Wind tunnel corner assembling method

A technology of corner grouping and alignment method, which is applied in the direction of measuring devices, instruments, aerodynamic tests, etc., can solve the problems of cumbersome assembly process and difficulty in meeting the trend of large-scale development of wind tunnels, so as to save the installation posture and reduce the The effect of combining difficulty and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

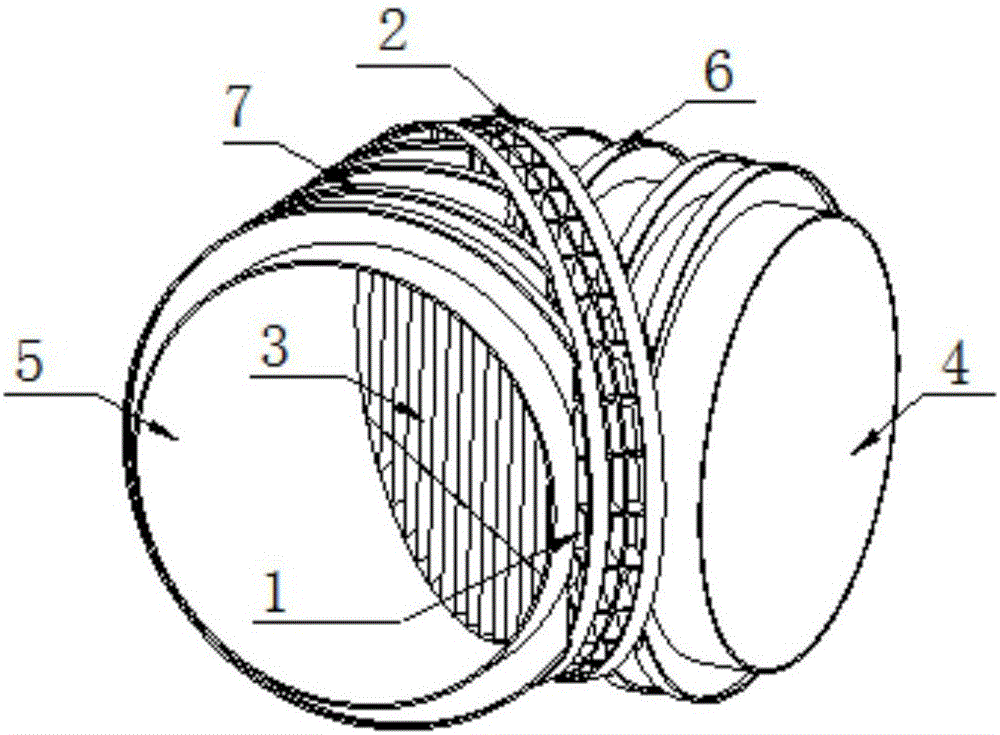

[0027] Below by embodiment, in conjunction with accompanying drawing, the technical scheme of the present invention is described further specifically, as figure 1 Shown, a kind of wind tunnel corner pairing method is characterized in that: comprises the following steps:

