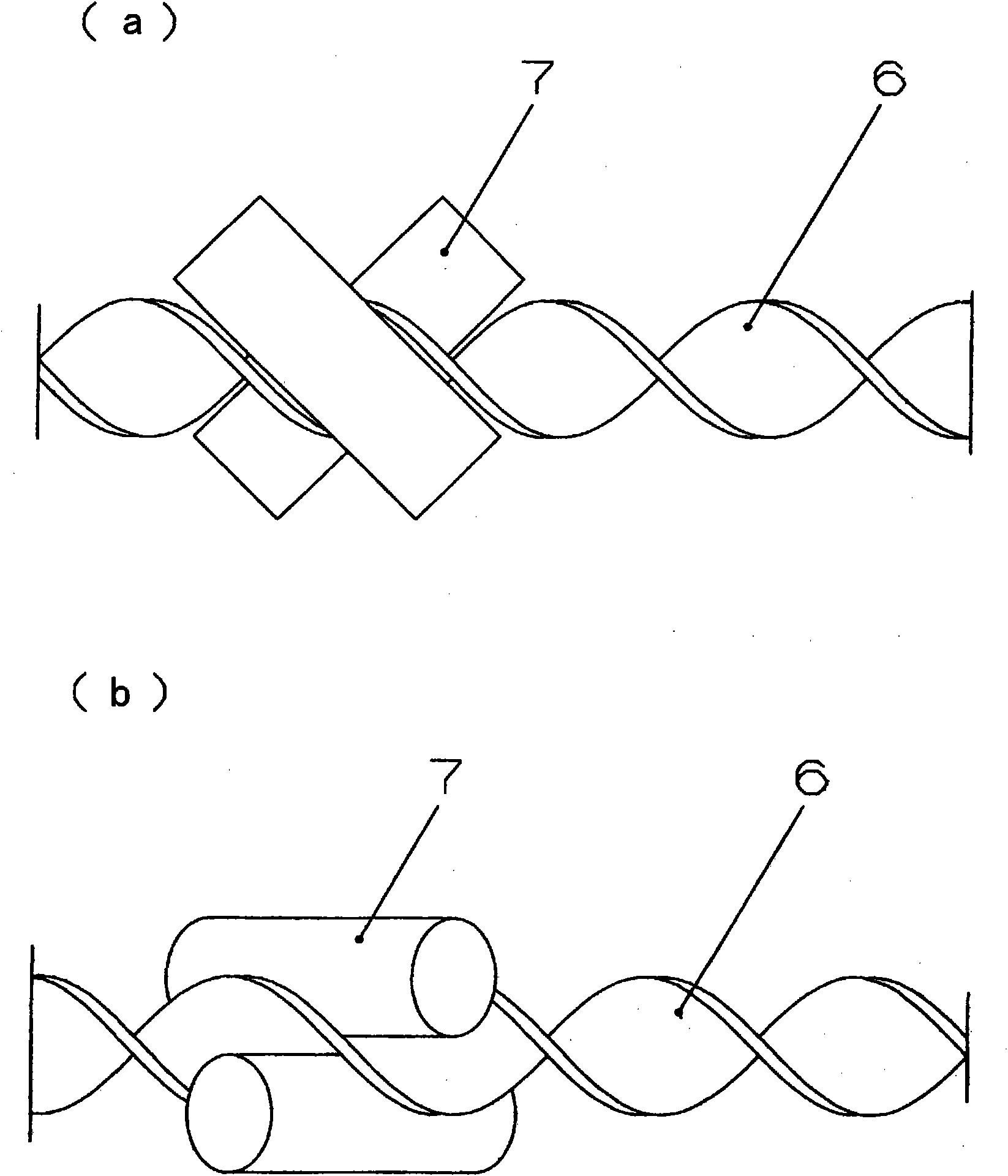

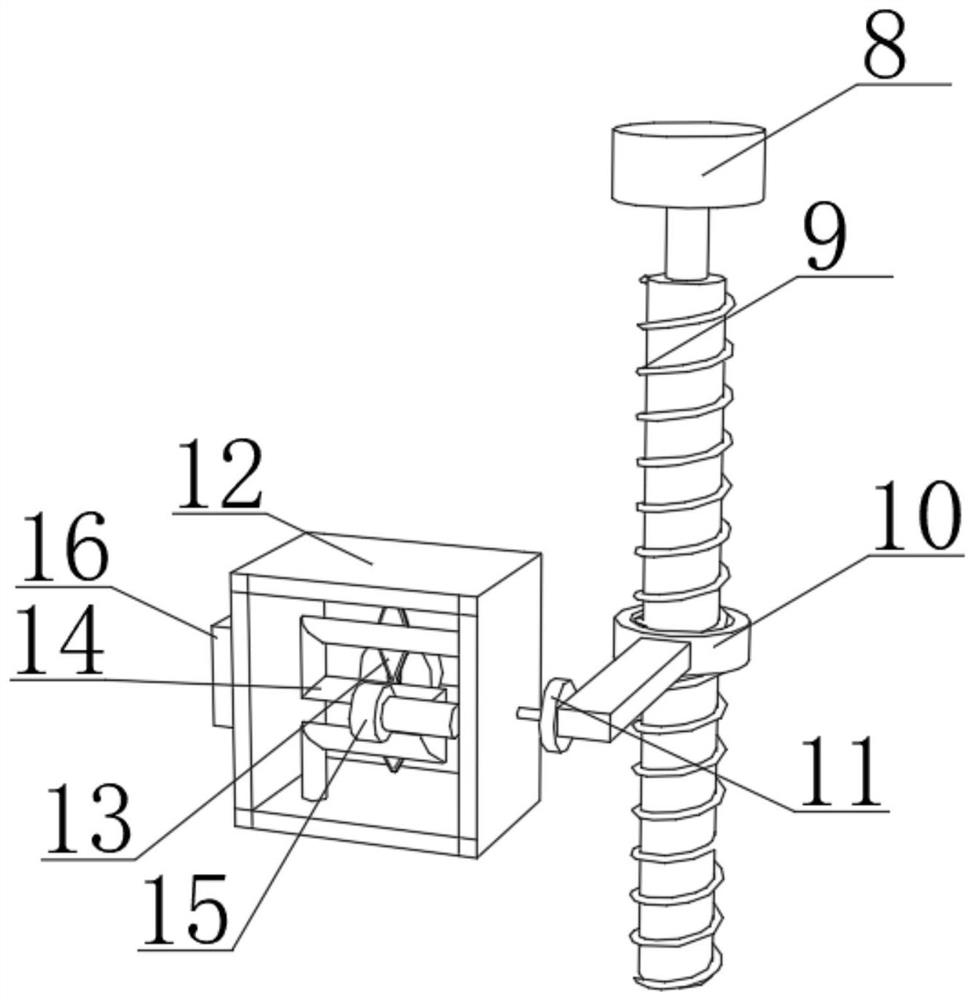

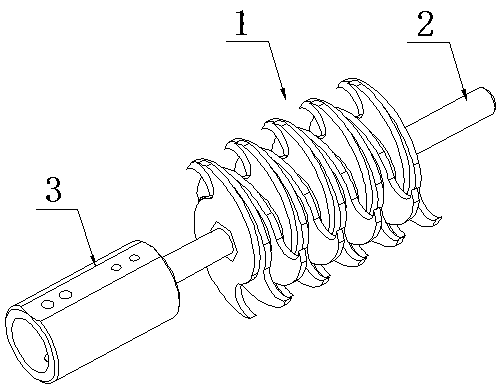

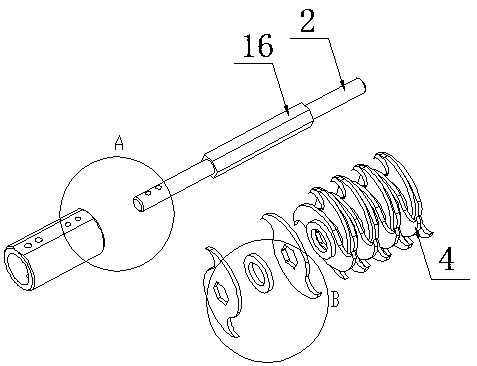

Intelligent mechanical feeding trolley

PendingCN108967237AReduce manual labor intensityStir evenlyAnimal feeding devicesAnimal ForagingEngineering

The invention discloses an intelligent mechanical feeding trolley. The trolley comprises a trolley body, on which a control box, forage stirring devices and quantitative feeding boxes are arranged. Arack is movably equipped with a gear. The center of the gear is fixedly equipped with a connecting rod in a penetrating manner. Two ends of the connecting rod are symmetrically equipped with driving bevel gears which are movably connected with driven bevel gears. The driven bevel gears are connected with cover boards through connecting blocks. The centers on one sides, away from the connecting blocks, of the cover boards are fixedly equipped with support columns. Spiral rods are fixedly arranged on the support columns. The side walls of the quantitative feeding boxes are fixedly equipped withsecond electric push rods fixedly connected with push boards. The intelligent mechanical feeding trolley is internally equipped with devices used for uniformly stirring forages. Therefore, human resources are saved. According to conditions of livestock, types of forages are flexibly selected and forage weight is adjusted. The trolley is simple in operation. Meanwhile, a built-in water tank is usedfor cleaning the trolley. The trolley has concentrated functions and is widely used.

Owner:ANHUI YOMO MACHINERY TECH

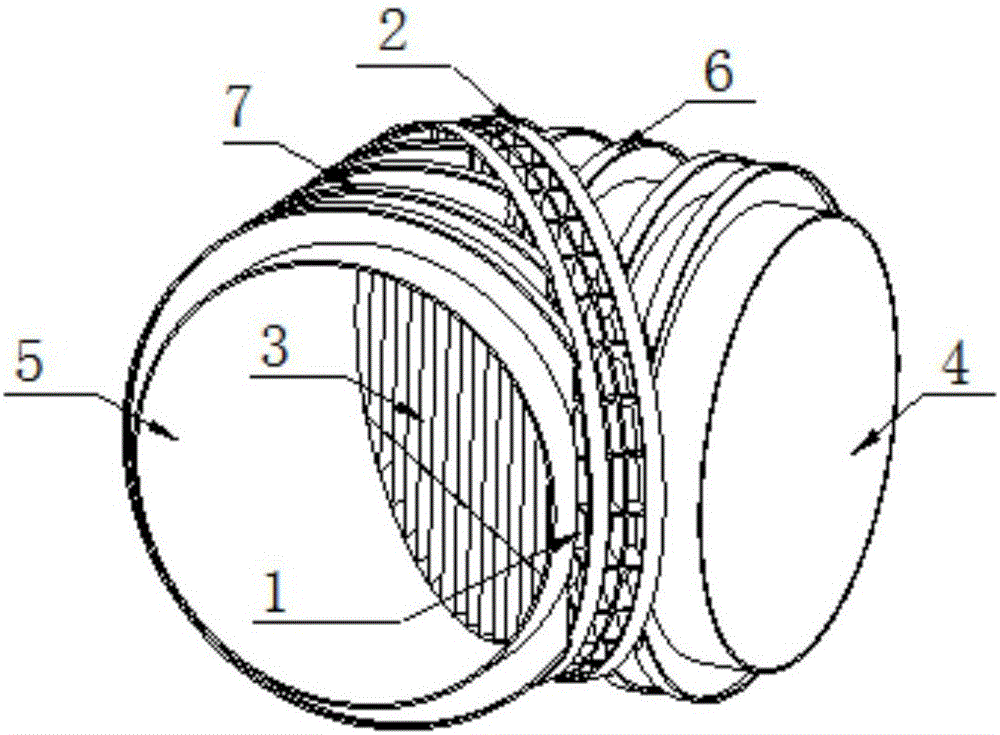

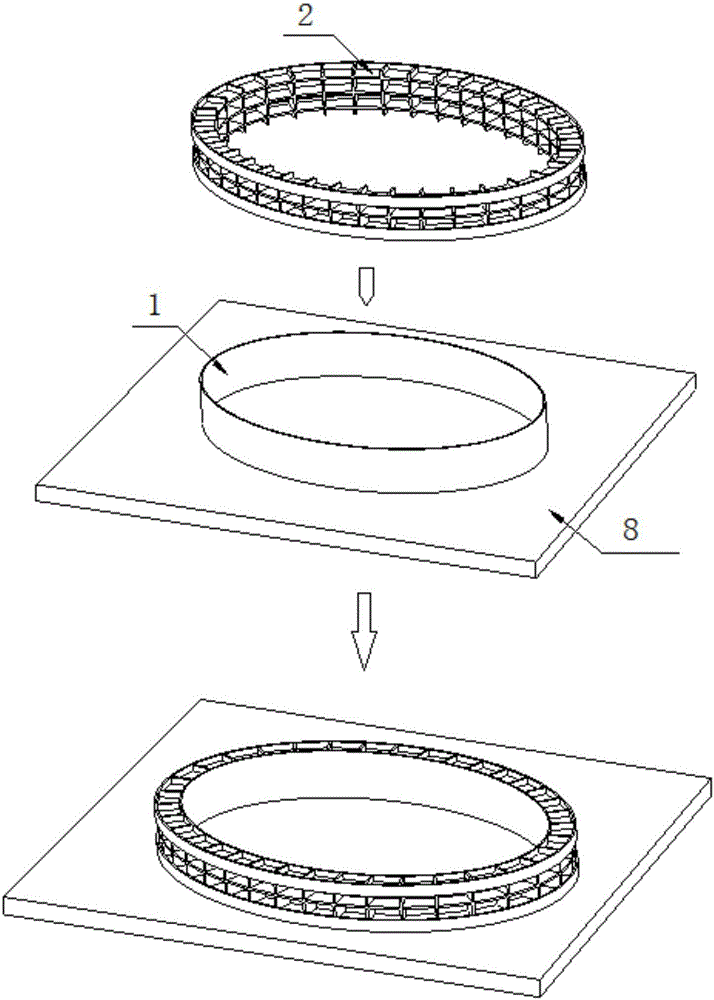

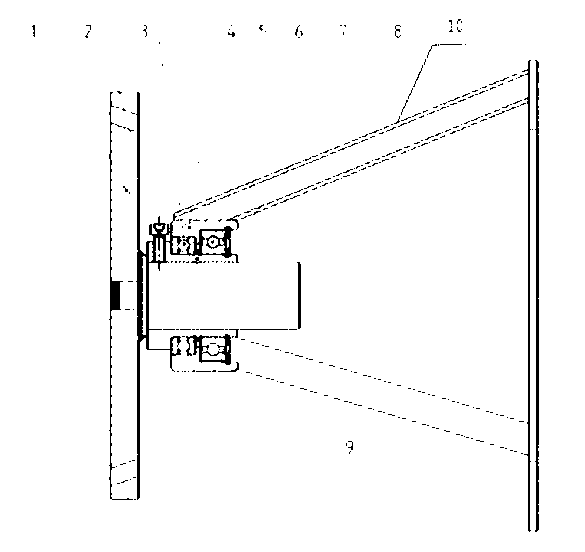

Wind tunnel corner assembling method

ActiveCN106323583ASolve the problem of precision controlSimple methodAerodynamic testingVertical planeEngineering

The invention provides a wind tunnel corner assembling method, the method is simple, the universality is high, the operation is easy, the precision is high, and the problem of precision control of assembling of a large-scale wind tunnel corner segment is solved. Guiding vanes of the wind tunnel corner segment and an elliptical ring shell are assembled in a horizontal plane so that the angle between the guiding vanes and the plane of the elliptical ring shell is adjusted more easily, the guiding vanes can maintain uniform space and consistent angle, and the assembling difficulty between the guiding vanes and the elliptical ring shell is reduced; and the elliptical ring shell of the wind tunnel corner segment and a straight cylindrical shell A and a straight cylindrical shell B are assembled in a vertical plane so that the bending moment generated in an assembling process of the straight cylindrical shell A and the straight cylindrical shell B due to shift of the center of gravity is eliminated, the assembling positioning of the elliptical ring shell and the straight cylindrical shell A and the straight cylindrical shell B is more accurate, the requirement of multi-time adjustment of the placement attitude of the straight cylindrical shell A and the straight cylindrical shell B of the conventional method is omitted, and the assembling process is simplified.

Owner:WUHAN YIYE STEEL STRUCTURE

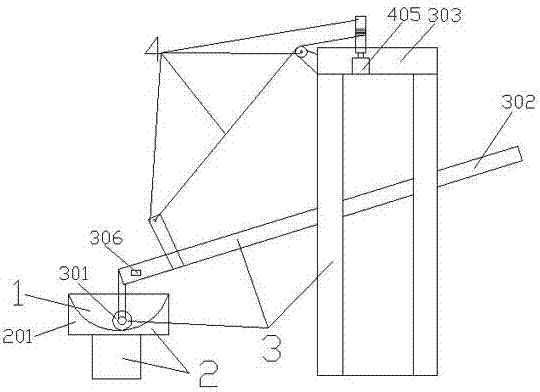

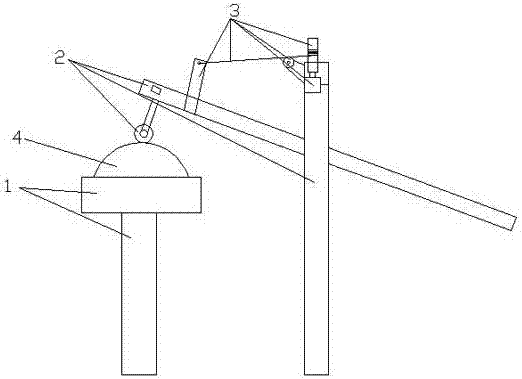

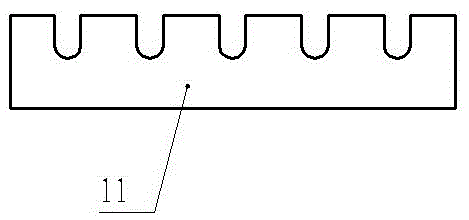

Polishing robot used for internal surface of iron pan

ActiveCN106891238AReduce wearEasy to adjustGrinding carriagesPolishing machinesRotary stageSteering wheel

The invention relates to a polishing robot used for the internal surface of an iron pan. The polishing robot comprises a rotating platform, a polishing mechanism, an adjusting mechanism and a control system. The polishing mechanism comprises a grinding wheel, an oscillating rod and a supporting frame. A rail is arranged between stand columns of the supporting frame. A sliding base is arranged in the rail. The sliding base comprises sliding blocks and a rotating shaft. The rotating shaft is connected with one end of the oscillating rod in a rotating mode, and the other end of the oscillating rod is provided with the grinding wheel. The adjusting mechanism is arranged above the oscillating rod. The adjusting mechanism comprises a fixing block, a pulling rope, a steering wheel and a rope winding bar. One end of the pulling rope is fixed to the fixing block, and the other end of the pulling rope winds across the steering wheel to be fixed to the rope winding bar. A motor II drives the rope winding bar to rotate, and the rotation is matched with oscillation of the oscillating rod in a rail groove; and then a pan blank to be polished is driven to rotate through the rotating platform so that polishing can be completed. Due to arrangement of the polishing mechanism, the adjusting mechanism and the rotating platform, the polishing robot is simple in structure, uniform in polishing thickness, and capable of saving manpower and material resources, improving production efficiency and reducing enterprise cost.

