Manufacturing method of badmintons

A manufacturing method and technology for badminton, which can be applied to sports accessories and other directions, and can solve the problems of turning into a swinging ball, affecting the overall balance of flight, and loss of oil components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

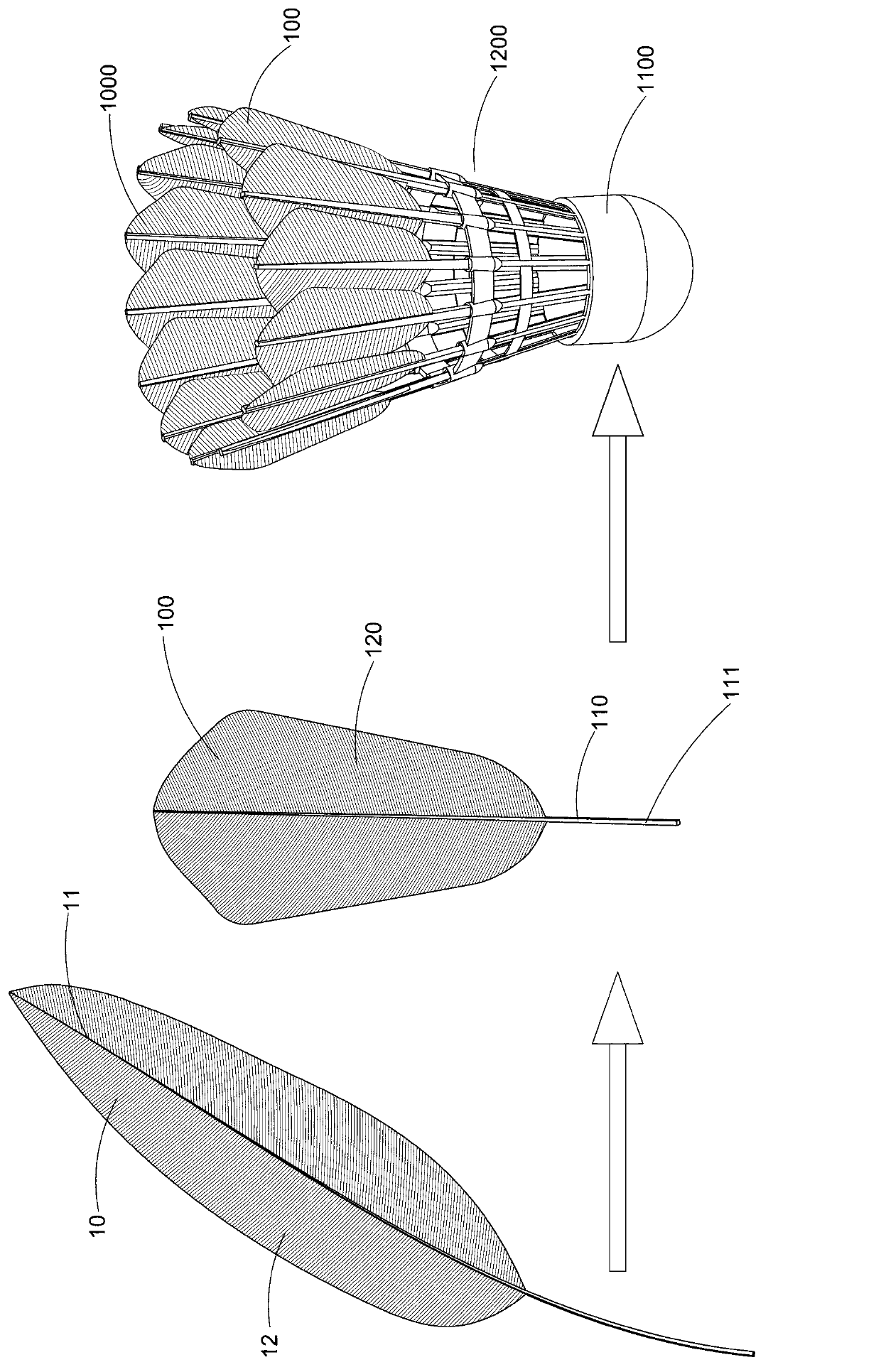

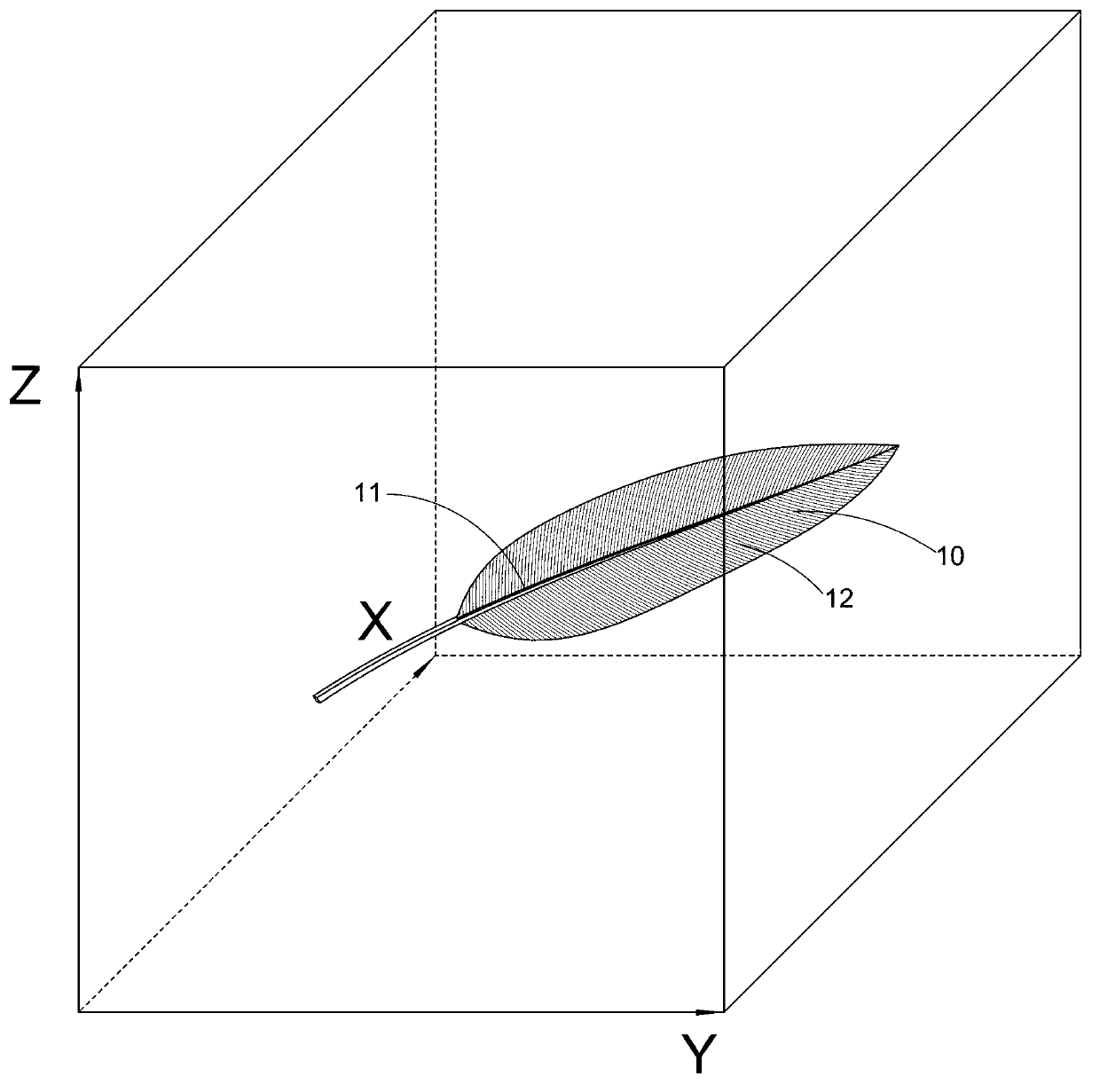

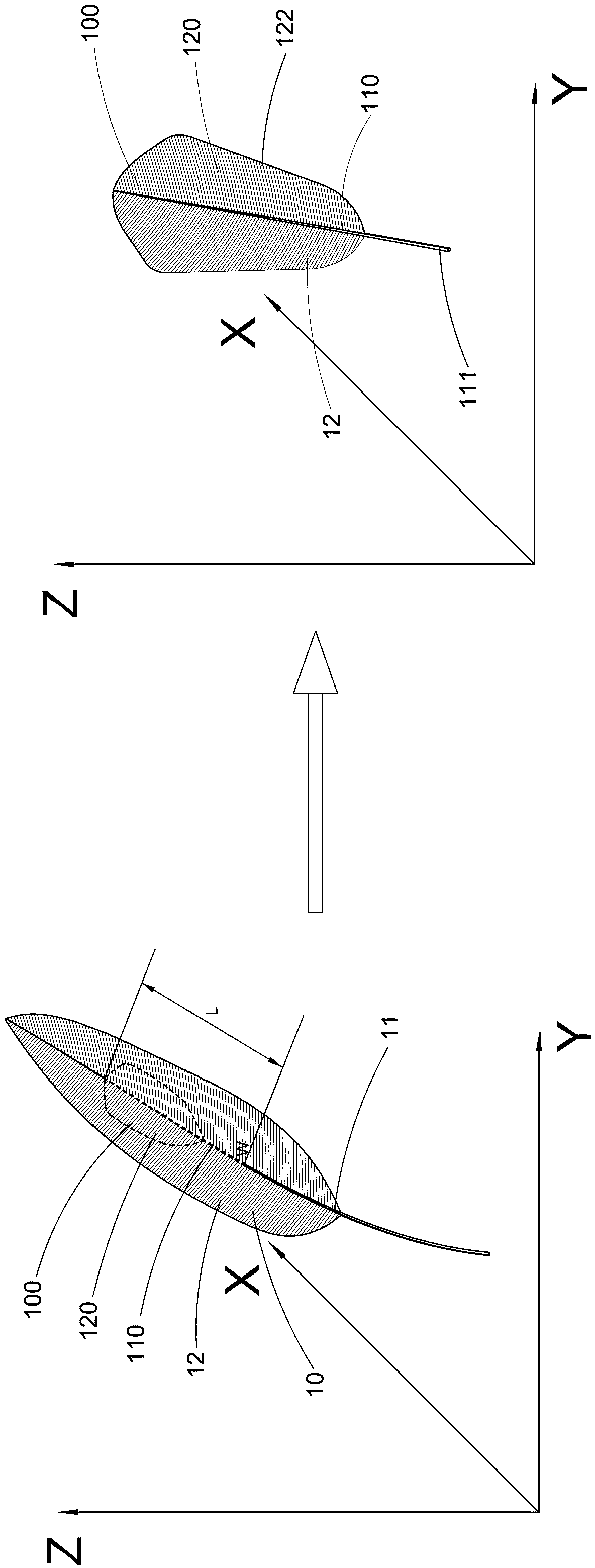

[0041] In a preferred embodiment of the present invention, the shuttlecock 1000 is made from natural feathers 10 . Because the thickness, curvature and bow of the hair stem 11 of each natural feather 10 are different from the shape and size of the feather wing 12, the natural feather 10 needs to be cut first to obtain a suitable feather blade 100, and then the feather blade 100 Made shuttlecock 1000. figure 1 Shown is an unprocessed natural feather 10, generally a goose feather or a duck feather, which includes a hair stem 11 and wings 12 on both sides of the hair stem 11, and four sides are defined on the hair stem 11: front 10a, back 10b , left side 10c and right side 10d, wherein, we will have the left side 10c of wing 12 germination and right side 10d to be called wing germinal surface. The smoother side of the hair stem 11 is called the front side 10a, and the outwardly protruding side of the hair stem 11 is called the back side 10b. The bending along the left side 10c ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com