Manufacturing method and manufacturing apparatus for twisted flat bar

一种螺旋扁钢、制造装置的技术,应用在螺旋扁钢的制造及制造装置领域,能够解决损害美感、难制造螺旋扁钢、难变钢施加均匀的扭转力等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

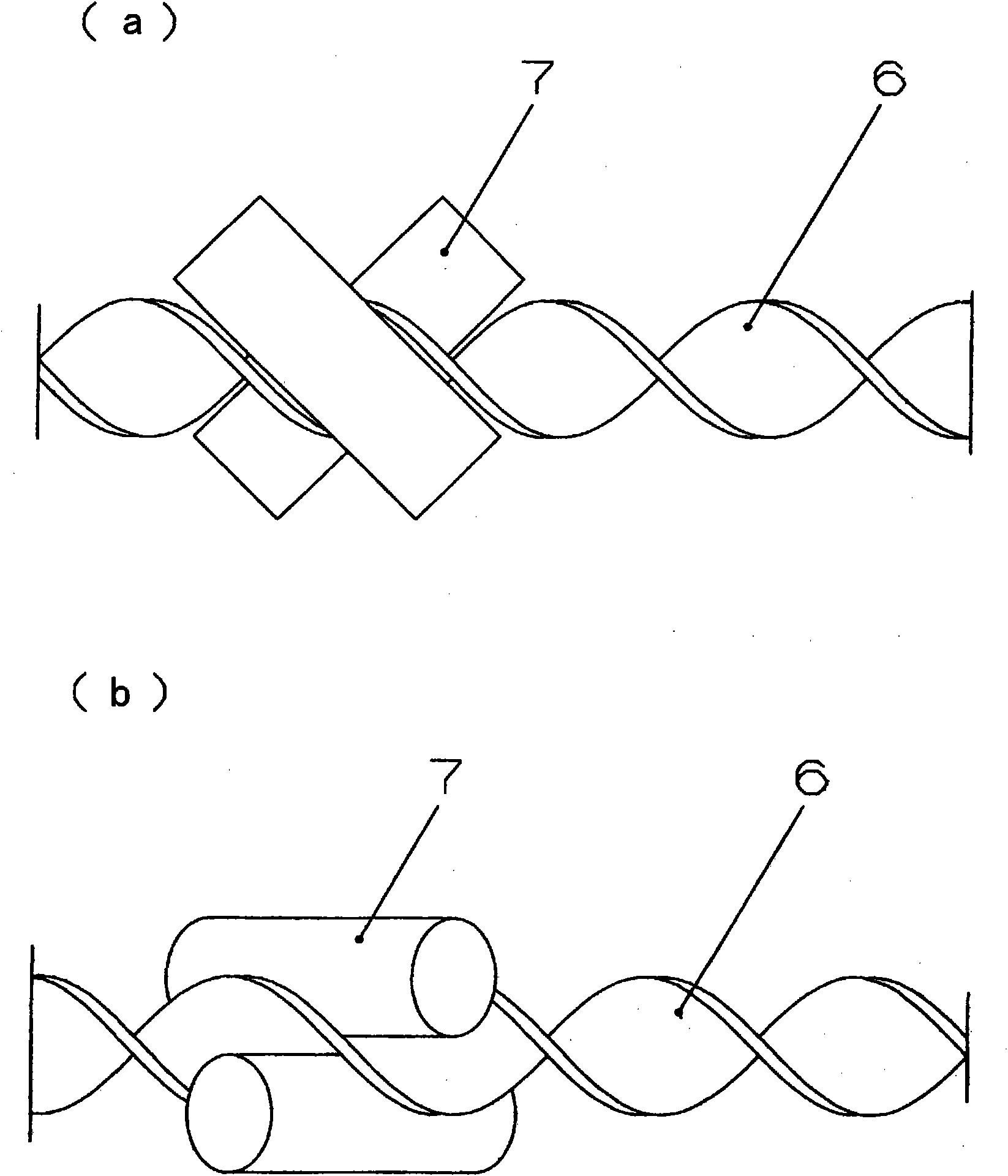

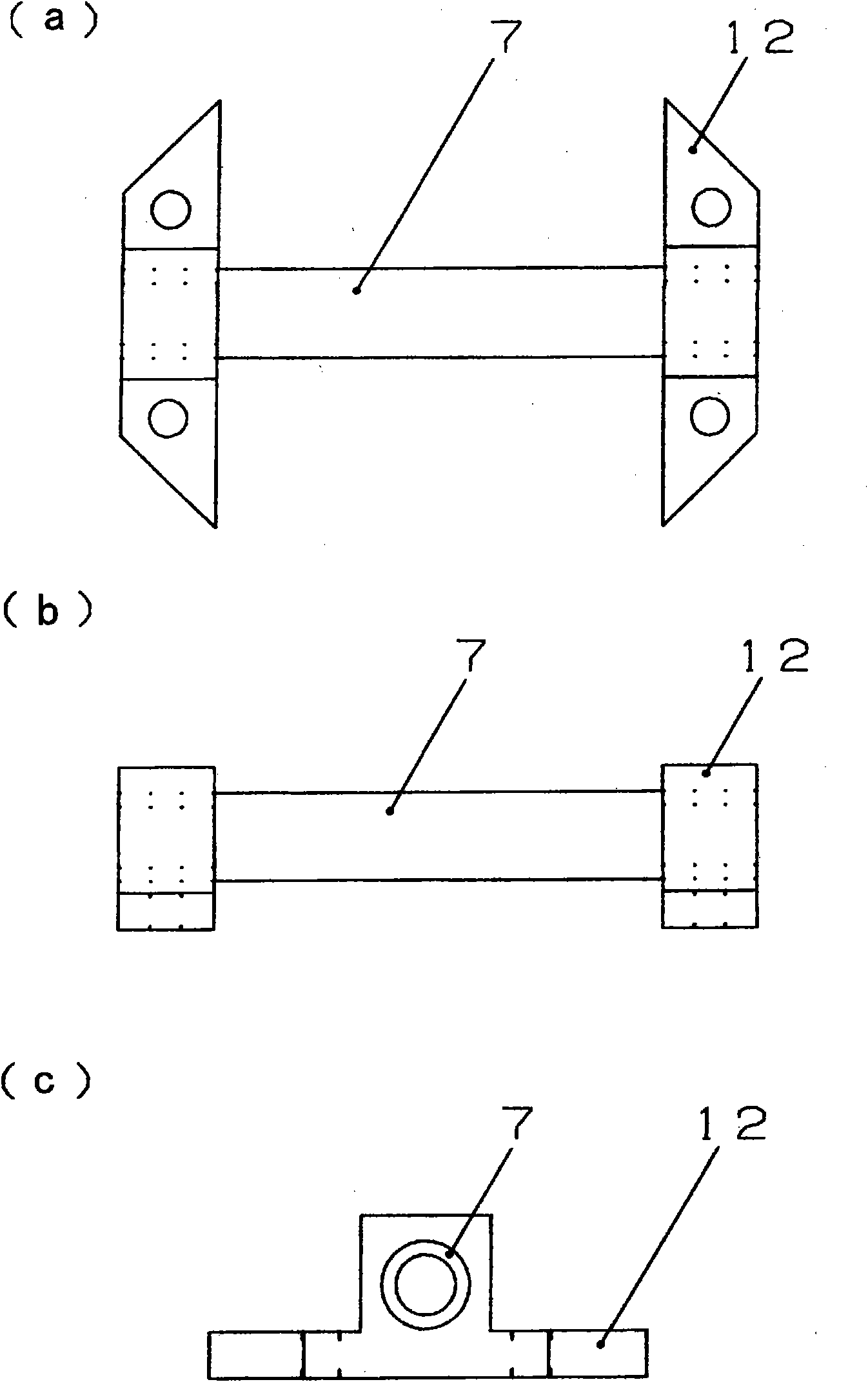

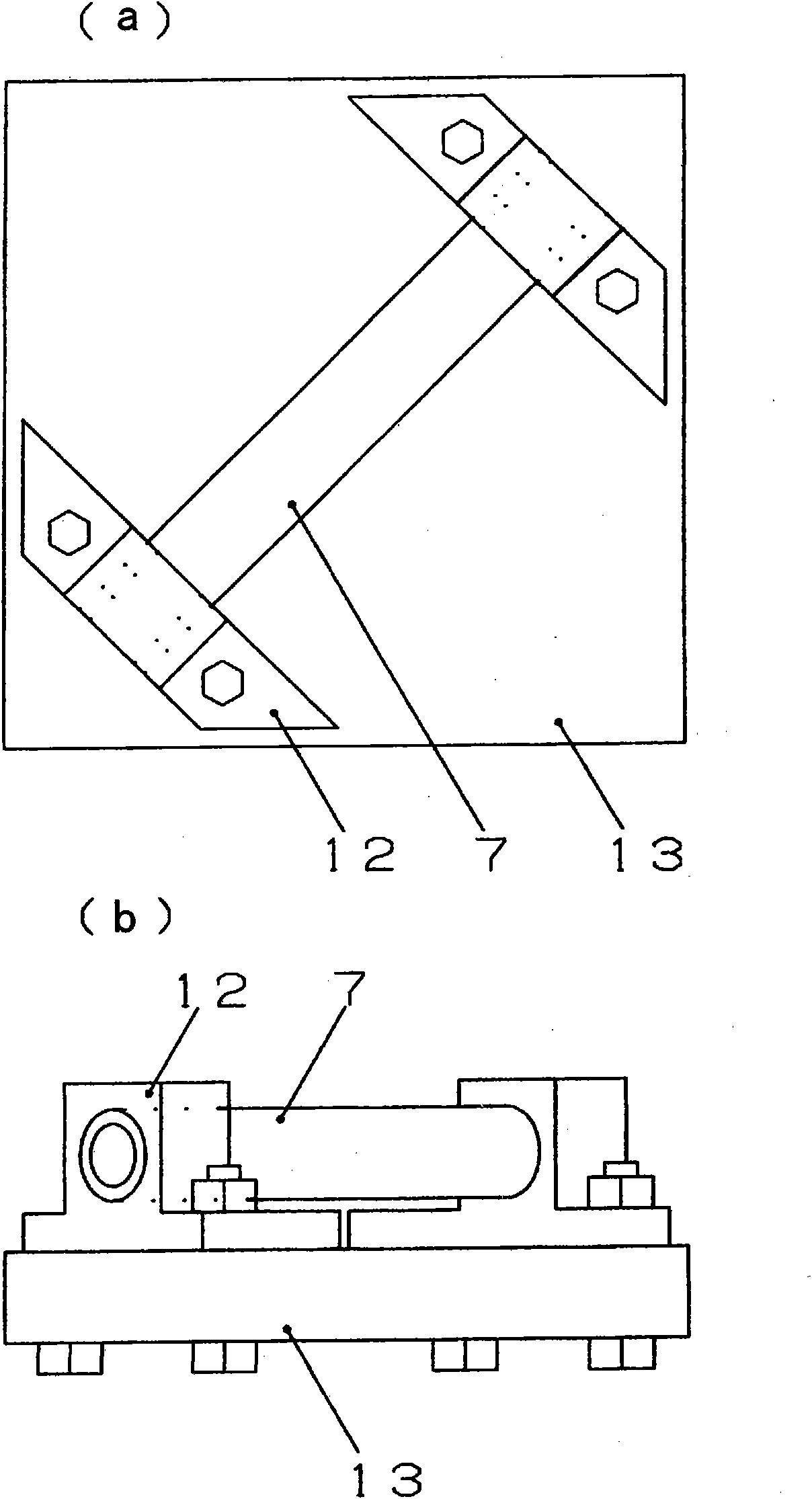

[0060] The manufacturing method of the spiral flat steel of the present invention is characterized in that two round steels arranged obliquely at the same angle to different directions with respect to the longitudinal direction of the flat steel sandwich the two faces of the flat steel, and the above two The round bar is relatively rotated with respect to the flat bar with the longitudinal direction as the rotation axis, and the flat bar is relatively moved in the longitudinal direction with respect to the round bar.

[0061] Next, the manufacturing method and manufacturing apparatus of the spiral flat steel of this invention are demonstrated in detail.

[0062] figure 1 It is a diagram showing the arrangement relationship of spiral flat steel and round steel, figure 1 (a) represents a top view, figure 1 (b) shows a front view.

[0063] The present invention is characterized in that the flat bar is twisted using two round bars arranged obliquely in different directions a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com