System and method for disposing dust collection ash of iron and steel plant through mesh belt type suspension combined reduction furnace

A reduction furnace and mesh-belt technology, which is applied in the field of comprehensive utilization of solid waste in the metallurgical industry, can solve problems such as high iron content, large liquid phase in the kiln, and affecting the production and operation of the rotary kiln.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0086] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

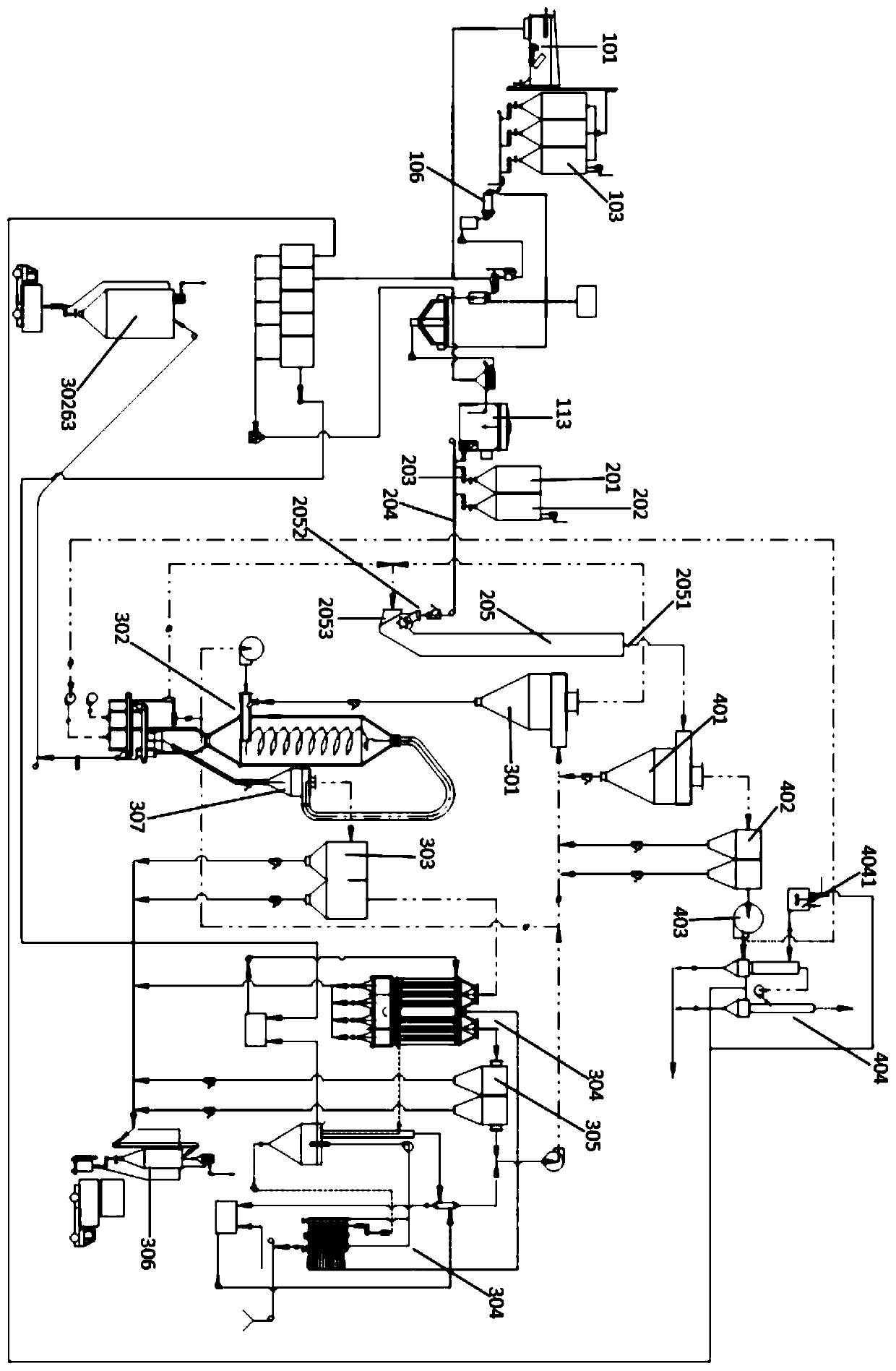

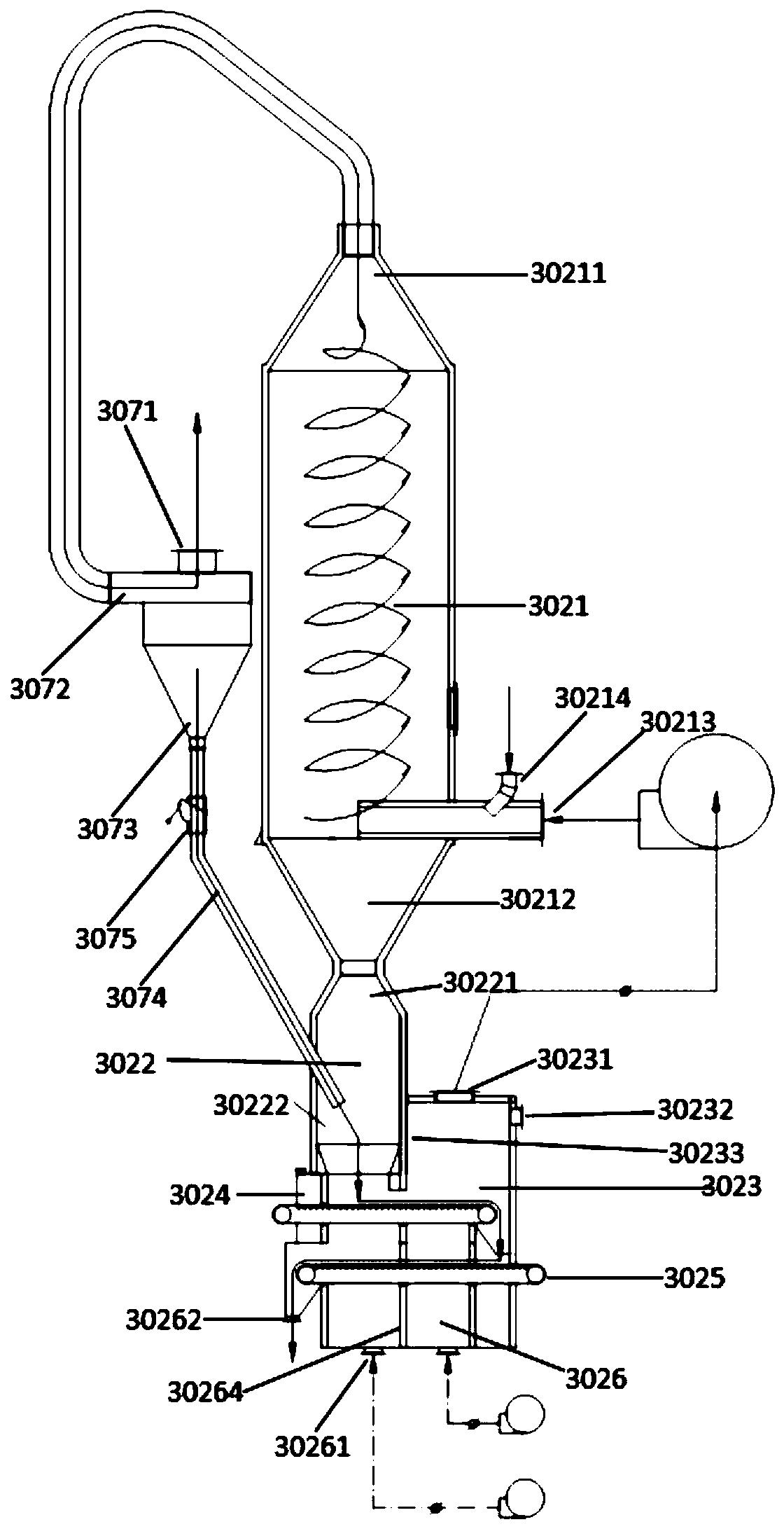

[0087] Such as Figure 1-11 As shown, this embodiment provides a mesh-belt type suspension combined reduction furnace to dispose of dust collection system in iron and steel plant, including washing and dechlorination system, drying and dehydration system, volatile zinc extraction system and flue gas treatment system; wherein the washing and dechlorination system The drying and dehydration system is connected to the volatile zinc extraction system in sequence, and the flue gas treatment system is connected to the drying and dehydration system. The devices in the system are all sealed and equipped with a suction machine to form a slight negative pressure.