Owner:HENAN MOXI MACHINE MFG

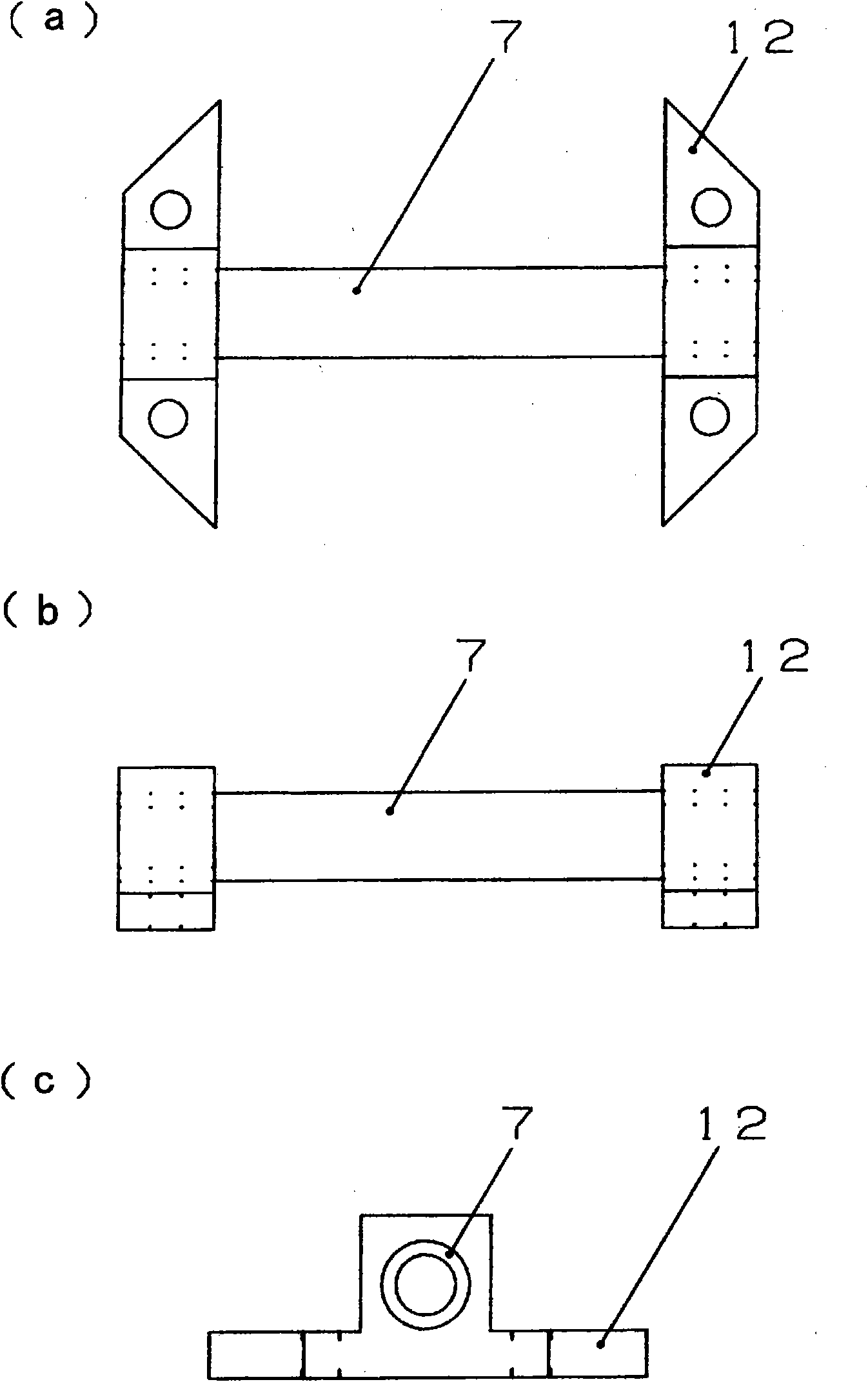

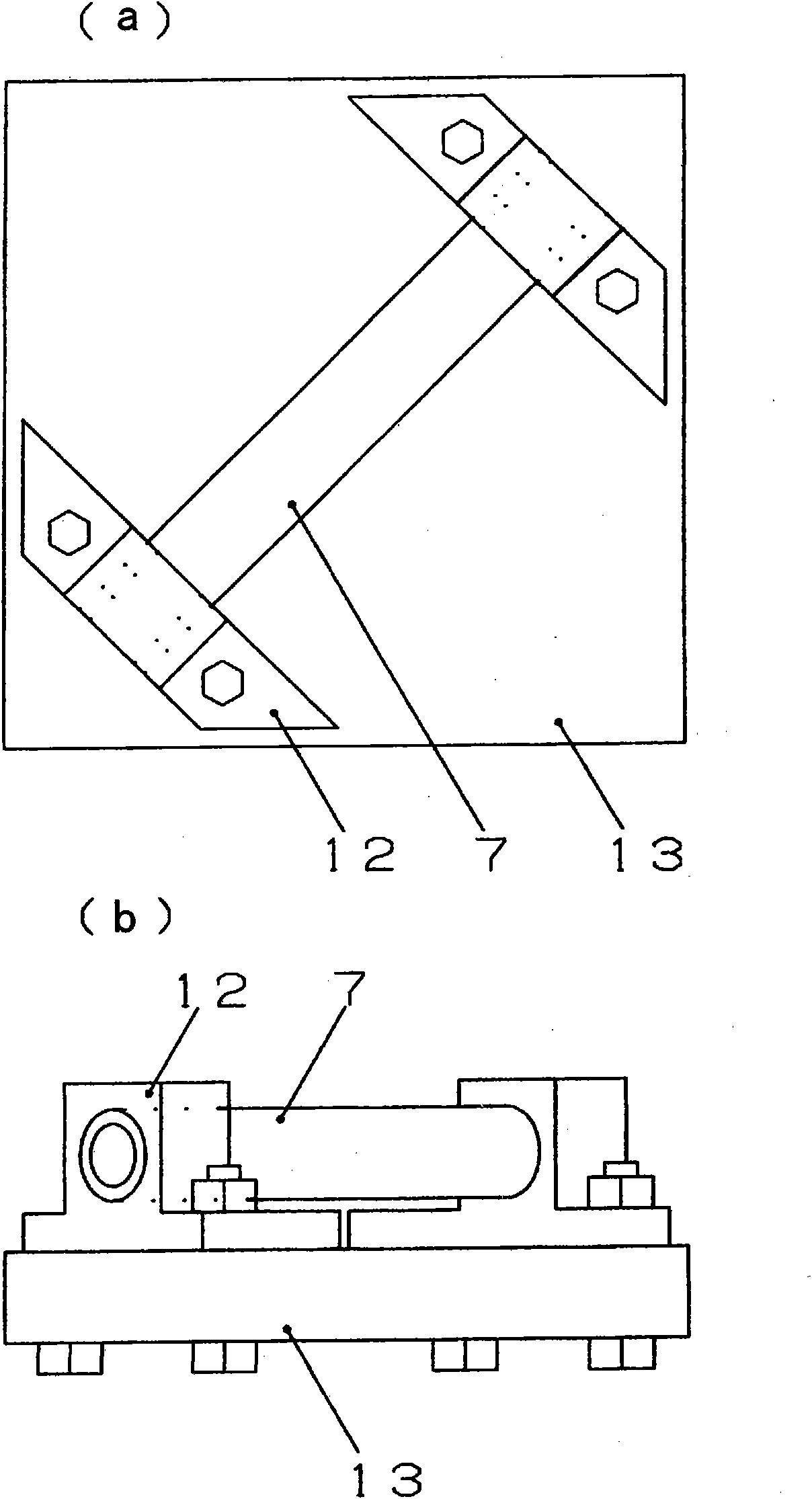

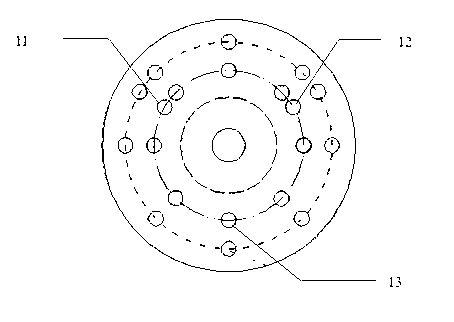

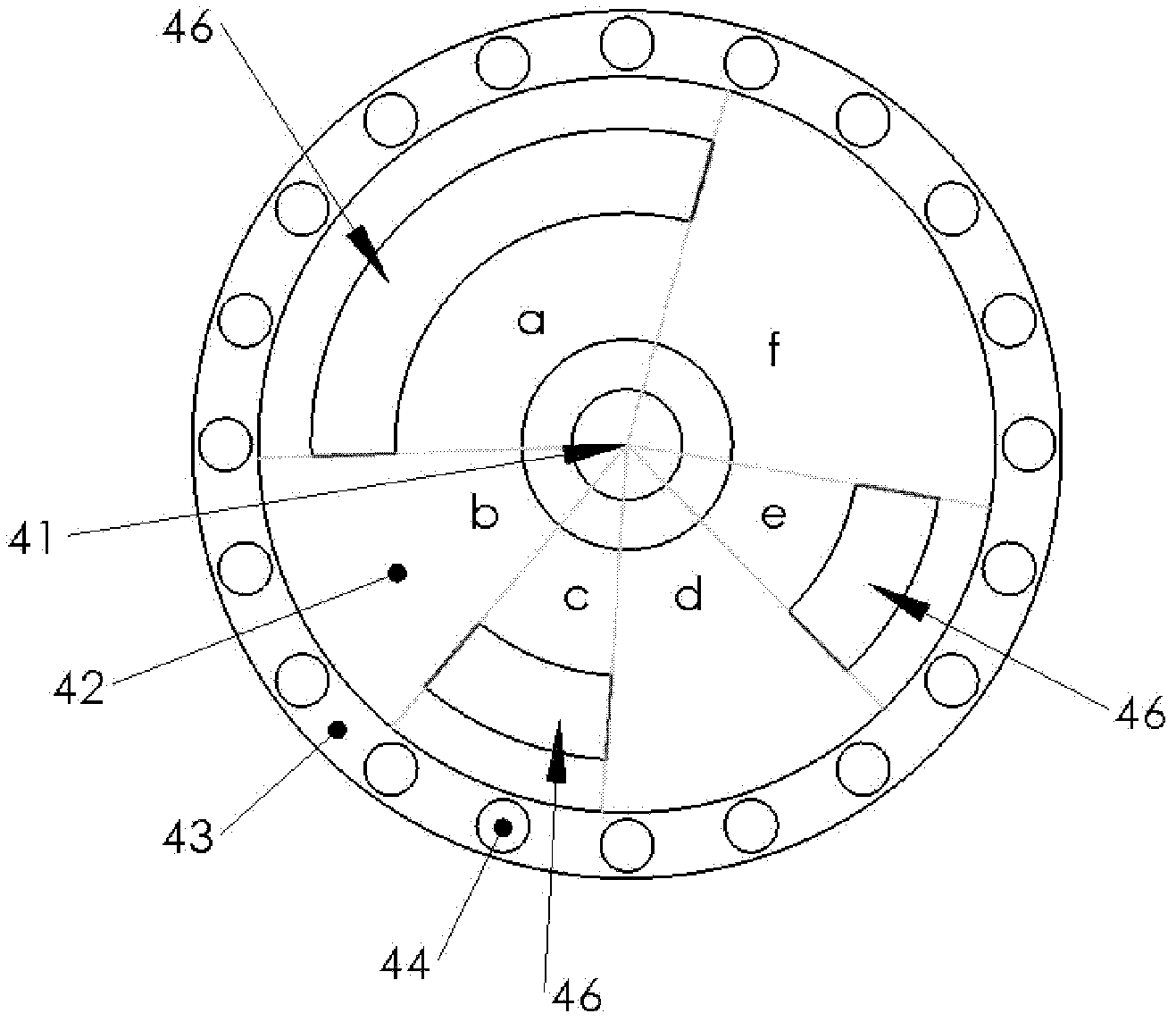

Device and method for adjusting twisting of rope twisting machine

The invention discloses a device and a method for adjusting twisting of a rope twisting machine. The device comprises a porous disc, a fixing support and a sleeve assembly, multiple small holes are formed in the porous disc and correspondingly distributed on vertexes of inscribed equilateral triangles, inscribed squares and inscribed regular octagons on corresponding circles, and different numbers of rope strands correspond to corresponding small holes. Included angles among the rope strands during twisting of the roper strands are evened through the small holes on the porous disc, so that tensile force on each rope strand can be evened by rotating the porous disc.

