Automatic conducting strip welding device and machining technology thereof

A technology of automatic welding and welding equipment, which is applied in the field of electronic product preparation process equipment, can solve the problems of wasting manpower and limiting production speed, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

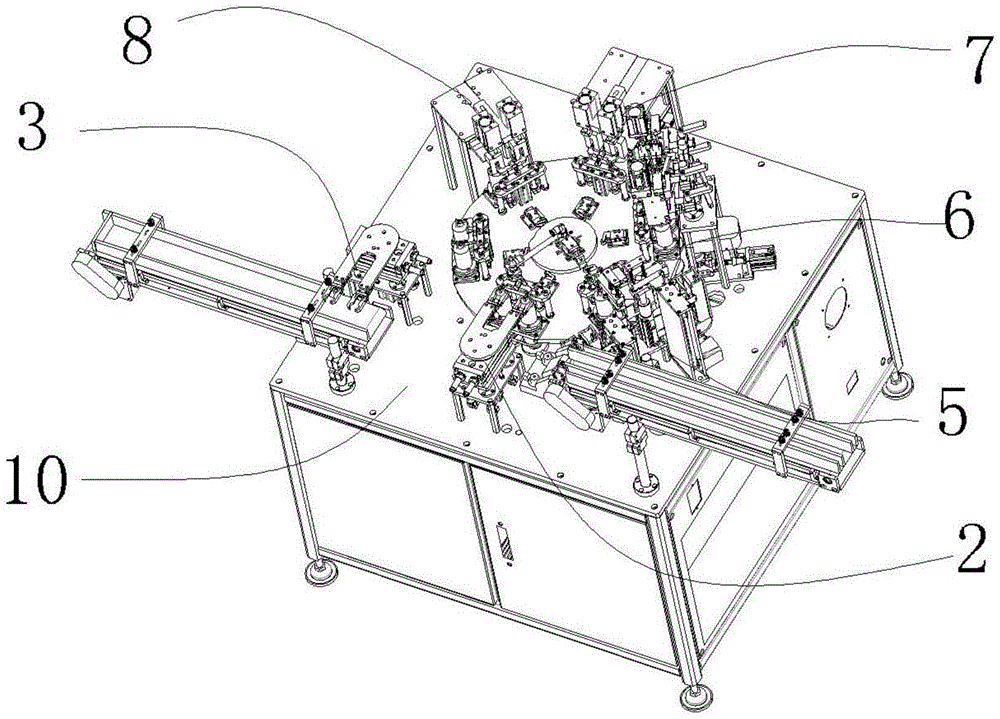

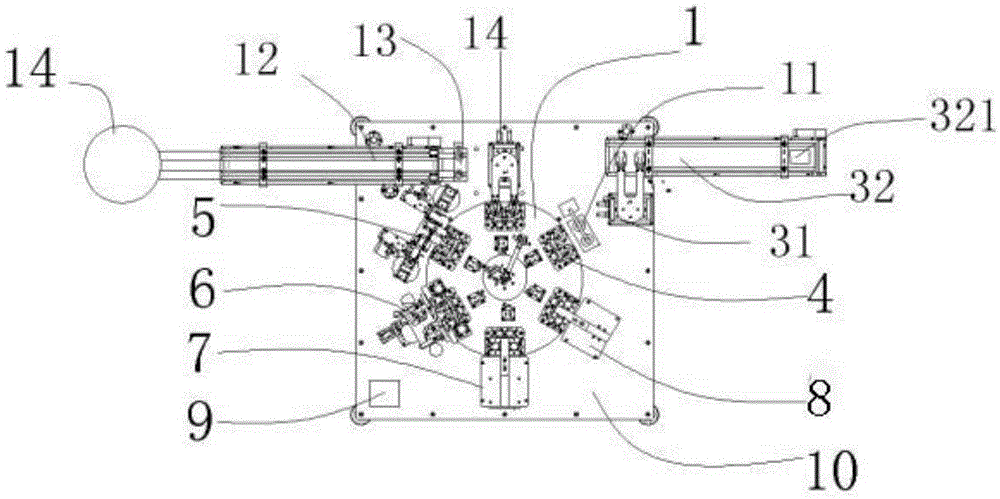

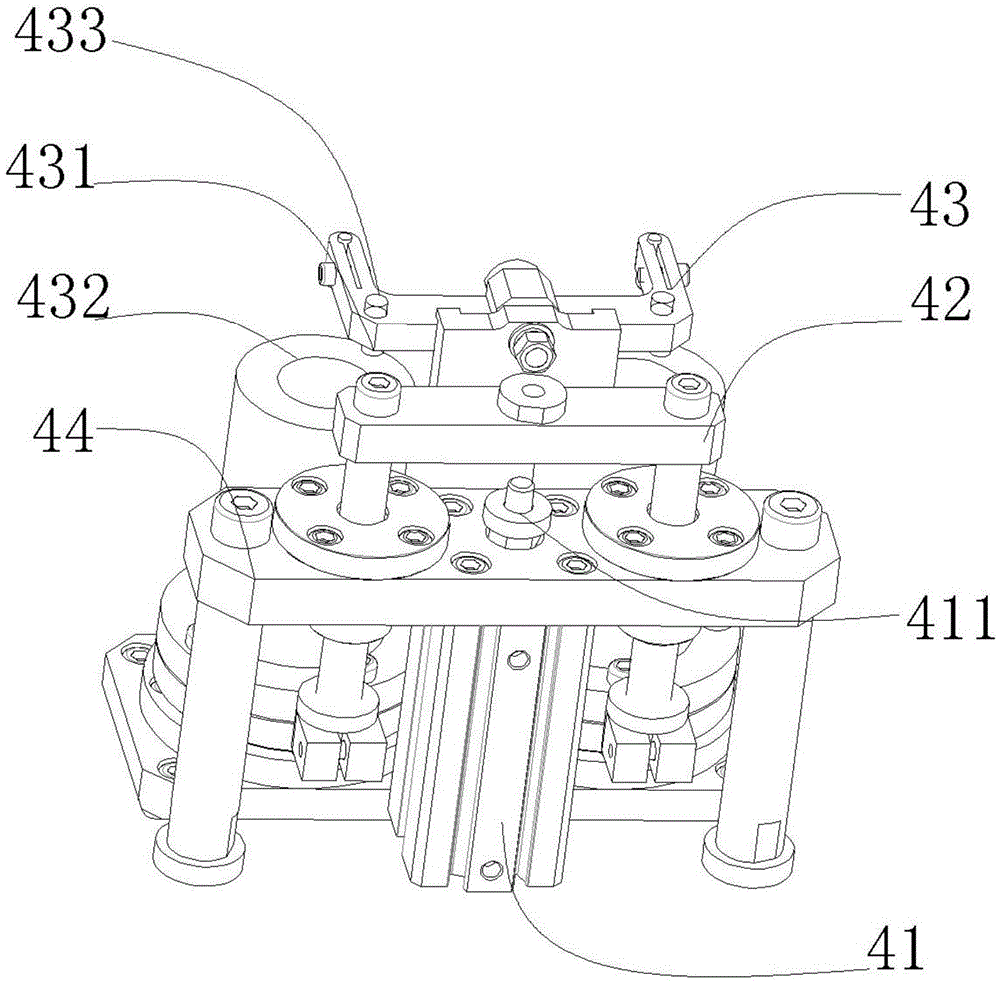

[0039] As shown in the figure, the battery conductive sheet welding and bending device includes a workbench on which a turntable 1, a feeding device 2 and a discharging device 3 are installed. The feeding device 1 includes a clamping device 14 and a conveyor belt 1. 12. A tray 13 is provided at the end of the conveyor belt one 12, and the discharge device 3 includes a clamping device two 31 and a conveyor belt two 32. It is characterized in that a grabbing device 4 is provided on the turntable, and the turntable Along the edge, a loading device 5, a welding device 6, a bending device 1 7, a bending device 2 8, a protective cover, and a monitoring device 9 are installed in sequence.

[0040] Described clamping device one 14 comprises movable plate 141, and described movable plate 141 is provided with the rotating shaft four 143 that cylinder nine 142 drives rotation, and described movable splint 141 is also provided with movable clip 144, controls movable clip by electric two 14...

Embodiment 2

[0056] As shown in the figure, the battery conductive sheet welding and bending device includes a workbench on which a turntable 1, a feeding device 2 and a discharging device 3 are installed. The feeding device 1 includes a clamping device 14 and a conveyor belt 1. 