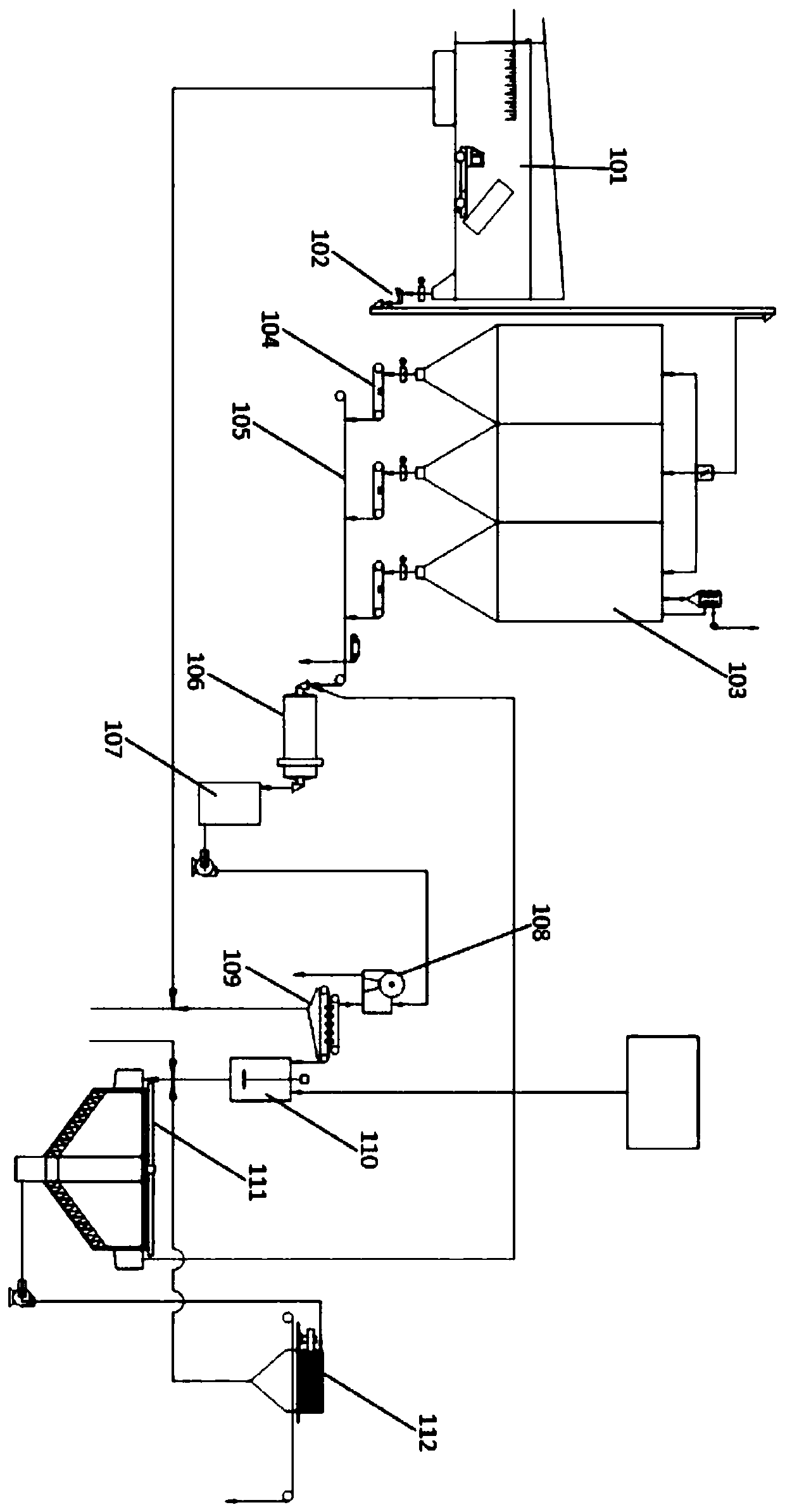

[0088] The washing and dechlorination system includes a discharge room 101, plate fee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com