Owner:TAIAN ROPE NET PLASTIC

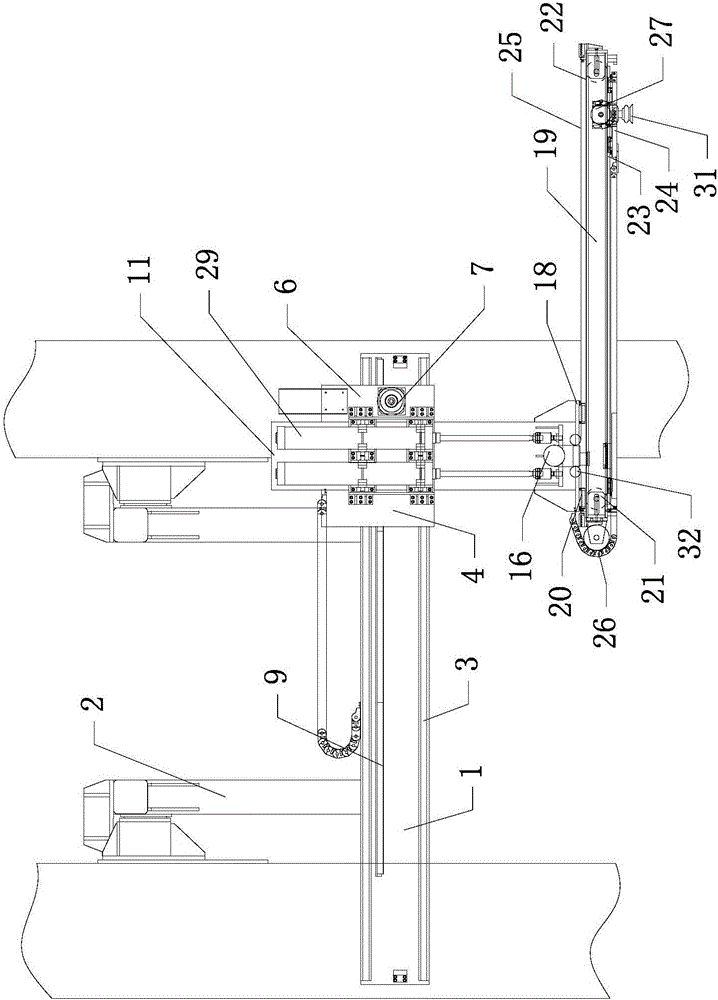

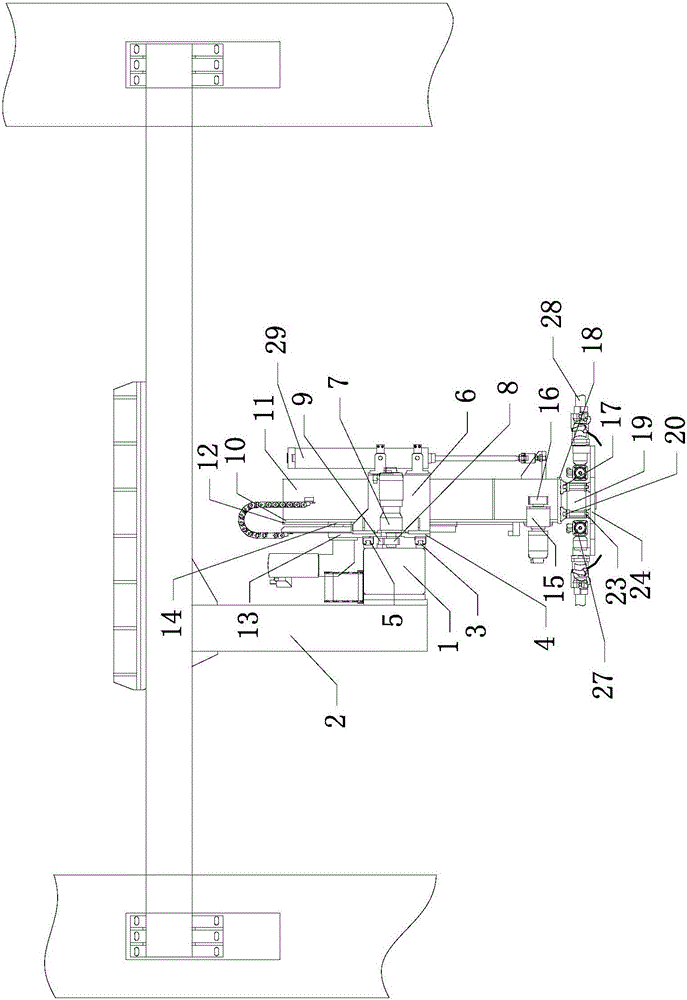

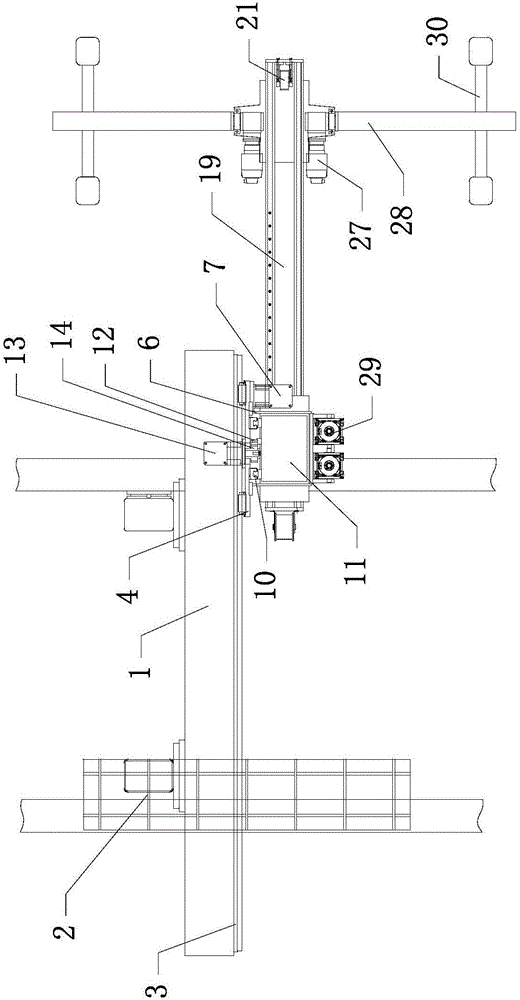

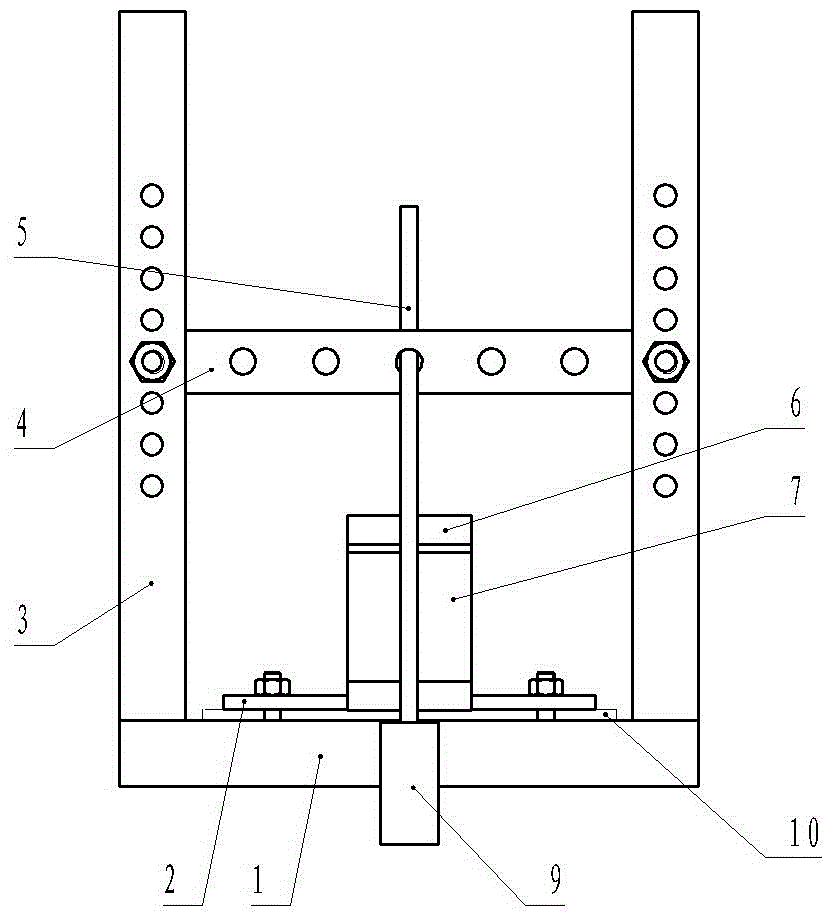

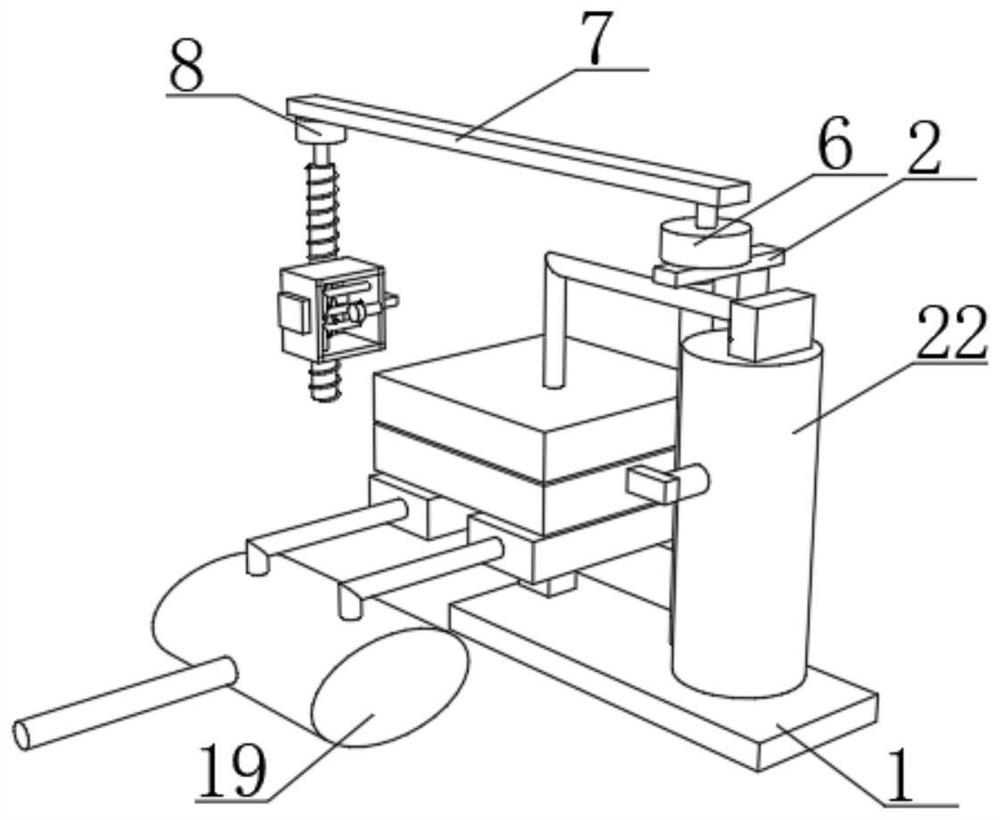

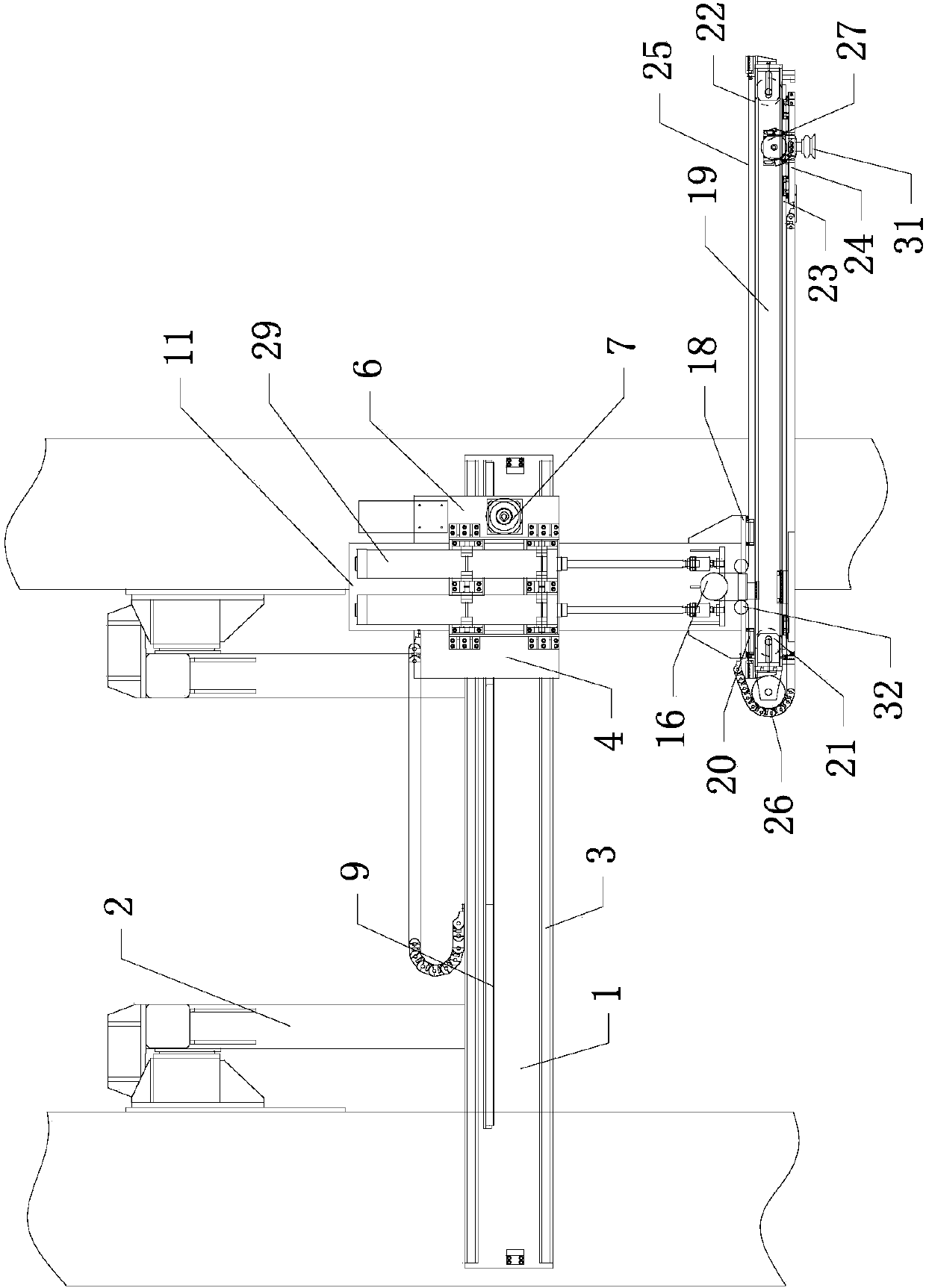

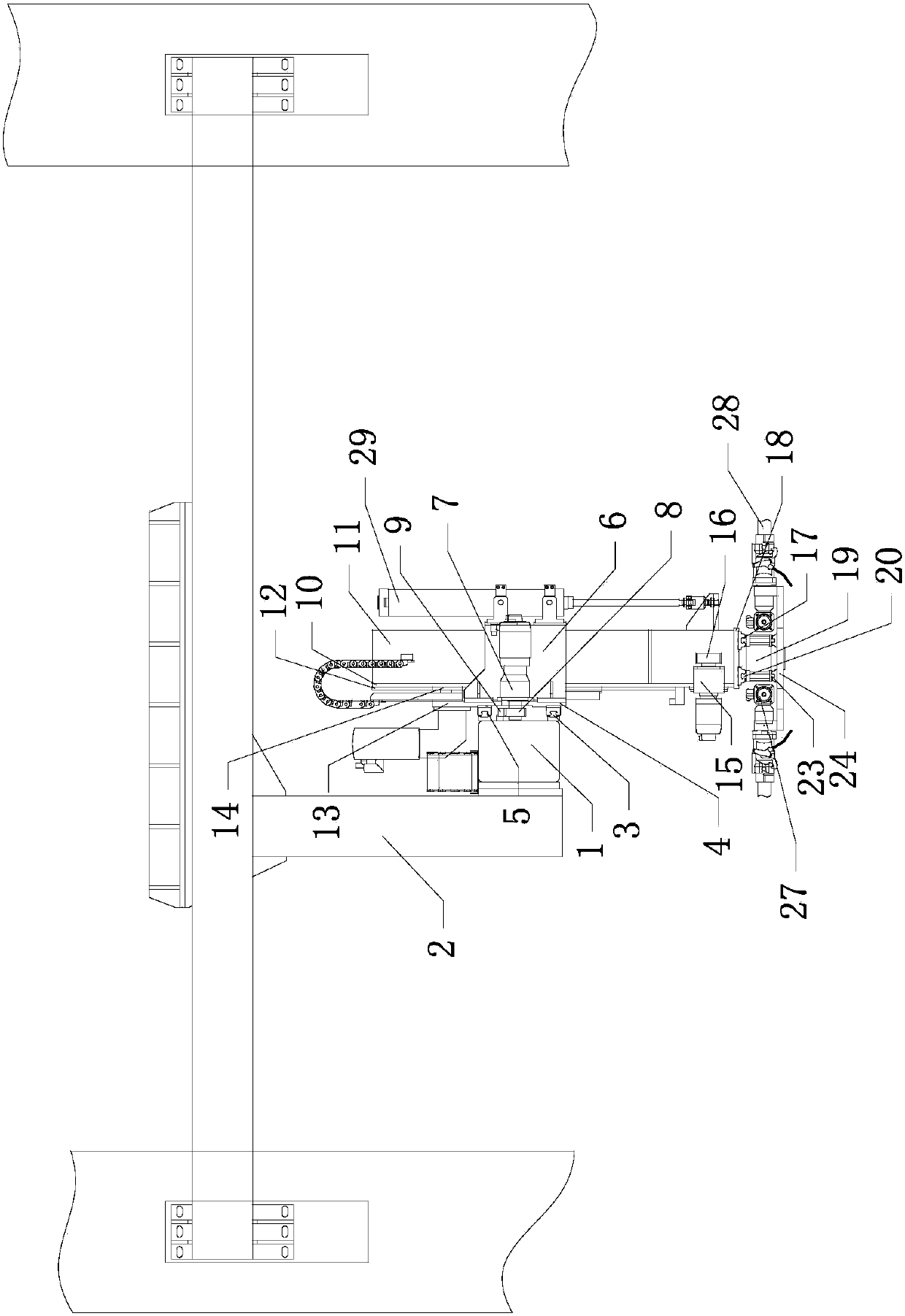

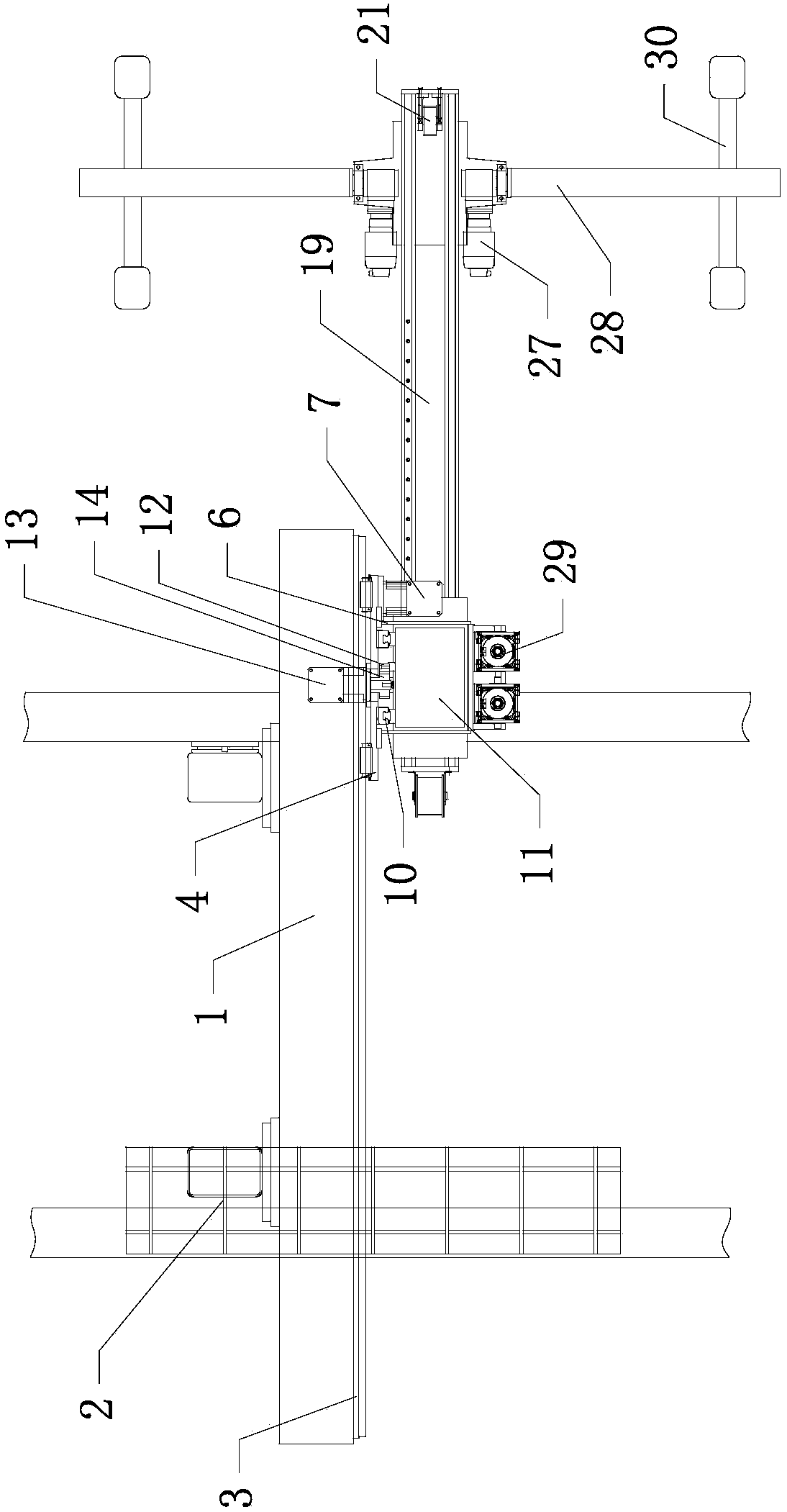

Five-axis carrying manipulator

The invention relates to the technical field of mechanical automation, in particular to a five-axis carrying manipulator. The five-axis carrying manipulator comprises a supporting cross beam, the two ends of the supporting cross beam are fixedly connected to a stand column, the side wall of the supporting cross beam is provided with two first transverse guide rails, the two first transverse guide rails are provided with a first transverse feeding mechanism, the first transverse feeding mechanism is provided with a lifting mechanism, the lower end of the lifting mechanism is provided with a second transverse feeding mechanism, the right end of the second transverse feeding mechanism is provided with a rotating mechanism, and the two sides of the rotating mechanism are each provided with a grabbing mechanism. The five-axis carrying manipulator is ingenious in structure, reasonable in design, easy to operate, high in flexibility, capable of conveniently stretching into a press and small in occupied space, achieves multi-axis simultaneous operation, is high in operation speed, high in carrying efficiency, stable in operation and high in safety in the robot operation process, more effectively meets requirements of people, and solves problems existing in the prior art.

Owner:JINAN FOUND AUTOMATION EQUIP

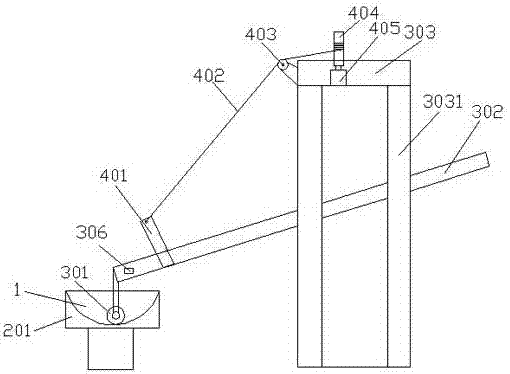

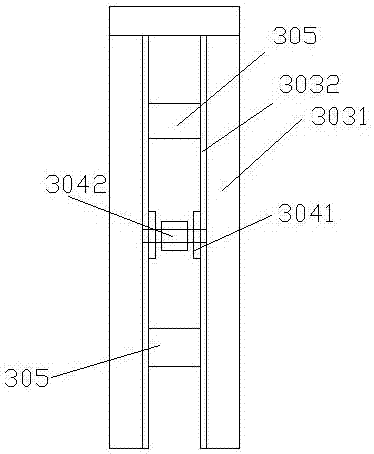

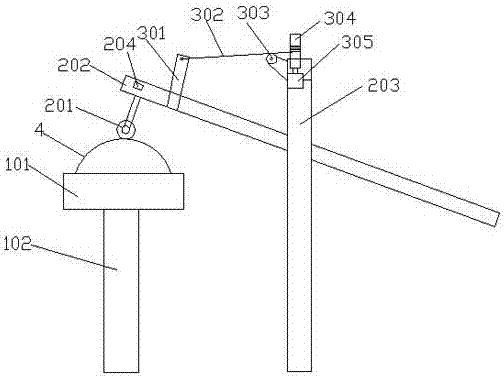

Polishing robot used for external surface of iron pan

ActiveCN106891239APrevent slippageLow costGrinding carriagesPolishing machinesRotary stageControl system

The invention relates to a polishing robot used for the external surface of an iron pan. The polishing robot comprises a rotating mechanism, a polishing mechanism, an adjusting mechanism and a control system. The rotating mechanism comprises a rotating platform and a rotating shaft. The upper end of the rotating shaft extends out of the rotating platform, and fixing rods are arranged on the rotating shaft in a radiation mode. Suction cups are arranged at the ends of the corresponding fixing rods. The rotating shaft and the fixing rods are both hollow. The polishing mechanism is arranged above the rotating mechanism and comprises a polishing wheel, an oscillating rod and a supporting frame. A rail is vertically arranged in the supporting frame. A sliding block is arranged between the two side walls of the rail in a sliding mode. One end of the oscillating rod penetrates into the sliding block, and the other end of the oscillating rod is provided with the polishing wheel. The oscillating rod can adjust the position of the polishing wheel through the adjusting mechanism, so that the polishing wheel is attached to the external surface of a pan blank to be polished and is further matched with the rotating mechanism to achieve polishing. Due to arrangement of the polishing mechanism, the adjusting mechanism and the rotating mechanism, the polishing robot is simple in structure, reasonable in design, convenient to use, and capable of saving manpower and material resources, improving production efficiency and reducing enterprise cost.

