Designing method for multi-partition optical phase plate in photo-etching illumination

A design method and phase plate technology, which are applied in the field of microlithography, can solve the problems of large amount of calculation, long time consumption, and inability to meet actual use requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereto.

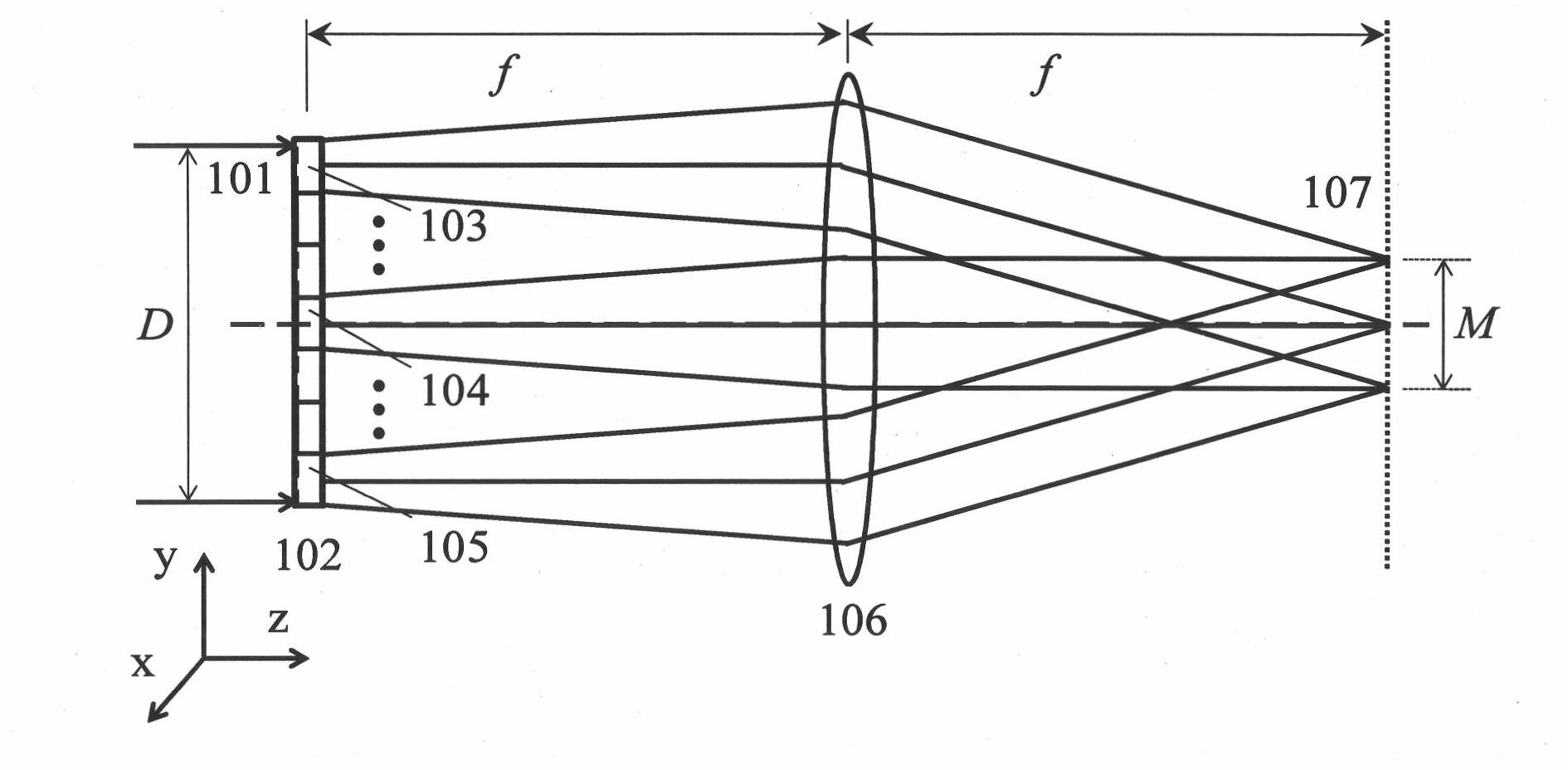

[0049] see first figure 1 , figure 1 It is a schematic diagram of the working principle of the partitioned optical phase plate 102 of the present invention, illustrating an optical path diagram for forming the required light intensity distribution with the thin lens 106 . After the parallel and completely collimated incident light beam 101 passes through each division of the optical phase plate 102, it will form sub-beams with small divergence angles due to diffraction, and these sub-beams will form the desired light on the image plane 107 after passing through the thin lens 106 strong distribution.

[0050] The optical phase plate 102 and the image plane 107 are located on the front focal plane and back focal plane of the thin lens 106 respectively, that is, the distance...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com