Light emitting diode (LED) device and production method thereof

A technology for LED devices and manufacturing methods, applied to semiconductor devices, semiconductor devices of light-emitting elements, reflectors, etc., can solve the problems of small light-emitting angle and uneven light-emitting, and achieve improved light-emitting angle, uniform light-emitting, and uniform light intensity distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

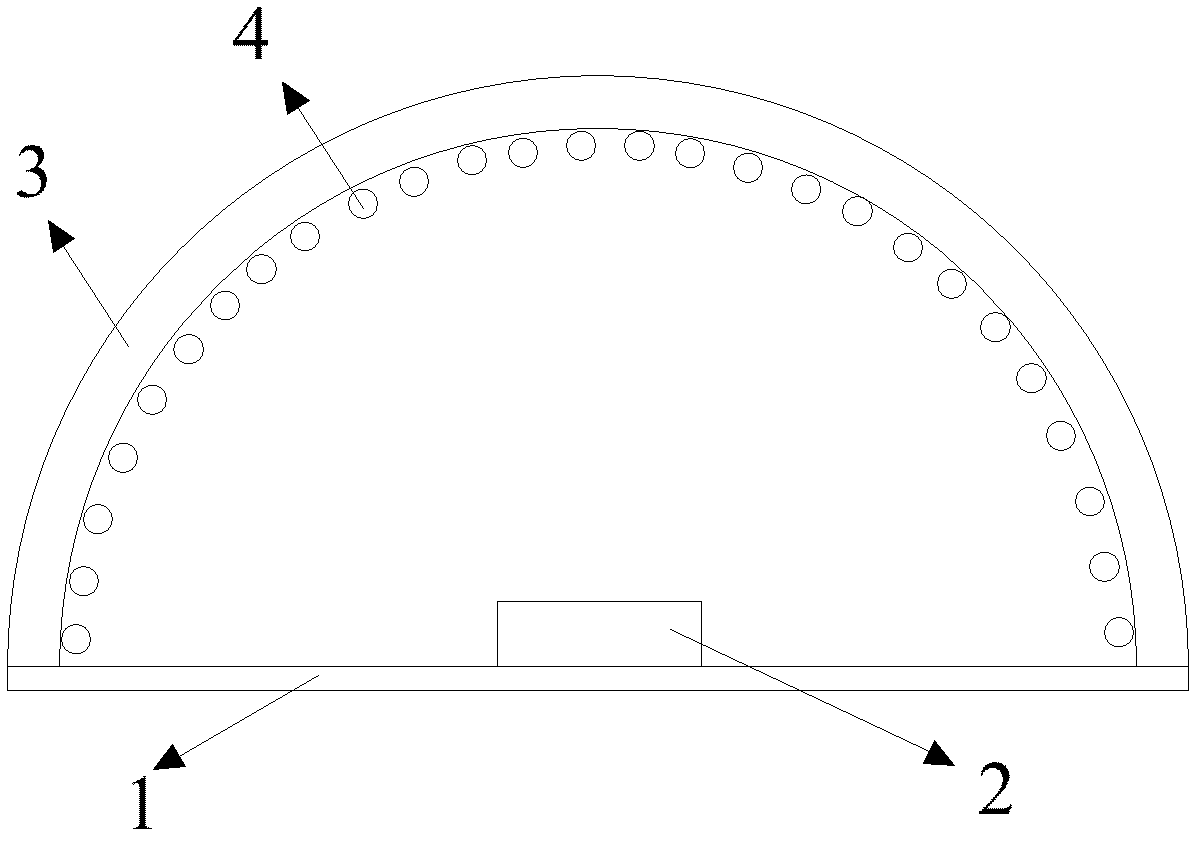

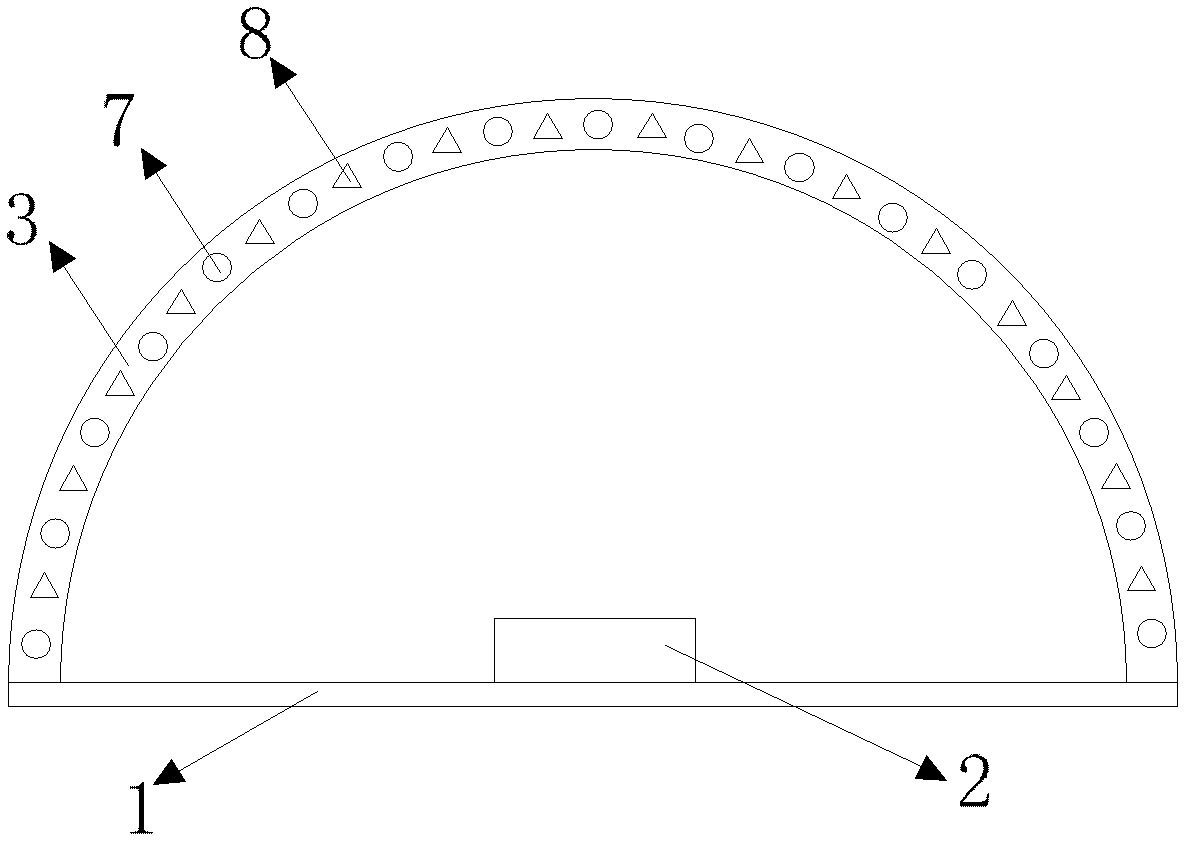

[0042] refer to image 3 , the LED device provided in this embodiment includes: a substrate 1; a chip 2 located on the substrate 1; a lens 3 located on the substrate 1 and covering the chip 2; particle layer. image 3 The shape of middle lens 3 is arc, certainly, also can be the lens of other shapes in other embodiments, for example be the lens of inverted U shape, refer to Figure 4 . The setting of the lens shape is not particularly limited in the present invention, and the following embodiments of this specification are all described by taking a curved lens as an example. In addition, when the lens 3 is a flat lens, it cannot be arranged to cover the chip 2 , and it only needs to be arranged so that the lens 3 and the chip 2 are placed opposite to each other.

[0043] The particle layer can also be coated on the inner surface or the outer surface of the lens, which is not particularly limited in the present invention.

[0044] The particle layer in this embodiment inclu...