12. The end of the conveyor belt 12 is provided with a tray 13, and the discharge device 3 includes a clamping device 2 31, a conveyor belt 2 32 and a waste recycling tank 321. The waste recycling tank is used to store unqualified products that have not passed the quality inspection. Finished product; it is characterized in that a grabbing device 4 is provided on the turntable, and the turntable is sequentially installed with a sheet loading device 5, a welding device 6, a bending device 7, a bending device 2 8, a protective cover, a monitoring device9.

[0057] Described clamping device one 14 comprises movable plate 141, and described movable plate 141 is provided with the rotating shaft four 143 that cylinder ni...

Embodiment 3

[0073] As shown in the figure, the battery conductive sheet welding and bending device includes a workbench on which a turntable 1, a feeding device 2 and a discharging device 3 are installed. The feeding device 1 includes a clamping device 14 and a conveyor belt 1. 12. The end of the conveyor belt 12 is provided with a tray 13, and the discharge device 3 includes a clamping device 2 31, a conveyor belt 2 32 and a waste recycling tank 321. The waste recycling tank is used to store unqualified products that have not passed the quality inspection. The finished product is characterized in that a grabbing device 4 is provided on the turntable, and a sheet loading device 5, a welding device 6, a bending device 1 7, a bending device 2 8, a protective cover, and a monitoring device are sequentially installed along the turntable. device9.

[0074] Described clamping device one 14 comprises movable plate 141, and described movable plate 141 is provided with the rotating shaft four 143 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com