Owner:HENAN MOXI MACHINE MFG

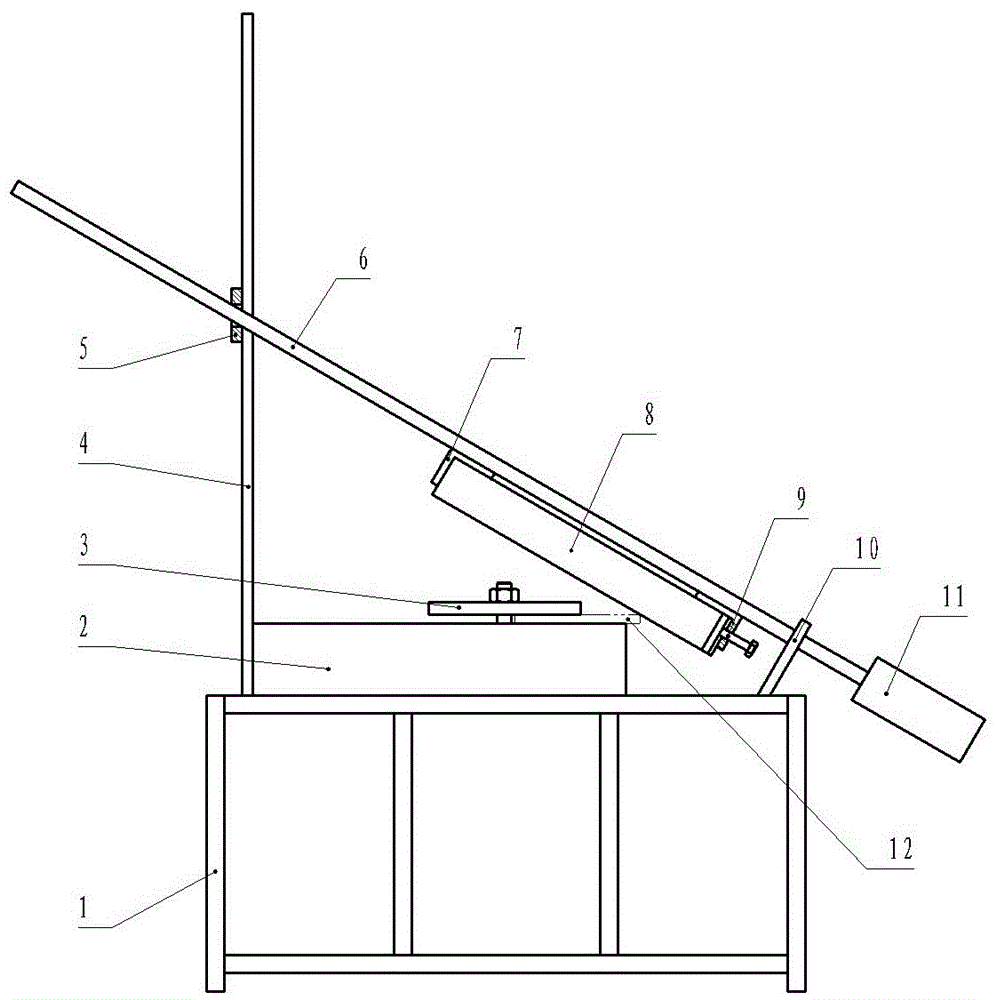

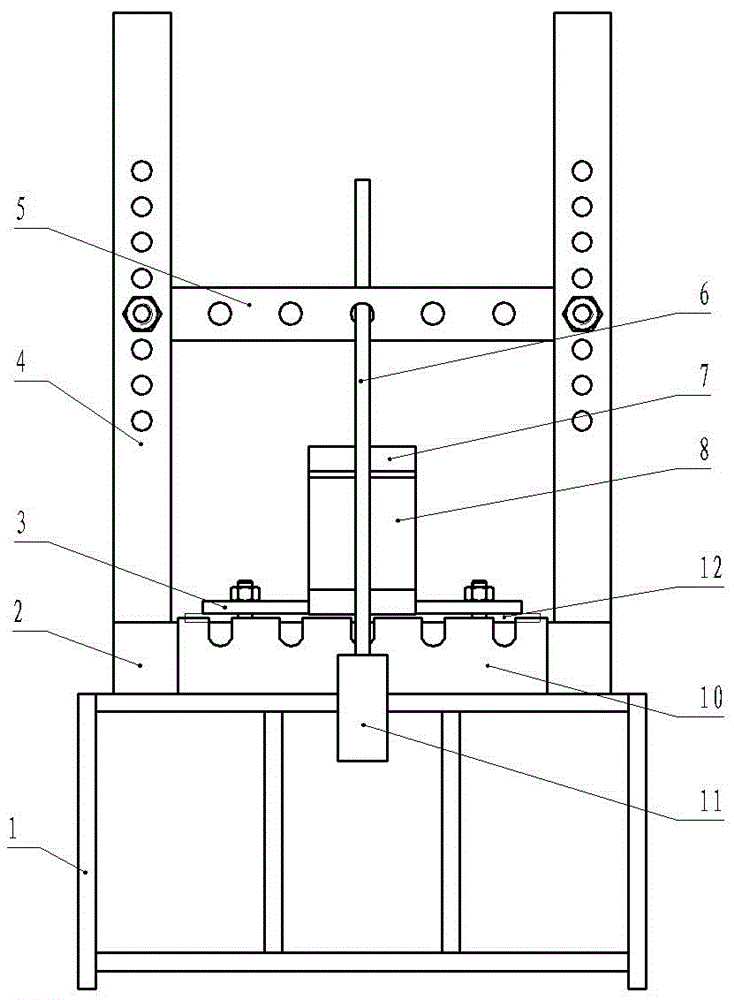

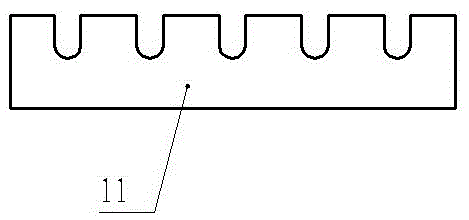

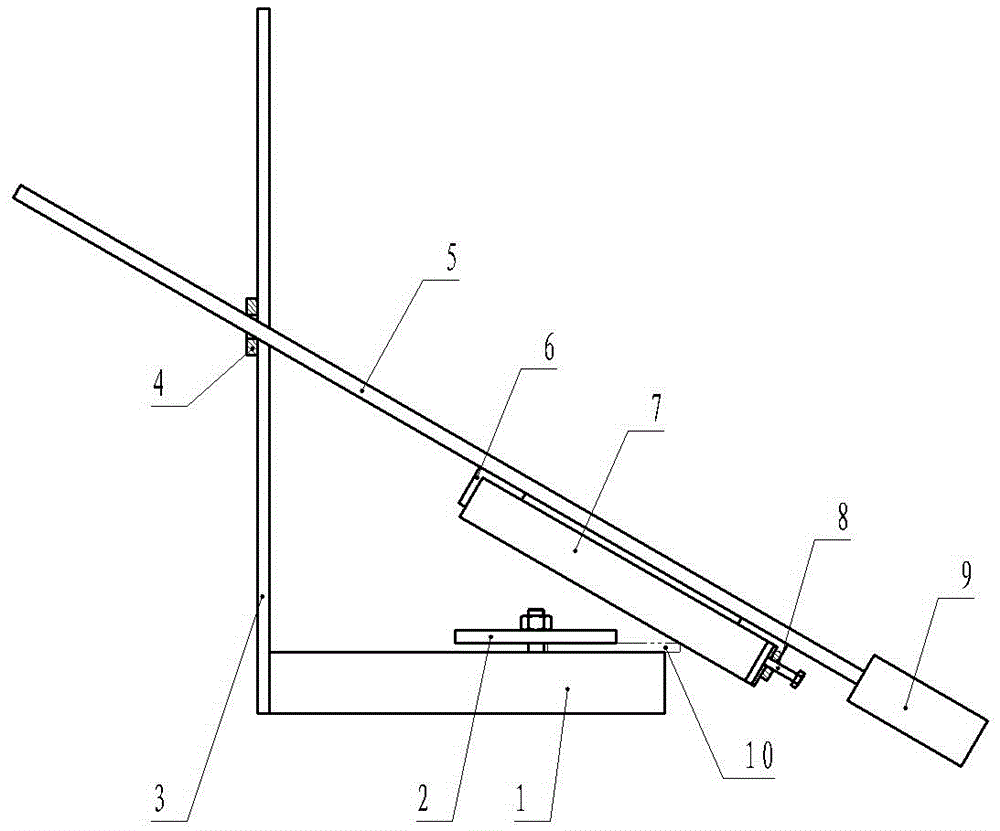

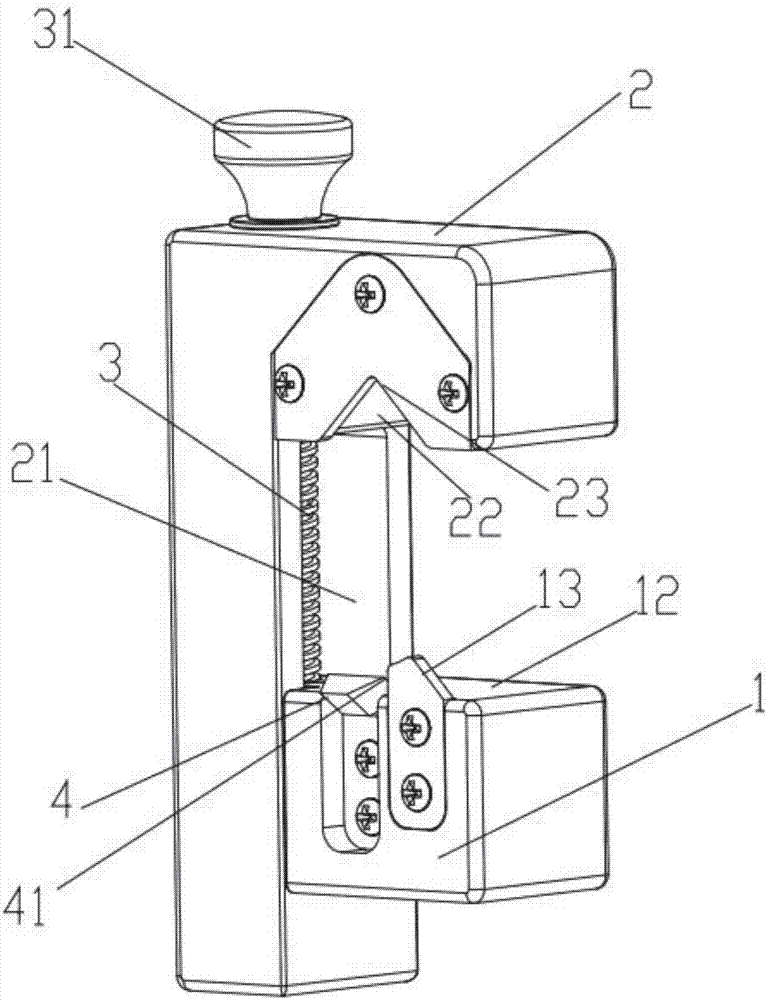

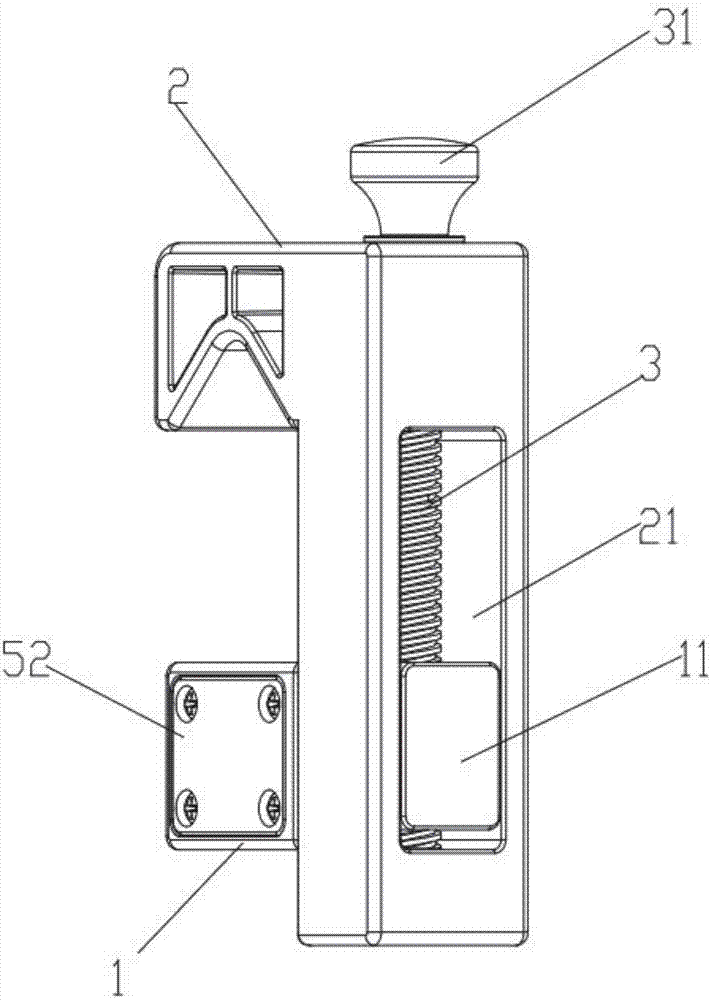

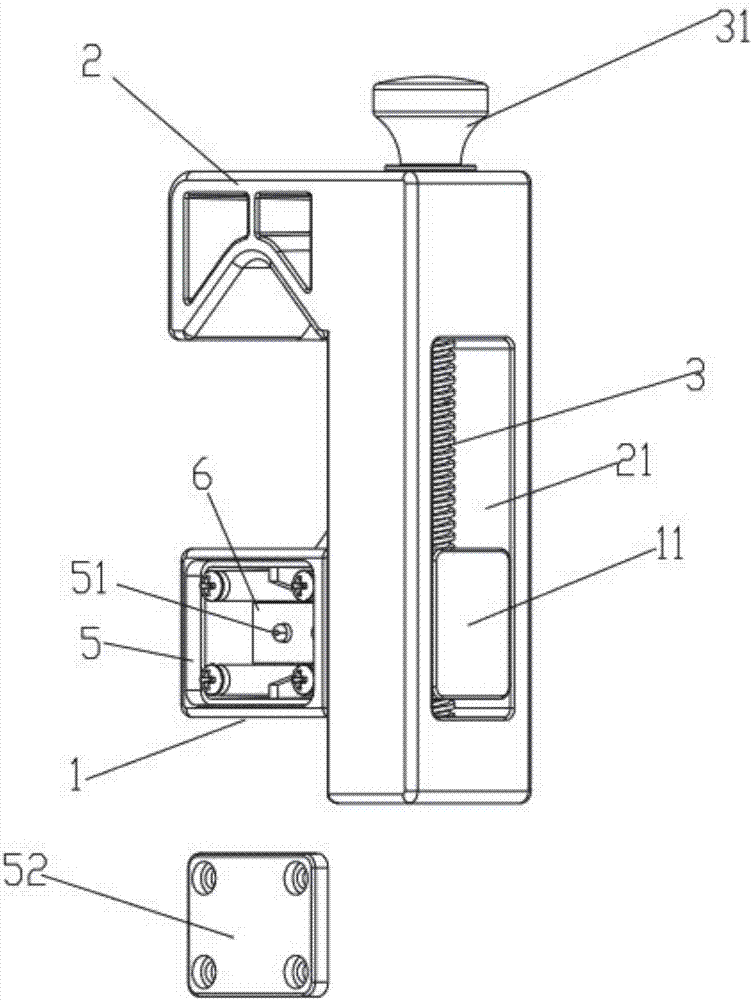

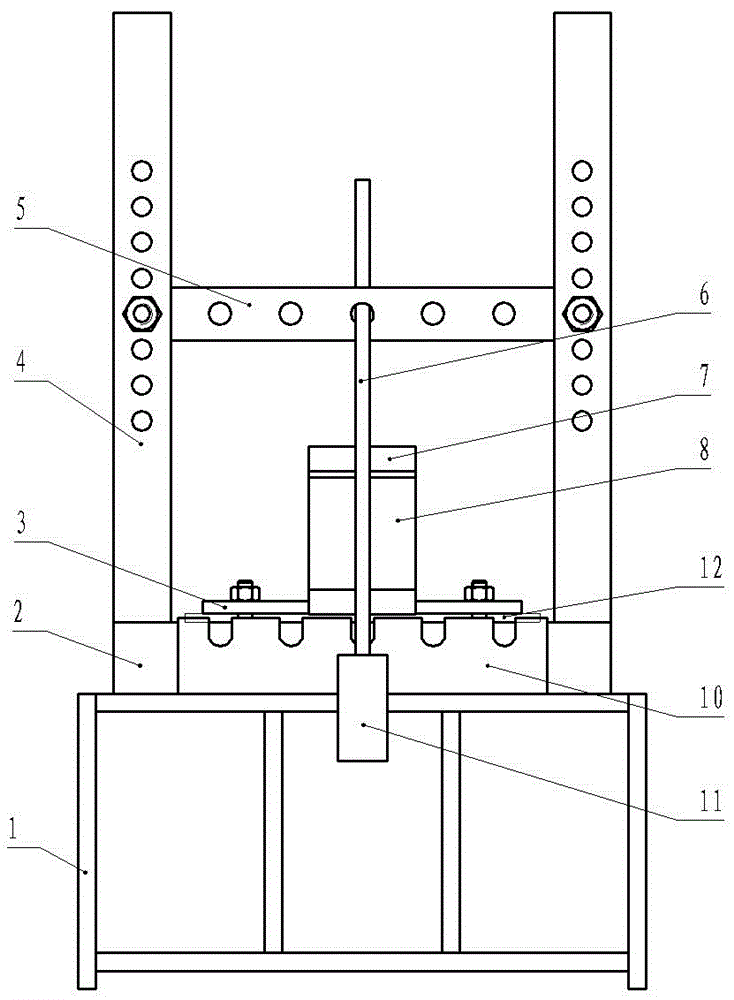

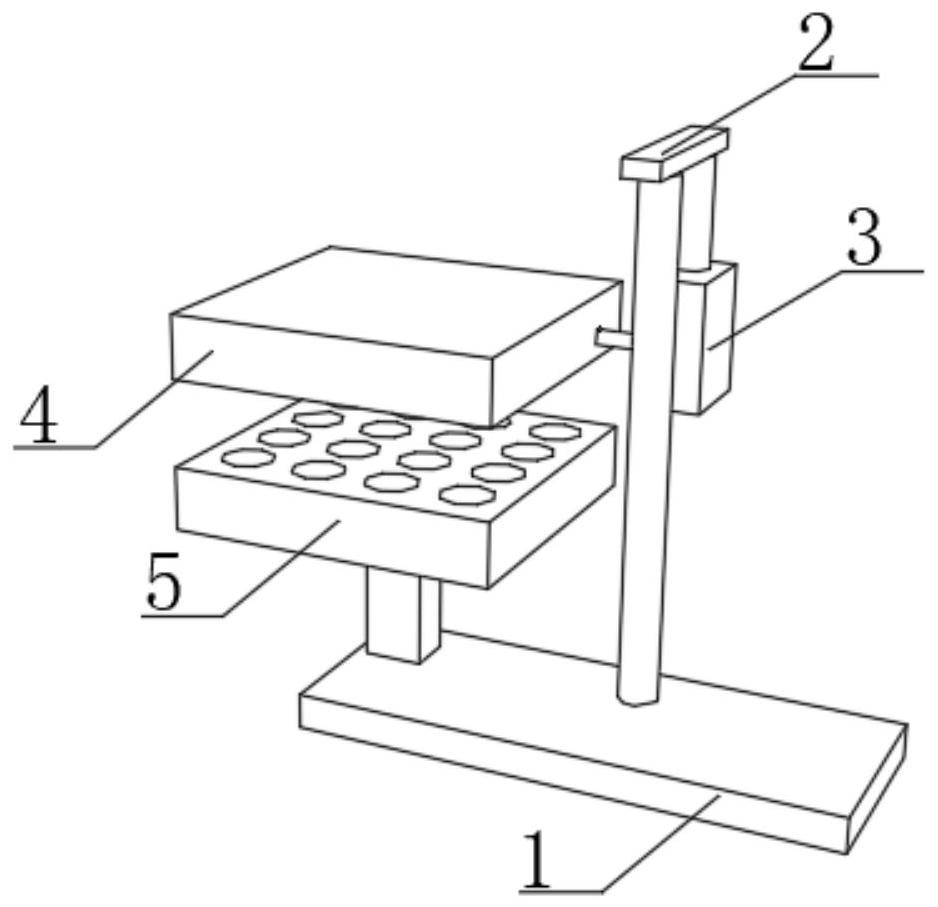

Sharpening support

InactiveCN106002661AControllable angleUniform angleGrinding/polishing hand toolsEngineeringSharpening

The invention discloses a sharpening support, and relates to the technical field of knife sharpening devices. The sharpening support comprises a clamping block installed on a supporting frame; a pressing plate is mounted on the clamping block through a bolt; two vertical plates are arranged on one side of the clamping block; a horizontal supporting plate with a plurality of through holes is mounted between the two vertical plates; a pull rod with a handle is arranged on the horizontal supporting plate in a penetrating mode; and a knife stone is arranged on the pull rod. A limiting baffle arranged on the supporting frame is arranged on the other side of the clamping block, and a plurality of limiting grooves are formed in the limiting baffle. Compared with the prior art, the pressing plate and the clamping block are used for clamping a knife; one end of the pull rod is arranged on the horizontal supporting plate in a penetrating mode, and the other end of the pull rod is placed in the limiting grooves of the limiting baffle; the cutting edge of the knife is sharpened through the knife stone arranged on the pull rod, and the cutting edge of the sharpened knife is even in angle and flat in surface; the limiting baffle limits the position where the pull rod moves towards the knife, and potential safety hazards are avoided.