Embodiment 2

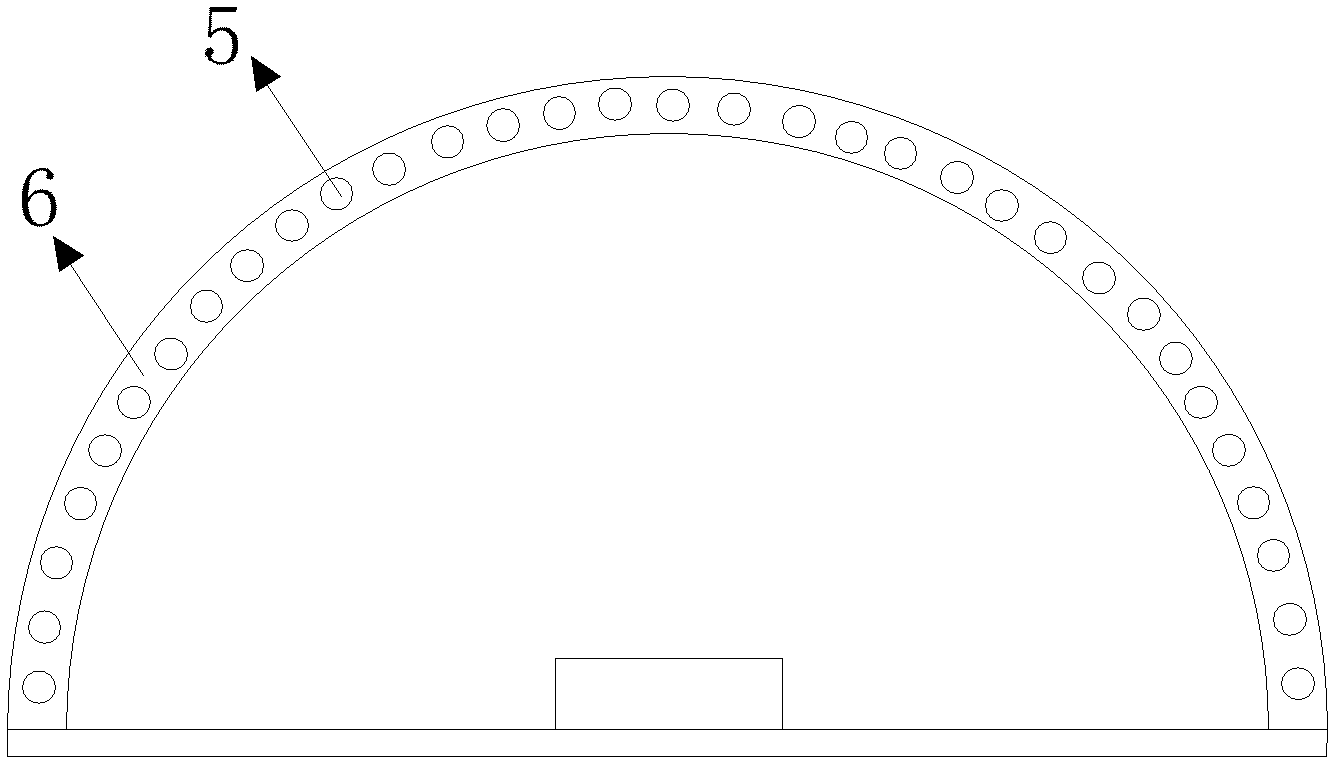

[0049] refer to Figure 5 , The LED device provided in this embodiment includes: a substrate 1; a chip 2 located on the substrate 1; a lens 9 located on the substrate 1 and covering the chip 2; a second lens arranged inside the lens 9 A particle layer.

[0050] The first particle layer can also be coated on the inner surface or the outer surface of the lens 9, which is not particularly limited in the present invention.

[0051] In this embodiment, the first particle layer includes fluorescent powder 7 and reflective particles 10 .

[0052] During the specific working process, the light emitted by the chip 2 is irradiated on the first particle layer, a part of the light is irradiated on the fluorescent powder 7 to excite the phosphor 7 to emit light, and a part of the light is irradiated on the reflective particles 10 to scatter around and to the direction of the substrate 1 Reflection, part of which passes through the phosphor powder 7 and the reflective particles 10 and is ...

Embodiment 3

[0056] refer to Figure 6 , on the basis of Embodiment 1, the LED device provided in this embodiment further includes: a reflective layer 11 disposed on the substrate 1 . When there is a reflective layer 11 in the LED device, the chip 2 and the lens 3 are located on the reflective layer 11 .

[0057] In this embodiment, the purpose of setting the reflective layer 11 on the substrate 1 is: the light emitted by the chip 2 irradiates on the light diffusing particles 8 and will be scattered around, and part of it will be scattered towards the substrate 1. When the reflective layer 11 is set on the substrate 1 Afterwards, the light scattered on the light-reflecting layer 11 will be reflected by the light-reflecting layer 11 so as to shoot to the particle layer, thereby increasing the utilization efficiency of the light emitted by the chip 2. Therefore, the LED device in this embodiment has a large light-emitting angle and light-emitting Uniformity, while further improving the ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Beam angle | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com