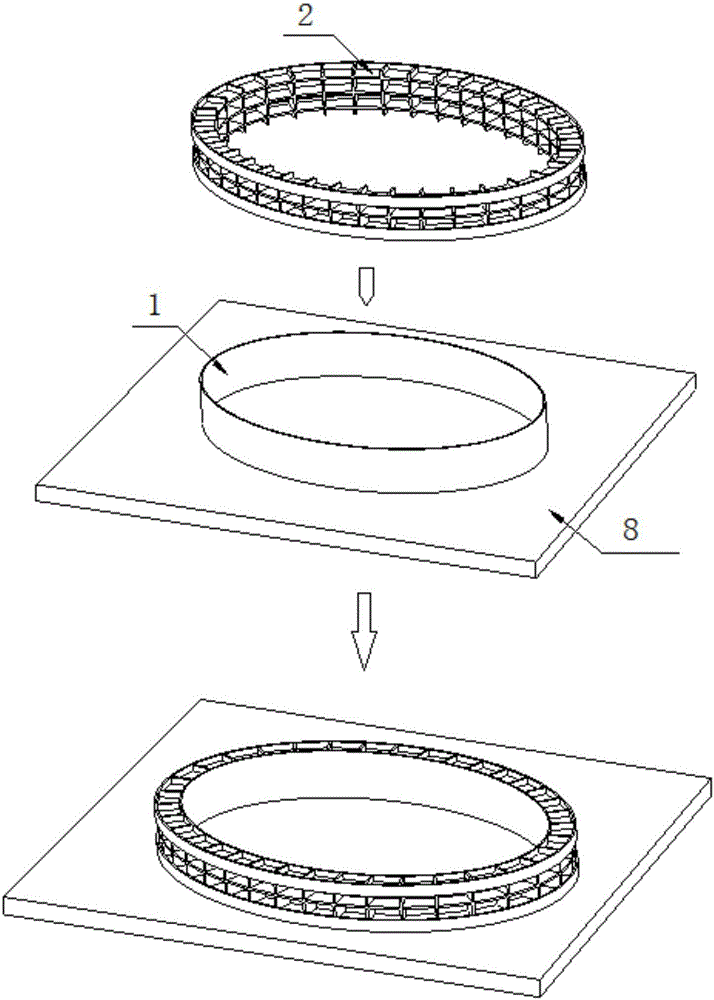

[0028] The first step is to assemble the elliptical ring shell and the reinforcing ring of the elliptical ring shell, such as figure 2 As shown, first place the elliptical ring shell 1 at the corner section of the wind tunnel horizontally on the surface of the paired platform 8 laid horizontally, and then assemble and weld the components of the elliptical ring shell reinforcement ring 2 with the elliptical ring shell 1 respectively ;

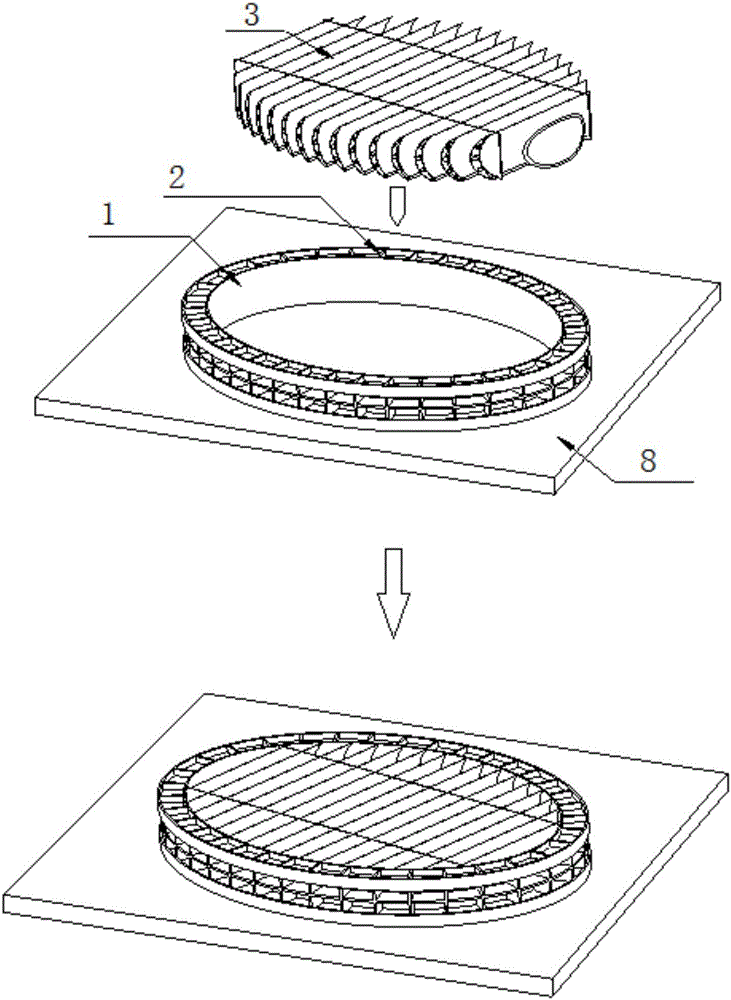

[0029] Step 2 is the assembly of the elliptical ring housing 1 and the deflector 3, such as image 3 As shown, after the welding of the elliptical ring shell 1 and the elliptical ring shell reinforcement ring 2 is completed, several neatly arranged flow deflectors 3 that hav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com