Owner:三江县善茶轩工艺品有限公司

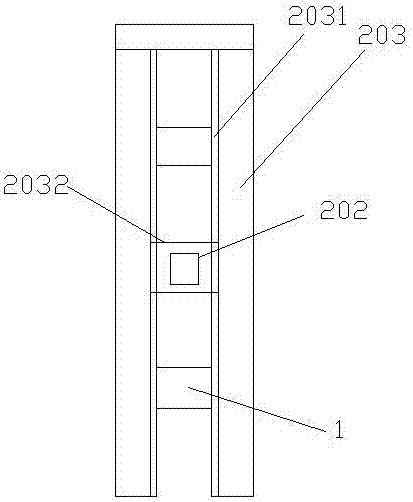

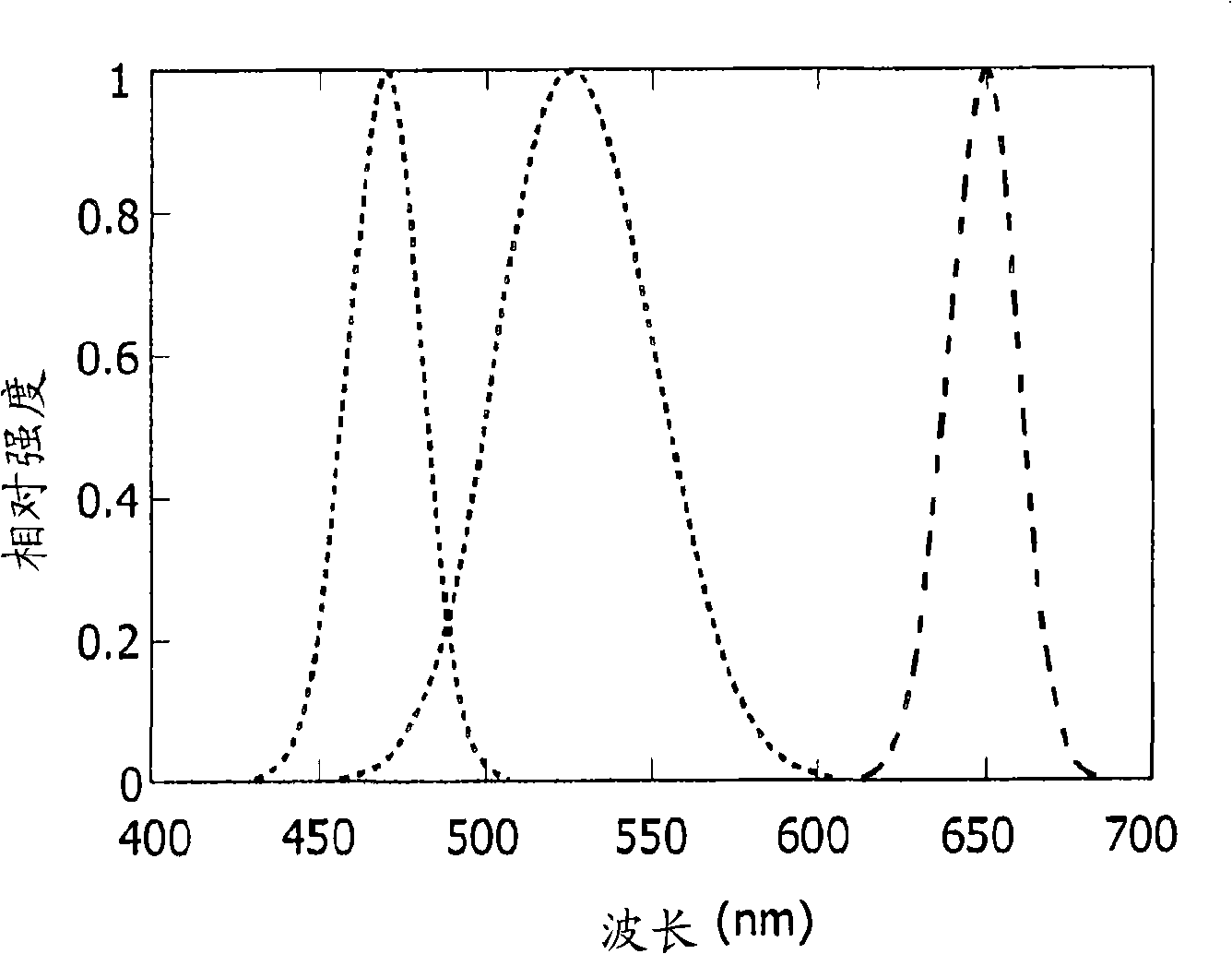

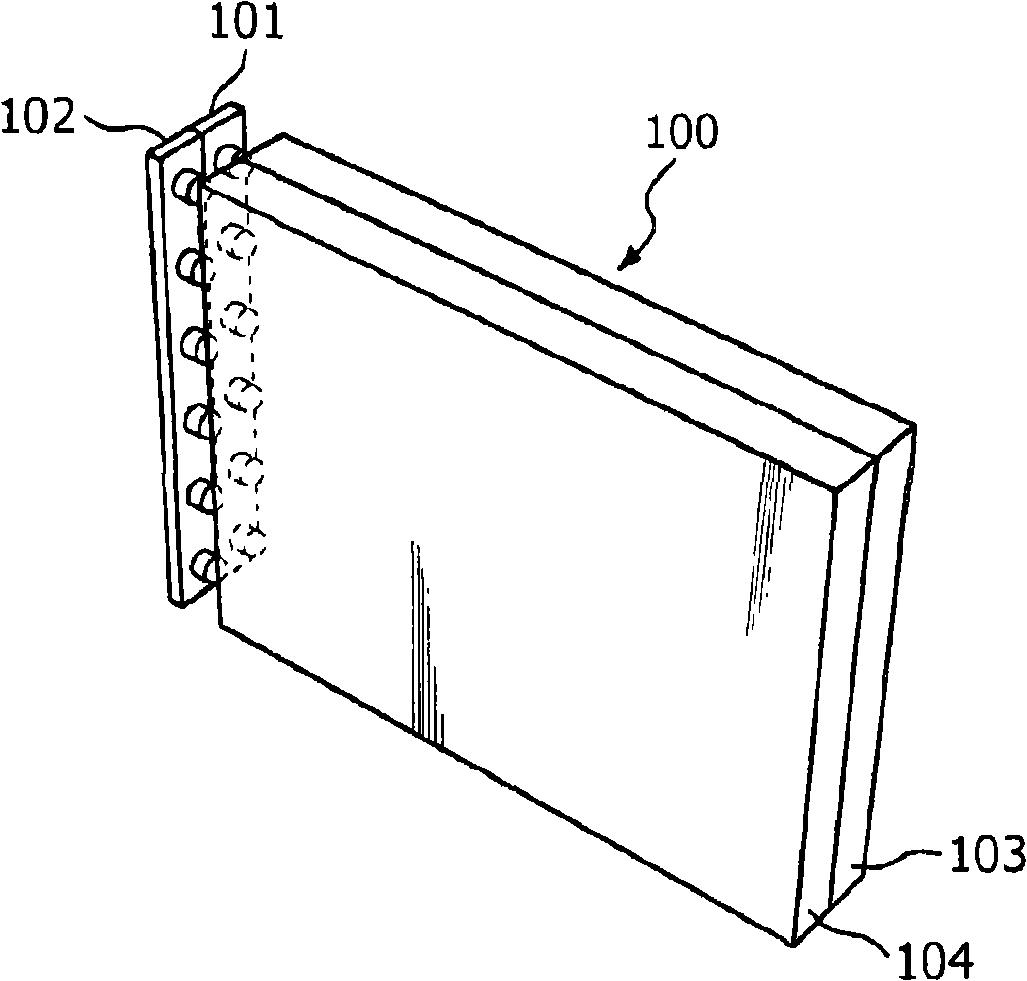

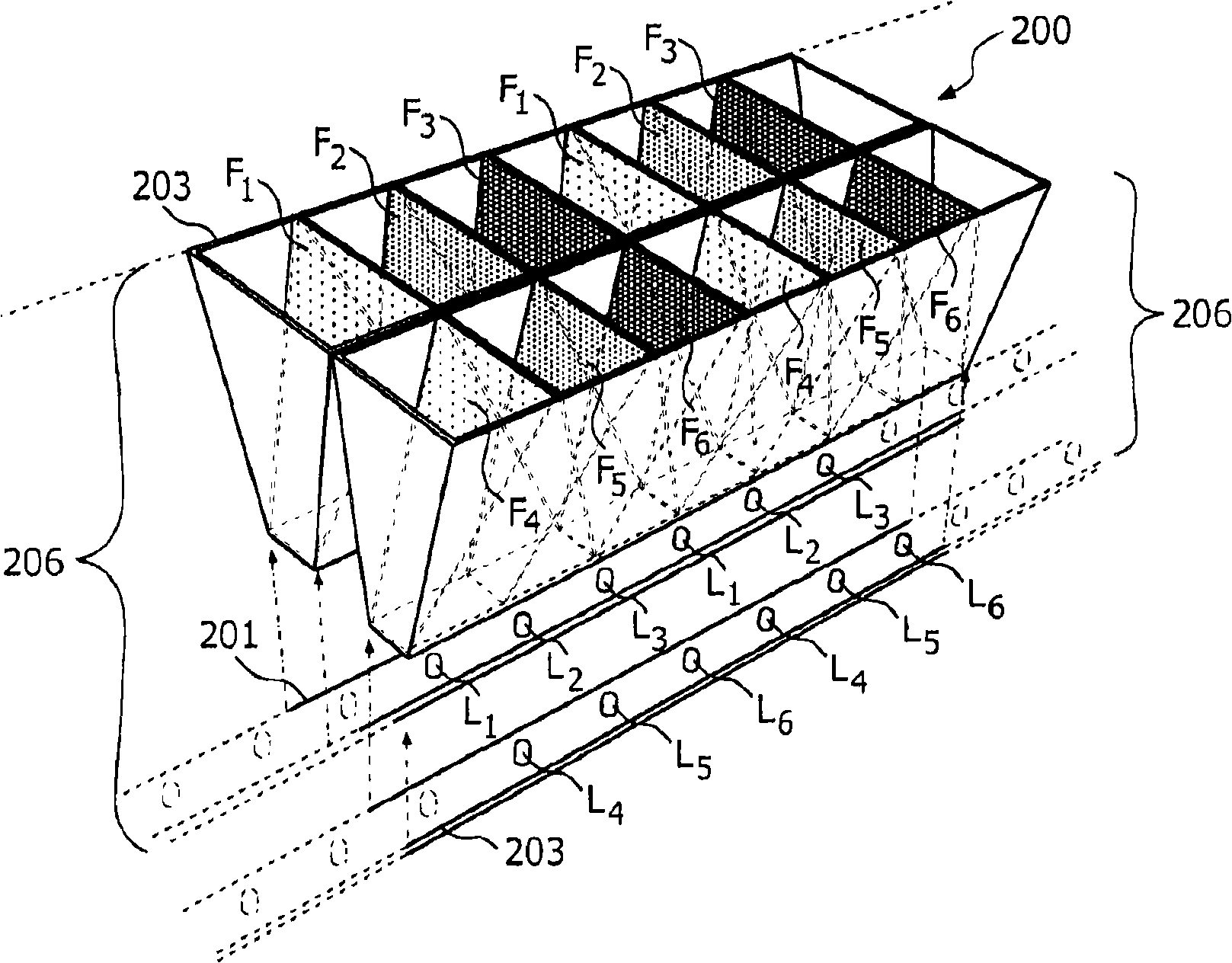

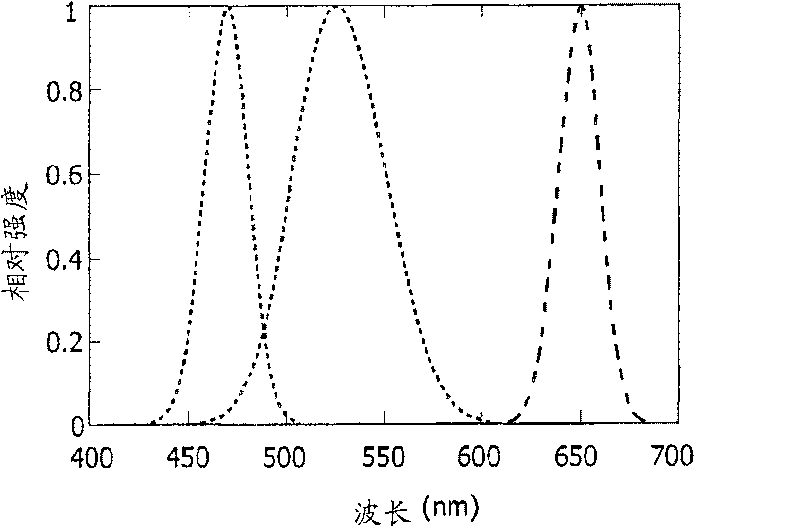

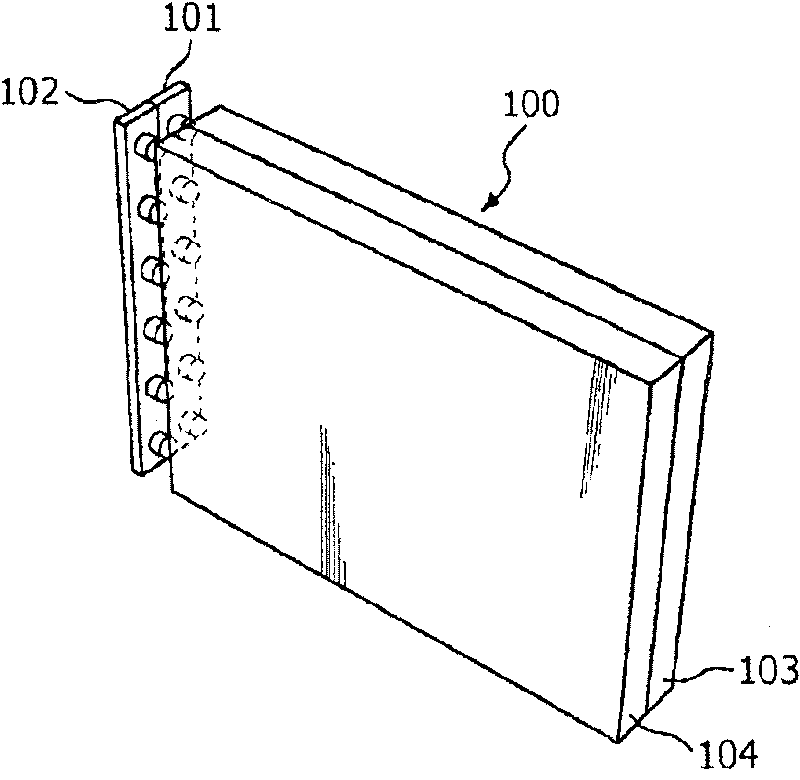

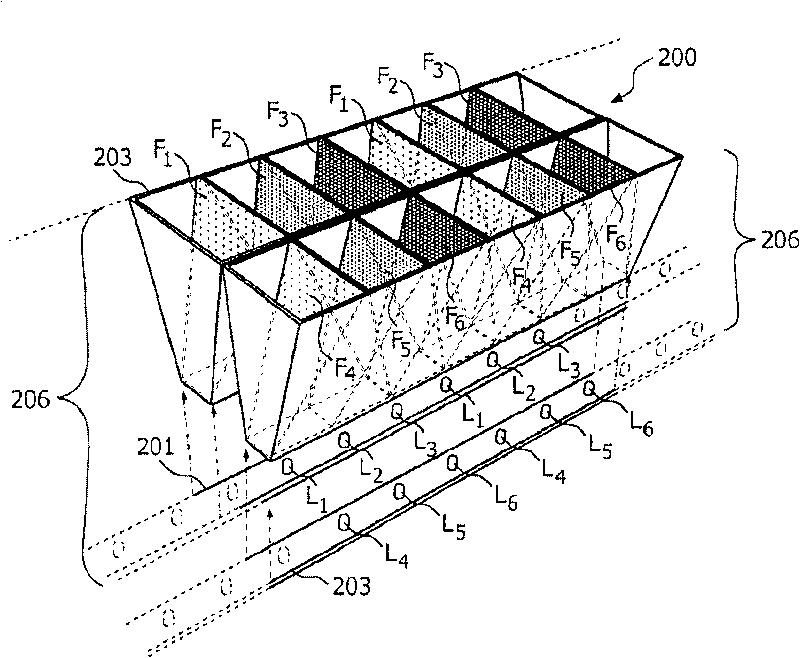

Illumination system with multiple sets of light sources

ActiveCN101313171AExact reproductionSimple designOptical light guidesSpectral modifiersColor rendering indexLighting system

The invention relates to an illumination system (200) comprising a first sub system (205). The first sub system (205) comprises a first set (201) of at least two differently colored light sources and a first light mixing device (203), wherein the first set (201) is provided with a first spectral distribution. The first light mixing device is arranged in a direction of light-emission of the first set of the light sources and is configured to mix light emitted by the first set of the light sources. The illumination system also comprises a second sub system (206). The second sub system (206) comprises a second set (202) of at least two light sources and a second light mixing device (204), wherein the second set (202) is provided with a second spectral distribution. The second light mixing device (204) is arranged in a direction of light-emission of the second set of the light sources and is configured to mix the light emitted by the second set of the light sources. The light sources are selected so that the first spectral distribution and the second spectral distribution complement each other, so that a color rendering index (CRI) of the light emitted from the illumination system (200) is greater than the CRI of the light emitted from each of the sub systems. Furthermore, the first sub system (205) and the second sub system (206) are arranged to emit at least one common color, such as a shade of white.

Owner:SIGNIFY HLDG BV

Knife sharpener

InactiveCN105965405AUniform angleEasy to installGrinding/polishing hand toolsKnife sharpenerEngineering

The invention discloses a knife sharpener, and relates to the technical field of cutter grinding devices. The knife sharpener comprises a pressing plate mounted on a clamping bottom plate through at least two bolts, wherein two vertical plates are mounted on one side of the clamping bottom plate; a transverse supporting plate provided with a plurality of through holes is mounted between the two vertical plates; a pull rod provided with a handle is mounted on the transverse supporting plate in an interpenetrating manner; sharpening stone is mounted on the pull rod; clamping plates fixedly connected with the pull rod are mounted at the two ends of the sharpening stone; an adjusting screw is mounted on at least one clamping plate in an interpenetrating manner; a plurality of mounting holes are formed in the vertical plates in the vertical direction; and the transverse supporting plate is connected with the two vertical plates through bolts. Compared with the prior art, the knife sharpener has the advantages that a cutter is clamped through the pressing plate and the clamping bottom plate, the pull rod is mounted in the through holes in different positions of the transverse supporting plate in an interpenetrating manner, the cutter with a relatively long cutting edge is grinded through the sharpening stone mounted on the pull rod, an angle between the surface of the sharpening stone and the cutter is easy to control, the angle of the grinded cutting edge of the cutter is uniform, and the surface of the cutting edge is flat.

Owner:三江县善茶轩工艺品有限公司

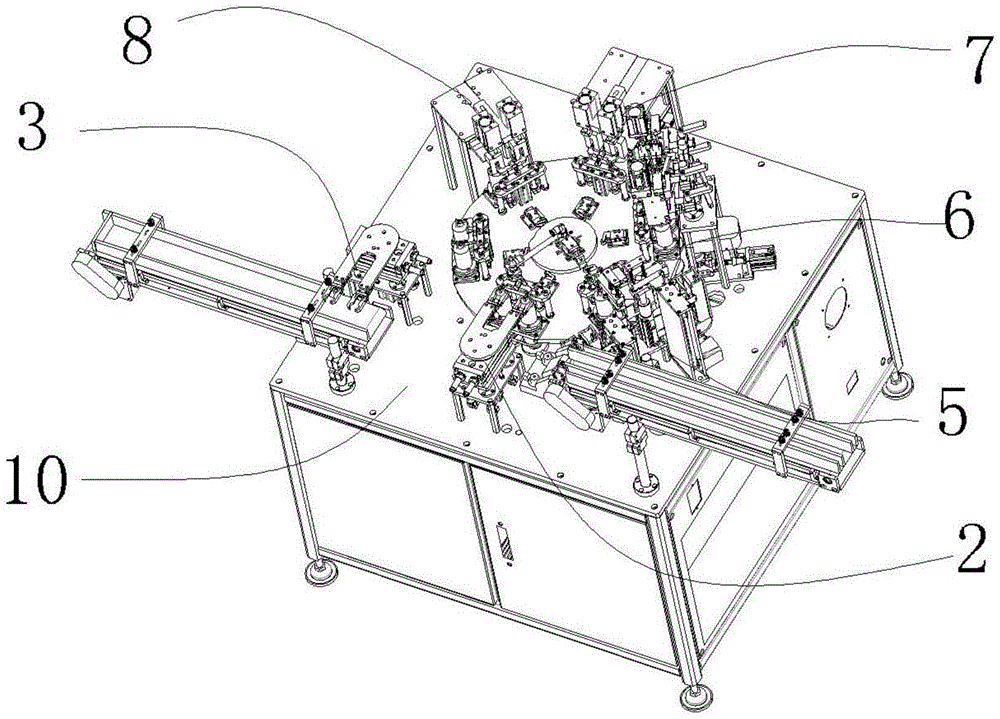

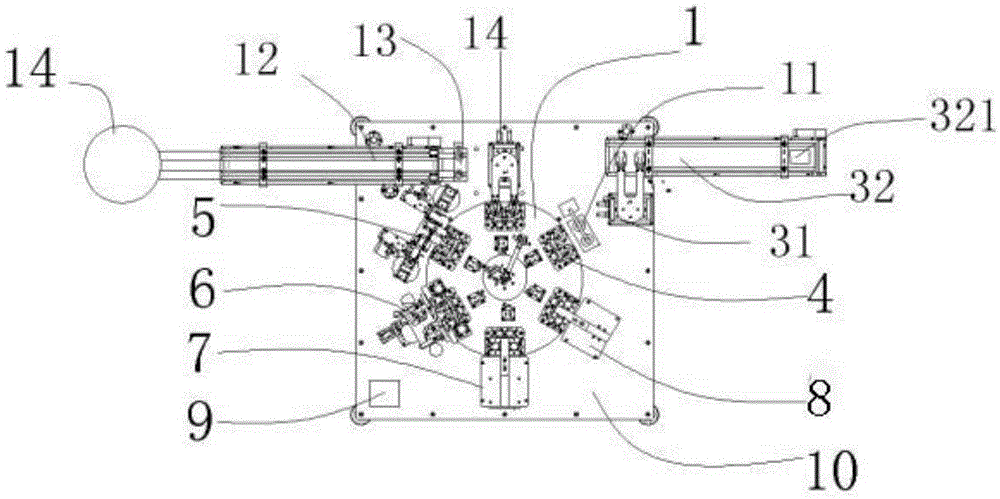

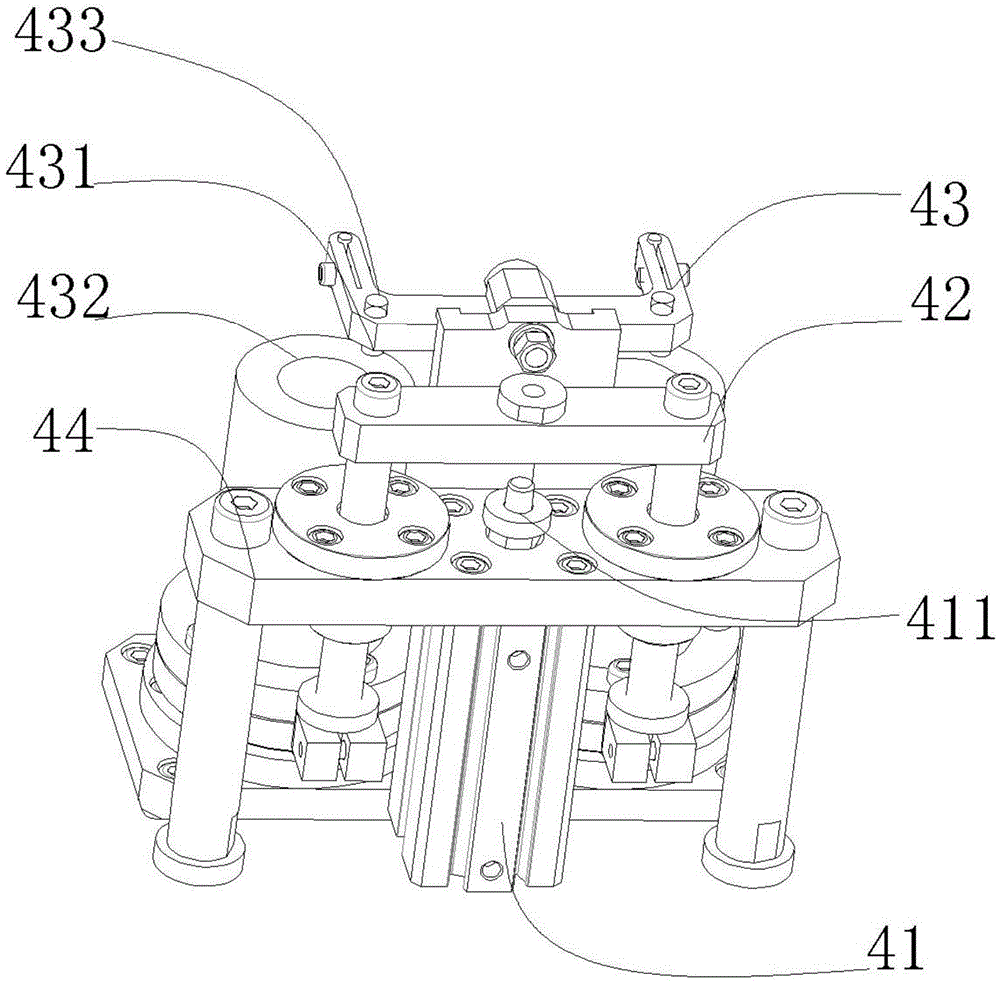

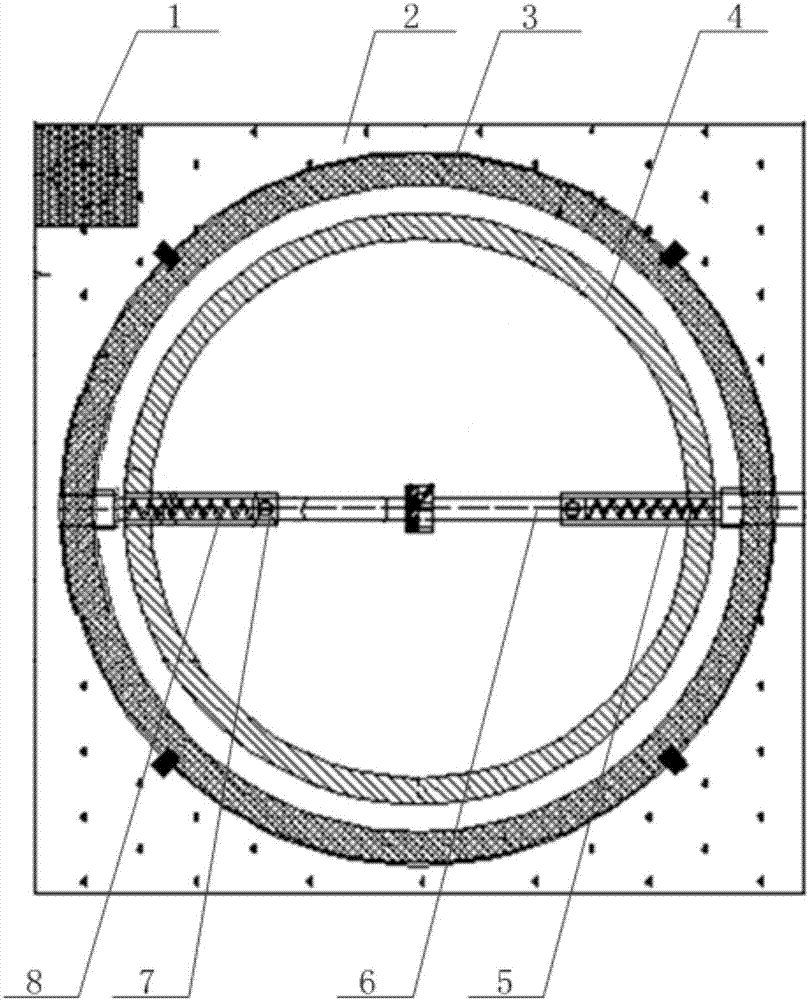

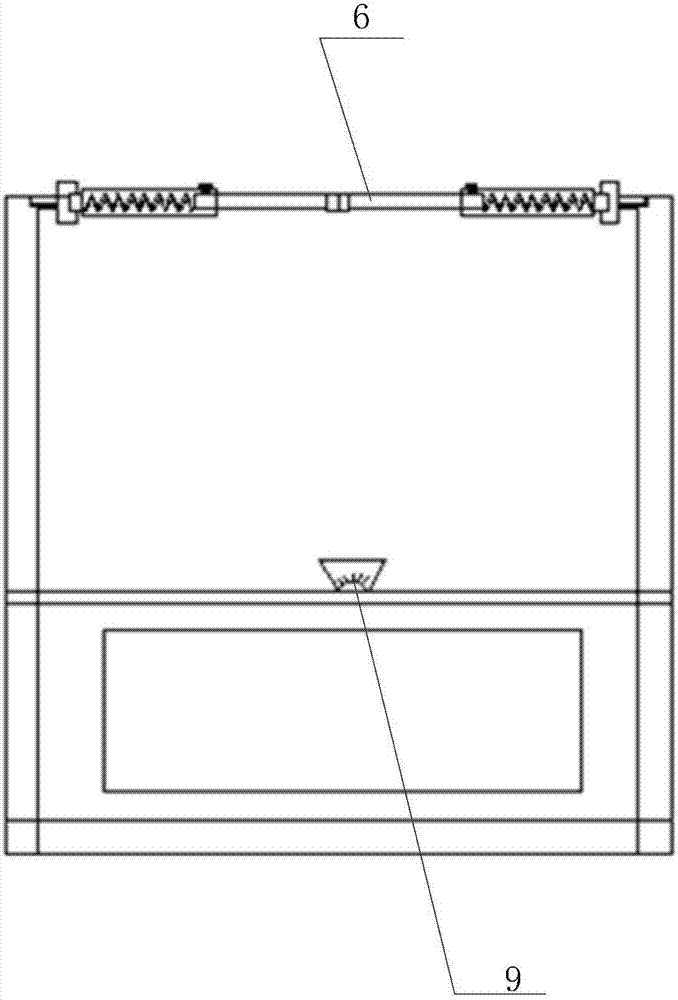

Automatic conducting strip welding device and machining technology thereof

InactiveCN105479121ADoes not affect the degree of weldingEven strengthManufacturing technologyOff phenomenon

The invention relates to electronic product manufacturing technology equipment, and particularly provides an automatic conducting strip welding device and a machining technology thereof. The automatic welding device comprises a workbench, and the workbench is provided with a rotary plate, a feeding device and a discharging device. The automatic welding device is characterized in that the rotary plate is provided with a gripping device and sequentially provided with a strip feeding device, a welding device body, a first bending device and a second bending device along the edge. By adopting the automatic welding device, a welding and bending machining technology for welding a bent battery conducting strip can be achieved, and integrated production of welding and bending can be achieved by arranging the welding device body, the first bending device and the second bending device on the workbench; meanwhile, through cooperation of the first bending device and the second bending device, the battery conducting strip can be stressed uniformly in the bending process, and the fall-off phenomenon cannot occur.

Owner:邓泽松

Cable chamfer peeler

PendingCN107508204AImprove chamfering efficiencyUniform depthApparatus for removing/armouring cablesReciprocating motionClassical mechanics

The invention relates to the cable cutter field, and specifically relates to a cable chamfer peeler comprising a first knife rest, a second knife rest, and an adjusting screw rod; one side of the second knife rest is provided with a guide straight slot; one side of the first knife rest is provided with a guide block; the guide block is embedded in the guide straight slot so as to make reciprocating motions; the adjusting screw rod penetrates the guide straight slot and is threaded with the guide block; two ends of the adjusting screw rod are respectively connected with two ends of the guide straight slot in a rotary manner; the first and second knife rests are provided with a first clamping surface and a second clamping surface arranged in opposite; either the first knife rest or the second knife rest are fixedly provided with a chamfer blade; a chamfer cutting blade of the chamfer blade extends outside the corresponding clamping surface, and form an obtuse angle with the clamping surface. The advantages are that the cable chamfering is high in efficiency, and the chamfering depth and angle are even, thus effectively preventing cable inner structure damages in a chamfering process; the cable chamfer peeler is suitable for cables of different diameters, good in versatility, simple in structure, and safe and reliable.

