Five-axis carrying manipulator

A technology of manipulator and lifting mechanism, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of high labor intensity, high operation risk, low handling efficiency, etc., and achieve high handling efficiency, high safety, and running speed. quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

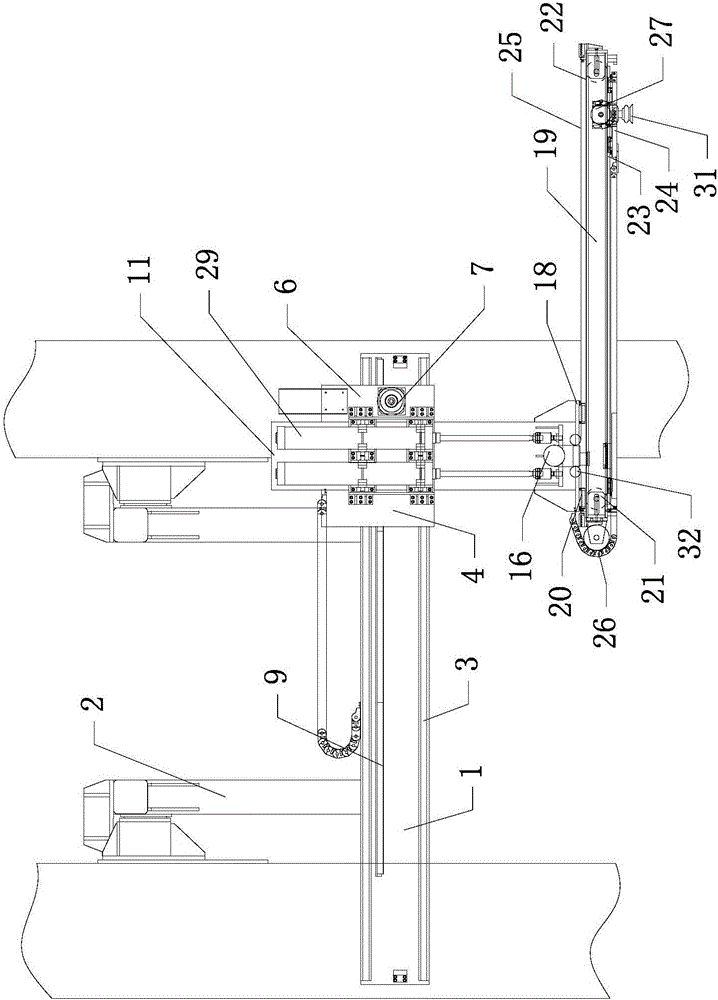

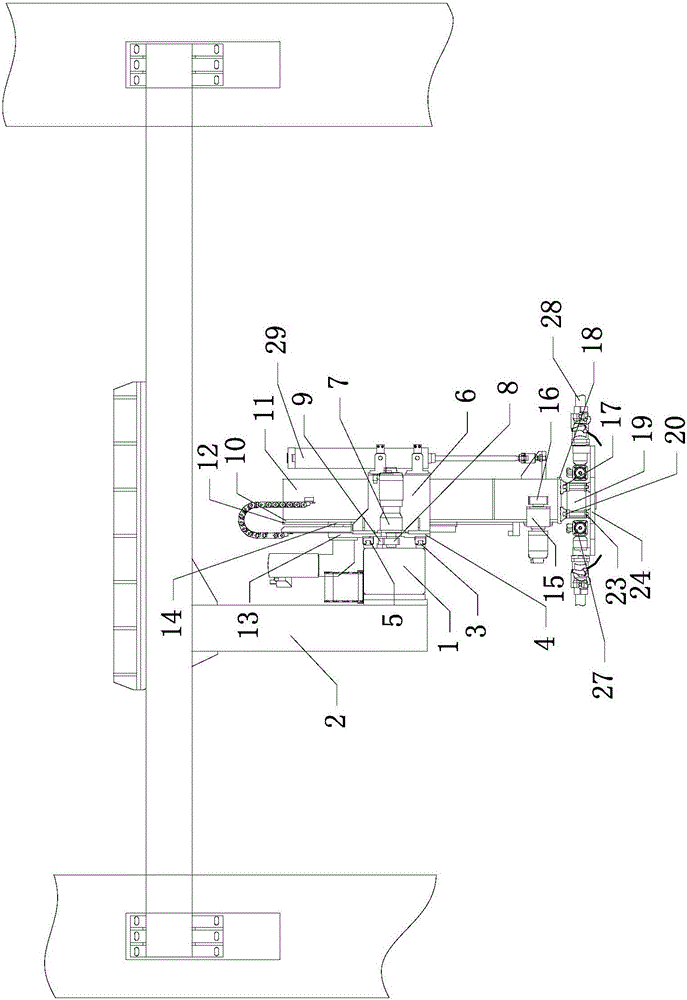

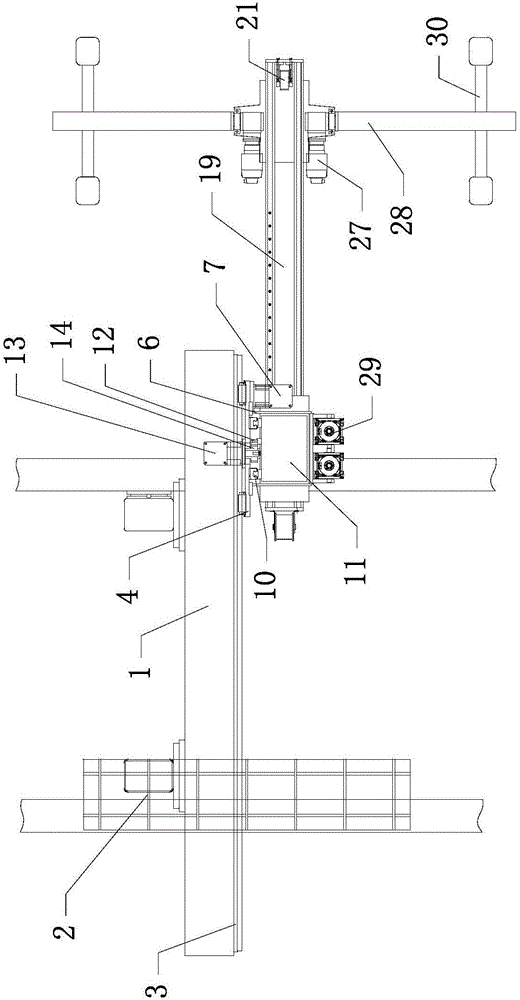

[0018] In order to clearly illustrate the technical features of this solution, the present invention will be described in detail below through specific implementation modes and in conjunction with the accompanying drawings.

[0019] Such as Figure 1-4 As shown in , a five-axis handling manipulator includes a horizontal support beam 1, the two ends of the support beam 1 are fixedly connected to the column through the beam bracket 2, and two parallel beams are arranged horizontally on the side wall of the support beam 1. The first horizontal guide rail 3 that is set, is provided with a first lateral feed mechanism on two first lateral guide rails 3, is provided with a vertically arranged elevating mechanism on the first lateral feed mechanism, is provided with a level at the lower end of elevating mechanism. The second lateral feed mechanism provided is provided with a rotating mechanism at the right end of the second lateral feed mechanism, and a grabbing mechanism is respecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com