Knife sharpening method

A whetstone and knife technology, applied in the field of knife grinding, can solve problems such as uneven cutting edge angle, difficulty in controlling the cutting edge angle, uneven cutting edge surface and potential safety hazards, so as to achieve uniform cutting edge and eliminate safety hazards , Simple and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

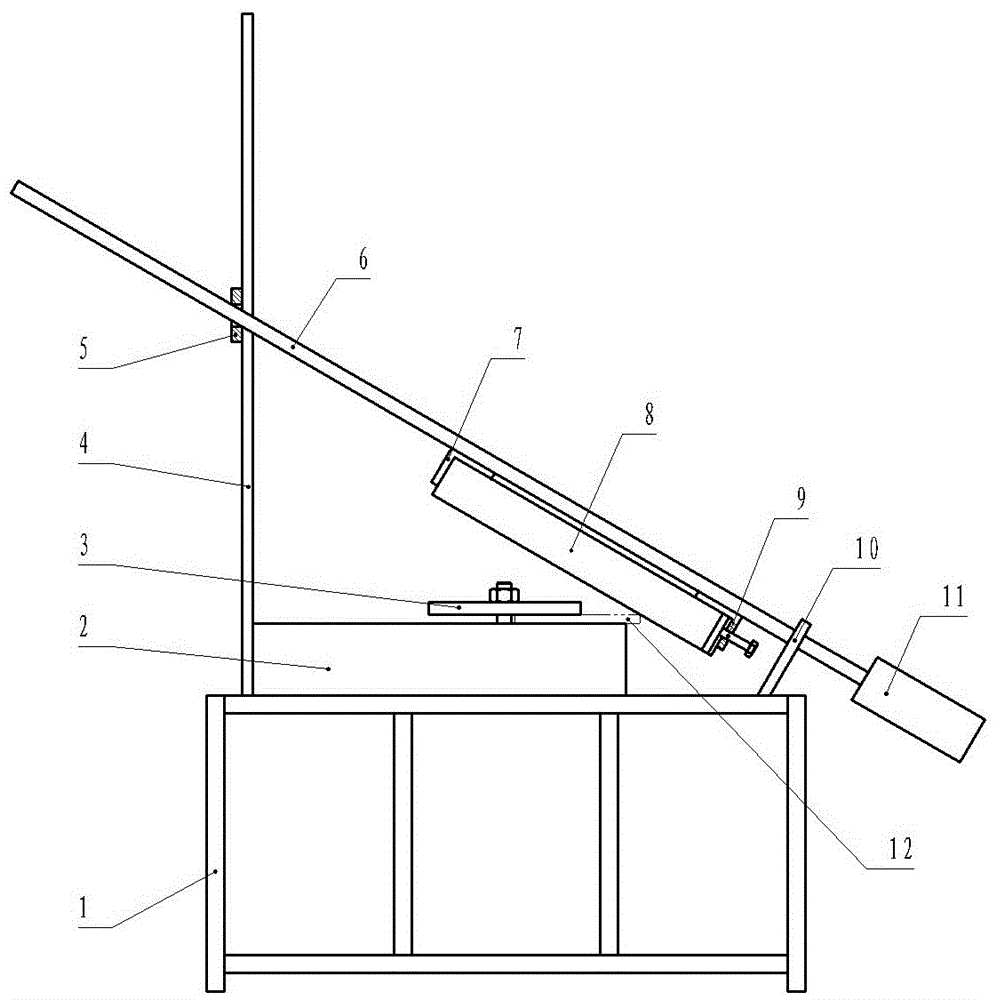

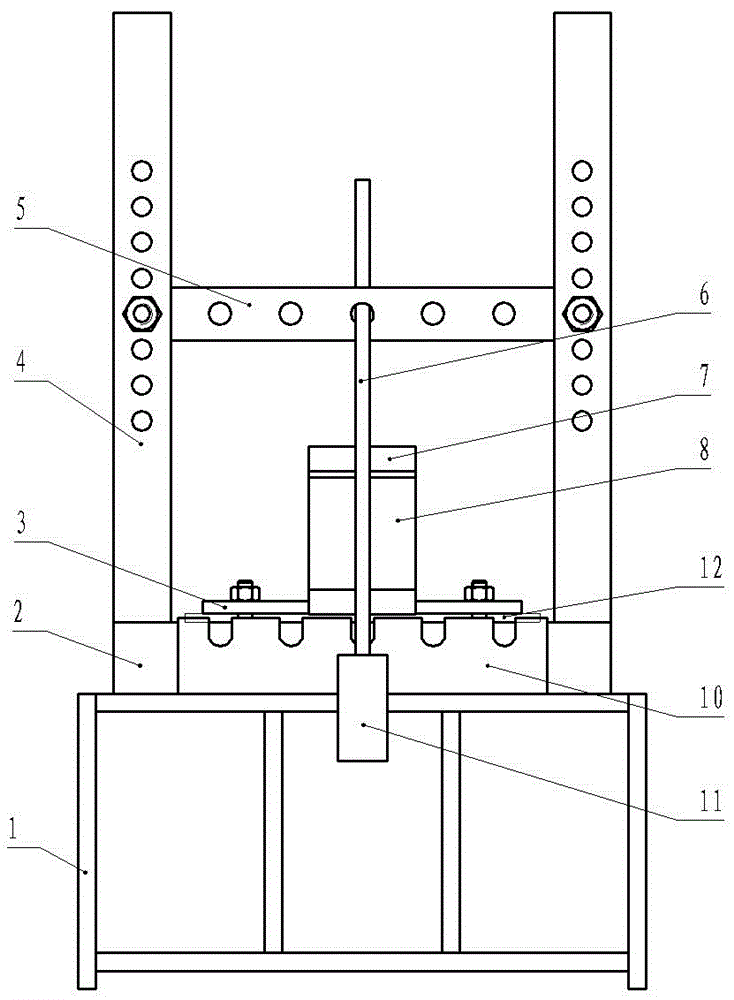

[0017] Below in conjunction with accompanying drawing embodiment, the present invention is described in further detail:

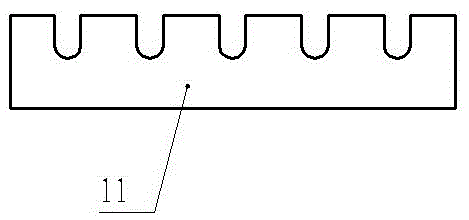

[0018] like figure 1 , figure 2 A knife sharpening bracket as shown includes a clamping block 2 mounted on the support frame 1, the clamping block 2 is equipped with a pressure plate 3 through bolts, and two vertical plates 4 are installed on one side of the clamping block 2. , a horizontal support plate 5 with five through holes is installed between the two vertical plates 4, the vertical plate 4 is provided with eight installation holes along the vertical direction, and the horizontal support plate 5 is connected with the two vertical plates 4 by bolts. A pull rod 6 with a handle 11 is fitted on the horizontal support plate 5, a whetstone 8 is installed on the pull rod 6, and the two ends of the whetstone 8 are respectively equipped with plywood 7 welded with the pull rod 6, and one of the plywood 7 is equipped with a Adjusting screw 9, a backing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com