Owner:GUANGZHOU PANYU CABLE WORKS

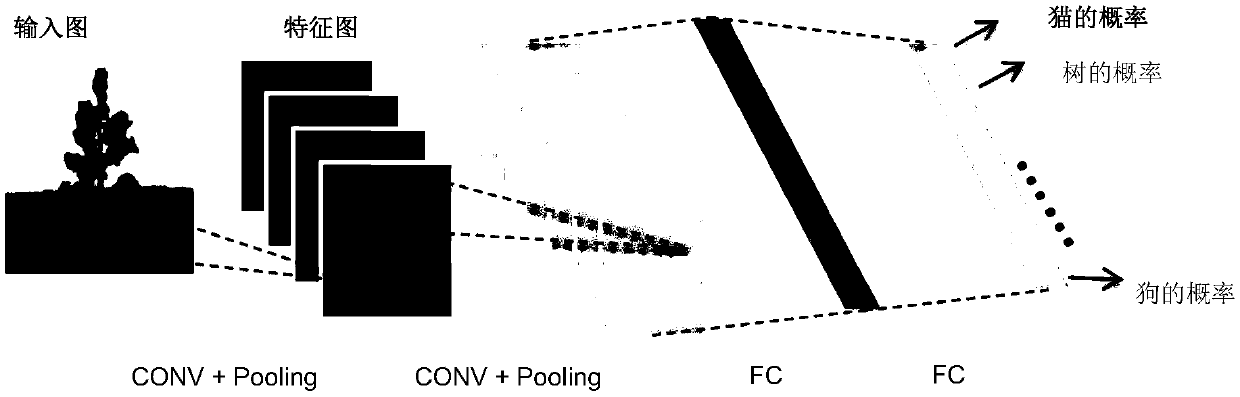

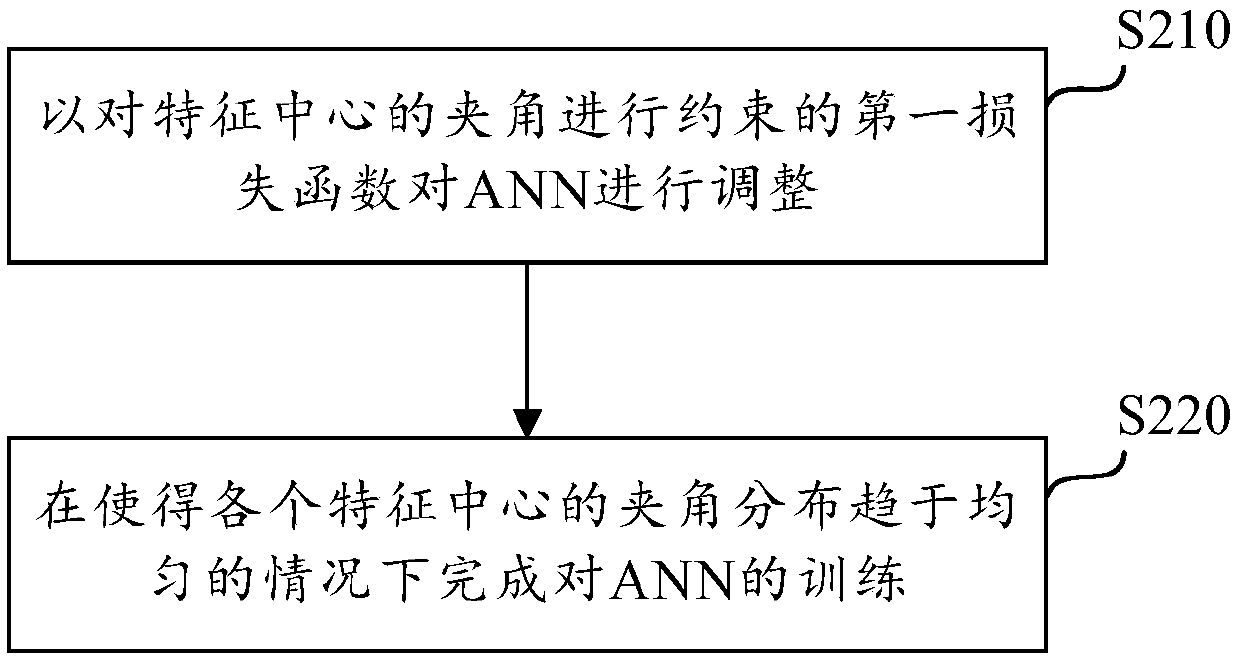

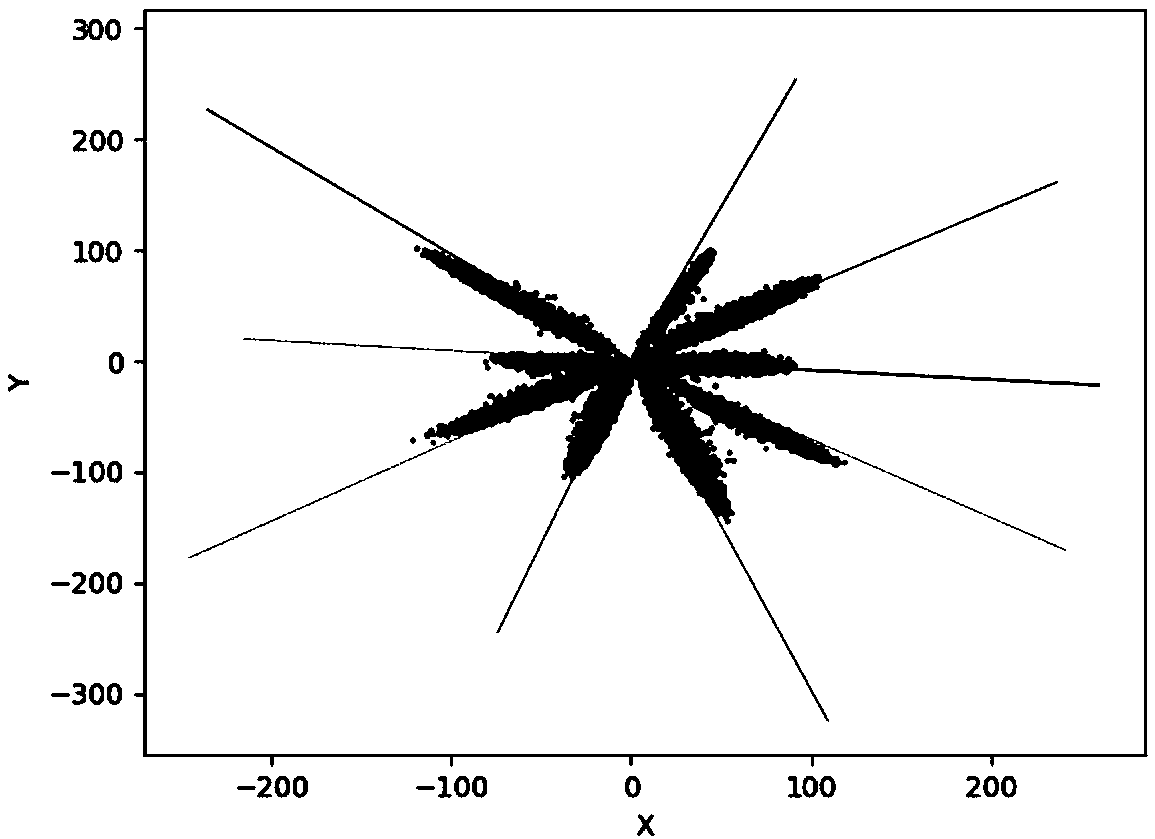

Artificial neural network adjustment method and device

PendingCN110598723AAddress adverse effectsUniform Feature Center Angle DistributionCharacter and pattern recognitionClassification resultAdverse effect

The invention provides an ANN (artificial neural network) adjustment method and device; the last full connection layer of the ANN is a classifier for classification, and the normalized weight of the layer represents various feature centers, and the method comprises the following steps: adjusting the ANN by using a first loss function for constraining an included angle of the feature centers; and completing the training of the ANN under the condition that the included angle distribution of each feature center tends to be uniform. According to the method, the angles of the feature centers are constrained by using the loss function, so that the included angles between the feature centers can be more uniform, and the problem of adverse effects on a classification result due to insufficient distinction degree of intra-class deviation and inter-class deviation can be well solved.

Owner:XILINX TECH BEIJING LTD

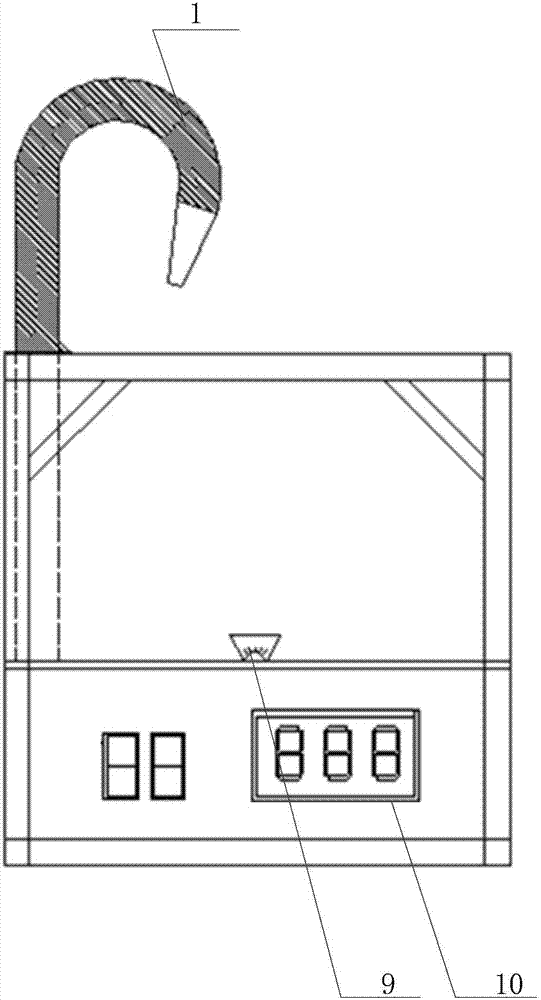

Instrument coding print wheel apparatus and coding method

InactiveCN102629338AUniform angleRealize direct reading of dataCounting mechanisms/objectsComputer architectureLinkage concept

Owner:昆明佳晓自来水工程技术股份有限公司

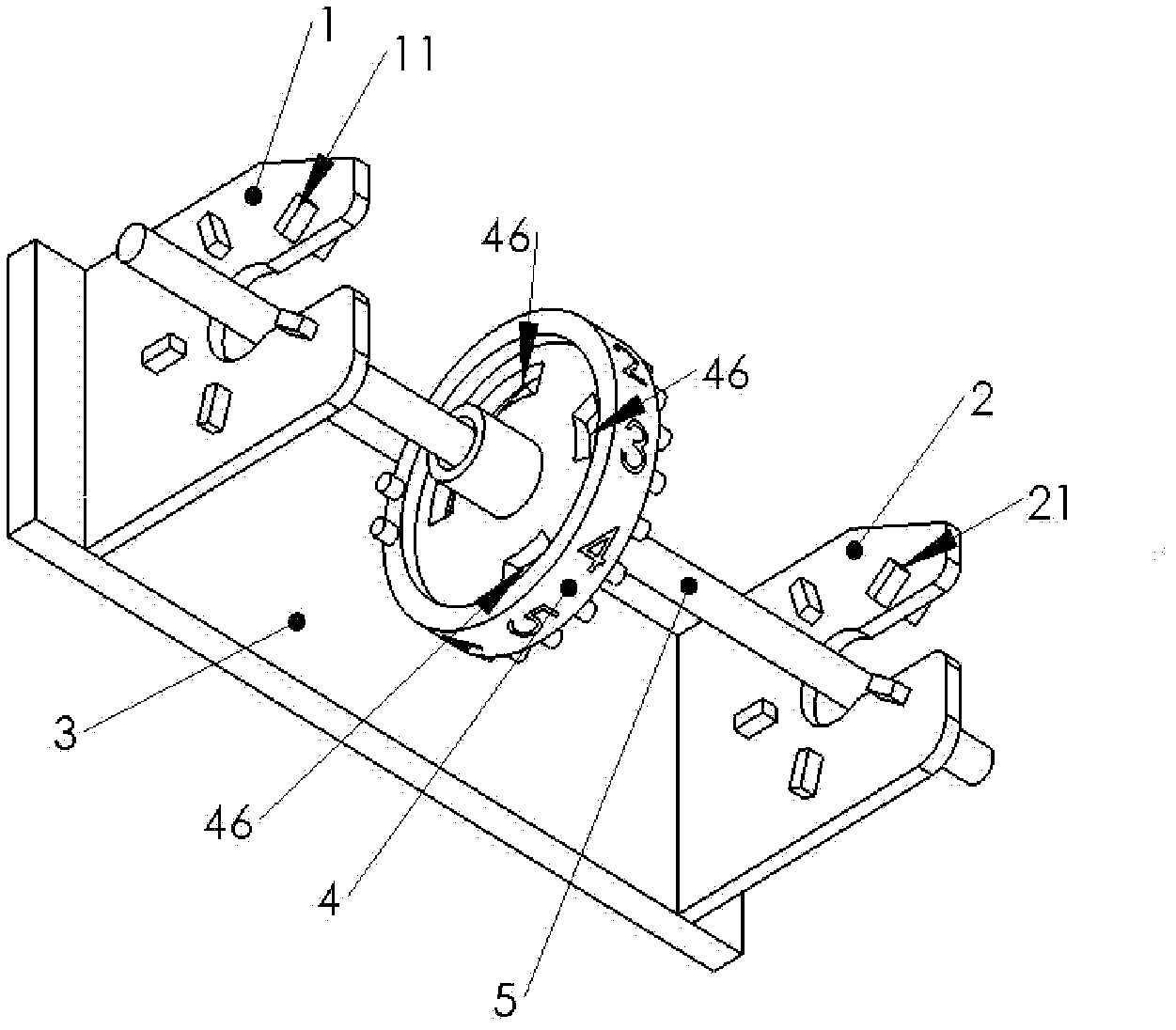

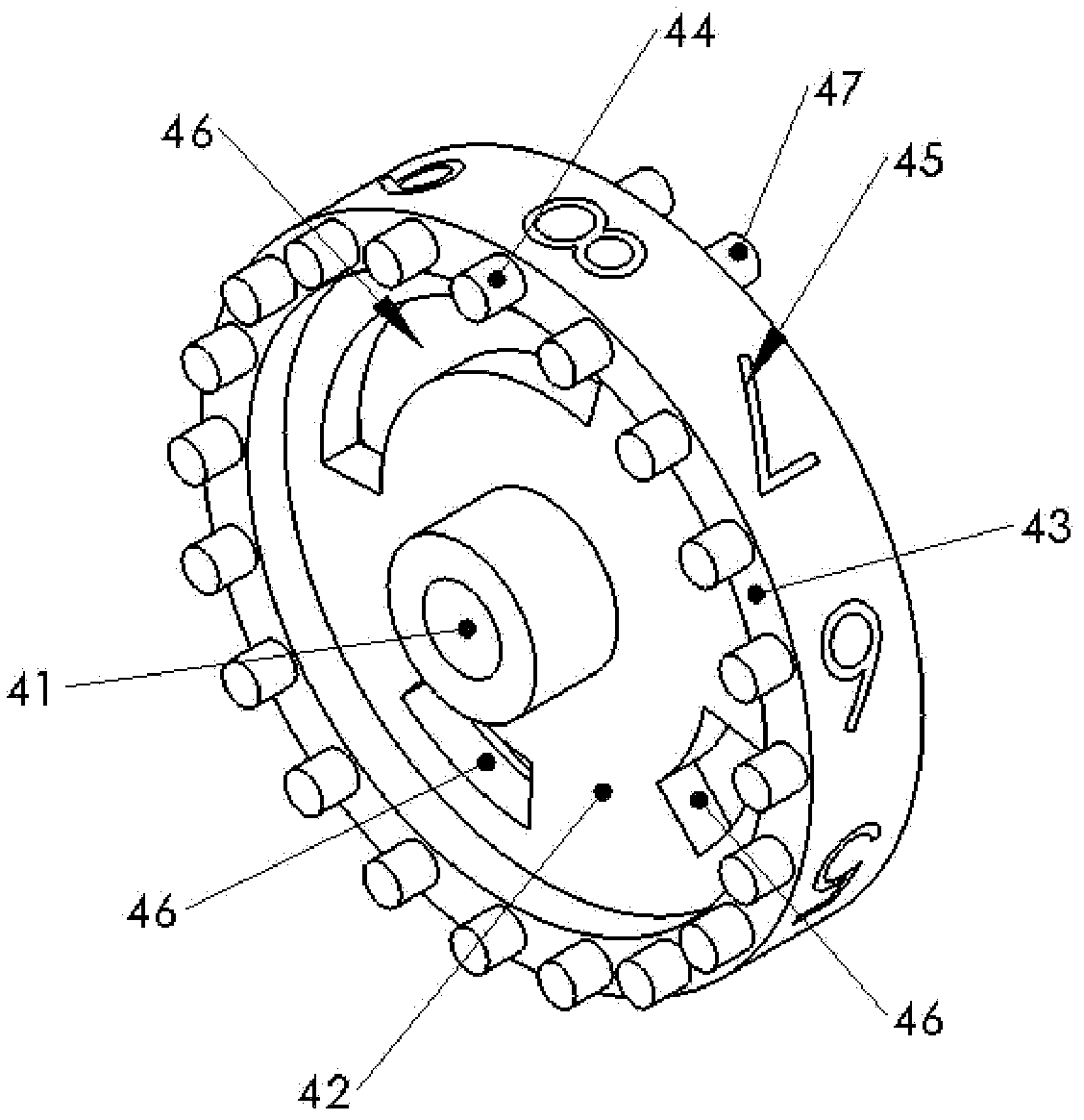

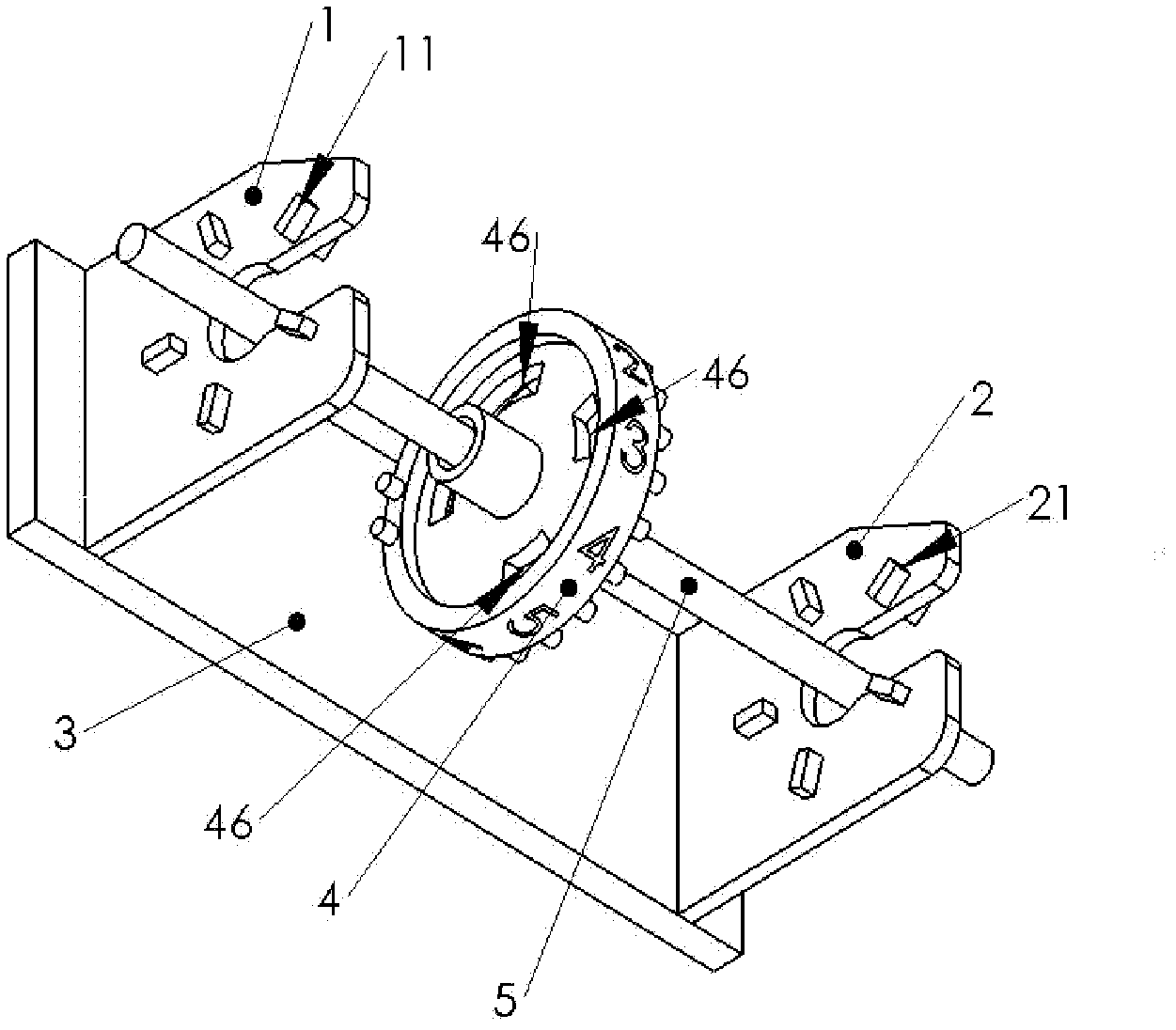

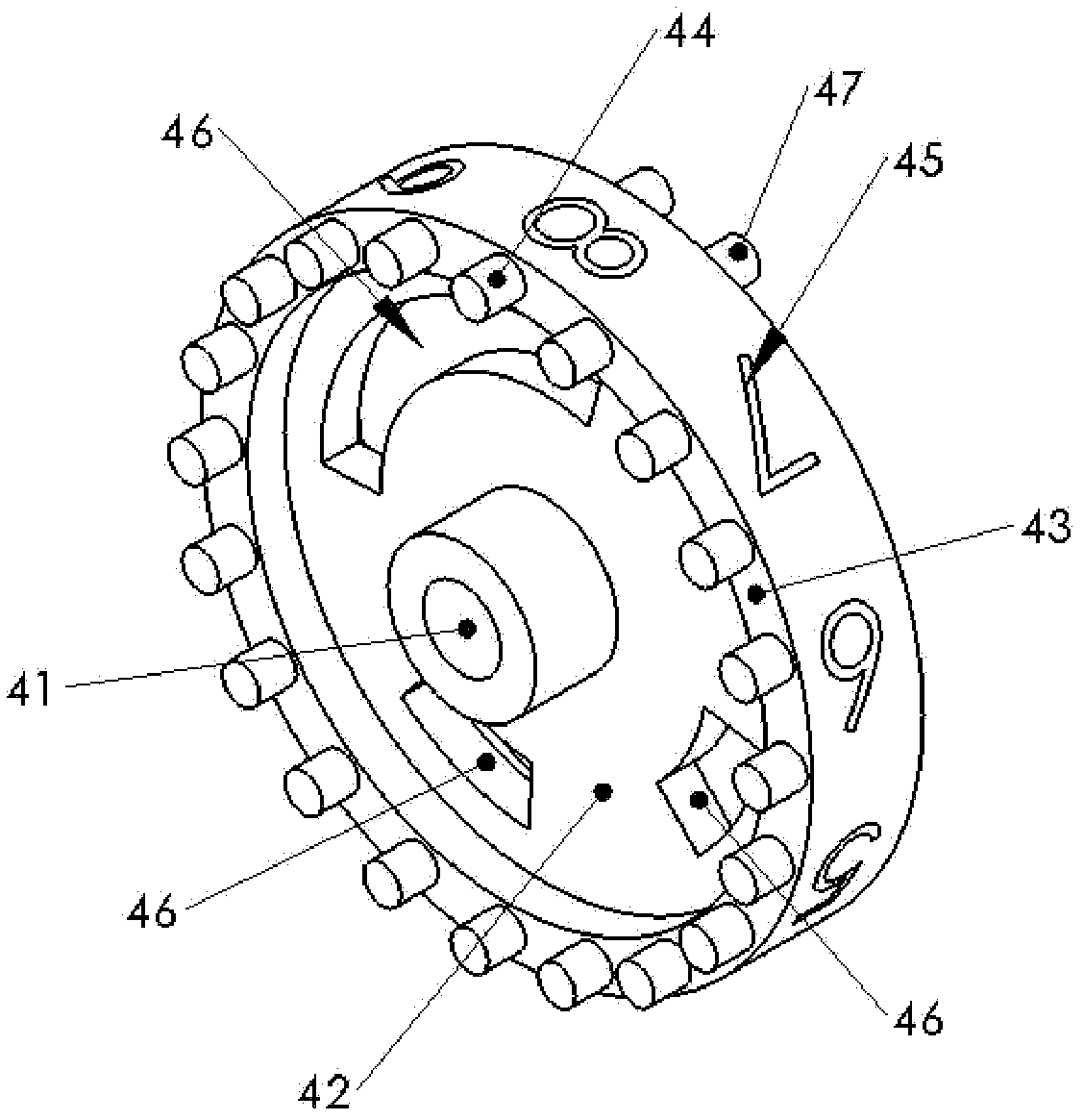

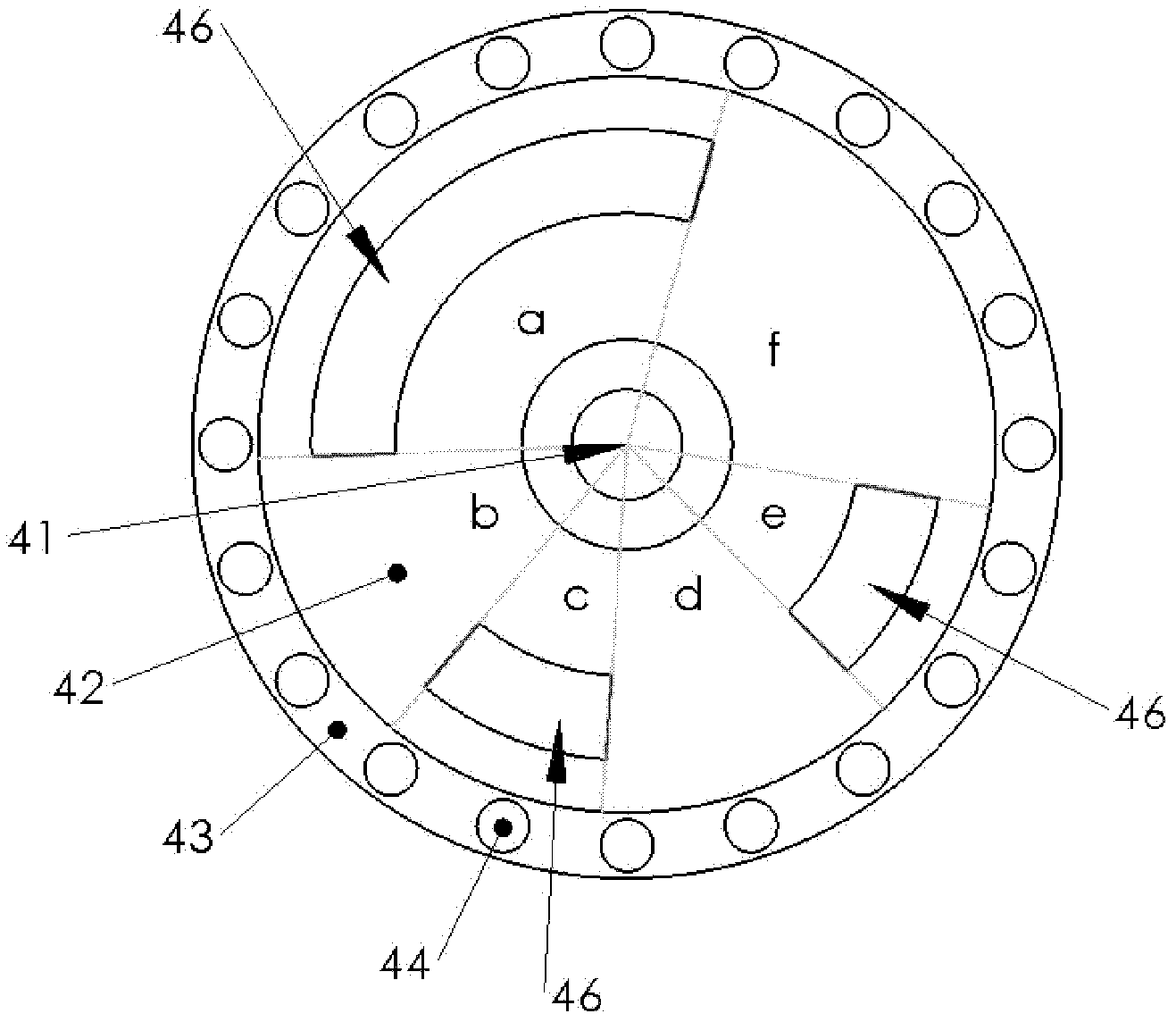

Hot wind heating table

ActiveCN107225302AUniform heatImprove processing qualitySoldering apparatusWork benchesEngineeringMachining

The invention discloses a hot wind heating table which comprises a platform, a horizontal rotating component, a vertical turnover component and a clamping component used for clamping a heated piece. The horizontal rotating component is rotationally arranged on the platform, the rotating axis is vertically downward, the vertical turnover component is arranged on the horizontal rotating component in a turnover manner, the turnover axis is horizontally arranged, and the clamping component is arranged on the vertical turnover component. By means of the hot wind heating table, a heated object can be subject to multi-angle heating. Through a wind feeding device or an external wind feeding device arranged on the platform, the heated object is heated, the problem that the heated piece at higher temperature is not prone to being controlled to rotate in the hot wind heating process is solved, the heat uniformity of the heated object is guaranteed, the machining quality of the heated object is improved, angle control of the heated piece is simpler, and the machining and production efficiency can be greatly improved.

Owner:SKY CHIP INTERCONNECTION TECH CO LTD

Manufacturing method of badminton

ActiveCN102989150BRealize automated productionReduce or eliminate manual operationsSport apparatusEngineeringMechanical engineering

The invention discloses a manufacturing method of badmintons. The method comprises the following steps of: (a) molding a flocking shelf with a group of flocking rods and a group of flocking tubes, wherein each flocking tube is respectively and integrally formed at one end of a corresponding flocking rod; (b) installing the flocking shelf at a fixed ball head; and (c) respectively implanting the inserting heads of a group feather blades into corresponding flocking tubes; or after inserting the feather blades into the flocking shelf, the flocking shelf with the feather blades is installed on the ball head. The method further comprises a step (d) that natural feather is cut according to the demands of a cutting model to obtain the feather blades. According to the method, machines are engaged to operate, the production efficiency of the badminton is improved, and the manufactured badminton has a molded flocking shelf, so that stable and accordant conical degree is formed for the badmintons, and the badminton quality is ensured.

Owner:ANHUI SANCAI SPORTS GOODS

Knife sharpening method

InactiveCN106392784AControllable angleUniform angleOther manufacturing equipments/toolsEngineeringSharpening

The invention discloses a knife sharpening method and relates to the technical field of knife sharpening. A knife sharpening bracket is used for sharpening the cutting edge of a knife; the knife sharpening bracket comprises a clamping block which is mounted on a supporting frame; the clamping block is connected with a pressing plate through a bolt; two vertical plates are mounted at one side of the clamping block; a horizontal supporting plate provided with a plurality of through holes is mounted between the two vertical plates; each vertical plate is provided with a plurality of mounting holes; the horizontal supporting plate is connected with the two vertical plates through bolts; a pull rod provided with a handle penetrates into the horizontal supporting plate; a piece of knife sharpening stone is mounted on the pull rod; a limiting baffle mounted on the supporting frame is arranged at the other side of the clamping block; the limiting baffle is provided with a plurality of limiting grooves; the knife sharpening method comprises the following steps: step (A) adjusting the angle; step (B) mounting the knife; step (C) sharpening; step (D) dismounting the knife. In comparison with the prior art, the knife sharpening method disclosed by the invention is used for sharpening a knife, and the sharpened knife has a cutting edge which is uniform in angle and the surface of the cutting edge is smooth; the limiting baffle is capable of limiting the movement position of the pull rod towards the knife, so no injuries are caused to a hand, and potential safety hazards are prevented.

Owner:三江县善茶轩工艺品有限公司

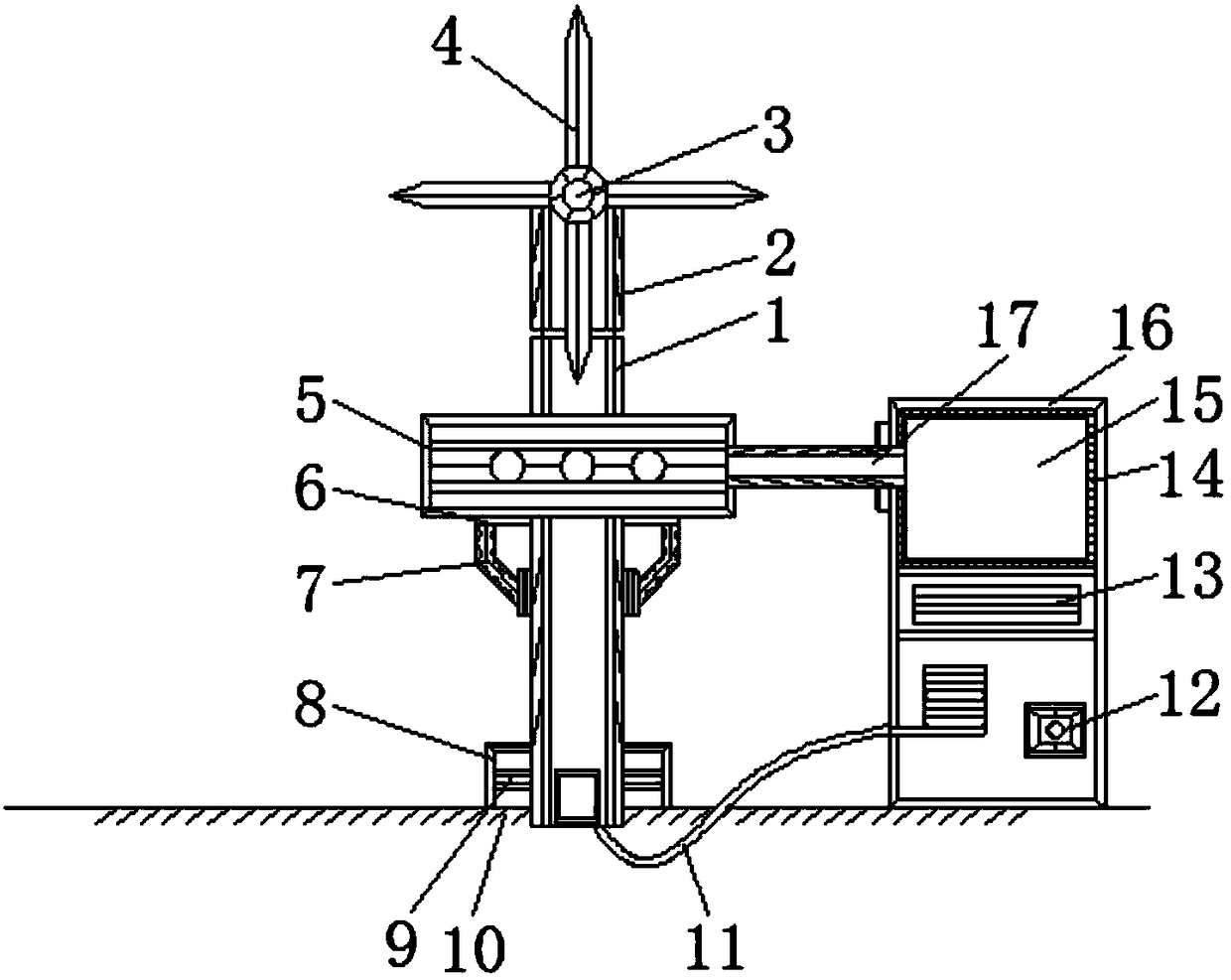

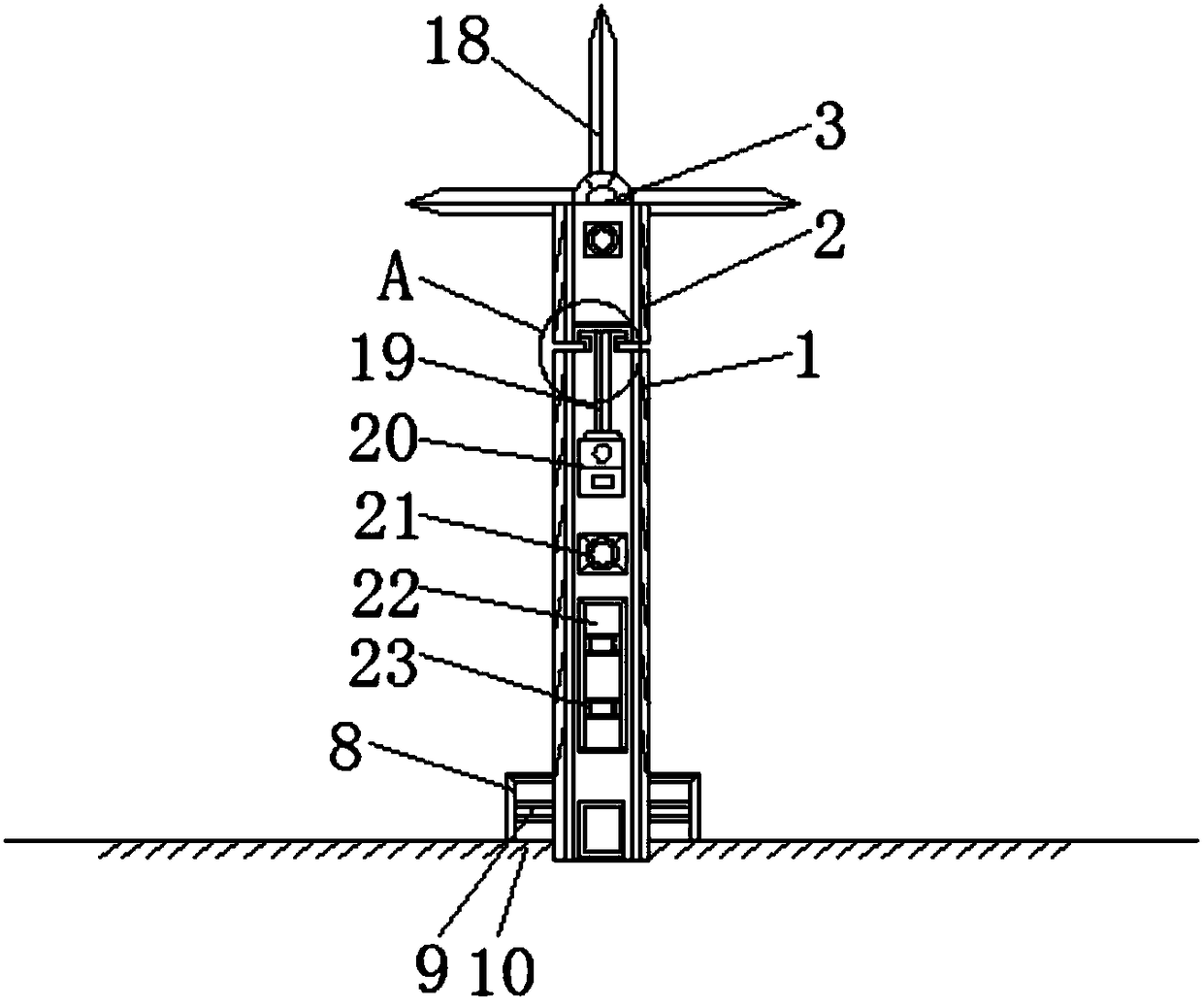

Wind-light-heat complementary parallel power generating and heating complete equipment

InactiveCN108386311ANormal power generation workWork lessWind motor with solar radiationBatteries circuit arrangementsHeat conductingEngineering

The invention relates to wind-light-heat complementary parallel power generating and heating complete equipment. The wind-light-heat complementary parallel power generating and heating complete equipment comprises a main tower frame, a first fan blade, a heat storage chamber and a heat conducting pipe, wherein a secondary tower frame is arranged on the top of the main tower frame, a movable shaftis movably arranged on the top end of the secondary tower frame, the first fan blade is connected to the outer side of the movable shaft, a frame is arranged on the outer wall of the main tower frame,a support plate is arranged at the bottom end of the frame, a movable body is installed at the bottom of the support plate, a stone column is arranged on the outer side of the bottom end of the maintower frame, and a reinforcing rebar penetrates through the outer wall of the main tower frame. The wind-light-heat complementary parallel power generating and heating complete equipment has the beneficial effects that the main tower frame, the secondary tower frame, the first fan blade, the movable shaft, a second fan blade and a generator are arranged, and the first fan blade is perpendicularlyconnected with the outer wall of the movable shaft, so that the connectivity of the first fan blade and the movable shaft can be enhanced, and the power supply operation can be performed on the device under the rotating action of the first fan blade and the second fan blade, so that the generator on the inner side of the main tower frame can normally generate power.

Owner:江苏兆平能源科技有限公司

Illumination system with multiple sets of light sources

ActiveCN101313171BExact reproductionSimple designOptical light guidesSpectral modifiersColor rendering indexShades of white

The invention relates to an illumination system (200) comprising a first sub system (205). The first sub system (205) comprises a first set (201) of at least two differently colored light sources anda first light mixing device (203), wherein the first set (201) is provided with a first spectral distribution. The first light mixing device is arranged in a direction of light-emission of the first set of the light sources and is configured to mix light emitted by the first set of the light sources. The illumination system also comprises a second sub system (206). The second sub system (206) comprises a second set (202) of at least two light sources and a second light mixing device (204), wherein the second set (202) is provided with a second spectral distribution. The second light mixing device (204) is arranged in a direction of light-emission of the second set of the light sources and is configured to mix the light emitted by the second set of the light sources. The light sources are selected so that the first spectral distribution and the second spectral distribution complement each other, so that a color rendering index (CRI) of the light emitted from the illumination system (200) is greater than the CRI of the light emitted from each of the sub systems. Furthermore, the first sub system (205) and the second sub system (206) are arranged to emit at least one common color, such as a shade of white.

Owner:SIGNIFY HLDG BV

Instrument coding print wheel apparatus and coding method

InactiveCN102629338BUniform angleRealize direct reading of dataCounting mechanisms/objectsComputer architectureLinkage concept

Owner:昆明佳晓自来水工程技术股份有限公司

Novel high-chromium cast ball equipment device

InactiveCN113084134AQuality improvementQuality assuranceDrying gas arrangementsMolten metal conveying equipmentsElectric machineryEngineering

The invention relates to the field of high-chromium cast balls, and provides a novel high-chromium cast ball equipment device. The device comprises a base and a rack, wherein the rack is fixedly arranged at the upper end of the base; a top casting mold and a bottom casting mold are arranged at one side of the rack; the top casting mold is arranged at the upper side of the bottom casting mold; a rotating rod is rotationally arranged at the upper end of the rack; a shell is vertically and movably arranged at the lower end of the rotating rod; fan blades are rotationally arranged in the shell; and a heat pipe is arranged in the shell and at the front sides of the fan blades. The device is novel in design, simple in structure and convenient to use, during drying, the heat pipe is firstly heated to a high temperature, then in the drying process, the temperature of the air is slowly reduced to be between 35 DEG C and 55 DEG C, the situation that the surface of a material is blown to crack by low-temperature air during air-cooling drying is prevented, a first motor drives the whole rotating rod at the upper end to rotate, and the shell and the fan blades at the lower end can rotate around the top casting mold and the bottom casting mold.

Owner:山东中天重工有限公司

Mixing and stirring device for exterior wall putty powder

InactiveCN107596948AFasten the connectionFirmly connectedRotary stirring mixersArchitectural engineeringPutty

The invention discloses a mixing and stirring device for exterior wall putty powder. The mixing and stirring device comprises a penetrating and connecting bar, the middle part of the penetrating and connecting bar is provided with a fastening and installing ring, one end of the fastening and installing ring is clamped by a transmission loop, and a stirring set is sleeved on the fastening and installing ring; one end of the penetrating and connecting bar is provided with two internally connected holes, and the transmission loop is provided with two externally connected holes; the stirring set is provided with several stirring vanes, the middle part of the stirring vane is provided with a clamp connection groove, one side of the stirring vane is provided with an insulation gasket, and the insulation gasket is provided with a through hole for connection; the outer ring of the transmission loop is provided with a concavely connected plate, a transmission loop is internally provided with atransmission rotary groove, and one end of the transmission rotary groove is clamped to an extension bar groove. Insulation gaskets are arranged on the stirring set between several stirring vanes, inorder to avoid wearing or bumping during rotation of the stirring vanes, reduce friction resistance during rotation, and guarantee usage life of the device. The device has operation convenience, and each component is flexibly connected.

Owner:佘峰

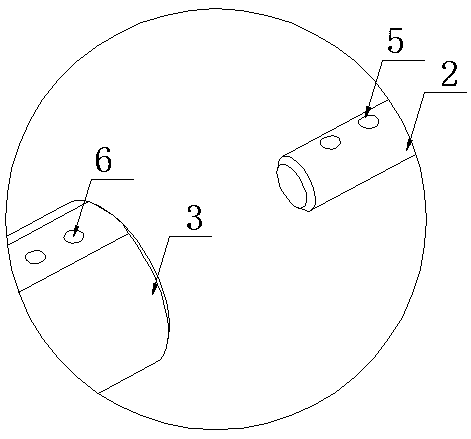

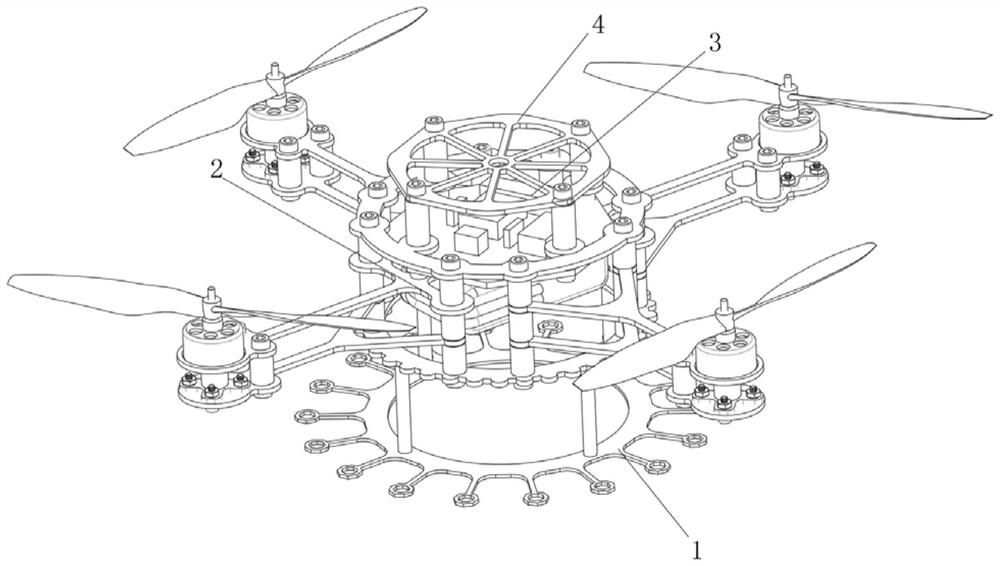

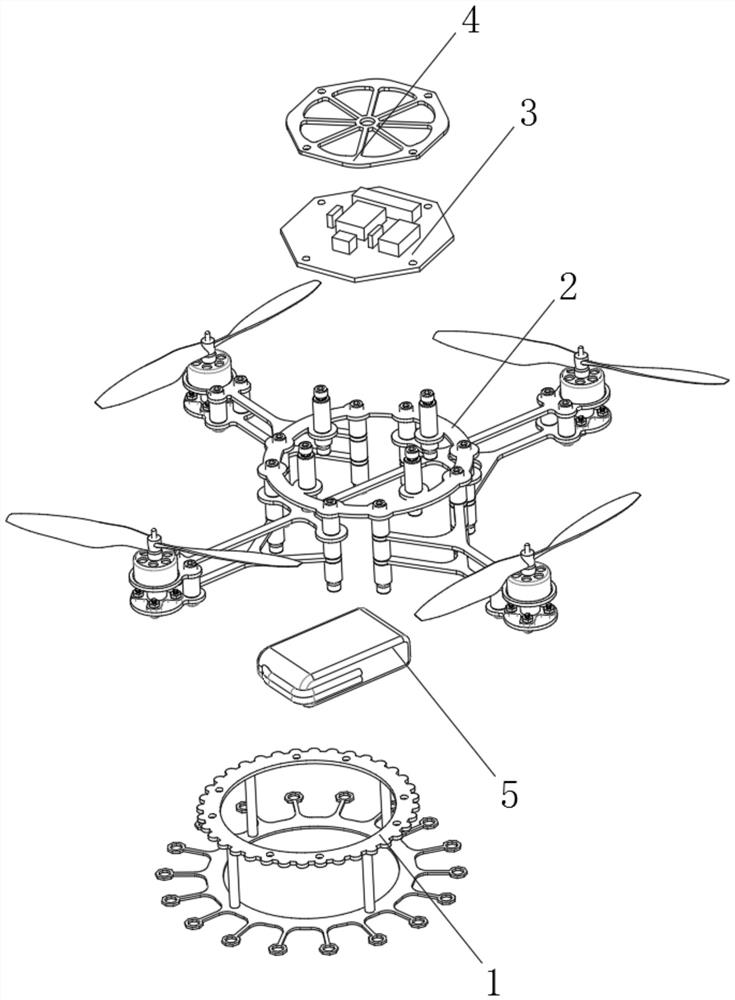

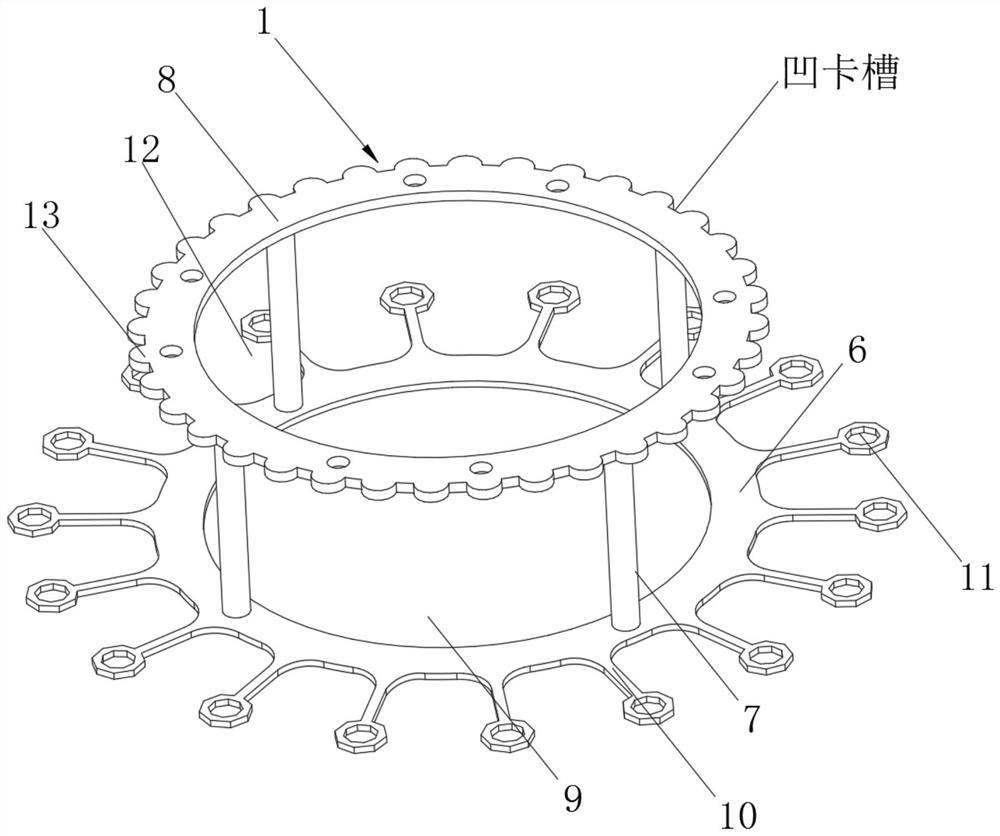

A protective structure of a forest inspection line fire inspection drone and its application method

ActiveCN110271664BFull angleVarious locationsFuselage framesRotocraftMarine engineeringUncrewed vehicle

The invention discloses a protection structure for a forest line fire inspection drone, which includes a storage frame, a guard plate, a main control board, a top defense board and a sponge clip. A protective structure is arranged above the storage frame. A baffle plate, and a main control board is sheathed in the middle of the baffle plate. The beneficial effect of the present invention is that: several concave slots set on the top ring are embedded and clamped to fix the components on the UAV, so as to ensure that the UAV is more stable and reliable for installation and use on the protective structure, and Cooperate with the sponge clip embedded between the UAV and the shield plate of the protective structure to provide shock absorption and buffer force for the UAV, reducing the vibration of the UAV during flight and the vibration between the UAV and the protective structure. The collision wear between them improves the service life of the UAV and the protective structure; the motor on the rotating bracket drives the rotor blade to rotate quickly to assist in driving the UAV flight work, ensuring the safety of the UAV flight inspection work. The power is more sufficient and the activities are more sensitive and faster.

Owner:南京拓恒无人系统研究院有限公司

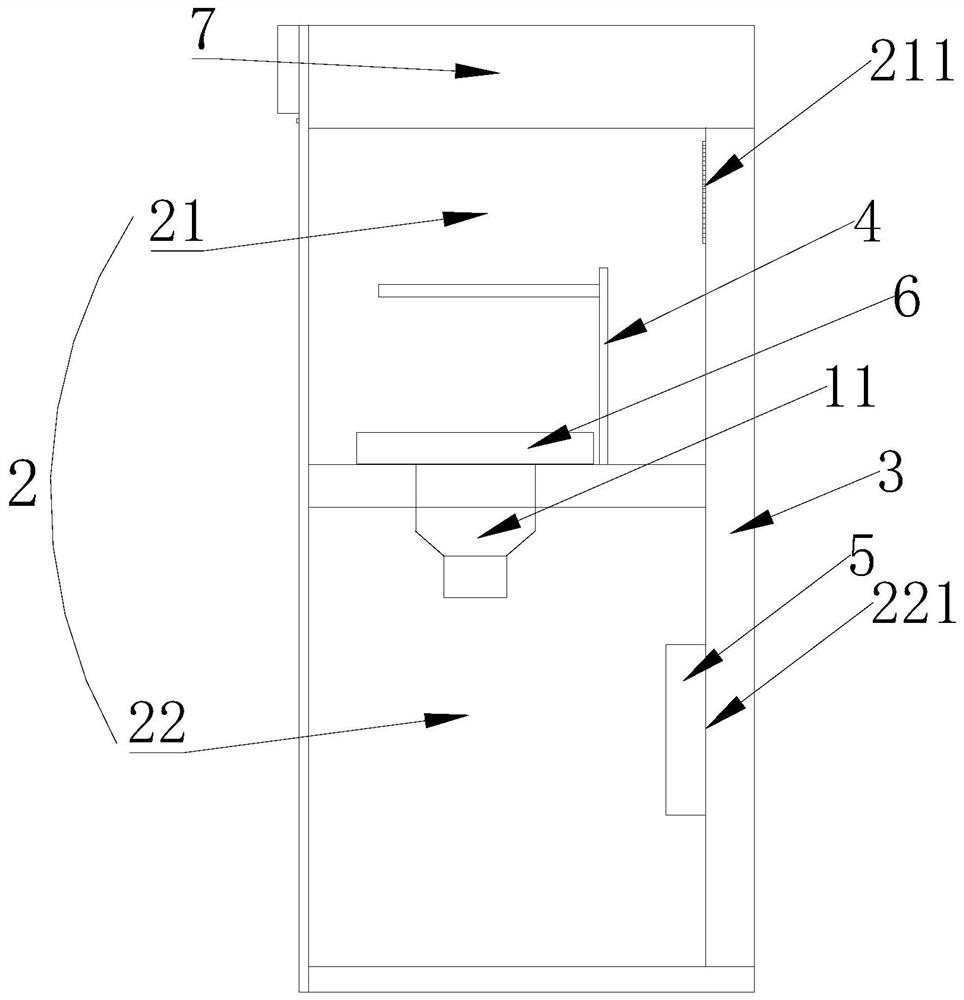

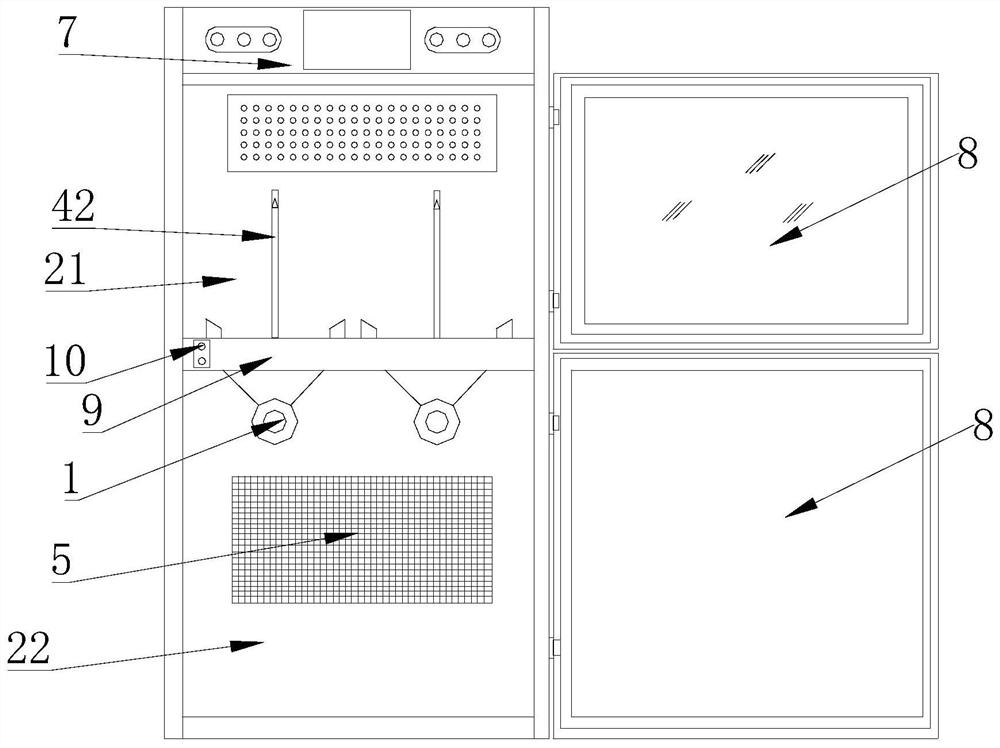

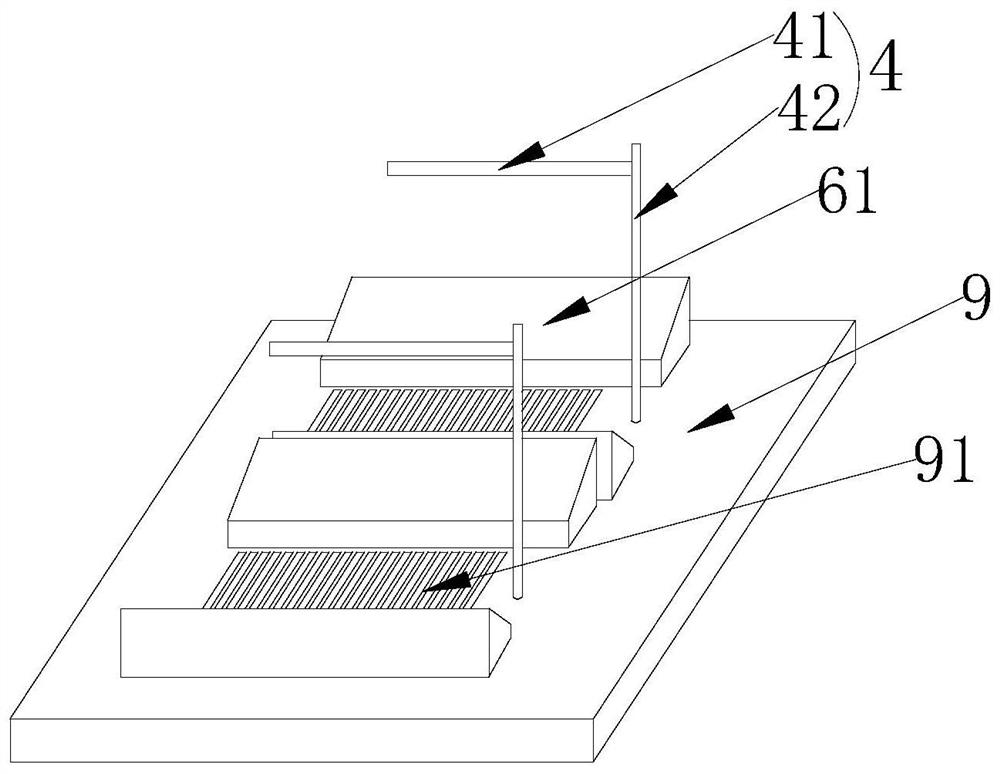

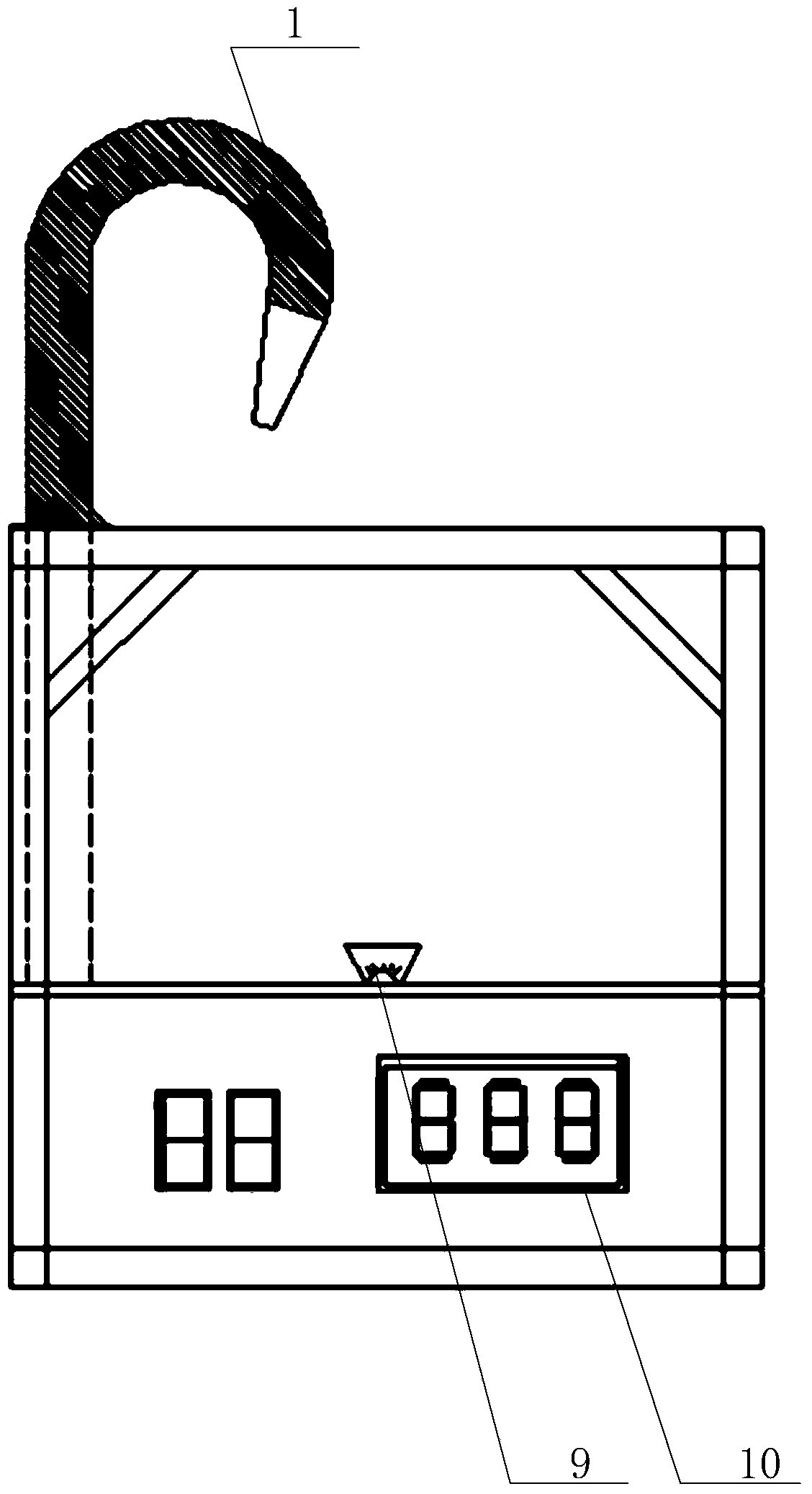

Purifier

PendingCN112023067AAchieve cycleSmooth circulationLavatory sanitoryHeatProcess engineeringMechanical engineering

The invention relates to the technical field of book processing, and particularly relates to a purifier. The purifier comprises a fan, a machine body, at least one fixing device, at least one purifying device and a flow guide channel, wherein the fan is provided with an air inlet end and an air outlet end; the machine body is provided with a processing cabin, a cabin door suitable for sealing theprocessing cabin and an air outlet communicating with the processing cabin, and the processing cabin communicates with the air inlet end and the air outlet end; the at least one fixing device is arranged in the processing cabin and is suitable for fixing a to-be-purified object, and the air outlet is arranged close to the fixing device; the at least one purifying device is arranged in the processing cabin and is used for disinfecting and / or sterilizing the to-be-purified object; and the flow guide channel communicates with the air outlet and the air inlet end. The purifier does not exhaust airto the external environment.

Owner:GREE ELECTRIC APPLIANCES INC

A hot air heating platform

The invention discloses a hot wind heating table which comprises a platform, a horizontal rotating component, a vertical turnover component and a clamping component used for clamping a heated piece. The horizontal rotating component is rotationally arranged on the platform, the rotating axis is vertically downward, the vertical turnover component is arranged on the horizontal rotating component in a turnover manner, the turnover axis is horizontally arranged, and the clamping component is arranged on the vertical turnover component. By means of the hot wind heating table, a heated object can be subject to multi-angle heating. Through a wind feeding device or an external wind feeding device arranged on the platform, the heated object is heated, the problem that the heated piece at higher temperature is not prone to being controlled to rotate in the hot wind heating process is solved, the heat uniformity of the heated object is guaranteed, the machining quality of the heated object is improved, angle control of the heated piece is simpler, and the machining and production efficiency can be greatly improved.

Owner:SKY CHIP INTERCONNECTION TECH CO LTD

A five-axis handling manipulator

The invention relates to the technical field of mechanical automation, in particular to a five-axis handling manipulator. It includes a support beam, the two ends of the support beam are fixedly connected to the columns respectively, two first transverse guide rails are arranged on the side wall of the support beam, and a first transverse feed mechanism is arranged on the two first transverse guide rails, An elevating mechanism is provided on the first infeed mechanism, a second infeed mechanism is arranged at the lower end of the elevating mechanism, a rotating mechanism is arranged at the right end of the second infeed mechanism, and a rotating mechanism is respectively arranged on both sides of the rotating mechanism. Grabbing mechanism. It has exquisite structure, reasonable design, simple operation and high flexibility. It can be easily inserted into the press and takes up less space. Multiple axes run at the same time, with fast running speed, high handling efficiency and stable operation. During the operation of the machine The utility model has high safety, satisfies people's demands more effectively, satisfies people's demands more effectively, and solves the problems existing in the prior art.

Owner:JINAN FOUND AUTOMATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com